In This Week’s Star

- Engineering for Earth: Marshall Research Leads to Sustainable Processes, Products to Benefit Space, Home

- Earth Day 2020: Tips for Keeping Green in Quarantine

- Marshall Spinoff Helps World Produce More Earth-Friendly Energy

- Mission Success is in My Hands: Angelia Walker

- Marshall to Open New Library, Welcomes New Librarian

- Astronauts Meir, Morgan Return from Science-Filled Space Station Expeditions

- Marshall’s Export Control Office Rolls Out New ‘e-Xport’ Automated System

- Key Marshall Organizations Collaborate on New Project Management Toolkit

- Names of All Past, Present Marshall Employees to be Engraved on Planned Memorial

- Redstone Construction Continues Despite Pandemic

- OSIRIS-REx Rehearses Sample Capture, Highlighted on ‘This Week @NASA’

- This Week in NASA History: Hubble Deployed – April 25, 1990

Engineering for Earth: Marshall Research Leads to Sustainable Processes, Products to Benefit Space, Home

By Janet Sudnik

While much of the engineering expertise at NASA’s Marshall Space Flight Center will help humans explore and live off Earth, the center is also engineering for Earth.

Here are a few of the revolutionary engineering technologies, processes and products being developed at Marshall with engineering for Earth in mind.

Oxygen Recovery Technology: As exploration of the solar system progresses, development of life support technologies with limited Earth reliance is vital. One key component of life support is the supply of oxygen to the crew. Although oxygen may be resupplied from Earth, it can also be recovered from carbon dioxide generated by the crew on-site, which is more sustainable and more readily available.

The state-of-the-art Environmental Control and Life Support oxygen recovery system — developed at Marshall and currently serving astronauts aboard the International Space Station — is capable of recovering roughly 50% of oxygen from metabolic carbon dioxide.

“An uninterrupted, reliable supply of clean air is obviously a requirement for survival, and having an onboard system capable of delivering that is crucial to future missions,” said Brittany Brown, a life support systems engineer. “Cleaning our atmosphere in controlled spaces like the ISS will hopefully lead to broader solutions here on Earth.”

For future long-duration missions, a minimum of 75% recovery will be required, with a target recovery goal of 90%. Research is focused on the development of a reactor that converts carbon dioxide and water into oxygen and ethylene. This technology is a potential method to take carbon dioxide removed from any process and convert it to oxygen and water, as well as hydrocarbons that could be used as a feedstock to make useful products such as medicine, food or fuel.

Helium Recovery System: Helium has unique properties that make it particularly suitable for scientific and engineering endeavors. Engineers with Marshall’s Valves, Lines, and Actuators Design and Development Branch, within the Propulsion Systems Department, use helium for the development, assembly and testing of spaceflight valves, actuators and other components. Helium is a key element for these operations, often used in testing to simulate flight-like pressurant systems, to perform leak checks or to safely purge hazardous fluids, such as hydrogen, from test hardware.

Because the element is nonrenewable and in high demand, supply constraints have resulted in a dramatic cost increase, and potential for a global shortage. To address these challenges, the branch is testing a helium recovery system, with the goal of capturing, purifying and reusing 70% to 80% of the helium used by testing.

The system consists of helium capture lines connected to test cells, which feed a flexible gas bag that temporarily stores the helium before it is pumped to the purification system. The purification system removes impurities and pumps the gas back to high pressure for storage. The branch is working to integrate the recovery system with existing facilities and certify it for operation.

“This system has the potential to serve as a guide for larger scale purification systems that could be used for cost reduction of test or launch operations across the agency,” said Cody Gilliland, a propulsion component engineer.

Solvents and Cleaning Techniques: Studies at Marshall have led to a new generation of environmentally friendly solvent replacements. A solvent is a substance — commonly a liquid — used to dissolve solids, often as a method of cleaning surfaces without damaging them. Organic solvents and aqueous detergents are used by Marshall’s Chemistry and Contamination Control Team, within the Materials and Processes Laboratory, for removing inorganic and organic contaminants by dissolving them or flushing them away.

Inorganic contaminants include metal additive manufacturing powder, machining residues such as metal shavings, lubrication fillers, and foreign object debris such as sand or dirt. Organic contaminants include machining oils, lubricants, preservative greases used for corrosion prevention, impurities from air/gas systems, and animal contamination.

Older formulations of solvents and detergents in both household and commercial formulations have been made from chemicals that were not sustainable, or contained ingredients that could contribute to air, water, soil or groundwater pollution.

Legislation has eliminated ozone-depleting organic solvents, but NASA has continued efforts to restore and protect the atmosphere by finding replacement solvents.

“The Chemistry and Contamination Control Team is committed to developing innovative ways to solve the cleaning challenges of NASA, the military and the American public by pioneering environmentally compliant cleaning methodologies for contamination removal,” said team lead Andrew Chaloupka.

Solvent replacement studies performed by the Chemistry and Contamination Control Team have resulted in implementation of a new generation solvents by several NASA sites, military installations and space/defense contractors.

Sudnik is a public affairs officer in the Office of Strategic Analysis & Communications.

