From Earth orbit to the Moon and Mars, explore the world of human spaceflight with NASA each week on the official podcast of the Johnson Space Center in Houston, Texas. Listen to in-depth conversations with the astronauts, scientists and engineers who make it possible.

On Episode 284, learn about a student-built experiment that recently made its way to the International Space Station. This episode was recorded on February 17, 2023.

Transcript

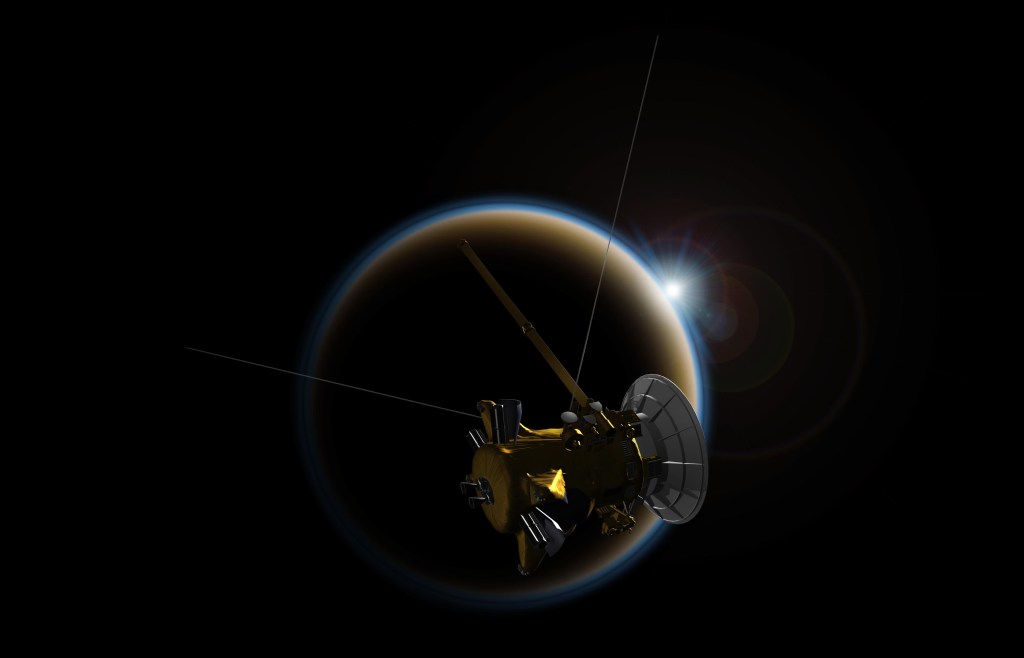

Gary Jordan (Host): Houston, we have a podcast! Welcome to the official podcast of the NASA Johnson Space Center, Episode 284, “The Student-Built Camera Mount.” I’m Gary Jordan, I’ll be your host today. On this podcast we bring in the experts, scientists, engineers, astronauts, all to let you know what’s going on in the world of human spaceflight and more. NASA loves working with students. Heck, that’s how I got a job at NASA was starting off as a student. But there are certain programs that allow students to work with NASA in a different way than what I’ll call your quote-unquote “standard internship opportunity.” I’m talking about a program that allows students in high school to design and build hardware that flies to the International Space Station and is used by astronauts. On this episode we’re going to be talking about HUNCH, which is, of course, an acronym that stands for High School Students United with NASA to Create Hardware. We’ve discussed the overall program on this podcast before — Episode 106, if you’re interested in going back, but don’t worry, we’ll briefly review the program on this episode. But today is focused on a specific student experiment that recently flew to the International Space Station aboard the SpaceX CRS (Commercial Resupply Services)-27 cargo mission. Astronauts have been looking for a tool that would make taking beautiful photographs of Earth a lot easier, so students took on the challenge, from design to construction and testing. On this episode, we have Flight Configuration Project Manager Mike Bennett; Design and Prototype Manager Glenn Johnson; and from the student team who actually design and built the hardware, we have Shane Johnson. All right, let’s learn about this student-built camera mount. Enjoy.

[Music]

Host: Mike, Glenn, and Shane, thank you so much for coming on Houston We Have a Podcast today.

Mike Bennett: Thank you for the opportunity, thank you.

Glenn Johnson: Thanks a lot, I really appreciate being here.

Shane Johnson: Super-excited to be here, thank you.

Host: All right. Now, we have Mike and Glenn here in the studio. Shane, you’re, you’re calling to us from your dorm room; congratulations. We’re, we’re going to be talking about a high school program, but, but you’re in college, right?

Shane Johnson: That’s correct. Yeah, I’m a first year.

Host: All right. Well, congratulations. So I’m glad to have you on, I’m glad you could take the time to talk about this experiment because this is really cool. I wanted to go around the room and get other listeners familiar with your voices. Let’s talk about your role, let’s talk about, just sort of what HUNCH is, kind of set a foundation for our listenership. Mike, why don’t we start with you?

Mike Bennett: OK. My role is flight configuration manager. I work with the high school students once a project has been identified to move on for development to flight. I work with them in their drawings, in their material selections, and they’re all high school students, which is the cool part of this.

Host: That’s great. How did you get this role? What are, are you an educator? Do you have a background in, in education or anything like that?

Mike Bennett: I have a background in education; I was in it for 30-plus years.

Host: Oh, fantastic.

Mike Bennett: And I was also a part of the HUNCH program for over 15 years; when I joined I came over into the HUNCH program itself. So I had students for over 15 years that were building, training and designing flight hardware, and then I had an opportunity to join the team and be on this part of it.

Host: All right. Well, I’m super-glad to have you. This sounds like something you’re very passionate about is working with students.

Mike Bennett: Absolutely.

Host: All right, Glenn, a little bit about your background.

