HiACT

High-Power Advanced Cable Technology

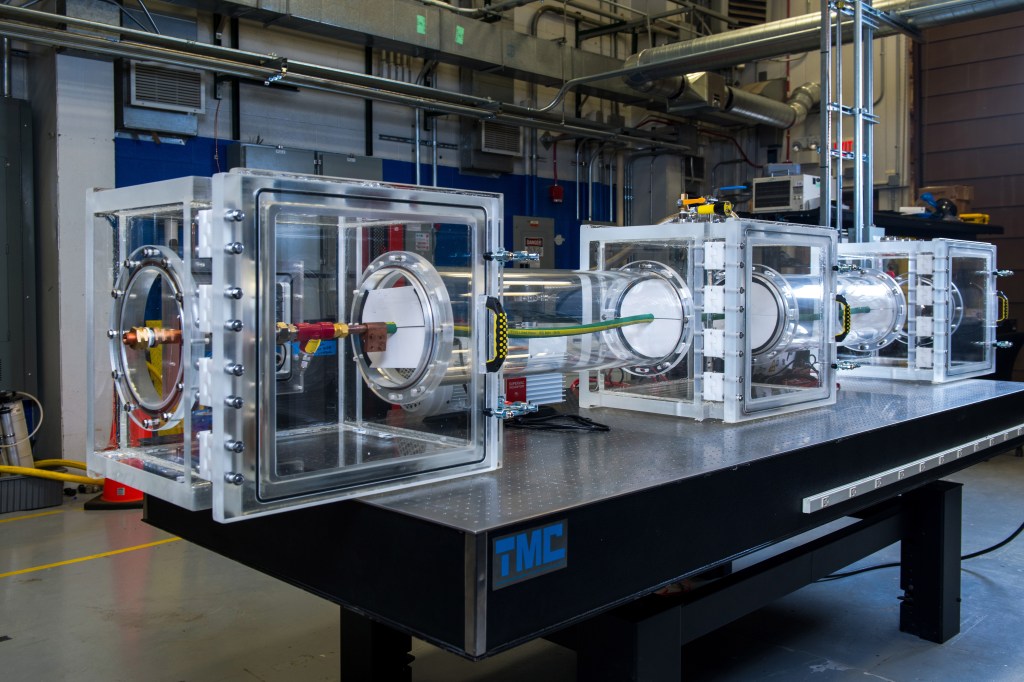

The High-Power Advanced Cable Technology (HiACT) rig at NASA’s Glenn Research Center in Cleveland is a specialized lab designed to evaluate the thermal performance of advanced wiring technology for future electrified aircraft systems.

Quick Facts

Overview

Research and development of electrified aircraft applications face new challenges in efficiency, reliability, and safety. Unlike traditional commercial aircraft, electrified aircraft systems must operate at significantly higher power levels with increased voltages and stronger electrical currents, while minimizing weight and ensuring efficient thermal management.

To meet the needs of advanced wiring technology for electric aircraft, the High-Power Advanced Cable Technology (HiACT) rig is designed to evaluate performance of next-generation electrical components under extreme operating conditions. The lab supports both high-current, or ampacity, and high-voltage testing in simulated high-altitude environments. Data collected by the HiACT rig will help inform future standards and close the technology gaps for commercial aircraft electrification.

Capabilities

Operating at around 35,000 feet, electric aircraft systems will be subject to thinner air, tighter spaces, and temperature shifts that will impact electrical wire and cable performance. Wiring technologies must be lightweight in order to minimize energy consumption but insulated enough to prevent safety hazards from arcing events where currents cross cables through the air.

Cables must also have effective thermal management and transfer heat effectively to optimize aircraft performance. The HiACT rig is built to address these challenges by evaluating cables at ratings higher than current aircraft standards and determining cable specifications for safe and effective operations.

The HiACT rig enables testing of electrical cable ampacities to determine size and weight specifications that operate efficiently under increased power and current levels while maintaining consistent temperature ratings.

