“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center, the home of human spaceflight, stationed in Houston, Texas. We bring space right to you! On this podcast, you’ll learn from some of the brightest minds of America’s space agency as they discuss topics in engineering, science, technology and more. You’ll hear firsthand from astronauts what it’s like to launch atop a rocket, live in space and re-enter the Earth’s atmosphere. And you’ll listen in to the more human side of space as our guests tell stories of behind-the-scenes moments never heard before.

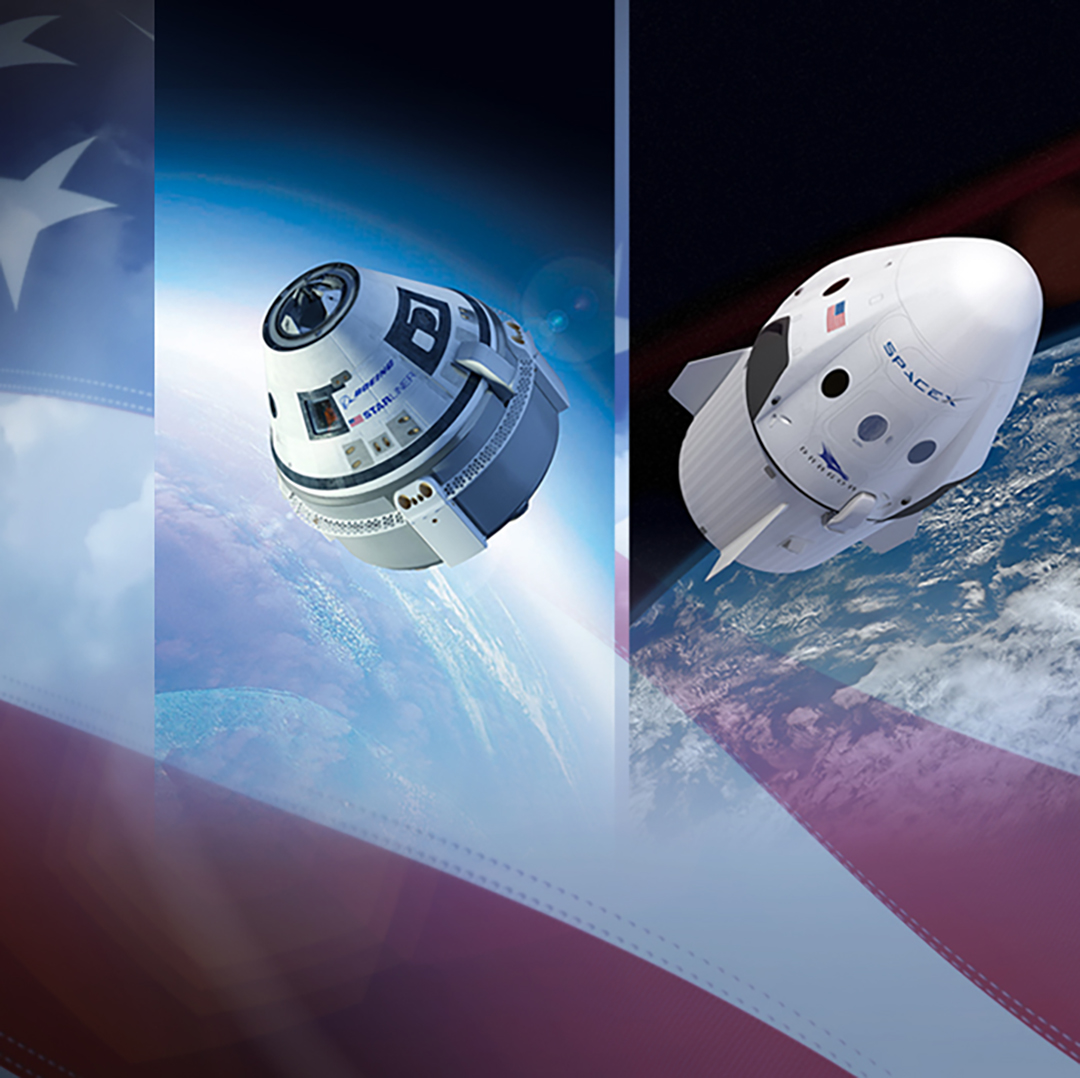

Episode 49 features Kathy Lueders, Manager of the Commercial Crew Program based at the Kennedy Space Center in Florida, and discussions of a brief history of the space program, how it started, and where it is now. Lueders talks about the two commercial companies, Boeing and SpaceX, and their space vehicles that will carry astronauts into low Earth orbit. This podcast was recorded on Wednesday, May 30th, 2018.