Earth Day 2020: Tips for Keeping Green in Quarantine

By Rick Smith

Donna Leach doesn’t just work green; she lives green.

As lead engineer for sustainability in the Environmental Engineering & Occupational Health Office at NASA’s Marshall Space Flight Center, Leach leads Marshall’s Green Team in implementing cost-saving federal guidelines to boost energy and water conservation and recycling. As coordinator for Marshall’s Environmental Management System, she also works to boost operating efficiency by developing green procedures and performance practices, and as the NASA Regulatory Risk Analysis and Communications program representative, she monitors the impact of environmental regulations on Marshall’s mission.

In her spare time, Leach makes her own dish soap, hand lotion and household cleaning agents. She even cultivates a year-round hydroponics garden — in her dining room.

She offers the Marshall community the following tips to reduce their environmental footprint and practice sustainability around the house.

Reduce energy consumption. “This is the simplest thing we can do to conserve power and reduce waste,” Leach said. “We’re all working from home right now, which often means more lights on, more heating and cooling costs, more refrigerator doors opening and closing, more TVs and radios murmuring in the background.”

Be aware of these energy drains, she said. Shut off lights when moving from room to room. Play music on the laptop while working instead of leaving the television on. Ride a bike to the nearby grocery store to pick up a forgotten item or a few necessities instead of taking the family SUV. And to avoid higher energy bills while teleworking, “don’t let the computer go to sleep at night,” she advised. “Power it down completely.”

Conserve water. With increased health precautions in place, families are washing their hands more often than usual — making it a good time, Leach said, “to challenge everyone to offset that by minimizing water use during routine activities, such as showering and brushing their teeth.”

It’s also a good time to begin collecting water in a homemade or purchased rain barrel. She suggested calling local restaurants to inquire about picking up their old 55-gallon pickle barrels and other suitable containers — most of which would be discarded otherwise — to be sterilized and repurposed to catch rainwater. “Attach it to a downspout on the house, and let it fill up during showers and storms,” she said — a smart alternative to watering plants and gardens with tap water. Visit Marshall’s Earth Day at Home page on or after April 22 for more information about rain barrels.

Recycle. “This is always a big thing for families and home owners,” Leach said. “It’s a great alternative to simply throwing out waste.” Americans generate more than 250 million tons of trash annually and recycle or compost 60-90 million tons of it, the Environmental Protection Agency reported — preventing the release of millions of metric tons of carbon dioxide and methane. That’s comparable to taking tens of millions of cars off U.S. roads for a year.

Composting — controlled retention of decomposing organic material, such as kitchen scraps, tea and coffee grounds, soiled paper products and leaves — is a great home sustainability project. Composting reduces landfill waste, suppresses pests and plant disease, reduces the need for chemical fertilizers and adds rich, natural nutrients to soil for home gardens, Leach said.

Buy locally. Wherever possible, purchase from local vendors, Leach advises. “It’s not just a smart investment in the community — it also helps sustain the planet. Buying locally cuts greenhouse gas emissions tied to transportation of goods, especially from overseas, and reduces packaging used for bulk and long-distance shipping, which spares trees and other pulp paper sources and can reduce the manufacture of plastic products as well.” The practice may be a bit more costly now, she noted, but as the trend gains momentum and demand rises, costs are likely to drop as volume sales economize the niche market.

Learn more about local vendors and opportunities to buy locally in the Huntsville area here.

Find chemical alternatives. “Green cleaning,” a staple of environmentally conscious stewardship at Marshall, is on the rise among homeowners. “It’s a challenge to live chemical-free in a modern home, but it can be done,” Leach said. A green cleaning tutorial video will debut April 22 on the Earth Day at Home site.

Most store-bought cleansers include harsh chemicals, she said — often in concentrations that can be harmful to pets, children and even the household materials they’re meant to clean. Alternate cleaning agents may be organically grown or sustainably developed and sold, often relying on natural cleansers such as lemon, vinegar or baking soda. Coffee and tea also make good substitutes when cleaning wood surfaces, Leach noted.

Sustainability isn’t just for Earth Day, but “a year-round commitment,” she said. “But it doesn’t have to be a daunting challenge. Start small. Pick one project. Engage family and friends. The planet — and NASA — are counting on us.”

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Spinoff Helps World Produce More Earth-Friendly Energy