Glenn Johnson: So I came into the program about seven years ago. I’m the manager of the design and prototype. And so my job is to find and come up with projects that NASA needs. So I work with engineers and astronauts at different occasions to find things for students to work on. And then I hand those projects out to students and they start giving us prototypes so that we can find the best ideas, kind of mix them together, and then I hand it off to Mike and some of his team and we turn it into the flight hardware that can make it to the space station.

Host: So do you have more of a technical or engineering background, or are you also an educator?

Glenn Johnson: So, I, I, my degree is in physics, I was a high school physics teacher for a few years.

Host: Wonderful.

Glenn Johnson: Then I came to NASA after several years and I was a trainer in crew systems, so I helped train the astronauts on the inside equipment for the space station. And after doing that for several years, I came into the HUNCH program as the design and prototyping.

Host: All right. Well, it’s great to have you, too. And I know you have a lot of history on the, on the beginnings of this particular experiment, so we’ll definitely go into that. But Shane, I wanted to know about your background, right, you’re, you went to high school, now you’re in college. What’s your story?

Shane Johnson: Yeah, absolutely. So, in terms of HUNCH, I guess I’ll start from the beginning. I’ll never forget the scene. It was the very first day of high school in freshman year, and I walked into my engineering classroom of which Mr. Bennett, Mike, was also my teacher, before he joined HUNCH. And he took me around the classroom and showed me all the posters of different hardware that high school students from my school have sent up into space. And I remember that day I made a goal and that I was going to have something I made on the ISS. And so here we are, and we’ll get to talk about that in a little bit. But yeah, so I joined the HUNCH program my junior year, worked directly with Mike and Glenn throughout my junior and senior year, so I know them very well. And now I’m a freshman studying mechanical engineering at the University of Texas at Austin. Hook ’em Horns.

Host: [Laughter] All right. And I, I, I am going to go off on a, on a limb here and say you are pursuing mechanical engineering because of your work on HUNCH?

Shane Johnson: Definitely a factor; yeah, 100%.

Host: All right.

Shane Johnson: I’m also very big into like, automotive and cars and that sort of thing, but yeah, that definitely HUNCH is huge, a huge influence in my life.

Host: Awesome. Mike, you must have given one heck of a speech for him to be like, this is my goal so early in high school.

Mike Bennett: It wasn’t hard to get him enthusiastic. He was enthusiastic, enthusiastic as soon as he walked in the door and saw what he could do and what we had the opportunities to do through HUNCH.

Host: That’s awesome. OK. Well, Mike, let’s go back to you for a second, and, because we keep talking about HUNCH, we keep saying this name, but for our listenership, just give kind of a brief overview of what is this program, what is it that we’re talking about today?

Mike Bennett: Well, it’s High School Students United with NASA to Create Hardware. Through its evolution we’ve gone through training hardware, we’ve gone to flight hardware now, we’re also into culinary. We’re into soft goods. And we even have video challenges for the students to do. And this is countrywide. This is around the entire nation. And so we’ve got schools again from the West Coast to the East Coast, and we have mentors that help, and these tremendous students.

Host: So it has a nice benefit of getting students hands-on opportunity, almost like a, a way to learn about actually designing and fabricating some hardware. But then we get the benefit – “we” meaning NASA — of actually getting to, you know, we have an additional source of, of hardware. We have these challenges, we have problems that need to be solved, and we reach out to high school students to do it.

Mike Bennett: Absolutely.

Host: All right.

Mike Bennett: Absolutely. It’s, it gives them a challenge, a thing that they didn’t know they could do. They go in, well, I, I can’t do that, I don’t have the skills, and then they get their confidence, and they see what they can do and what they can achieve, and that helps them throughout their career. And the hardest thing sometimes is convincing people that, yes, as a high school student I actually did build this flight hardware, or I designed this flight hardware. So, and it helps their career, it helps their career choices, their college choices, too.

Host: Yeah. That’s one heck of a thing to put on a resume for a college application is, by the way I designed something in high school that flew to space.

Mike Bennett: That’s right.

Host: And I haven’t even worked in the space industry yet, I don’t have previous, like, five-years of experience or anything like that. No, they actually flew something. That’s pretty cool. All right, Glenn, this project that we’re going to be talking about today, it’s a camera mount. Now, you mentioned, you mentioned you’re the one that’s interfacing with engineers, with astronauts; there must be some communication path that gets to, here’s a problem that we need solved, and you come in and say, I think I know just the right people to do it. How does that process work?