Transcript

Dan Huot (Host): Houston, we have a podcast. Welcome to the official podcast of the NASA Johnson Space Center. This is episode 49, Launch America. I’m Dan Huot and I will be your host today. On this podcast, we bring in the experts, NASA scientists, engineers, astronauts, and leaders to tell you about all the coolest stuff taking place here at NASA. Today we’re talking once again launching from American soil with two different vehicles developed by two different companies, Boeing and SpaceX. It’s part of the Commercial Crew Program to enable the capability to launch people into space by private American businesses. Today I’m sitting down with the manager of that program, Kathy Lueders, who’s based over at the Kennedy Space Center in Florida. We got a brief history of the program, how it started, and where it is now, a little bit more about the companies and their two different vehicles, and what’s ahead for the future. Very soon, we’ll be announcing the crews that will be the first to travel on these vehicles, so stick around until the end to find out how to watch that live.

So, with no further delay, let’s go light speed and jump right ahead to our talk with Kathy Lueders. Enjoy.

[ Music ]

Host: I am sorry we’re recording this in a refrigerator today. So, I wish we had a jacket for you.

Kathy Lueders: Oh, I’ll try to keep my teeth from chattering.

Host: But– so, Commercial Crew and kind of want to get into, you know, where it all started. So, the Space Shuttle Program was America’s ride into orbit for about 30 years, but then it came to an end and that’s kind of where the seeds for Commercial Crew started, correct?

Kathy Lueders: Actually, I think Commercial Crew really started with the original concept that America could fly payloads on commercial vehicles. So, I really think it started in the 90’s in a lot of ways. Yeah, even sooner, because I think when people started to think about flying, you know, DoD payloads on ELVs, that was kind of the beginning of starting to think about is there ways to use what’s an emerging capability, a national capability, in ways that would help the space program. And so, there was a couple different initiatives that were out there, Alternate Access to Space, a few other things that kind– that really kind of planted that seed in several administrations about is there ways that we can kind of make space not just for NASA.

You know, for the longest time, space was just NASA’s and then really in the 90’s when you start moving into these commercial launch vehicles and launch– and reliable capabilities, then that really– once you had that reliable capability that’s there, then it– there’s an option of, well, how can the space program potentially use this capability rather than create the capability. So, I think this has been 30 years in the making. And really as industry has shown that they can do and perform a function, I think then there’s been this natural progression of then using that capability for the missions that industry can support and then that allows NASA to really move out into the areas where we’re kind of pushing the envelope and where there’s more risk, right?

And where really doing the research and the exploration that is really the government’s role.

Host: So, when did we start getting really serious? Really serious– I’m talking setting up programs, moving into buildings, stuff like that– about using these capabilities for people.

Kathy Lueders: So, in the 2008, 2009 timeframe, I think when we were– I was working on cargo and at that time from, you know, the policy perspective, the White House, they started looking at, OK, well, we’re developing this capability for cargo, really what then potentially would we be able to use this– could we use this for crew? I remember the COTS Program originally had been, you know, they had gone out with their initial proposals or their requests for, you know, proposals in the 2006 timeframe had been for Commercial Crew and Cargo. It’s why it was C3PO, right? It was Commercial Crew and Cargo and so–

Host: One of my favorite acronyms.

Kathy Lueders: Yeah, mine too. Alan was always way better at putting together a name of a program than we obviously were. So, when they came in with those initial, you know, requests, companies did come in with concepts for how they were also developing their crew capability. It wasn’t just cargo. We, at the time, you know, as we saw that evolving, really because station at that time really needed cargo capability with the– with shuttle retirement. At that time, you know, on the– I was working for station and I– we came in and built our initial concepts for being able to use the capability that Alan Lindenmoyer and his team were investing in over– under the Space Act Agreements. So, when the CRS contracts– commercial resupply services contracts– were then awarded and we were making progress towards actually conducting the missions, and working certification activities with Alan, then I think people started thinking, well, maybe there’s a construct here that we can start working on for crew.

Host: Kind of the cargo stuff was laying all the ground work and now we’re going to springboard off of that and not just launch stuff, but launch people too.

Kathy Lueders: On top of it, too, we learned a lot from cargo. I learned a lot from cargo. How to set it up, how to set up the certification phase, and so we did learn things about cargo that we said, for crew, this will have to be different. And it’s why starting in the 2009, 2010 and then, you know, we started working whitepapers on how do we do crew. What are the different options for crew? At the very beginning, it wasn’t really– you know, remember the first investment in crew was really through the ARA [assumed spelling] investments in 2010 and so there’s very, you know, working the CCDev proposals, some very initial investment and because one of the things that we realized was under cargo, the infrastructure when the SAs were originally awarded, the companies had very little infrastructure there. And so it was– CRS was a very high risk– high risk, high gain, high benefit, you know, procurement for us because really, before we awarded CRS, we did not have return capability for science.

Right? We did not have, you know, extensive cargo capability going up and down. It was really just going to be progress after shuttle retirement, so that was– that was high risk, high reward for us. But with crew, it has to be safe, reliable– the risk level and the tolerance is– it goes down. So, then it was really important for us to lay– start laying the foundation of how do we go look at what are current gaps in industry that we need to beef up and invest in over the next few years. So, that was kind of the 2010, 2011, 2012, you know, timeframe. And then in 2013, we said, OK, it’s time to go do a certification contract and then start buying missions for crew.

