In This Week’s Star

- Welding Wonder Completes Hardware for First Flight of NASA’s SLS Rocket

- New Test Structures will have NASA SLS Rocket Hardware Feeling the Force

- David Burns Named Deputy of Marshall’s Space Systems Department

- Astronaut Kjell Lindgren Credits Marshall for Successful Mission

- ‘Greening’ of Marshall Continues: Center Operations Teams Move Into Building 4260

- NASA Announces Preliminary Winners of Student Launch, Winners of Mars Ascent Challenge

- NASA Tests Earthquake Mitigation System at the University of Alabama in Tuscaloosa

- I Will Launch America: Launch Vehicle Deputy Manager Dayna Ise

- Space X and New Expandable Module Dock with International Space Station

- This Week in NASA History: Apollo 16 Lands on Moon — April 21, 1972

- Student Rocket Launches and Mars Sample Challenge Featured on ‘This Week @NASA’

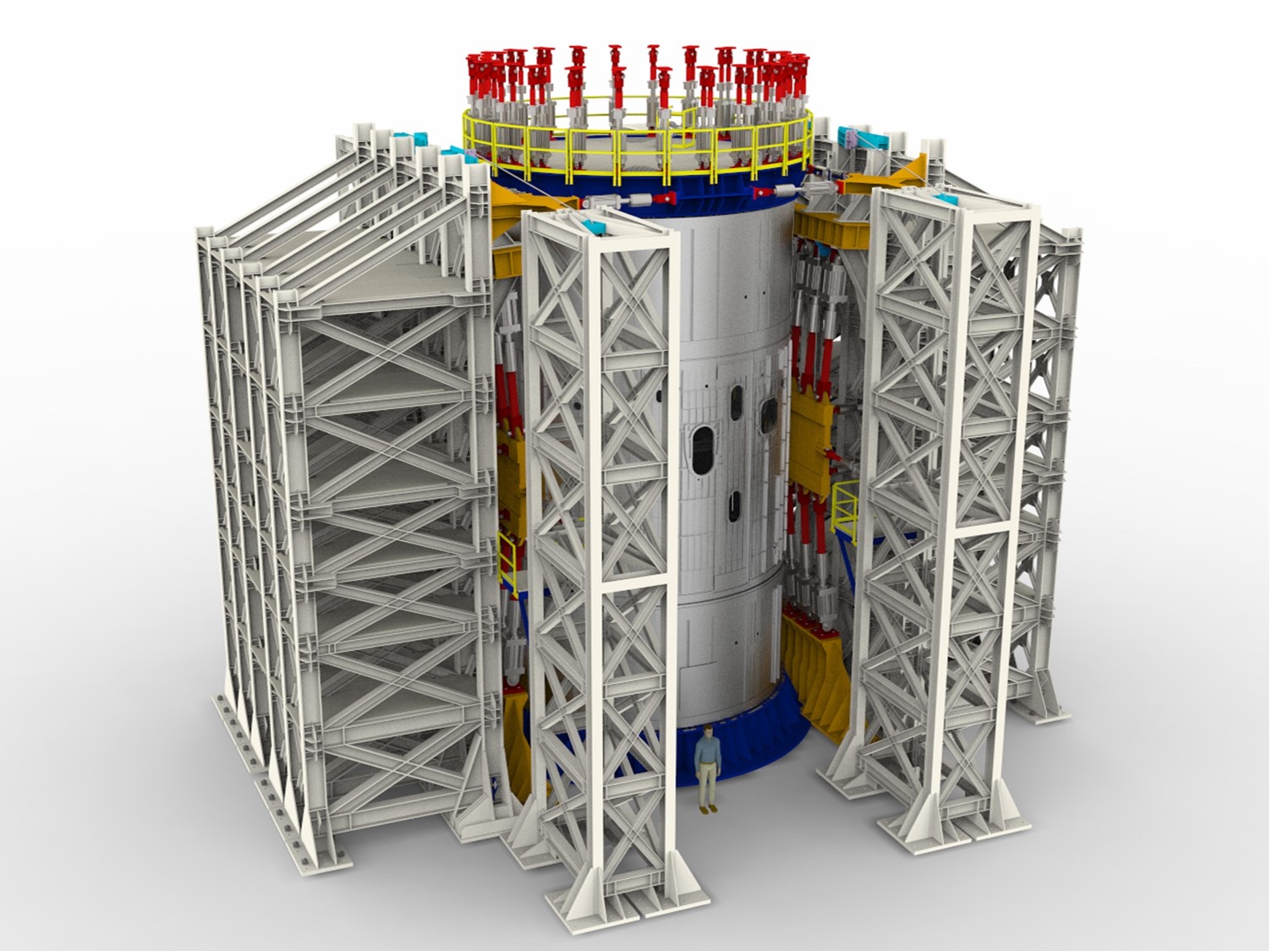

Welding Wonder Completes Hardware for First Flight of NASA’s SLS Rocket

Flight hardware for the core stage of the world’s most powerful rocket, NASA’s Space Launch System, finishes final welding and is moved off the 170-foot-tall Vertical Assembly Center at the agency’s Michoud Assembly Facility. The hardware is for the engine section, and is the first major SLS flight component to finish full welding on the massive tool. The engine section is located at the bottom of the rocket’s core stage and will house the four RS-25 engines for the first flight of SLS with NASA’s Orion spacecraft in 2018. The SLS core stage will stand at more than 200 feet tall and store cryogenic liquid hydrogen and liquid oxygen that will feed the launch vehicle’s RS-25 engines. A qualification version of the engine section, which also has completed welding on the Vertical Assembly Center, will be shipped later this year to NASA’s Marshall Space Flight Center to undergo structural loads testing on a 50-foot test structure currently under construction. All welding for the core stage of the SLS Block I configuration — including confidence, qualification and flight hardware — will be completed this summer. Traveling to deep space requires a large vehicle that can carry huge payloads, and SLS will have the payload capacity needed to carry crew and cargo for those exploration missions, including Mars. (NASA/Michoud/Steven Seipel)