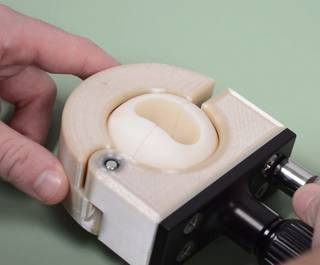

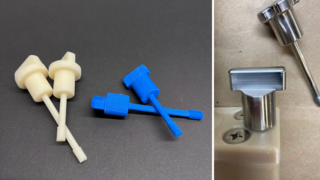

Glenn Johnson: Well, and on this particular one, I had a good friend, Bruce Blazine has been somebody I’ve worked with for many years. He’s in the, he had been in the OSO (operations support officer) team. Their job was to repair and keep the space station running all the time. And he had gone to a meeting one day and with the astronauts and he said, Glenn, they’ve got this problem where they want to be able to put the camera in the middle of the module so that it’s, it’s a better view of what’s going on, and all of the hardware that we have right now puts it over to the side of the modules so they can’t see right down the center of, of the module and be able to display what’s really happening; do you think we could work on this? And so, we sat around talking. Bruce had had this original idea of what we call a ball clamp, and it allows a, a piece of hardware to attach to a handrail and then be able to swivel so that, so that you can reposition things very easily. And so we started talking about how we could get kind of a long stick attached to this ball clamp, and then put a camera shoe on it so that it would hold the cameras the way that we want. And so, I went home later that night and I got myself a couple of pieces of, of aluminum tubing, square aluminum tubing, and I slid them together and I put a couple of holes in there so we could have different positioning and things, and I took one of the ball clamps that we had had printed up, and I attached it to one side. And then I, I, I don’t think I had a camera shoe on the other side. And I, I walked it in, and I said, hey Bruce, what do you think of this? I happened to bring it along with me. And so, it, there wasn’t anything special about it other than just that we could represent the idea, and that’s all we needed to do. And so, I took it around to a couple of the astronauts and I said, hey, what do you think about this? You guys were asking for this thing. And I took it to Don Pettit, and I took it to Paolo Nespoli, and I said, hey, what do you think? And they said, well, yeah, that’s kind of what we’re looking for, but you know, it’s kind of clunky. Yeah, it is. Well, we need something that’ll slide a little bit: you know, can you give me, instead of one every inch with a pip pin, can you give me something that’s a little bit more slidey, you know, a little bit more variable? And a, a, after they told me that I said, gosh, how come, how come I’m not trying to use a, a monopod just straight off the shelf? And that took a little while because we — you know, if, if it’s, if it’s not sitting in front of you, you don’t always think about it.

Host: Right.

Glenn Johnson: And so, after I, I went over to a store and found one that would fit kind of our needs, and then we started saying, wow, wait a minute, you know, if you want to set up a video camera or a camera in the middle, a lot of times you’re talking to, like, a president of a, of some country, or you’re talking to some pretty high-end people, and you need a teleprompter because you’ve got a speech or a long talk. And so, we started saying, hey, can, can we add like a piece of seat track, and a, a piece of seat track is a way of how things on the space station are attached to either a handrail or mostly onto seat track, and it’s kind of a long piece with buttons on it so you can place it in lots of locations. So we put a small piece of, of seat track on the side of it so that you could attach like a, an iPad or something like that, and be able to read the teleprompter, you use it as a teleprompter while you’re working and talking on, to this, whether it’s the president or somebody else, and be able to kind of be consistent. But it also means that you could add cam, you could add lights to it. So we took a monopod, we put the swivel on the bottom, we put a camera shoe and a swivel on the top, and then we added some other pieces to make it so that it was a little bit more usable for their specific case. And then, you know, it’s easy to come up with ideas, but to make it ready for space, that’s where I started running into trouble. And that was when Mike came in and started giving us, hey, well, you know, how long do we really want each one of these pieces? What kind of materials do we want? And, and, and so that really made a big difference.

Host: Awesome. I’m glad you actually brought that piece of hardware for our listeners. That clinking and clanking was the thing that you fabricated at home, right? That was it.

Glenn Johnson: Yeah. So it started off in my garage. And now to bring this back a little bit, the student portion is what’s really important here.

Host: Yeah.

Glenn Johnson: So Bruce Blazine and I came up with these general ideas, but the problem is that we really need it to be, there’s a lot of details in there. And that’s where we got, that’s where we brought our students in. So for example, the camera shoe, we didn’t want to use the, a standard NASA camera shoe because it has like 20 parts and it costs a lot of time and machining to be able to put it all together. And so, that’s where I, I, I wanted to hand that off to Mike.

Host: Yeah. Mike, take it from there. So you came almost kind of with the solution as he was, as Glenn was kind of troubleshooting some ideas.

Mike Bennett: Right. And we had, and that’s a strength: we have such support from NASA mentors and all that to guide the students. And then we took it, and we would take it and do prototyping. We’d make our models; we’d do our presentations back and forth. We’d get the invaluable feedback from all stakeholders, and then just keep refining until we did get a very, very good and workable solution to it. And the students have the opportunity to work through that process that maybe they’re not used to doing, and that gives them such a, a step up on doing that type of system.

Host: So what’s the, what’s the process of Glenn comes to you with a problem; he says, he says, all right, I have, I think I have an idea of how I want this; how do you get that to students?

Mike Bennett: We actually have a, like a roundtable meeting with the students and we get which students may be involved, and I, I look at their skill levels, which will fit, so they can be successful. And then we present the problem, we kind of identify where we want to go with it, and we just go through feedback iterations on the design, and then constant communication back and forth until we get it. And quite a few 3D prints.

Glenn Johnson: Yeah. [Laughter]

Mike Bennett: And things like that, prototypes.

Host: So where does, so was, is it Shane and a small team that you, you kind of pulled on? Or was it, you mentioned HUNCH kind of goes, you know, coast to coast…

Mike Bennett: Right?

Host:…so how, how big was your, was your army of students?

Mike Bennett: It really, counting additive manufacturing it goes all to the East Coast even on that. We have a school that does our 3D printing for ULTEM…

Host: OK.

Mike Bennett:…for flight ULTEM. Our design team was north of Houston, in Conroe.

Host: That’s right.

Mike Bennett: And they did the design for the camera shoe. We did the ball clamp on the par, on the part of that, and Shane came in with an invaluable redesign on the thumbscrew for it, because we had feedback…

Glenn Johnson: Didn’t realize Shane’s the one that did that.

Mike Bennett: Shane is the one. Sorry about that. Sorry about that, Shane.

Glenn Johnson: That’s funny. [Laughter]

Shane Johnson: It’s all right. It’s all right.

Mike Bennett: So he did an invaluable redesign, so it was easier to tighten up the ball clamp.

Host: OK. All right. Yeah. So Shane, talk about the, what, we’ll go to you for a second, because he’s talking about, you know, there’s a lot of different parts here. Mike comes to you with the problem, you know, what was, what was that like, the introduction of this, of this, of this design and, and how you went about solving it?

