Facilities Used for SLS and Orion

Operations & Checkout Building High Bay

When the agency’s Orion spacecraft arrives to Kennedy following initial manufacturing at NASA’s Michoud Assembly Facility in New Orleans, it is placed in the Neil A. Armstrong Operations and Checkout Building (O&C). The O&C contains a large room called a high bay that operates as a high-tech factory, where spacecraft will be assembled and readied for new missions to deep space destinations. The high bay includes unique tooling stations, test fixtures, chambers, and clean rooms for the buildup and testing of the spacecraft.

Orion assembly consists of joining the crew module, crew module adapter, and the service module, which will carry the consumables astronauts will need for missions into deep space. The Orion vehicle that launched atop NASA’s Space Launch System rocket for the Artemis I mission in 2022 also was processed, tested, and prepared for launch in the O&C.

The O&C has played a major role in NASA’s spaceflight history. It was the first building finished at Kennedy and has housed the Astronaut Crew Quarters since the mid-1960s, where the Gemini astronauts stayed prior to launch. The high bay underwent an extensive two-year renovation starting in 2007 to outfit the facility for assembly of the Orion spacecraft. Space Florida and NASA provided the funds for a full refurbishment that involved everything from replacing the entire facility support infrastructure to new overhead cranes to support manufacturing and assembly work. General contractor Hensel Phelps performed the work.

Multi-Payload Processing Facility

A unique facility at Kennedy Space Center, the Multi-Payload Processing Facility (MPPF) is used to fuel the Orion spacecraft with hazardous propellants and other fluids the spacecraft and astronauts will need to maneuver and carry out their missions in space.

When Orion returned to Earth after the Artemis I mission, it was transported to the MPPF, where specialized equipment was used to remove unused hazardous propellants from its tanks during spacecraft postflight processing.

Launch Abort System Facility

After fueling in the MPPF, the Orion spacecraft is moved to the Launch Abort System Facility (LASF). The 44-foot-tall launch abort system (LAS) is positioned on top of Orion for launch and ascent into orbit. The LAS has a solid-fueled rocket system that will activate in the unlikely case of an emergency occurring where the astronauts’ safety is threatened during launch or ascent. In that case, the LAS will ignite and lift the crew module and its crew away from the launch vehicle with more thrust than the Atlas booster that launched John Glenn into orbit in 1962.

The LAS is prepared horizontally inside the LASF. The facility is taller than many processing facilities at Kennedy to allow clearance for vertical assembly of the Orion spacecraft with the LAS. The LASF has cranes and other equipment needed to integrate the system during launch processing. After the LAS is integrated with Orion, the entire stack is moved to High Bay 3 in the iconic Vehicle Assembly Building, where it is lifted and secured atop NASA’s Space Launch System rocket on the mobile launcher.

The completed SLS/Orion stack is transported atop the mobile launcher on crawler-transporter-2 to Launch Pad 39B for liftoff on deep space missions, including to the Moon and Mars.

These unique facilities at Kennedy play a significant role in processing the Orion spacecraft for ambitious missions far beyond Earth orbit.

Rotation, Processing and Surge Facility

The Rotation, Processing and Surge Facility (RPSF) is located near the Vehicle Assembly Building and the mobile launcher parksite in the Launch Complex 39 area at NASA’s Kennedy Space Center. The facility receives the booster segments for the Space Launch System (SLS) rocket and prepares them to be integrated with other hardware in the Vehicle Assembly Building prior to launch.

Launch Equipment Test Facility

Located at NASA’s Kennedy Space Center in Florida, the Launch Equipment Test Facility, or LETF, provides NASA with a proving ground to safely assess machinery and designs intended to support the launches of the biggest rockets ever built. A rocket leaving the launch pad subjects the launch structures to intense vibrations, staggering forces, and prolonged blasts and flames from the exhaust.

To reduce the chances of a failure, engineers build prototypes of their designs and try them out at the LETF on machinery that duplicates sections of a launch pad and simulates the pressures that will come during a launch. The connecting arms used for launches also are tested at the LETF before they are connected to the mobile launcher for use on a rocket. The LETF is a unique set of structures, equipment, and tools built during the 1970s.