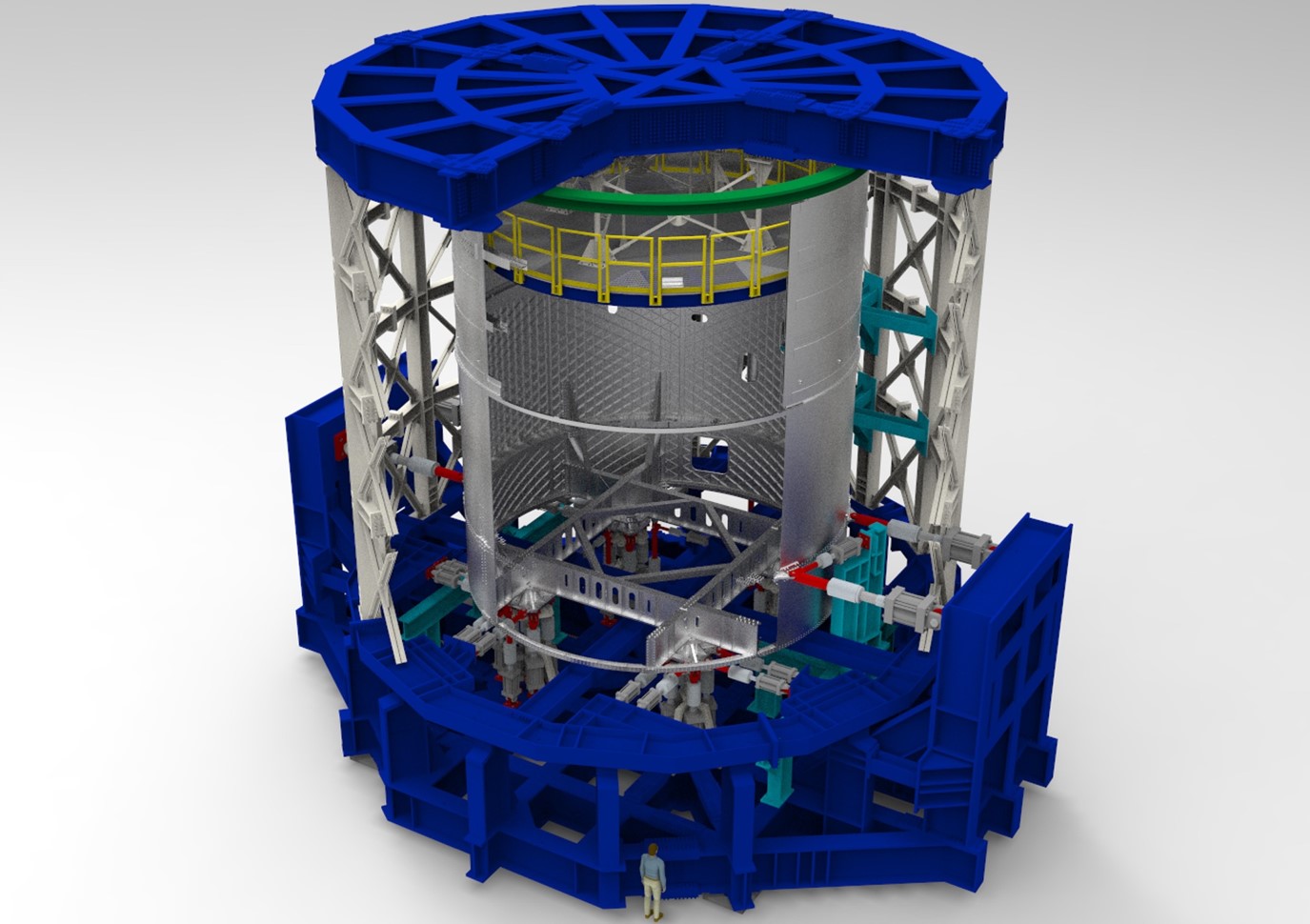

New Test Structures will have NASA SLS Rocket Hardware Feeling the Force

By Megan Davidson

If walls could talk, Building 4619 at NASA’s Marshall Space Flight Center would have a lot to say about testing rockets.

The multipurpose, high-bay test facility has been a hotbed for all types of testing, including loads, acoustics, vibration, extreme temperatures, high-and-low pressures and environments that simulate the cold, black conditions of outer space. More recently, it served as the hub for a series of large-scale “can-crushing” tests to study buckling in structures with the purpose of building lighter, more efficient and affordable launch vehicles.

Today, teams are breathing new life into the 4619 load test annex — part of Marshall’s Structural and Environmental Test Laboratory — for the next era of space exploration with the world’s most powerful rocket, NASA’s Space Launch System. SLS will launch crews of up to four astronauts in the agency’s Orion spacecraft on missions to explore multiple, deep-space destinations, including Mars.

Construction is underway at the facility on steel reaction towers and fixturing that will be used for structural loads testing on the SLS core stage intertank and engine section. The core stage, towering more than 200 feet tall with a diameter of 27.6 feet, has two separate tanks for storing cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines. The core stage intertank is the connection component between the liquid hydrogen and liquid oxygen tanks, and the attachment point for the rocket’s two, five-segment solid rocket boosters. The engine section structure, also part of the core stage, houses the rocket’s four RS-25 engines.

“It’s exciting to be a part of the future of human spaceflight,” said Tim Flores, integration manager for the SLS Stages Office at Marshall. “Testing this hardware is a major stepping stone before the first flight of SLS.”

Twelve, 55-foot intertank main tower panels, built and delivered by Weldall Manufacturing Inc. of Waukesha, Wisconsin, have been installed in the 4619 load test annex. One of the next steps will be the delivery and installation of four additional tower structures, which are being manufactured by Steward Machine Co. of Bainbridge, Georgia. In late April, the base frame for the engine section test structure will be delivered from Weldall and installed into another bay of the 4619 load test annex.