Shane Johnson: Absolutely. Yeah. So obviously the first step is figuring out what the heck is going on, because, you know, I had heard of like ball clamp and foot restraint and thumbscrew and all these different things, but you, you have to, you know, place names to actual items because, like Glenn said, some of these components have, you know, dozens of different things that put them together in the assembly. And so, for my thing, what I focused on with a partner, Matthew Rubis, was a redesign of the thumbscrew, like Mike was talking about. And so, just to give a bit of background on that, what Mike and Glenn came to us with was this thumbscrew that had traditionally had a little keyhole at the top of it, where the astronauts would use a, a tool to tighten, to tighten it down, excuse me, whether it be on the foot restraint or the monopod for the camera. And so, basically, now they wanted to be able to tighten it without that tool. I’m not sure if that tool was no longer standard issue carry, but regardless they wanted to be able to tighten it down sufficiently with just their fingers. And they couldn’t do that, especially if they were wearing, you know, thick space gloves on. And so, what we had to redesign, Matthew and I, was the top portion of the thumbscrew specifically, to where they could get that tightness that they wanted to with just their fingers. Yeah.

Host: OK. So Sha, so Shane, you were presented just the thumbscrew problem?

Shane Johnson: I think, we were presented kind of like a multitude of things, and we just ended up going down that path. We did do some side tangent projects, some smaller scale stuff, but yeah, that was definitely like the main focus of, of my junior year.

Mike Bennett: And one of the things that Shane had to do too is with this redesign, he also had to make sure that it fit in the current clamps in the ball clamp assembly itself. So not only did he do that one portion, he had to make sure it interfaced and worked well with everything else.

Glenn Johnson: Right. Well, I, I know nobody else can see it, but I brought it in because I’m much easier, I’m, I’m much better at talking with my hands than just talking out loud. What Shane was handed is, imagine a long screw, and then on the top of it it’s got kind of a, kind of a flower-shaped grip for it. And we thought we had started off, we thought we had done this well because, wow, we tested it on lots of stuff and it seemed to work pretty well. But then after Shane had come back with a much simpler design, that was just kind of like a, a, a single kind of big tab at the top, I don’t know how to describe it any better…

Mike Bennett and Shane Johnson: That’s correct.

Glenn Johnson:…it was so much easier that we could get an extra, almost a full turn out of it because of being able to have a different grip, and just a lot easier to kind of grab onto and hold. It made a big difference in this project, but also in future projects. It’s funny, most engineers work on these little, tiny things and when they have to try to talk about what, what kind of cool things they’re working on at, at home or whatever, people say, that’s all you did? But it’s the most important part because, [Laughter] because when you, if that final connection doesn’t work right…

Host: Yeah.

Glenn Johnson:…then people don’t want it.

Host: But, and it has that residual effect too, right? You’re talking about this tiny, little piece on the monopod, but you just said that that design was good enough that now it’s being considered for other things, because you avoid the need of a secondary tool, and you can get extra strength. I don’t know. It sounds like it’s kind of a flat piece, right…

Glenn Johnson: That’s exactly right.

Host:…so you can kind of like work your thumb into it.

Glenn Johnson: That’s right.

Host: But yeah, you can apply that to other things.

Glenn Johnson: Yeah. So, the, the iterative process that we end up with and, and this happens for all engineering, but it really makes a difference to have these different people coming in, a slightly different perspective, because they think about it a little bit different so that we can all benefit out of it. And we keep trying all of the diff, all of these different iterations to try to make the best one that we can.

Host: So when you present — so this is for Mike — when you, when you presented this challenge to Shane, what tools, what resources did you give him and the other students? Like, did you give them mock-ups? Did you, like, do they have facilities that they can access? You know, CAD (computer-aided design) software? Like what, what tools do they have to actually help out with this?

Mike Bennett: Well, Shane was in toward the advanced years of the classes that he’s in, so he was very proficient at CAD work.

Host: OK.

Mike Bennett: And he was using parametric CAD, so he could make the 3D models and he could actually create the files needed to go to the 3D printers that he had. So we came in with the basic package of what we had and then identified where we needed to go with it so he could see what we had, see the models that we had for the first iterations of it, and then troubleshoot it and problem-solve it and come up with one that gave a, a, as we said, almost another full turn of torque on that. So, and then he used those skills to do it.

Host: So Shane, how did you approach that? Did you, you know, like, what, what was that like when they said, all right, Shane, take it away, come up with a cool design. What were some of the, what were some of your first steps to come up with your solution?

Shane Johnson: Sure. Yeah. So, obviously, like Mike just said, we were given the previous iteration and just the general direction as to how we wanted to go from here on out, or where we want to end up at, rather. And so, you’re, and this is arguably my favorite part and that’s the brainstorming part of it, because you just have so many ideas on where you can take this. And there’s, there’s a beauty in the creativity that comes with that, but it’s also at the same time daunting because you’re like, OK, I have so many cool ideas, now which one do I choose? Which one do I invest my time and effort into? And so, yeah, again, like we, we ended up with the flathead design that gave us a lot more torque, but I remember going through the entire like engineering design process, and I, I loved every moment of that, you know, starting with brainstorming and then going through different, like bring it into CAD and, iteration by iteration, having like people test it out and say, oh, how does this feel in your thumb? You know, and, and just tweaking small little things. And like Glenn said earlier, you know, when you come back home and you say, oh, I worked on a thumbscrew, people go, really? Like, that’s it? But, but there’s so many little things that were so fun about it. Like just changing the different radii of certain edges and the fillets to see which is most comfortable and which you can get like the mo, excuse me, the most surface area of your thumb on it. Different, tiny considerations that all, that all add up into a, a perfected product in the end.

Host: You know, it sounded like because of the, what you, what you were working on, this thumbscrew, right, sounded like you had kind of an opportunity to, you said, you said you got to play with a lot of different designs, but was it all on the computer or were you 3D printing some models, testing them out, making some changes going back into CAD? What was your process?

Shane Johnson: Absolutely. Yeah. Yeah, it was, it was an iterative process.