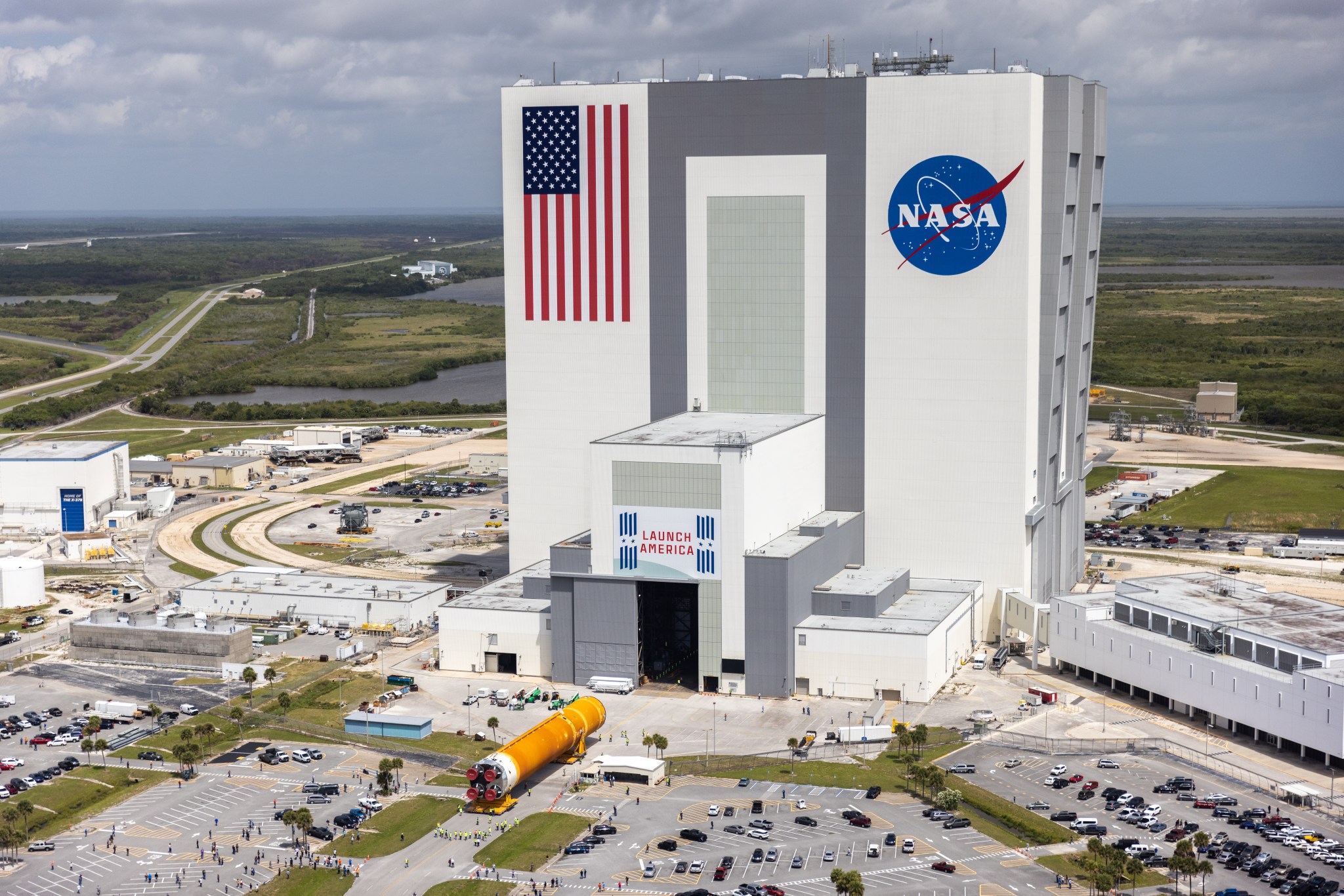

Vehicle Assembly Building

The Vehicle Assembly Building, or VAB, at NASA’s Kennedy Space Center in Florida, is the only facility where assembly of a rocket occurred that carried humans beyond low-Earth orbit and on to the Moon. For 30 years, it also served as the final assembly point for space shuttles to external fuel tanks and solid rocket boosters.

The iconic facility serves as the central hub of NASA’s premier multi-user spaceport, capable of hosting several different kinds of rockets and spacecraft at the same time. Whether the rockets and spacecraft are going into Earth orbit or being sent into deep space, the VAB will have the infrastructure to prepare them for their missions.

The VAB was constructed for the assembly of the Apollo/Saturn V moon rocket, the largest rocket made by humans at the time. The last structural beam was positioned in the VAB in 1965. The interior construction, including the construction of the extensible work platforms, was completed in 1966. The building is located 3.5 miles from Launch Pad 39A and 4.2 miles from Launch Pad 39B.

The tallest portion of the VAB is called the high bay. There are four high bays, two on the east side, and two on the west side of the building. Each has a 456-foot-high door, enabling rockets to be stacked vertically and then rolled out to the launch pad.

Combining established capabilities with modern needs is the primary goal as the world’s most famous landmark of space exploration is being upgraded to support NASA’s 21st century launch complex.

Fun Facts:

- One of the largest buildings in the world by area, the VAB covers eight acres, is 525 feet tall and 518 feet wide.

- The VAB high bay doors are the largest in the world at 456 feet high and take about 45 minutes to completely open or close.

- The building is home to one of the largests American flag, a 209-foot-tall, 110-foot-wide star spangled banner painted on the side of the VAB.

- It is made up of 65,000 cubic yards of concrete and its frame is constructed from 98,590 tons of steel. It stands atop a support base of 4,225 steel pilings driven 164 feet into bedrock.

- The VAB was painted in 2007, when the repairs were completed after the 2004 Hurricanes Frances and Jeanne tore 845 panels off the building.

- The flag originally was painted onto the VAB in 1976 for the Bicentennial Exposition on Space and Technology.

- It will take more than 500 gallons of paint to repaint the American flag, and the NASA meatball, which measures 110 feet tall by 132 feet wide.