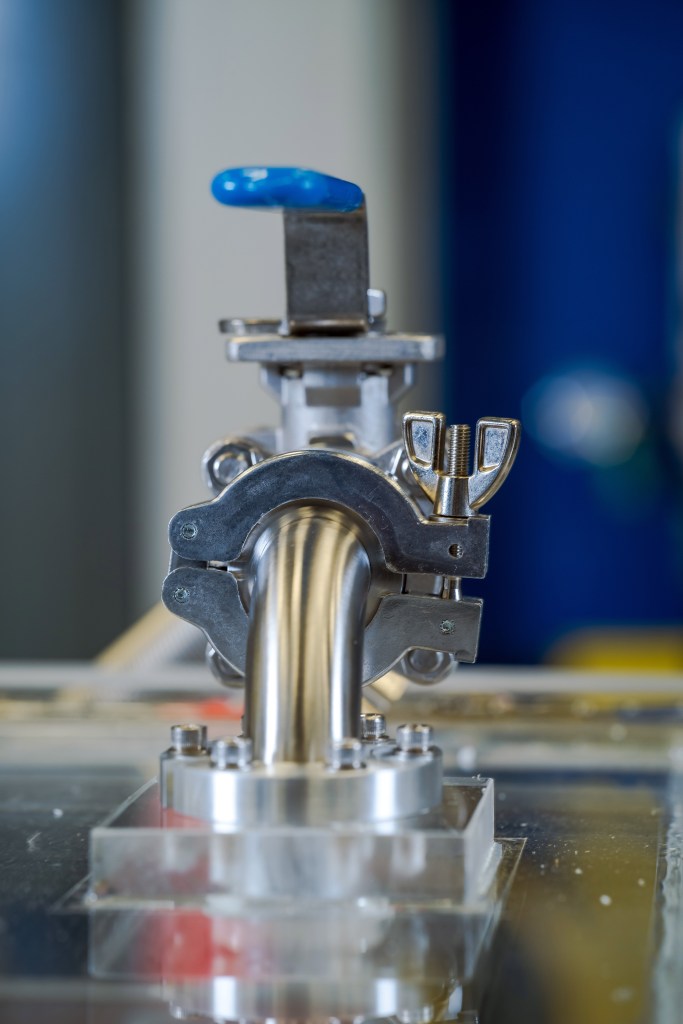

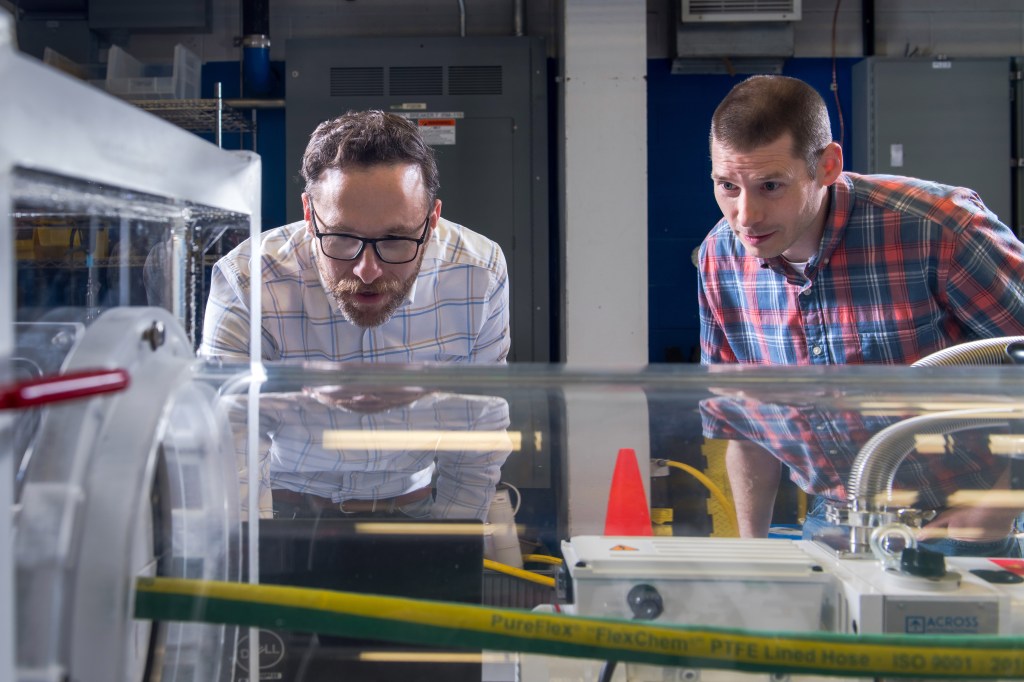

To test and evaluate these new standards, the HiACT rig operates in a room temperature environment at sea level pressure. The lab’s ampacity test chamber can push advanced cable designs to their limits by running up to 1,500 amps of electrical current through them while performing precise thermal measurements to determine the level of current the cables can safely carry before exceeding safe operating temperatures. The chamber is instrumented to perform testing on both traditional cable types as well as more advanced liquid-cooled designs.