Host: And so that’s what actually got us to where we are kind of today where there’s two companies getting ready to fly American astronauts again.

Kathy Lueders: Two companies. They have their– spacecraft is really, really cool right now. I can’t tell you– go out to SpaceX, you see spacecraft in the building, one– our DM1 vehicle’s getting ready to roll out to go to Plum Brook in a week and a half. You go over into the C3PF down in Florida and the Boeing spacecraft, you get C3 spacecraft, the Spacecraft 1’s getting ready to get shipped out to go support pad abort test. Spacecraft 2’s getting ready to get shipped to California to go through environmental testing and that will eventually come back and become our first crewed flight test vehicle. And Spacecraft 3 is getting assembled and will be getting ready to fly later this year. So, it’s– we have– it’s really, really cool. We have six spacecraft in different stages of construction and really final integration and testing right now to support all the critical system-level tests, but also for the demonstration test.

And on– and getting ready for our post-certification mission. So, it’s really a fun stage of the program right now.

Host: It’s kind of like all of those years of this being on paper and presentations and stuff like that, but now there’s– you can walk into a room at multiple places around the country.

Kathy Lueders: Lots of hardware. Lots of hardware.

Host: And see something that’s getting ready to go to space.

Kathy Lueders: When I– when I came over from station in 2013, as deputy program manager at JSC, I had just launched– had been launching both the SpaceX demo flights and the initial CRS missions for SpaceX and we were getting ready to launch the demo flight for Orbital and had three spacecraft in work on the Orbital side. And I was just so excited and then Alan asked me to come over and be deputy and I thought, oh, here I’m going to go all the way back to that paper stage that you’re talking about just after working all– doing and putting all this work into it and get these vehicles and it’s so exciting to see the vehicles and then we were back at the paper stage. But we quickly started getting into really what it takes to go start putting vehicles together and go fly these missions.

Host: So, you moved over to the Commercial Crew Program. Let’s talk a little bit about that. Kind of– so where is it based? What is– what is the Commercial Crew Program on NASA’s side doing with these companies?

Kathy Lueders: So, I kind of view the Commercial Crew Program as like tech transfer on steroids. That’s how I kind of view it, right? Because we have really been like the conduit for providing, you know, the 50 years of NASA human spaceflight experience to both these companies. And allowing them to have that is really the great thing about NASA going and doing this exploration– I mean we are still using the data off of the early manned flights. You know, Apollo has been a wealth of experience for both these companies and all the chute testing and all the tests that they did, you know, amazing amount of experience. So, as we’re doing these missions, you just don’t know that 30, 40 years that that data is still relevant and helpful for us to then be able to then– for these companies, it would have been cost-prohibitive for them to have been able to go and replicate all the data and what we learned out of doing those, you know, early human spaceflight missions with the capsule designs.

I mean they really, really learned from that.

Host: Has it gone to the level, like, do you have old Apollo engineers that have come back in or has somebody been, you know, digging up old schematics from an archives room somewhere?

Kathy Lueders: All– there’s definitely been a lot of digging and pulling data and pulling everything. You know, the companies will come in and say, hey, we’re having this kind of a problem and having people that have been out there and have learned and said, hey, I had that problem, you know, this is what we did, but most importantly, I say it’s been tech transfer on steroids from a NASA perspective, but it’s also tech transfer from the company’s perspective. We’ve– you know, we’ve– our engineers on Commercial Crew have been– have had the opportunity to be able to work on not, you know, the two spacecraft designs, but then also be working with Sierra Nevada on, you know, their winged vehicle designs. And also have been able to work with Blue Origin on their suborbital vehicles. And so, when you think about how you’re tooling the next industry of explorers, there’s nothing better than having an engineer that’s been able to have this exposure to all these different vehicles.

One of my favorite stories is one of the co-ops here at JSC was doing their outbrief and they talked about how they did aerodynamic studies on three different spacecraft.

Host: Wow.

Kathy Lueders: Now, you know, Orion, you know, the Boeing CST-100, and the Dragon. I mean just think about how many people could be out there in the world that could say that that was their co-op project for the year?

Host: That’s a competitive resume.

Kathy Lueders: That’s a very competitive resume for a student. I thought, you know, yeah. Amazing.

Host: Well, let’s get into the vehicles a little bit because we are going to be launching crew, but I mean these are the– these are the slick new cars in the garage that everyone’s excited to see. So, I’ll just go alphabetically and we’ll start with Boeing. So, the Starliner. Tell us a little bit more about that spacecraft.

Kathy Lueders: So, the Starliner has really, you know, they– the way the Boeing company has built this, they really built off– they have a tremendous amount of experience in human spaceflight and so they’ve really taken a lot of their– the experience out there, using a lot of the aero– it’s a capsule design. It’s aerodynamically operates a lot like other capsule designs.