Host: OK.

Shane Johnson: So I would create something in CAD, 3D print it, because we were fortunate enough in my high school to have some 3D printers available.

Host: Awesome.

Shane Johnson: 3D print it, and because they’re relatively small screws, they don’t take long. So after a couple hours I’ll have those ba, that batch out and, you know, I’ll see how it feels. I’ll put it into the, into the foot restraint or the monopod, make sure that, you know, it screws as tightly as it needs to, and then say like, maybe we can tweak this. And again, I’ll present it to Mike or Glenn, and they’ll say, yeah, we need to tweak this or this or this. And so, I’ll go back and tweak that. And it’s just recycle of that process over and over and over again until we have a good product.

Glenn Johnson: How many of those do you think you printed out?

Shane Johnson: Oh gosh; probably, probably three digits, three figures.

Mike Bennett: Yeah. They were several iterations, because what he had to do, not only was it had to be functional it had to be comfortable, and you had to look out for, you know, how does this interface, or are we creating stress if we do this design? So he had all that, not only just functionality of it, but is it comfortable to use?

Glenn Johnson: Well, and, and so, I don’t know about Mike, I think I probably have ten or 20 of those still rolling around in my drawer at work.

Shane Johnson: I am the exact same way.

Host: Probably have, with that many, probably have multiple thumbscrew drills. Yeah. Yeah. Shane, you said we, when you’re doing this, were you working with a team; who was your, did you have, you know, did you have folks with you, teachers, who was helping you out with this?

Shane Johnson: Yeah, so, obviously on the NASA side of things, I had Mike and Glenn, my NASA mentors that I would give my revisions to. But then on my side of things, obviously I had my, my CAD teacher, Mr. Jarrall Ford, and then I had my partner, Mr. Matthew Rubis, and it was mainly him and I that were working on the iterations and, and the CAD and 3D printing and so on.

Host: How long did that process take you from the time, from the time you started with the initial designs to the print, try again, print, try again? It sounded like a lengthy process if you’re in the three digits.

Shane Johnson: Yeah, yeah. So, the time from like, you know, we got presented the project basically at the start of the school year, so August, September, what have you, and then I remember finishing it basically, going through the entire process, around the end of that year, that school year. So it would be maybe like May-ish, maybe just before May. So yeah, basically an entire school year was put into this project.

Host: How did you split your time with your other classes?

Shane Johnson: Are you referring to my other high school classes?

Host: Yeah, yeah. Like, was this all this work after school or did you, you know, sign up for extra, some extra, extra periods of, of 3D printing class to try to get a lot of this done? What, where was, how was your time spent?

Shane Johnson: Right, yeah. So my engineering class as is, was, was a block period. It was about, about two hours, as a part of my actual school day. And so, of course, those two hours went into it. And then, you know, of course I, I put time in at home as well, though that’s harder to quantify. But yeah, it was, it was mainly done during class time. And of course I did have other things to do during class as well, but, my teacher, Mr. Ford was, was accom, accommentable? I’m not sure if that’s a word. He was accommodating; accommodating…

Host: There it is. [Laughter]

Glenn Johnson: There you go.

Shane Johnson:…to let me work on this in class.

Host: Ah, that’s fantastic. Yeah. I can relate just a little bit. I was, when I was in school, I, I was really into film, filmmaking.

Glenn Johnson: Yeah. Yes.

Host: And you find something you’re passionate about like this, right, where you have a couple of hours in school, like you got a period where you can dedicate to, you know, in his, in Shane’s case engineering, in my, in my case it was film. But I found myself, I signed up for track and, it was my senior year I signed up for track and field; I like never went because I was always in the studio, playing with film and getting to, you know, enhancing my skills because I just found a bigger passion with that. So I think that’s when you know that you like something, right, is if you’re doing that. And then you said you put some hours in at home too. I mean, you must have, you must have loved this. You must have been like, I got to get this done. You know, this is something that you must have been really passionate about.

Shane Johnson: Absolutely. Yeah. It was a passion project, it was a project of love. And so, you know, when you’re, when you’re passionate about something, whatever it is, whether it be engineering or film, you, you find yourself putting more hours into it just because it’s fun, right?

Host: Yeah.

Shane Johnson: And so, yeah, definitely.

Host: Mike, Shane’s not the only one doing, you know, he’s, this is not a thumbscrew project…

Mike Bennett: Right.

Host:…this is, this is a whole thing.

Mike Bennett: Right.

Host: So, so you are doing this, you must be having this oversight…

Mike Bennett: Right.

Host:…with, with folks like Shane, right, who, who is making redesigns, go back, try it again, and you have to be doing that with all of the different components of this monopod, is that right?

Mike Bennett: Correct. Correct.

Host: With all the different students.

Mike Bennett: Correct. We had students working on the ball clamp, we had students working on the iterations and the, the hemispheres they go in to make sure they fit correctly on the, on the handrails, so there were little teams all around in the different school districts around, between, again, from the camera shoe, and once Shane did his incredible work that was passed off to Mr. Bill Gibson as, who’s one of our mentors and he worked with his machinist students, and they manufactured these.

Glenn Johnson: That’s right.

Mike Bennett: So.

Glenn Johnson: Yeah. And, and so, for example, Lorenzo Farrales is one of our students who was up in Conroe working with Eric Canestorp, and yeah, we went back and forth several times, and I, again, I’ve got a whole bunch of those 3D print jobs sitting in my drawer, and we’re saying, oh, you know, make it, you know, one more millimeter here and round off this edge there. But then the machinists also have to be doing some really excellent work. So, the students that are going over to, to do the machining for the, for the camera shoe, the students that are doing the 3D printing for the, the ball clamp, they all had to be doing some really excellent work for us as well. And they, they certainly deserve a lot of the credit of making this look like a good flight hardware piece.