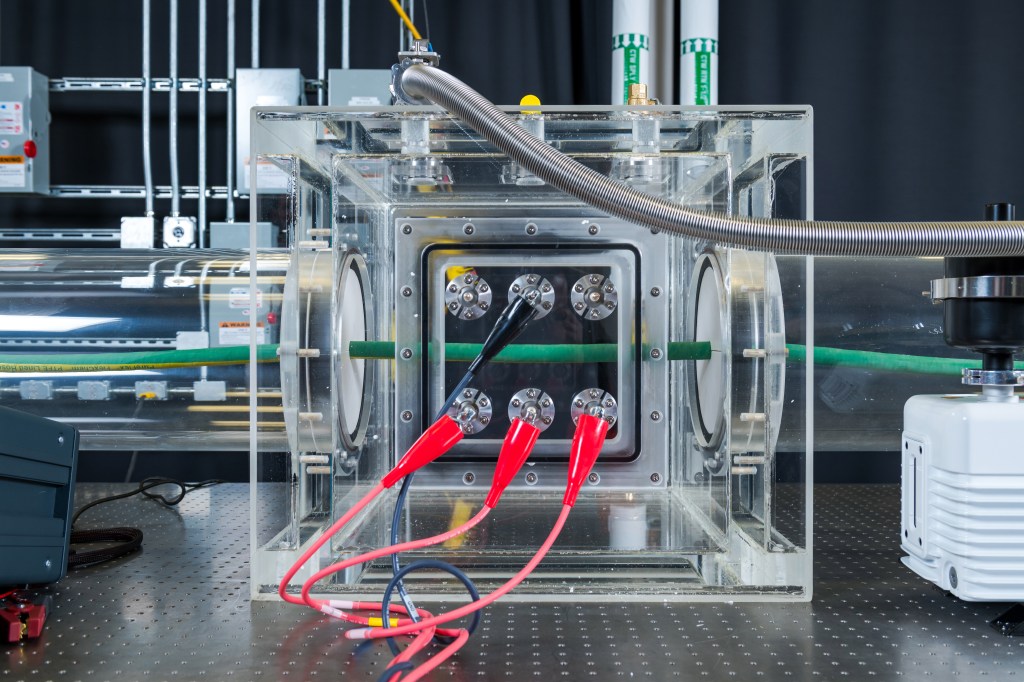

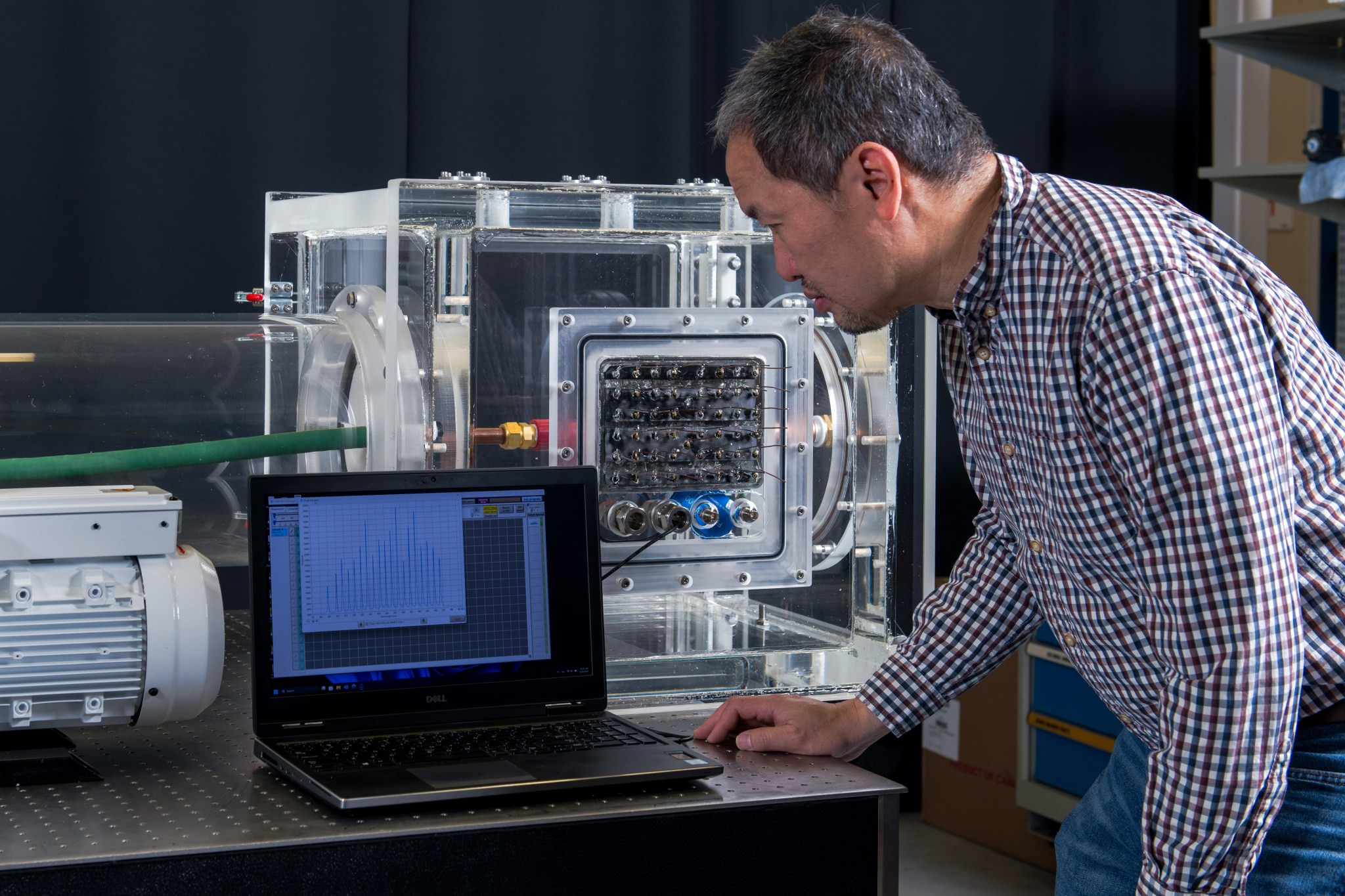

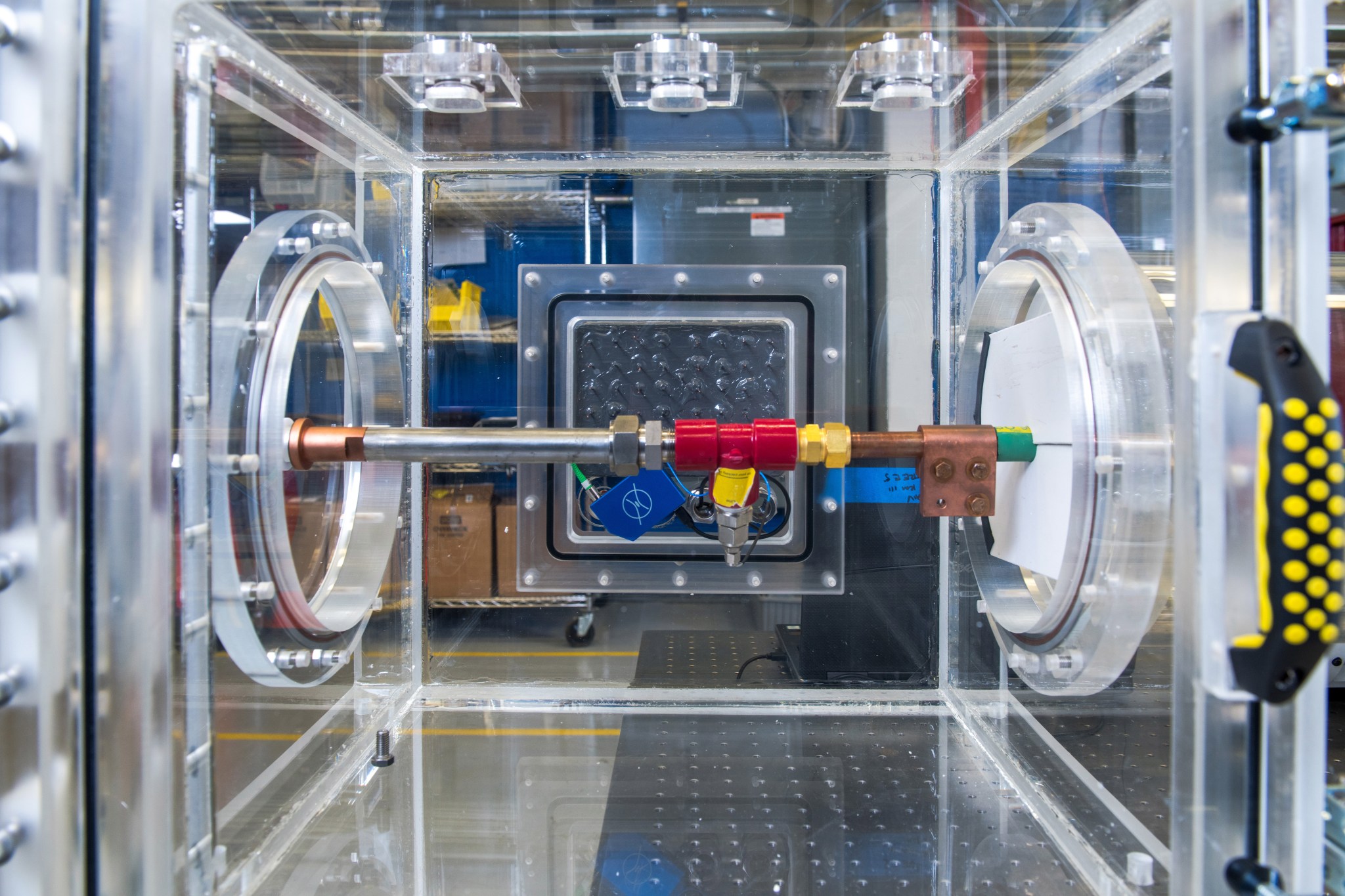

The lab’s acrylic high-voltage test chamber is used to evaluate cables and connectors under low-atmospheric conditions at a simulated altitude of up to 60,000 feet above sea level at voltages up to 6 kV, or 6,000 volts. The acrylic chamber is also built to be non-conductive, minimizing the amount of heat, electricity, or sound that passes through. This enables researchers to study partial discharge and other high-voltage effects without interference from metal