Host: One thing I wanted to bring up because people always– any time they see Orion, any of these other spacecraft, they always ask us, well, that looks like Apollo. Why do these– why are all these brand-new spacecraft, why do they look the same as something from, you know, decades ago.

Kathy Lueders: Because it goes back to there’s two really important things to be able to design a safe vehicle. One is to really understand the environments and two is to understand how to build something that can, you know, hold up to those environments. And how many times has a spacecraft come hurdling down and, you know, landing on the earth? Not very often. And so, what– you can go try to go build your own data sets, or you can really leverage off of the data sets that are out there. And so, I think both companies, they– what they were trying to– their number one goal was not to expand the knowledge of– that’s the nice thing about commercial is they’re trying to say how do I get from the– with the data I have, how do I get to a spacecraft as quickly as possible?

And so, their whole goal is what’s the data that’s already out there and how can I use that data to then be able to design a spacecraft– and know enough about the environments to make sure that that spacecraft will operate within regimes that I know that it can survive. Right?

Host: So, kind of like we know this shape works for– we know that if we build it and it looks like this and it’s coming back from space, we know that that–

Kathy Lueders: We should have a good idea about what it is. Obviously, there’s different variants, right? The Apollo– when you look at the Apollo and Orion, they’re spacecraft, they are– they’re way bigger because of the way their missions are, right? The CST-100 and the Dragon, they’re like ferry flights. Right? So, it needs to be big enough to get at least the four people up and, you know, be able to not kill each other in the two or three days or the day that it takes to get to station and have a little bit of movement and be able to do some basic functions and stuff like that, but no party room. Right? And it needs to be on orbit and a place where people can go hang out if they need a safe haven function, but it’s not for doing a long-term mission. Right? So, if when you look at the vehicles, you know, the companies with our goals in mind– and we didn’t tell them you have to have a spacecraft this big.

We said we need a spacecraft that can fly four people safely to the International Space Station and back that has to be reliable and we want it to be cost-effective. So, then they said, OK, how do I optimize that for the mission I have and also for hopefully flying on the cheapest rocket. Not the cheapest from a reliability standpoint, but to be able to have it in the smallest rocket as possible to be able to support the mass. It’s always this big mastery that people have, right? So, you know, when you look at Apollo and you look at Orion, those vehicles are really tailored for their mission. When you look at the CST-100 and the Dragon, they’re tailored for this ferry flight mission that they have.

Host: Gotcha. Well, back to CST-100. So, four seats? Four people launching inside the capsule?

Kathy Lueders: So, they actually have– they have more capability. They actually have proposed a fifth seat, so we have a fifth seat capability. We right now are focused on kind of optimizing it for our mission, which is the four seat and the cargo for that, but they actually proposed a fifth seat. And then the SpaceX, we’re working a four-seat with all our cargo complement, but they actually also advertised seven, commercially. So, it’s always– you can go– what’s really cool, you can go on websites and see what commercially they’re offering and then we can, you know, we’ve kind of optimized for our mission certain cargo complements, certain crew complements that kind of support the station mission.

Host: It is pretty cool because you– you said we kind of gave them this is what we need it to do and this is what they come back with and you’re seeing two different companies, two different designs, two different capabilities, but they’re each going to accomplish our mission, but then we now have these commercial companies that might have their own thing.

Kathy Lueders: I think that’s one of the funnest [phonetic] things about this job is that people– when our NASA engineers work with the companies, we– it’s a collaboration, right? It’s a partnership. And we come to the table and said, well, this is kind of what we did for shuttle, you know, this is kind of what we did here and this is what we have– this– you know, this is what we’ve been working with on the Orion side. But then they’ll come in and say, well, this is what I learned on cargo Dragon for the SpaceX guys and the Boeing guys will say this is what we’ve been working on, this is how it optimizes it. And we’re all learning together and it’s really– I think that’s kind of the funnest part is I’ve seen our crew come in and say, well, we think this is what it is, but let me go talk to them and we’ll go figure out. Let’s go understand what are they optimizing because these are flying a safe and reliable vehicle and having it be cost effective, it’s like this big puzzle. Right? And so, you’ve got to get all the puzzle pieces together right to have it work perfectly, but each of the puzzles look a little bit different.

Right? And so, you’ve got to be careful sometimes. You can’t come in and– with your Orion puzzle piece. That doesn’t necessarily– isn’t optimized for a CST-100 or a Dragon. Right? You’ve got to be careful. So, it’s– the team really is learning a lot. It’s really a fun, fun project.

Host: All right. Well, let’s talk about everybody’s favorite moment, launch. How are these vehicles getting into space?