Host: Where does the integration happen? How do, you have all these pieces, it sounds like a multi, parts all over the country, really…

Mike Bennett: Correct.

Host:…how do you bring them together into a design and then get it flight ready?

Mike Bennett: We, we come up with a finalized design. We have one group of students that, for example, at this school that came up with what we thought was the best flight drawing, and then we choose the different parts for the schools that show interest in it. For example, our 3D printing school in, I believe Alabama?

Glenn Johnson: That’s ri…Georgia.

Mike Bennett: Georgia, Georgia. They are amazing. They produce wonderful parts. They are doing the flight parts and, they take care of that, the documentation and all that. So we know that right now they’re the school that we go to for flight. For prototyping, we’ve got schools also across the country that do fantastic prototyping and get to to us for study models. And they can, another pair of eyes on it to see if it works as it come together, and other suggestions and feedback.

Host: All right.

Mike Bennett: So it’s a, it is a huge team effort. It absolutely is a team.

Glenn Johnson: Now, once the parts are machined and we get them all finalized in terms of the surface materials that we want on them and things like that, then they come to one of the schools here by Johnson Space Center, and we have an assembly there. And that’s done by Carlos Valencia. And he, his job, he’s a professional assembler. And so, he does a lot of assembly work for other NASA hardware, and we use his excellent skills at getting it all put together because there are specific information that we have to put into it. For example, what’s the torque value of each of the screws? What kind of epoxy material do we use to hold the threads and things like that? And so, unfortunately, we don’t get to have students do a lot of the final assembly work, just because there’s a lot of detailed work in that assembly process.

Host: Yeah. That requires a lot of expertise.

Glenn Johnson: And unfortunately, we can’t teach it in a year…

Host: Yeah.

Glenn Johnson:…you know, and so it’s something that we’ve got to have a NASA professional working on.

Host: OK.

Mike Bennett: But the students will go through an inspection process, so as they manufacture this, they still go through the, their inspection process, their documentation, they’re tracking of materials, so they’re still doing that. And then when they send the parts to us, we go through, and all that material is there, we may double check the, we’ll double check the, the parts, and then they’re good to go.

Host: Shane, have you seen the flight ready model? Have you gotten a chance to take a look at it?

Shane Johnson: I have seen pictures; I have not seen it in person. The, granted, I’ve been in Austin, away from, away from the Houston area for the past couple months, but yeah, I, I’ve seen pictures.

Host: That’s, that’s awesome. So how do, so yeah, I guess what’s, what’s comes after that? Now, you get the, you have someone who’s, has the expertise of getting it basically ready for flight.

Glenn Johnson: That’s right. Correct.

Host: And then comes the, the job of manifesting. So what’s, is it, are, do you just have one, one monopod that’s going up? You got an, a fleet of them? What’s going up?

Glenn Johnson: Right now we’re sending up one.

Host: OK.

Glenn Johnson: The crew are going to evaluate it, tell us what they think. We have hopes that they might want another one, or that it might fly on some of the later vehicles. So for example, the Gateway might want one, for similar kind of reasons. And so, we’re just hoping to be able to, I, I think what we’re going to do is probably build like six of them total, because we also have to have some on the ground for training and other testing for different procedures and things like that. And so we’ll probably have, we’re, we’re going to have to have several to be able to hand around to different places.

Mike Bennett: Right, right.

Host: This is going to be launching soon, right? This is…

Mike Bennett: The SpaceX-27 is what is slated for.

Host: Is coming up.

Mike Bennett: It’s exciting.

Glenn Johnson: It’s very soon, so I think we’re talking March 12 is the last I heard. So.

Host: Yeah. I think by the time this comes out SpaceX-27 will have already launched. [Editor’s note: It did, on March 14.]So it should be, I mean, I don’t know where we’ll be at. Maybe they’ll be, have tested it or what, but we’ll at least have a nice preview. You guys, this has got to be a pretty exciting time. When you, when, when it gets manifested, what generally the students’ reactions?

Mike Bennett: We try to contact everybody that’s worked on it and let them know, and they’re just so excited that what they worked on, because it’s a multi-year process…

Host: Yeah.

Mike Bennett:…it is a multi-year process. And so, we always try to communicate back to them and their teachers that all that work and all those iterations that Shane went through and everybody else went through, that here it is, it’s paid off and now it’s actually going to fly.

Host: Shane, how do you feel? You’re one of those people; you actually contributed something that’s going to be going to space.

Shane Johnson: Yeah, yeah. It really is a dream come true. Like I said in the beginning, it was a goal for, since the fresh day, first day of my freshman year. And I remember when I got the call from Mike saying that it was, it was going to be on the, on the flight out that, like, when I went home, it was towards the end of the day, and when I got back to my car I just sat there in the parking lot and screamed for a couple minutes. I remember calling my girlfriend and my mom and my dad and my best friend and just saying, like, it’s finally happening. It’s finally happening. And yeah, it, it, it just, even now, like, it’s, it makes me so giddy. I have such a huge grin on my face right now. It’s, it’s so awesome.

Host: Wow, that is unbelievable. This, Mike, this has got to be probably one of the best things about this program is, you know…

Mike Bennett: Absolutely.

Host:…you said it’s a multi-year process, right, and I, I don’t expect it to be easy; with that amount of coordination that’s happening, with all the, the process, it’s a, very lengthy. But the reward is this.

Mike Bennett: Absolutely.

Host: The reward is a student kind of jumping for joy in the, in the, in the parking lot. That’s…

Mike Bennett: Absolutely.

Host:…I mean, that’s worth it.

Mike Bennett: Absolutely. It is about the students. Absolutely.

Host: Yeah. Yeah. That opportunity is absolutely amazing. So, yeah, the, the, it sounds like this is something that you already have deeper visions for as well, right? So this is what we’re, what we’re doing is sort of a test. You’re going to get feedback from the astronauts — oh, it’s a little too loose up here, or, hey, I would appreciate a couple more inches here — I’m guessing that that has a whole process…

Mike Bennett: Absolutely.

Host:…of feedback that’s going to be happening.

Glenn Johnson: That is, that is exactly right. So, and we’ve had other things where they fly up and the crew says, you know, this is really good, but we’d like this changed. And, and so, we have projects that keep coming back to us, but the other thing that we get back is that the crew call down and they say, you know, these HUNCH projects are really working out well for us. And if, if you go online with us, sometimes you’ll see that there’s, there’s crew talking about, you know, hey, this is something that the students of this school sent up to us and we’re really liking how this works. It, it’s, it’s terrific for the crew because they feel like they’re reaching right back down to Earth and talking to the students directly about what they really like about the space station.

Host: You know, this is something that’s, I think, more visual in terms of HUNCH projects as well. I mean, this is, this camera mount, Glenn, you were sort of laying out sort of what the vision is for how it’s going to be used. We’re going to see a lot of pictures, video, you talked about, I don’t know if this thing can hold teleprompters or what, but there’s a chance that if the astronauts really like this and you start sending more up, they could be using these all the time.

Glenn Johnson: That’s exactly right. Right now they’re using what we call a multi-use bracket, which is a, it’s a great tool, and you see them all over the space station. But, as great of a tool as they are, they don’t fit every function. And the same thing goes for this, right? It’s a great tool; how many different functions is it going to fit? We really don’t know yet. I mentioned being able to get right into the middle of the module because it’s long enough to be able to do that, but the other thing that one of the astronauts had mentioned to me was how, when you’re in the Cupola looking down and trying to follow a particular object on the ground — let’s say it’s a, a volcano is going off — keeping yourself steady and being able to follow it as the, as the space station flies over, it’s really helpful to have something to be able to kind of slowly pan with. And we hope that this is going to be helpful for them to be able to, to follow objects on the ground as well as being able to keep it steady when they want it steady. So, we’ll see how this works out. You, another place was when they’re using the, the glove box, the microscience glove box…

Host: Oh, yeah.

Glenn Johnson:…being able to get into the, the right window and position so that they can see what kind of experiment they’re working on is also really helpful. And so, we’ll see how it works out, but we’ve got a lot of places that crew think that it might get used.

Host: That is very ambitious. I mean, this is, I mean, this is a really interesting project. Mike, when you, when you talk about the HUNCH project and you talk about the benefits of it, what are some of the key things that you try to communicate to students, to, you know, the space station program, to others that want to get involved in HUNCH and do stuff like this — you know, stuff where you can be working on, I mean, it could be simple as like a thumbscrew, but it could be on, something that is used all the time on space station, it can be something that’s almost, you could even call it critical and a step forward for space exploration — how do you, how do you pitch it?

Mike Bennett: Well, first thing we try to tell them is they are part of our team. Just because they’re working on maybe something small or just because they may be a sophomore in high school or a junior in high school, or even earlier in high school or other grades, they are part of our HUNCH team and their contributions are invaluable, and they’re going to, working toward a real solution — it’s not just a hypothetical, they’re working in the real industry right now. And we want them to gain as much benefits out of it themselves, too, through exposure to subject matter experts that we work with, and just gain some interest in it and see which direction it may carry them.

Host: Are you or any of the students planning to go out to Florida and see this thing launch to the space station?

Glenn Johnson: I’d love to. I’ve never…

Mike Bennett: I’m not at this time. Not at this time. [Laughter]

Glenn Johnson: We’ll see.

Host: OK.

Glenn Johnson: I, I’ve never gotten to see one of the SpaceX vehicles land, and so that’d be really exciting.

Host: Oh, yeah.

Glenn Johnson: And, but, yeah, I think it’d be terrific, if it’s launching when it says I, I might have some time at that moment, so, I’m going to give it a shot.

Host: That would be great. Usually I’m stuck here to work missions from Houston — and I say “stuck,” it’s awesome in its own right — but I don’t get to see the smoke and fire out it. And I did get to see it one time, and it is, it is truly spectacular.

Glenn Johnson: Yeah.

Host: I would highly, highly recommend it.

Glenn Johnson: Shane, are you interested?

Shane Johnson: Absolutely. Yeah. It’s actually the very beginning of my spring break, so I should also be…

Mike Bennett: OK.

Shane Johnson:…should be good to go.

Host: Road trip.

Glenn Johnson: Road trip. [Laughter]

Host: Road trip. All the way down I-10. Yeah.

Shane Johnson: There you go.

Host: [Laughter] All right. Shane, what’s your ambitions? You’re, you’re going for mechanical engineering, it sounded like you were into cars and, and automotive industry, but how you going to, how you going to take what you learned from HUNCH, apply it and what’s, what’s the next dream for you?

Shane Johnson: Absolutely. Yeah. So, HUNCH has given me inval, invaluable experience, real industry-grade experience. And I’m applying that each and every day to, to this day in a, in a organization I’ve joined called Longhorn Racing, which is basically a, a organization where students make an FSAE car. FSAE, I believe stands for Formula Society of Automotive Engineers; it’s like an F1 style race car. And this goes on all across the world, even in Europe and, and Asia, and we all compete in, in the summer, and I believe Michigan and, have different dynamic events and basically put our cars to the test, and we’re scored and judged and so and so on and so forth. But yeah, I’m, I’m applying that knowledge, applying the skills that I learned in HUNCH in my, in my future endeavors, in LHR, and I have no, no intention of slowing down.

Host: [Laughter] That is awesome.

Mike Bennett: That’s great. That is great.

Glenn Johnson: That is great.

Host: What a cool project to be a part of. Oh, that’s great.

Glenn Johnson: Hey, Shane, have you seen any other HUNCH students when you’re, when you’re in college now?