By Will Bryan

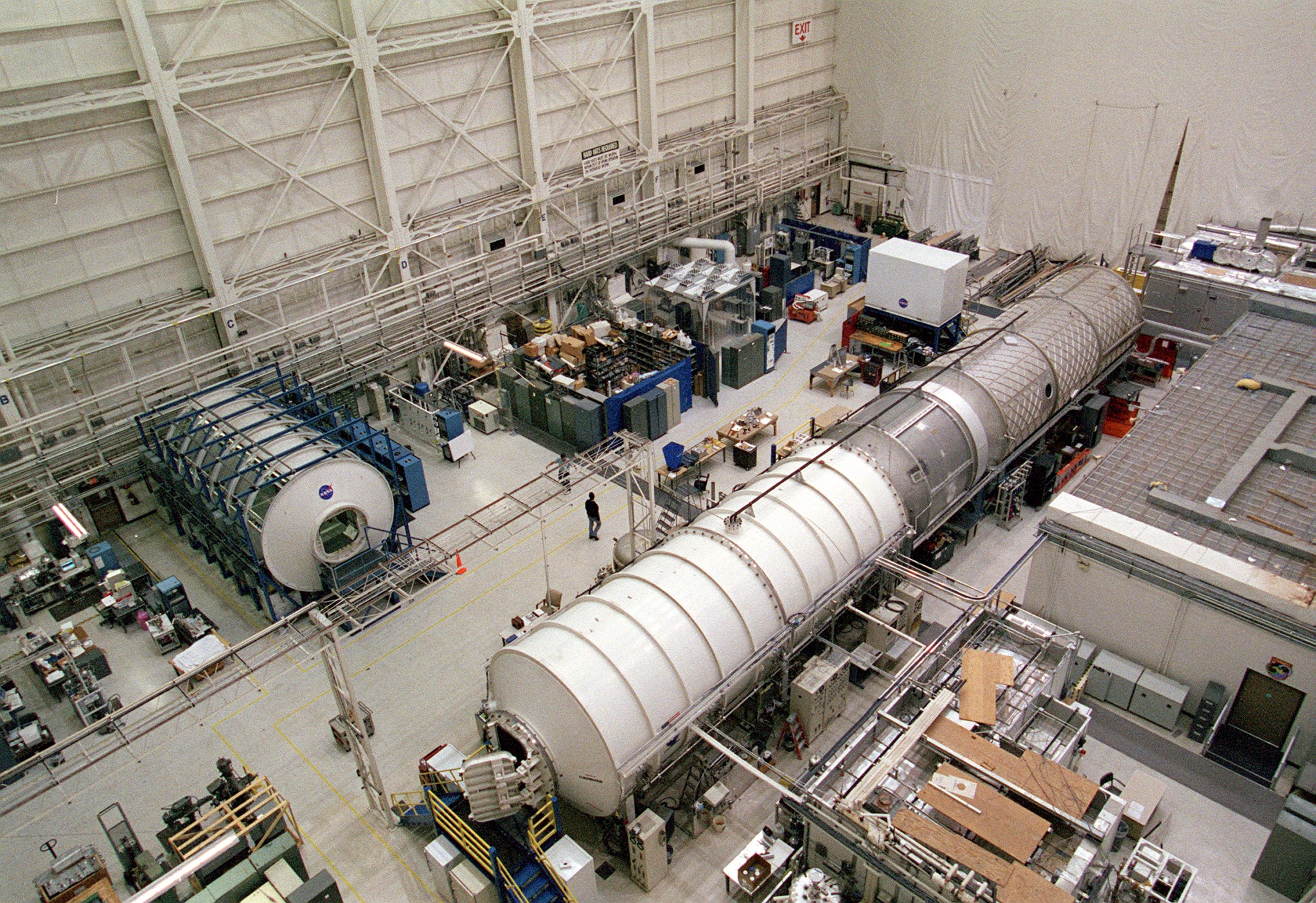

It’s no secret that energy production is not always the cleanest or most environmentally friendly activity humans engage in. While burning fossil fuels produces relatively cheap energy, some of the byproducts are less than desirable. Using expertise gained from decades of rocket engine development for NASA’s Marshall Space Flight Center, Gas Technology Institute of Des Plaines, Illinois, developed the R-Gas gasifier which uses a cleaner method to convert coal into energy.

Gas Technology Institute is a nonprofit research, development and training organization that seeks to address global energy and environmental challenges. In 2015, it acquired the energy portfolio of El Segundo, California-based Aerojet Rocketdyne — a longtime rocket engine developer. That portfolio included intellectual property, facilities and technology.

Rocket engines produced by Aerojet Rocketdyne for Marshall and NASA include the F-1 for the Saturn V and the RS-25s used on the space shuttle and Space Launch System. The company used those experiences to develop its energy portfolio for use in the private sector before the company was sold. During the transfer of resources, many Aerojet Rocketdyne researchers also went to work for Gas Technology Institute.

The R-Gas device uses gasification, a process that converts carbon-rich fossil fuels — such as coal — into a gas called syngas, short for synthetic gas, which is comprised primarily of hydrogen and carbon monoxide. The process uses heat and pressure to break the coal into its components by controlling the chemical reactions that lead to combustion.

The resulting products are syngas and an ash that will not contaminate soil or groundwater. The Fischer-Tropsch process — which converts hydrogen and carbon-based substances into other fuels — can then be used to convert the syngas into end products such as methane and ammonia.

Expertise of working on and developing rocket engines enables Gas Technology Institute teams to create “recipes.” Temperatures of rocket engines must be tightly controlled to prevent damage to the engines. The thermal control experiences enable the team to create and operate units that perform at higher temperatures and pressures than previous systems. The control also allows the team to modify conditions to create specific liquids and gases based on the ultimate end product needed.

The benefits of expertise do not end there. While older gasifier systems are the size of a building, such as Marshall’s Building 4619 or 4705, Gas Technology Institute used expertise from making powerful rocket engines fit into smaller packages to make its R-Gas gasifier about the size of a semitractor-trailer.