Kathy Lueders: So, it’s really cool for me because my house is at– in Florida. So, it used to be when I was getting ready for the cargo vehicles I’d have to go down and stay in Florida and wait and wait and wait for when we’re ready to launch, right? But both these provide– but now I have my house in Florida, so I can wait and wait and wait at my house while we’re waiting for– sleep in my own bed while we’re waiting to launch, yes. But both providers are launching from KSC. The Boeing vehicle, CST-100, is launching on Atlas V, so it’s flying out of the complex 41. I always have to think it through, 40 is SpaceX, 41, 39A, and then SpaceX is 39A, so they’re– you know, they retrofitted one of the shuttle pads and so they’ll be flying their crewed missions and the Falcon heavy missions out of 39A, so that’s going to be really, really cool.

It’s nice, I can see both of them out of my office window. So, it’s– I already got to see how the Atlas V complex has changed with the crew access arm already being on and we’ve changed– already Commercial Crew has changed the look of that pad and we’re getting ready to change the look of 39A when the crew access arm starts going up this late summer out at– with SpaceX. So, it’s pretty exciting.

Host: So, Boeing on the Atlas V and SpaceX on their Falcon 9. Both of those rockets have launched stuff, but not people and there’s some extra work to make sure that you can put people on them, right?

Kathy Lueders: Yes. There is a lot of extra work. You know– and, you know, both– like always, the two companies have kind of taken it a little bit different route. Really with Atlas V they’ve gone– really they have their proven reliability, they’ve been doing their systems a certain way, and so we’ve been really working with them on working through all the certifications and understanding and building off of really what the Air Force folks have already done and our own NASA Launch Services Program folks have been doing to go make sure that all the human rating requirements that we need for crew launches– that they’re still meeting them. And the SpaceX folks, they’ve been doing a major upgrade for their Block 5 upgrade and as part of that they’ve added– they chose to add some additional redundancy in parts of their vehicle to be able to fly crew. But, for both companies, really what we’ve been working with them on is how do they insert the whole crew insertion into their timeline while still making sure that we keep consistent loading and launch profiles as close to what they do for payloads.

Because you really want consistency.

Host: Yeah.

Kathy Lueders: Right?

Host: So, there’s one thing I’ve always kind of wondered and it’s when it comes to human rating a rocket, I guarantee there’s a million and one requirements, but what are some of kind of the big differences between a rocket that, yeah, we can launch a satellite that and, yes, we can launch a human on that? Are there any– again, I bet there’s, you know, a million and one differences, but are there any kind of like big– like you cannot have the rocket doing this, a rocket must have this– that kind of stuff?

Kathy Lueders: So, we– one of the things we worked really, really hard on was how to have requirements– I already gave you my examples of the requirements, so I just said flight for crew, right? And so, we tried not to have requirements that were prescriptive, but what we wanted to make sure is that the systems that they had in place controlled the hazards that were– that the vehicles expose the crew to. And that they had the necessary hazard controls in place for us to be able to put crews on their vehicles. And so, really, this has been a kind of an arduous process with the providers is that you don’t typically have to do that for the payloads. But, for crew, we’ve had to go through a safety review process with both companies where we’re going through, OK, how do you get ready for launch, how do you process a vehicle, and then how are you making sure that– and that you’re listing all of the hazards that are involved.

Obviously, you know, a rocket’s kind of like a controlled explosion in some way. Like how do you make sure that that– that all those things that are needed for the rocket to work are done in a way that minimizes the risk to the crew? And so, we’ve gone through kind of an extensive process where they’ve listed their hazards and then what are all their controls and then how are we going to verify those controls. That’s been probably the biggest part of our requirements. That is, really making sure that they have controls for their hazards in place. The second part of it is typically for commercials for payload users, they don’t necessarily come in and say here’s your design and construction standards. Here’s how you– you know, this is what we view as kind of the key parts of making sure you have a reliable and safe vehicle. And the Air Force and Launch Service Program have typically said give us your standards and we want to make sure that you are following your standards and that’s really the process that they go through to certify.

With human rating requirements, we have a list of standards that engineering or SNMA have come in and said for them to be human rated you have to show compliance to those standards, to the human standards. But– so this has been a big challenge for the program because, one, we don’t really want– we would like to have their standards really– them be able to operate to their standards. We don’t want a special group of standards because we would really like– if they’ve been flying reliably, it would be good to continue processing in that way. So, the big challenge that the program’s had is going and comparing the commercial provider standards to our standards and saying do these meet the intent. And maybe there’s been a few small focused areas where we’ve had to work with the providers on, but overall I think both providers have had– have had good standards, good processes, and been able to work it.

The two areas that are unique that no commercial providers work, but that have been human rating standards for us are fracture control– that was– is a new kind of requirement set. It’s really making sure that you have materials that don’t fatigue and if they fail that it doesn’t– they don’t fail in a way that’s catastrophic. That’s very important to us. And typically hasn’t been applied for launch vehicles because those are– these are, you know, very short mission typically, and with the robustness of the vehicle, typically haven’t had to do that. But with crew, that’s an area that we really want to make sure that there’s not some kind of a fatigue failure that could end up being a catastrophic failure. There’s a new mechanism standard that’s pretty new for us and so that hasn’t been necessarily flowed out to industry. One of our goals is is to not only– is to really help industry develop their human rating standards.

You know, my dream one day would be I don’t have to do an equivalency because somebody else has already gone through. Just like when I get on a plane, it would be beautiful if somebody else has already certified the rocket, right? But right now we’re the only people that certify human-rated rockets, but that doesn’t mean that that’s not– that could change in the future. You know? We’ve been working with other agencies and different, you know, the AIAA and other organizations to go look at is there some way that we could take our learning that’s been in our standards and make them available so that industry at some point adopts standards that they then can use so that we’re not in the middle of the certification. But this is just a step, right? This is just a step.

Host: We go through the painful process now, so hopefully down the road everything’s safe and already laid out for everybody.

Kathy Lueders: The tech transfer on steroids.

Host: That’s right.

Kathy Lueders: Tech transfer on steroids. This is another place, right? We’ve got all this experience, you know, and really our standards are just key things– they’re like our book of hard knocks, right? We’re like, oh, crap, write that one down. Don’t do that again. You know? Oh, crap, please do this. Don’t do that one again. Right? And so– so, that learning, I mean, has already been out there in industry over time. You know, there’s aerospace standards that have been out there because companies have been working with NASA for the last 30, 40 years. This is another area where I think we just– the human part of it we just have to work on.

Host: All right. So, they’ve launched. How are they controlled? Because this is also kind of a whole new thing for us. I mean, throughout NASA’s history, we have– we have our mission control and, you know, that’s the room, that’s who has their finger on the button kind of thing, but for these providers, it’s going to be different.

Kathy Lueders: Well, so what’s really cool is when we went out for our certification and our services, we said you go figure it out. You know? You figure out where you want to be– where you want to be controlled. So, both of them actually– you know, KSC, once you launch, they– both of them have, obviously, launch control centers at the Cape to go to support the vehicles. And then they also have mission control centers to handle the initial, obviously, comm with the spacecraft. Right? But then, for SpaceX operations, they hand back over to MCCX, which is in Hawthorne. And for–

Host: In California.

Kathy Lueders: In California. Hawthorne, California. Yeah, thank you. And for Boeing, it actually is going to be controlled out of MCCH. Boeing has a arrangement– task plan– with our mission control, our FOD, our Flight Operations Directorate–

Host: Here in Houston.

Kathy Lueders: Here in Houston. Here in Houston. So, it– and so, we’ll be– along with the ISS control center here, there will be a Boeing mission control center here too that will be monitoring and operating that vehicle and working together for joint ops. The same control center for– that works the cargo vehicles for SpaceX right now will be also– it’s in the process of being upgraded to also be handling the crewed missions.

Host: And this might get into the weeds a little bit, but how much– so, these new spacecraft, are they going to be– because, for example, the Russian Soyuz, largely automated, automated docking, you know, the crew has some tasks on board, mission control is largely monitoring. Shuttle was a lot of, you know, onboard flying for the crew and stuff like that. Where are these vehicles going to kind of fall and are they– again, are they different?

Kathy Lueders: So, I think both of them are fairly autonomous. If you think about it, it kind of goes back to once again the commercial concept. Right? If you’re a company that wants to have control over how your vehicle is operating and with the capabilities they have today, with computer– the processing capability and everything else– they’re really developing very sophisticated autonomous rendezvous and docking and reentry capabilities. And so, really crew is there as a monitoring function and back up in case some– like something really goes wrong, but these, they’re really– both companies are designing their spacecraft to be two-fault tolerant to a failure. All along the way. Very robust, which is really our intent. We wanted to have very robust vehicles. Right? Very robust vehicles. We asked them to design their vehicles to be two-fault tolerant and to not have crew as a control. So, we– that was a– kind of goes back to safe and reliability being kind of important tenets and the companies have really come through.

They have different strategies for how they do that and they’ll be checking out that autonomous capability on their first demonstrations because they’ll be uncrewed [phonetic]. They’ll be uncrewed demonstrations to the ISS, so that will kind of prove out that autonomous capability. I always tell people I’m– I know we’ve got self-driving cars out there, but I’m really hoping that before they roll out their first commercial one, the first commercial self-driving crew vehicle that’s being bought by the government is going to be a crew transportation vehicle that’s going to the ISS and so–

Host: It’s going to be a spacecraft.

Kathy Lueders: Yes. It’s going to be a spacecraft. We’re ahead of the game. We’re in front of them.

Host: Very cool. Well, so it’s launched, it’s flown itself flawlessly to the space station. The crew has been onboard, they undock, it’s time to come home.

Kathy Lueders: You know, and if it goes flawlessly to the space station, I’m like then really good in my life. So, it’s like– we’ll learn things along the way, right, but it will go and it will reliably– safely and reliably get there– and we’ll be docking and we’ll be learning stuff along the way. I absolutely know that.

Host: And then when it’s time to come home, how are these vehicles coming back? Because that’s going to be different, too, right?

Kathy Lueders: Yeah. They have– so both of them use, you know, they have orienting thrusters, kind of, and then they both use a parachute landing, you know, a parachute-assisted landing. Boeing is going to be landing on the western part, they have five landing sites on the western part of the United States. Kind of ranges from California– you know, all your, like, the Dugway, Wismer [assumed spelling], all the, you know, the open desert kind of areas.

Host: Lots of emptiness.

Kathy Lueders: Lots of empty– oh, yeah, don’t want anybody nearby. And then SpaceX is going to be– they’re looking at two water landing sites near the– off the Florida coast on both sides of the Florida coast, and so kind of trying to give themselves kind of as many options as possible. Primary is off the east coast of Florida right now.

Host: So, that’ll be– I mean that’ll be pretty interesting because, I mean, Soyuz we’re landing on land over in Kazakhstan, so–

Kathy Lueders: The big open space– we don’t have this big– as much big– I wish we had– I wish we had a Kazakhstan, but we don’t have that.

Host: Well, I think New Mexico will be close. That desert’s pretty sparse from what– but I mean have we– have we ever landed American spacecraft on land in America before?

Kathy Lueders: We have not. I don’t think. We have not.

Host: So, that’ll be an exciting first.

Kathy Lueders: Now, there’s, you know, not from orbital.

Host: Oh, I mean other than shuttle. Sorry.

Kathy Lueders: Blue Origin did suborbital demos, but, yeah, this will be the first time. And, you know, so the other– I’m going to say it again, tech transfer on steroids, but the other really cool thing about this is it’s– we’re learning how to work with different agencies. So, if you can imagine, you know, the first– the demonstration missions are NASA missions, so we’re going to be working with FAA for clearing airspace for those and with our contractors. But, when we start getting into our post-certification missions, those will be FAA-licensed missions and so we’ve been working with them on how do you clear airspace for a capsule that’s coming across L.A. or, you know– you know, like– I mean there’s– so, yeah, so there’s– it’s going to be– we’re learning on how are we going to do this. How do we really do commercial spaceflight and landing and landing in these different areas and working with other agencies and Air Traffic Control and all these other things and doing these for these commercial missions.

Not just– not things that people really think about, but it’s really what makes it work.

Host: So somebody, you know, on final approach at LAX doesn’t look out the right side and see a spacecraft and parachutes coming at them.

Kathy Lueders: That would be bad. That would not be good.

Host: Well, all right, well, so you’ve mentioned the PCMs, the demos, kind of lay out the cadence of how this is all going to unfold for us for both of these companies. You know, what missions are kind of, you know, on the schedule and what does a PCM even mean?

Kathy Lueders: Oh, OK. So, we call– both providers– originally when we did the contract, we said, you know what, we don’t want to just jump into missions, our long-term long-duration missions to the space station. Because we’d really like to have a trial run with the vehicles. And so, we originally put in the contract just to have a demonstration mission. A crewed demonstration mission that kind of checked out the whole vehicle. We got to have on-orbit time with the vehicle before we start using these vehicles for our post-certification missions. When I say PCMs, it’s really the crew rotation flights. It’s the– it’s the long-term– like the– like a Soyuz increment– equivalent. Right? So, actually both providers came back and offered up both an uncrewed demonstration mission and a crewed demonstration mission before we run into the cadence of doing the long-term missions.

Now, we are– they’re both getting ready for their uncrewed demonstrations and they’re both shooting for this fall for the uncrewed demonstrations. And then, within three of four months, both of them are planning to fly their crewed demonstration missions after the uncrewed demonstration missions. Just as a– we– just as a– I would say almost a security blanket, but it’s not quite. You know, we– one of the things as program manager that I worry about is making sure the– that, A, the space station has capability to fly their crews and to support on-orbit operations for space station. They need crews on-orbit. And what’s really– so, we need to get there, and we need to get there fast, but we need to get there safely and we need to get there reliably. And so, one of the things we just did a few months ago was we just added the capability contractually for Boeing to be able to– if everything goes well on their orbital flight– their uncrewed flight test– for them to be able to potentially stay up longer for their crewed flight test.

What that does is it gives them– it gives us potential additional capability, but then it also lets them have if they need more time to then get their orbital flight test vehicle back, they use that vehicle again, so it gives them more time to then be able to refurbish that vehicle and get that vehicle ready for then their first post-certification mission. Which right now is in the 2019– late 2019, early 2020 timeframe. The first time you’re refurbishing anything that goes back to– I maybe was a really great person my whole life, but what I found out as a manager and engineer is you learn stuff. Right? They’re going to learn things about that vehicle and how it operates and how it comes down and we need to make sure that that vehicle has the time that it needs to be checked out and made sure that it’s all ready to go before we send it back up for one of our post-certification missions.

Host: That’s right.