walls or grounded surfaces that could potentially affect measurements and general cable performance.

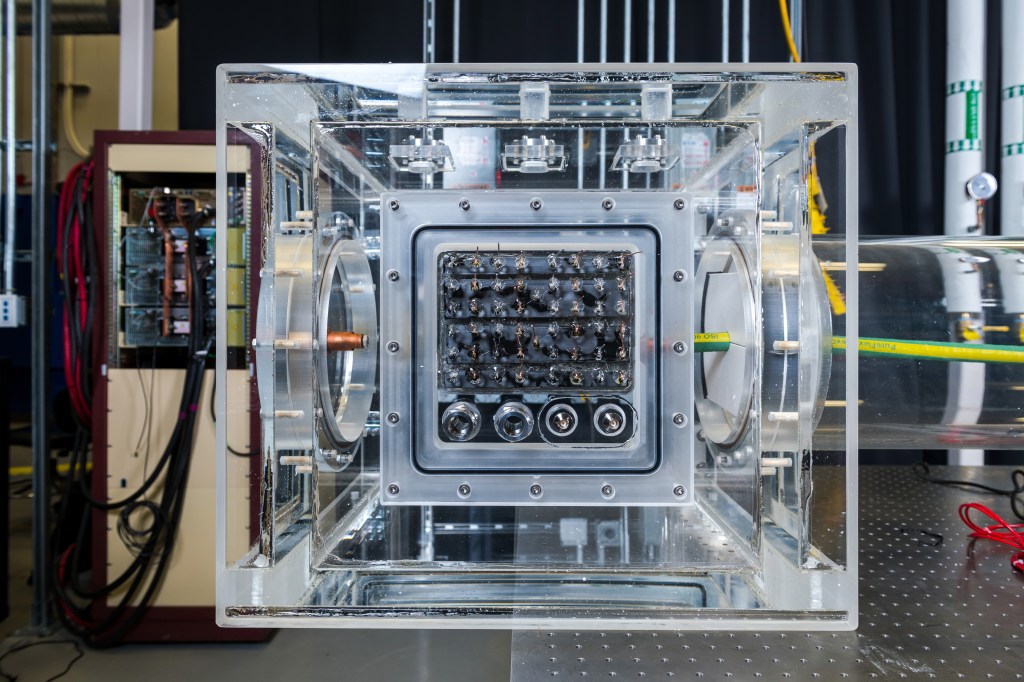

In addition to testing the thermal performance of electrical cables, the HiACT rig is used to test various cooling methods for high-powered electronics. A 32-kilowatt resistive load in an aluminum housing is used to simulate electrical interfaces and thermal loads of high-density powered electronics in megawatt (MW)-scale electrified aircraft propulsion. A range of heat exchanger designs can be tested to find the optimal geometry, materials, and manufacturing process for high heat flux applications like power switches in MW-class converters.

Collaborating with industry partners, evaluation of cable performance based on new requirements for electrified aircraft will be key in establishing future standards that keep electric aircraft systems efficient with minimal heat and energy loss. Initial checkout tests of the HiACT rig aim to provide key data that will define the next set of tests and research questions for further assessment before eventually establishing new standards for future electrified commercial aircraft.