The environmental benefits of gasification are numerous, including reduction of ozone-depleting gases, toxic slag and contaminated wastewater. While fossil fuels cannot be used without some pollution, Gas Technology Institute has managed to eliminate some of the harmful effects.

Syngas can also be the basis for creating other chemicals. When it is used for chemical production, gasification makes it easier to capture and sequester carbon.

Economically, gasifiers reduce the need for expensive environmental, pollution mitigation controls. They also cost less to set up than a traditional coal power plant, making it more appealing to developing countries.

A demonstration at Gas Technology Institute’s headquarters processed 18 tons of coal a day. In late 2019, a demonstration plant built for a nylon factory in China anticipated processing 800 tons of coal a day. The plant also took advantage of the R-Gas’s recipe technology to produce ammonia — required for creating one of the components for nylon. The benefit allows the plant to reduce its power needs while establishing a new income stream.

NASA’s charter directs that the agency make technology and scientific knowledge gained through the exploration of space and improvement of aeronautics available to the public for commercial use.

“For over 50 years, the Technology Transfer Office at Marshall has worked with center innovators to identify technologies with commercial potential and license those technologies to companies that have created new commercial products that have improved life here on Earth,” said Terry Taylor, manager of Marshall’s Technology Transfer Program. “Team members who have a technology that could make a difference are encouraged to submit a New Technology Report.”

To learn more about the R-Gas gasifier, visit here. To read the latest issue of Spinoff, go here.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Mission Success is in My Hands: Angelia Walker

Editor’s note: This is the first in a series of articles spotlighting how eight team members at NASA’s Marshall Space Flight Center make meaningful connections between their jobs and the safety and success of NASA and Marshall missions.

By Daniel Boyette

The space shuttle Columbia accident in 2003 forever changed Angelia Walker.

Walker, currently deputy director of the Spacecraft and Vehicle Systems Department at NASA’s Marshall Space Flight Center, was part of the Columbia readiness, failure investigation and recovery efforts.

“To lose NASA family members so tragically was one of the worst days of my career,” said Walker, who has been with the agency for nearly 33 years. “I’ve learned to not accept the fact that we have experienced a problem or failure in the past as good flight rationale. One must ask questions and understand the limitations of the analysis that has been performed. We must lead risk assessments, control and mitigate risk and, when it is understood, be courageous enough to accept and communicate the risk or reservations about the safety of the mission.”

Walker now helps oversee the management of the Spacecraft and Vehicle Systems Department’s approximately 450 team members. She supports the design, analysis, testing and system integration of the Space Launch System and Mars Ascent Vehicle. She also provides insight for the Commercial Crew and Human Landing System programs, and development of new technologies to support science, space and Moon and Mars exploration and surface operations.

Through all those endeavors, Walker keeps safety at the forefront. She leads the efforts to identify risks and offer mitigation and/or control recommendations to programs and projects to ensure that hardware is safe to fly. She encourages team members to perform their duties safely and to identify safety hazards in the workplace.

“We must intentionally value, respect, listen to and hold accountable each other and the work we contribute toward flight and personnel safety,” Walker said. “We should realize that the sum is better than its parts. Diverse answers and perspectives contribute to better solutions than what one may come to on their own.”

Among Walker’s past positions was manager of Marshall’s Safety, Reliability and Quality Assurance Policy Assessment Department. That role, along with her past and present duties in the Engineering Directorate, have helped her to develop a strong appreciation for “Mission Success is in Our Hands,” a campaign by Marshall’s Safety and Mission Assurance Directorate and partner Jacobs Engineering of Huntsville, that promotes and strengthens the center’s focus on mission, hardware and crew safety.

“It means that I am personally responsible to make sure I and my fellow employees go home every night to our families without any accidents or casualties,” Walker said. “It also means that I am responsible to ensure that the hardware and missions we fly are as safe as they can be and that all risk has been appropriately identified for mitigation or acceptance.”

Boyette, an ASRC Federal/Analytical Services employee and Marshall Star editor, supports the Office of Strategic Analysis & Communications.

Marshall to Open New Library, Welcomes New Librarian

By Taylor Goodwin

NASA’s Marshall Space Flight Center is making progress toward a new satellite library.

NASA’s Mission Support Future Architecture Program implemented a NASA Library Modernization plan, in which all agency libraries will be centralized under the Logistics Management Division at NASA Headquarters.

Named the NASA Library Network, the new organization includes centralizing structure and control of all library assets and services across the agency, centralizing subscription procurement processed through NASA Shared Services Center and integrating all NASA library assets into the Galaxie catalog.

Previously, Marshall’s library services operated as part of the Redstone Science Information Center. Established as a joint library between the U.S. Army at Redstone Arsenal and Marshall in 1962, it housed scientific and technical information in the form of books, journals, technical papers and artifacts from 70 years of missile, rocket and helicopter development at Redstone Arsenal and Marshall.

In 2003, Marshall’s technical library merged with the Redstone Science Information Center. The latter facility closed its physical location in September 2019.

As of January, over 16,500 books, volumes of bound journals and other materials have been acquired by Marshall managers, scientists and engineers. Most of these journal volumes will be housed in the Annex — located in Building 4708, Room B32.

Marshall, the Headquarters Logistics Management Division and the Agency Chief Scientist Office are currently working to advance the facility and services available to the Marshall workforce.

Overseeing the details of the new facility is librarian Paula Laurita, who joined the Marshall team March 16. With a large task already at hand, Laurita began her role in the midst of Marshall’s mandatory telework status in response to COVID-19 — unable to access physical resources. However, Laurita and the library team have established the Marshall Library LibGuide to Databases & Resources — a list of open literature resources available until physical access to the facility is available.

“The library is more than a space,” Laurita said. “Libraries have never really been in the book business. We’ve been in the information business. Whether the information is conveyed on a clay tablet, rolls of bamboo, hand-lettered parchment, trade paperback or an e-book, the library’s mission remains the same: assisting you with the information needs that you have now and in the future, no matter the means of communication.”

Laurita earned her bachelor’s degree in elementary education from Georgian Court University in Lakewood, New Jersey, in 1986. In 1997, she graduated from the University of Alabama in Tuscaloosa with a master’s of library and information studies. Prior to joining Marshall, Laurita was coordinator of public services and assistant director of the Athens-Limestone, Alabama, Public Library, and later was its executive director. She is a U.S. Army veteran, married to an Army retiree and is the mother of two Army veterans.

For updates on the Marshall library status, visit the MSFC Library ExplorNet group. Questions or comments can be left by using the “Ask MSFC Library” option on the group’s page, or by emailing paula.s.laurita@nasa.gov.

Goodwin, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Astronauts Meir, Morgan Return from Science-Filled Space Station Expeditions

NASA astronauts Jessica Meir and Andrew Morgan returned to Earth on April 17, along with Soyuz Commander Oleg Skripochka of the Russian space agency Roscosmos.

The trio departed the International Space Station at 8:53 p.m. April 16 and made a safe, parachute-assisted landing at 12:16 a.m. Friday in Kazakhstan – where it was 11:16 a.m. local time.

During their first spaceflight, Morgan and Meir contributed to hundreds of experiments in biology, Earth science, human research, physical sciences and technology development. The Payload Operations Integration Center at NASA’s Marshall Space Flight Center manages science operations for the station.

Morgan’s nine-month mission began July 20, 2019. His 272-day flight spanned Expeditions 60-62, encompassing a total of 4,352 Earth orbits and a journey of 115.3 million miles. Morgan’s extended stay in space will increase knowledge about how the human body responds to longer-duration spaceflight, through the various investigations he supported, including the Fluid Shifts study. He also conducted seven spacewalks — totaling 45 hours and 48 minutes.

Meir and Skripochka, who launched on the Soyuz MS-15 spacecraft Sept. 25, 2019, spent 205 days in space, making 3,280 orbits of Earth during a trip of 86.9 million miles. During her first spaceflight, Meir was part of the first three all-woman spacewalks with crewmate Christina Koch of NASA, totaling 21 hours and 44 minutes. Among the investigations she contributed to is a study, co-led by a former Brown University colleague, examining how human heart tissue functions in space.

For more on Meir and Morgan’s science journey aboard the station, visit here.

Skripochka completed his third spaceflight for a cumulative 536 days in orbit.

Marshall’s Export Control Office Rolls Out New ‘e-Xport’ Automated System

By Rick Smith

In this quick-tempo era of rigorous hardware requirements, unprecedented international partnerships and awe-inspiring new missions to return to the Moon and send the first human explorers to Mars, it’s fair to say there is still little romance in paperwork.

But U.S. export laws are evolving, due to the ever more complex business endeavors between NASA and its global industry partners. Under the Export Control Reform Act of 2018, jurisdiction over the control and protection of certain space technologies was transferred from the U.S. State Department to the Commerce Department. Adherence to NASA’s export control guidelines and procedures is crucial — now more than ever — to safeguard innovation, protect national security and foreign policy interests, foster economic growth across the industry and ensure America’s strong technological leadership in space.

Fortunately, the paperwork is getting a little easier to negotiate.

The Export Control Program Office at NASA’s Marshall Space Flight Center is part of a NASA-wide program that supports the center’s and agency’s portfolio of engineering and scientific projects, ensuring all exports and transfers to foreign partners of identified commodities, software or technical information are consistent with Export Administration Regulations and International Traffic in Arms Regulations, as well as agreed-upon international cooperative activities.

The office was restructured in 2019, moving from Marshall Protective Services to the Office of Center Operations, with an emphasis on being a service-focused, mission-enabling partner with center programs and projects. The reorganization was a result of NASA’s new Mission Support Future Architecture Program, which is transitioning all mission support services to a more robust, enterprise-oriented operating model.

The process for exporting space technology is changing as well, said Terry Odum, center export administrator at Marshall. Traditionally, the process was intricate and time-consuming, requiring case-by-case analysis of export laws regarding jurisdiction, completion of numerous forms and checklists, and multiple signatures of approval.

Now, thanks to the organization’s new e-Xport digital software, much of that paper trail is automated and streamlined. It’s built using Nintex for SharePoint, software already in use across NASA to manage digital forms and automate workflow. With e-Xport, accessible by the 4-HELP page on Inside Marshall, users can request an export license, seek to ship or mail an item internationally, obtain an export classification for a commodity or technical information, request customized export training or ask for policy interpretation.

Data fields offer handy popup instructions, and meet all related requirements, from jurisdictional and classification insight to logistics and shipping information. The e-Xport tool even captures critical metrics for reporting to management and to NASA Headquarters — previously a separate, user-initiated function.

“We’ve compressed 10-12 pages of checklists and authorizations into one easy-to-follow form,” Odum said. “The exporter only has to fill in the data and submit the form for technical review and a single authorized signature at the center level. We review and approve each submission and send it to our logistics and shipping team to expedite.”

“It’s our goal to give the Marshall team the best, most efficient guidance possible, in the most concise language possible — to get exports out the door as quickly as possible,” said Sean Benson, Marshall’s assistant center export administrator.

The new digital process is in place and available for use. Since late 2019, the Export Control Office team has been developing and testing it internally and with stakeholders working under Space Act Agreements with foreign partners, including the European Space Agency.

Odum’s team is updating training for roughly 80 Center Export Control Representatives — support personnel certified and annually trained to assist their respective organizations with the export control process — to assist project leads in using the new digital form. Find the complete list of representatives and other key export control personnel here.

The organization also can conduct customized export control training in classrooms or via Microsoft Teams.

“Our goal is efficiency,” Odum said. “By simplifying this process, we reduce the burden on our center exporters, expedite the work of the center and make it easier to extend Marshall’s global value to the aerospace industry as a whole.”

For more information, contact Odum or Benson, or visit the Export Control Program Office on Inside Marshall.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