Hydraulic cylinders mounted to the main towers will apply force, or test loads, to the core stage intertank to simulate prelaunch, launch and spaceflight structural load conditions. The 62-foot-tall intertank test structure and 50-foot-tall engine section test structure will use up to 96 hydraulic cylinders on each piece of hardware, with some cylinders weighing more than a car.

The intertank and engine section qualification test articles will be installed in the new structures, and the hydraulic cylinders will be electronically controlled to push, pull, twist and bend the test articles with millions of pounds of force. Engineers will record and analyze approximately 4,000 channels of data for each test. The tests will verify the capabilities of the structures, and validate that the design and analysis models already in place accurately predict the amount of loads the core stage can withstand during launch and ascent.

“It’s amazing that right outside my office in our laboratory high-bay, we’re constructing the facility, structures and systems to perform such crucial tests on the SLS intertank and engine section,” said Robert Bobo, the lead for Marshall’s structural testing branch. “Test engineers, designers, analysts and skilled technicians have been planning and preparing for this work for months, and now we’re seeing it actually happen. We’re anxious, and excited, to get our hands on the hardware.”

Both test structures in the load test annex are scheduled to be completed later this year, along with two new test stands that will be used for structural loads testing on the core stage liquid hydrogen and liquid oxygen tanks, plus related hardware. The first test of the series will be on the engine section and is planned to begin in the summer of 2017.

Read the full version of this story here.

Davidson, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

David Burns Named Deputy of Marshall’s Space Systems Department

NASA Marshall Space Flight Center Director Todd May announced April 18 that David M. