What kind of aircraft combines the speed of an airplane with the vertical take-off and landing capabilities of a helicopter – and could be your traffic-beating air-taxi ride of the future?

Give up?

A tiltrotor aircraft, that’s what! And NASA’s Tiltrotor Test Rig is being used to improve tiltrotor technology for future aircraft designs.

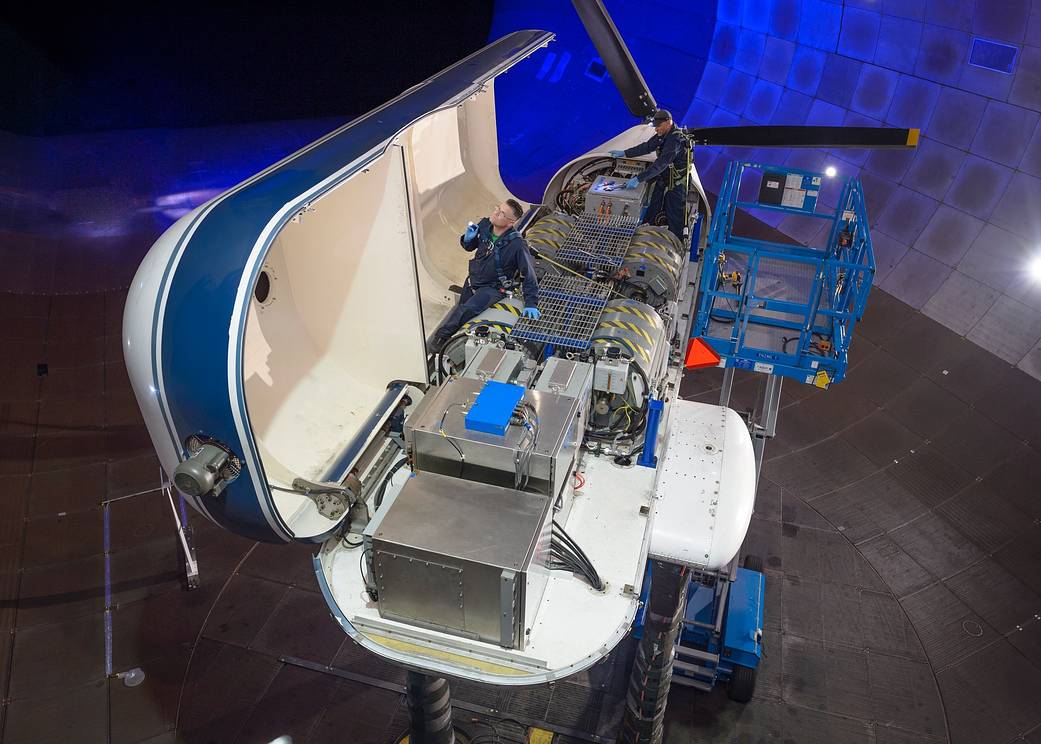

The Tiltrotor Test Rig, also known as TTR, is a new, full-scale proprotor test system, undergoing testing in the biggest wind tunnel in the world – the U.S. Air Force’s National Full-Scale Aerodynamics Complex or NFAC, located at NASA’s Ames Research Center in Silicon Valley.

TTR was developed to fill gaps in understanding of proprotor performance at higher speed and power conditions than have been previously tested.

The TTR set a speed record in August 2018, achieving 314 m.p.h., or 273 knots, the highest airspeed test condition ever achieved by a proprotor of this size in any wind tunnel. And this maximum speed was limited by the wind tunnel, not the test rig!

For the test, a 26-foot diameter research proprotor (seen on top of photo) was installed on the TTR inside the 40- by 80-foot wind tunnel. As of October 2018, data has been collected to include 35 combinations of airspeed and angle of air blowing at the rotor, from edgewise (helicopter mode) to straight-on (airplane mode), simulating flight conditions from vertical takeoff through conversion to high-speed horizontal flight. Testing included control variations, motor power checks, effects of temperature and vibration tests.

The tests are part of NASA’s research for 21st century tiltrotors and other advanced rotorcraft concepts, which require improved capability for wind-tunnel tests of full-scale proprotors. The TTR is providing critical data for validation of state-of-the-art design and analysis tools for vertical-lift vehicles. The recent tests demonstrate that the new test rig is “go for green” to provide proprotor performance measurements at previously unseen levels of power, speed and accuracy.

The TTR is a partnership with the U.S. Army and Air Force. Bell Helicopter Textron, Fort Worth, Texas, now Bell, and Triumph Aerospace Systems, Newport News, Virginia, or Calspan Systems Corporation, designed and manufactured the TTR and supporting equipment under NASA contract.

For news media:

Members of the news media interested in covering this topic should get in touch with the aeronautics representative on the NASA Ames media contacts page.