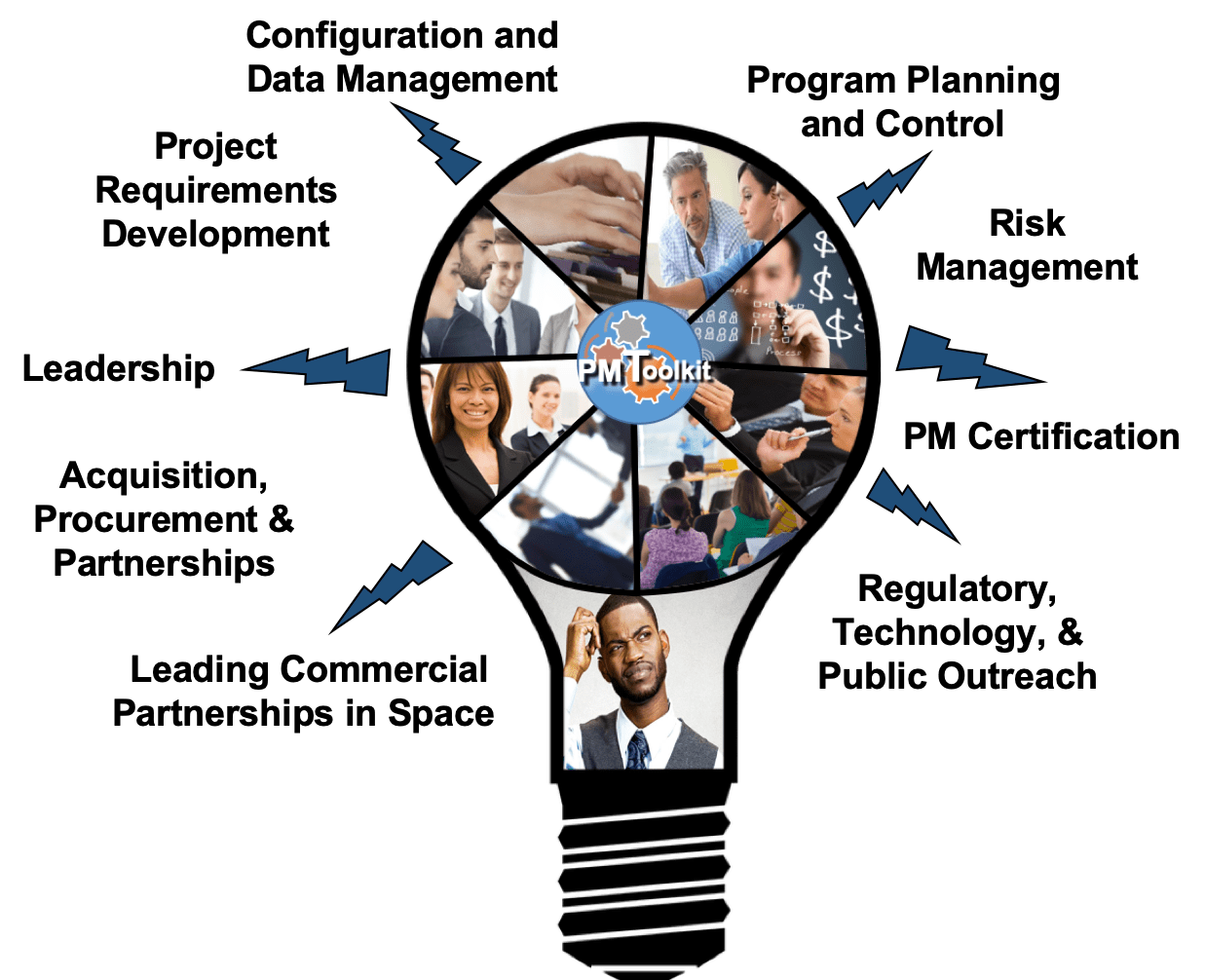

Key Marshall Organizations Collaborate on New Project Management Toolkit

By Rick Smith

A coalition of mission-critical organizations across NASA’s Marshall Space Flight Center has launched the Marshall Project Management Toolkit — a digital resource to assist new managers, mentor midcareer managers and serve and support the whole spectrum of Marshall’s engineering, science and space exploration endeavors.

“This is more than just a clearinghouse for mastering and sharing documentation,” said Samantha Harris, toolkit technical lead at Marshall. “It’s a one-stop shop, providing program, project and activity managers with the tools and legacy-based knowledge resources they need to effectively pursue the work of the agency and sustain the nation’s leadership in space well into the 21st century and beyond.”

Joseph Pelfrey, deputy manager of Marshall’s Human Exploration Development & Operations Office, said the new resource is “part of an overall project management development approach we’re crafting to strengthen Marshall’s execution of programs and projects critical to NASA’s Artemis-era missions and the future work of the center.”

The toolkit is structured around nine “communities of practice,” each dedicated to skill sets a good project manager must understand and master. They include program planning and control; acquisition, procurement and partnerships; project requirements developments; risk management; configuration management/data management; regulatory, technology and public outreach; leadership; Marshall program manager certification; and leading commercial partnerships in space.

The site also folds in proven systems engineering tools, such as documentation strategies and requirements tailoring techniques developed by the Engineering Directorate’s Systems Engineering Advancement & Leadership Team.

“From a first-time project manager tapping Marshall’s history of world-class project and program management experience, to a veteran science program manager seeking to refine the workflow with the application of a new tool or technique, this resource ably serves the full spectrum of Marshall’s mission,” said Rae Ann Meyer, deputy manager of the Science and Technology Office.

The toolkit is also a critical support system, enabling seasoned managers and those learning the management ropes to glean best practices and standards from their counterparts across the center and among agency partners, said project manager Erin Betts.

“Seeing how other managers solve challenges — through a deep, interactive network of tools and reference materials — helps promote consistency and reliability,” said Betts, who is also acting manager of the Science and Technology Office’s Exploration Systems Development Branch. “It can offer fresh insight and innovative approaches trusted across different management styles — and across the whole gamut of mission classifications as well.”

Van Strickland, acting manager of the Space Launch System Program Operations & Strategic Communications Office at Marshall, concurred. “This is a comprehensive and efficient way to share useful information and resources among managers across their entire careers,” he said.

Harris, who also supports the Lunar Flashlight propulsion system project led by NASA’s Jet Propulsion Laboratory, said she’s particularly excited to be part of developing the toolkit, which already has refined her own long-term managerial ambitions and made her a more confident project lead.

“When you’re just starting on this path, the sheer volume of resources and documentation out there can be overwhelming,” Harris said. “The PM Toolkit is intended to gather, distill and maximize usefulness of all that history and knowledge. It’s a great jumping-off point, providing context and clarifying options.”

The PM Toolkit was refined with help from a team of civil service and contractor subject matter experts “with decades of experience across a wide variety of disciplines, from acquisitions and procurement to ground-level engineering and scientific research,” Meyer said. Additional benchmarking across NASA and industry is planned.

The toolkit currently is in beta release, with full rollout set for April 30. The development team encourages Marshall managers and those interested in pursuing project/program oversight, or merely seeking a deeper understanding of the process, to browse the site and fill out the survey now available.

The Project Management Toolkit is jointly funded and curated by Marshall’s Science and Technology Office, Space Launch System Program Office and Human Exploration Development & Operations Office. In addition to Harris and Betts, the development team includes Rajiv Doreswamy, manager of HEDO’s Exploration & Transportation Development Office, and Patrick Johnson, program specialist in the SLS Program Operations Office. Meyer, Strickland and Pelfrey lead the toolkit steering committee.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Names of All Past, Present Marshall Employees to be Engraved on Planned Memorial

The Marshall Space Flight Center Retirees Association is seeking biographical information of past and present center employees for a memorial it is planning that will honor those who made more than six decades of U.S. space exploration possible.

The association is working with officials from Marshall and the U.S. Space & Rocket Center to create the Space Exploration Memorial at the rocket center. The memorial will contain engraved names of all Marshall civil servants since the center opened in 1960. The names of Marshall-associated companies and representations of some of the center’s best-known rockets and spacecraft will also be engraved on the memorial.

Retiree association members, along with representatives from Marshall and the University of Alabama in Huntsville, have created an online database that contains the names of 22,000 current and former employees. Memorial organizers request that past and present Marshall civil servants verify their names and add biographical information to the database by visiting www.marshallretirees.org.