Kathy Lueders: As we get through the demonstration missions, then, ideally, you know, we’ve kind of stacked up our missions because one thing– it kind of goes back to the theme of making sure the providers have the time that they need to fly safely and reliably. We’ve made sure that they– both contractors have the capability to be able to fly a consecutive crew mission if we need– if the other one needs help. Right? So, we’ll be monitoring. We’ll be looking at it– both providers will be learning things, and then– but eventually we have two crew rotation missions to station and so each of the providers will have a mission to station and then we’ll see. We’ll see what other kinds of missions. You know, we’re in the process right now of understanding how do we commercially use the space station and so we already are working with both providers on maybe they have other passengers or other missions or other things that they’re working on proposing and so we’re really hoping that, through us using these folks, that that then will jumpstart– potentially jumpstart their use by other providers.

And then kind of, you know, provide a platform for other commercial and research and other uses in low-Earth orbit.

Host: So, it’s not just us.

Kathy Lueders: I– you know, I always tell people, space is not for– just for– is not just for NASA anymore. Space is not just for NASA anymore. It is for all of us. It is for every American. It is for you. It is for my children. It is for all of us. It’s just not there for somebody with a gold badge.

Host: Well, you just checked off a whole bunch of stuff I was going to ask you about, but– so, I mean, the future looks really bright right– especially right now, as we’re getting so close to these test flights getting off the ground and like that will be super exciting. And then we’re going to have people launching from Florida again to the space station and then we might have non-NASA people launching on these vehicles and these companies doing all kinds of crazy stuff. What about beyond low-Earth orbit? Do you see eventually these commercial companies spreading their wings even a little bit further out? Maybe not specifically these ones, but right now we’re working really hard to commercialize low-Earth orbit. What about beyond that?

Kathy Lueders: Who knows. You know, I think if you– when I first started working commercial cargo in 2005, 2006, people would say you’re never going to fly. You guys are never going to fly. This is crazy. And look at– we’ve– we’re on CRS 15.

Host: Oh, yeah.

Kathy Lueders: Yeah. I– so, who knows–

Host: There’s an orbital vehicle up there right now.

Kathy Lueders: Yeah, there’s an orbital vehicle up there right now. So, in 2008, if you would have said we’re flying crew– even when we were doing the whitepapers and looking at it, people said you’re crazy. This is like– we’re never going to do that. People will never– people are never going to be able to do it. So, who knows? You know? I think our job is to dream for the nation. Right? And so, I think, yes, I think they will be out there. I think it’s going to be like, you know, Solo just opened up over the last, you know, in the movie theaters– I guess not very well, but in the movie theaters over the last few weeks– and who knows, right? There’s a reason why we keep having these same dreams. We’ve been having these dreams for a long time. Maybe it’ll take us a little bit longer to get there, but for some reason we’ve been having these dreams for all of us to have our own spaceship one day. You know, I grew up on the Jetsons. We’re not there. But who knows? Who knows?

I don’t think we can stop dreaming. So, I think when we say we can’t is when we stop. So, I think– I think they can be out there. It may take us another hundred years, it may take us another, you know, who knows. But who knows? What I do know is that when I’m down at the Cape and I see what just people doing cargo has done, you know, just our investment in cargo meant that the Launch Services Program had another viable launch vehicle to be able to fly medium-class missions. And it meant that you got a bunch of other space companies out there now– Blue Origin’s got a fantastic facility, you know, on the outside of the gates at KSC, and look at– I just saw a sign that said, you know, it was advertising Titusville, Florida, and it said we’ve had more launches from the Space Coast than we’ve ever have.

Huge resurgence, right? So, who knows? But it’s the dreaming, I think– I think there was a dream and we made it happen and then who knows.

Host: All right. That’s awesome. I like that one a lot. I think we just about exhausted it for today. That’s kind of it. I want to thank you for coming and sitting down with me and spending a little time. Glad we could steal you away from a couple of meetings for a little bit.

Kathy Lueders: Yeah, I got to turn off my phone. I was pretty excited about that.

Host: Wonderful. All right. Thanks, Kathy.

Kathy Lueders: OK. Thank you.

[ Music ]

Host: Well, thanks again for listening. We just scratched the surface on NASA’s Commercial Crew Program. If you want to go learn more, get online, head over to nasa.gov/commercialcrew or, as always, you can follow our multiple social media accounts. Commercial Crew is on Facebook at NASACommercialCrew, on Twitter at Commercial underscore Crew, and you can use #AskNASA on your favorite platform. Submit your ideas for podcasts and we’ll also answer some questions. Be sure to check out some of our other podcasts. We have things like Gravity Assist and NASA in Silicon Valley. You can find those everywhere you can find this podcast. This podcast was recorded on Wednesday, May 30th, 2018. Thanks to Alex Perryman, Kelly Humphries, Kyle Herring, Starr Reynolds, Pat Ryan, Bill Stafford, and, of course, Gary Jordan. And thanks again to our guest, Kathy Lueders, for coming on the show. We’ll be back next week.