Shane Johnson: Not to my knowledge, but then again I don’t really go around asking, right?

Glenn Johnson: You’re not wearing your HUNCH patch? Come on.

Shane Johnson: Oh. You’re, no, you’re so right. You’re so right.

Host: I think the expectation, Shane, is you got to be wearing that at all times.

Glenn Johnson: That’s right.

Mike Bennett: That’s right.

Shane Johnson: True. Very true.

Host:[Laughter] Awesome. Well, hey, this was, this was so fun to be talking to you guys today. It’s, this is very exciting. It’s going to be launching very soon, and you guys are going to be getting feedback on this, this monopod…

Mike Bennett: That’s correct.

Host:…from, from astronauts from space, something that could be used all the time. Let, kind of wanted to go around with just some closing thoughts, closing words. Mike, we’ll start with you, just on — I like to end this way sometimes — which is just the idea of exploration and space and all of that. You know, like for example, Shane, Shane going for, you know, having a, an interest in cars, but being subtly influenced by space. It’s something that, to me, is, is very transferable in that space exploration is, is a little bit about, you know, exploring and doing new things but it could be these pathways to very interesting places. Not everybody has to go to space. Not everybody has to go out into the cosmos to explore their passions, but it has this interesting path to get people there. I don’t, this is just sort of my rambling, but I wonder if you have more thoughtful words than me.

Mike Bennett: Well, and, and again, I’ve, I’ve just seen what this program and what these type of activities do for our students.

Host: Yeah.

Mike Bennett: The confidence it gives them, the direction it gives them sometimes, and sometimes they may not go into the direction we think, but those skills they carry with them always. And I think it just improves everything. It gives them a confidence, like I’ve said, that they may not have had when they came into the program. It gives them a passion, as you can hear in Shane’s voice.

Host: Yeah.

Mike Bennett: And it’s just a win for the students, I think, and for us too.

Host: Glenn, what’s next for you? You’re, I’m sure you, you’re talking with the astronauts, thinking about, they’re giving you some feedback, the engineers are wanting some projects. What are you, what are your…

Glenn Johnson: Well, you know, so we are working on, I’ve got three projects on my desk right now, all of which are, you know, first we start off with, what do the engineers need, and then we start handing it out to students to help us out with. So I mean, we have a, a project potentially for the Orion vehicle going to, around the Moon, which is exciting. We have things to help out on the space station. You know, and all of these things are little things, right? And the value of that is that engineers all understand at some point that the space station, the space vehicle, whatever it is that you’re building, it all starts off as one bolt, one rivet, one panel at a time, and every one of those is contributing to what that final vehicle is going to be like. And so, we, we hope that our students get that same kind of feel that they are making a difference in what that space program is going to be like in the future.

Host: That’s wonderful. Wonderful words. Shane, I’ll, I’ll end with you. And you know, I’m thinking about, you seem to have an immediate passion for this, early in high school, and you pursued it, you know, and, and it kind of influenced to where you are today, but I wonder if you have some words of advice to, you know, students that are in their first year of high school, and maybe not sure of where they want to go, maybe scared of trying something new, and I wonder what piece of advice you have for them?

Shane Johnson: Absolutely. Yeah. So, the first, the two things that come to mind, one is get involved. Regardless of what programs your high school has or doesn’t have, find something. If there isn’t anything, make something yourself. And, and find something that you’re truly passionate about it and get and be great at it. Excel at it. And bec, and it’ll be, it’ll come naturally to you because you’ll, you’ll want to put the extra time in, you’ll want to put, go the extra degree. And yeah, so first thing, get involved. Second, you know, you mentioned if, if you’re, if you’re scared or something like that, find a mentor. For me, it was Mike and Glenn, and I’ll forever be grateful to them. But yeah, just find a mentor. Find someone that knows something that you don’t know or, or has done something that you want to do, or something along those lines, and, and connect with them. Build a relationship with them. And if you can align your interests with the interests of others, things are going to work out for you.

Host: Wonderful. Oh, this was such powerful ending words from all of you, you guys are so awesome. This was so fun to be talking to all of you today. Very exciting. I’m, I’m happy for you guys to, all that work and now you have the monopod going up to, to the space station, it’s going to be tested out. Very, very exciting and I’m glad to have all three of you on today. So I appreciate your time.

Mike Bennett: Thank you for the opportunity.

Glenn Johnson: Thanks for having us.

Shane Johnson: Thank you so much. Yeah.

Glenn Johnson: Excellent.

[Music]

Host: Hey, thanks for sticking around. I had fun talking with Mike, Glenn, and Shane today, learning all about the camera mount. Very cool stuff to be hearing from the team and how long it took and the passion that they have for creating something and contributing to human spaceflight. I really hope you enjoyed. You can check out HUNCH at www.nasahunch.com. And then you can also go to NASA.gov to find HUNCH and some of the other resources and opportunities we have with students, and then of course, a lot of the things happening aboard the International Space Station. If you’re into podcast, though, don’t worry, we have a lot of them at NASA. You can just go to NASA.gov/podcasts. That’s where you can find us, Houston We Have a Podcast and our full collection, as well as, other shows we have across the agency. If you want to talk to us on social media, we’re on the NASA Johnson Space Center pages of Facebook, Twitter, and Instagram. And on any one of those platforms, you can use the hashtag #AskNASA to ask a question, and if you want to reach out to us specifically, just make sure that in your question, you mention us, Houston We Have a Podcast. This episode was recorded on February 17, 2023. Thanks to Will Flato, Pat Ryan, Heidi Lavelle, Belinda Pulido, Jaden Jennings, Erin Anthony, and Rachel Barry. And of course, thanks again to Mike, Glenn, and Shane for taking the time to come to the show. Give us a rating and feedback on whatever platform you’re listening to us on and tell us what you think of our podcast. We’ll be back next week.