“It will be the only such employee list created in the history of NASA,” retiree association president Rick Chappell said. “And it will be a 60th birthday gift from the Marshall Retirees Association to Marshall Space Flight Center.”

The online database will be accessible beside the memorial. It will include the names of the civil servants and the companies and will show the location of the names on the memorial. The names of all known employees from Marshall-associated companies will also be listed in the online database. Memorial organizers are working with the contractor community to identify their employee names.

Later phases of the memorial will add dynamic water fountains showing the power of rockets conceived in Huntsville — including the Redstone, Saturn I, Saturn V, space shuttle rockets and Space Launch System.

Former Marshall Acting Director Gene Goldman is among the retiree association members leading the memorial project. He noted the center’s role in vital programs, missions and technology for NASA, including Apollo, the Lunar Roving Vehicle, Skylab, the space shuttle, Spacelab, the International Space Station and the world’s most powerful space telescopes.

“Marshall and the Huntsville community have made an invaluable contribution to our nation’s leadership in space exploration,” he said. “A lasting memorial will be a most appropriate way to honor that legacy, as well as to teach and inspire future generations of explorers.”

Redstone Construction Continues Despite Pandemic

By Wendy Reeves

Construction is one activity that COVID-19 hasn’t stopped on Redstone Arsenal.

“We are full steam ahead,” said Glen Strobach of the arsenal’s Directorate of Public Works. “In fact, we’re pushing to get more road work completed while our traffic flow is light and the weather stays good.”

In addition to ongoing work at the new Redstone Gateway project near Gate 9, Strobach said crews have been working to complete new road construction leading to Gate 3, which is currently closed because of COVID-19. He said paving was completed April 6 on the new intersection of Hobbs Road and the Haysland Road extension, which will offer another option for entering and exiting Gate 3 on Redstone Road, north toward Grissom High School.

Strobach said road striping and a new traffic signal are scheduled for completion the week of April 20, weather permitting. That means commuters can expect a slight traffic change as they approach and exit Gate 3 when the workforce returns to the arsenal. The biggest change will be for those exiting Gate 3. Strobach said traffic will be limited to the right lane, unless motorists are turning onto Haysland Road. The left traffic lane will be dedicated to left turns only. Strobach said the change is anticipated to occur when the road reopens, likely before the workforce returns.

Construction workers are practicing all recommended safety and social distancing measures and additional guidelines from the Centers for Disease Control and Prevention, U.S. Army, Department of Defense and state and local governments, he said.

The same safety practices are being observed at the Redstone Gateway construction site on Rideout Road, said James Lomax, director of asset management for Corporate Office Properties Trust of Columbia, Maryland, which is developing the 468-acre office park with Wilson & Associates of Montgomery, Alabama.

“It is a mass construction site,” Lomax said. “We’ve got approximately 800,000 square feet of space under development right now.”

Among sites under construction include:

- A multibuilding campus for defense contractor Yulista, which will include 366,000 square feet of space on the site.

- A 100,000 square-foot, four-story office building at 8000 Rideout Road.

- A single-story, 40,000 square-foot office space at 6000 Redstone Gateway.

- A 20,000 square-foot building, which will be home to Ardent Preschool & Daycare.

Lomax said that all projects are on schedule, and that another two buildings are scheduled to start construction this month.

Seven office buildings, totaling 669,000 square feet, have already been completed at the site, including The Shops at Redstone Gateway, which houses three restaurants and a conference center; and a TownePlace Suites by Marriott.

The biggest impacts COVID-19 is having on Redstone Gateway are the delayed grand opening of the new Offbeat Coffee Shop and a change in restaurant traffic.

“It was supposed to open this month but it will be pushed out,” Lomax said. “It’s exciting that we’ll have a new drive-thru and walk-up coffee shop when this is over.”

He said all three Redstone Gateway restaurants — Rocket City Tavern, Fiero and DipWich — are providing takeout orders to help weather the COVID-19 pandemic.

This story originally ran in the Redstone Rocket. Read the entire story here.

Reeves is a staff writer for Redstone Arsenal’s Redstone Rocket.

OSIRIS-REx Rehearses Sample Capture, Highlighted on ‘This Week @NASA’

NASA’s OSIRIS-REx recently performed a rehearsal of its sample-capture maneuver and is featured in “This Week @NASA,” a weekly video program broadcast on NASA-TV and posted online.

On April 14, the agency conducted the first practice run with OSIRIS-REx in preparation for its August attempt to collect a sample from asteroid Bennu and safely return that sample to Earth. The rehearsal, known as “Checkpoint,” placed the spacecraft the closest it has ever been to Bennu – 246 feet. This is NASA’s first sample return mission to an asteroid.

OSIRIS-REx is a project of the Science Mission Directorate’s New Horizons Program, managed by NASA’s Marshall Space Flight Center.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

This Week in NASA History: Hubble Deployed – April 25, 1990

This week in 1990, the Hubble Space Telescope was deployed from the cargo bay of space shuttle Discovery. Here, Hubble has one of its two solar array panels deployed while still in the grasp of Discovery’s remote manipulator system. NASA’s Marshall Space Flight Center was responsible for the overall design, development and construction of the observatory. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)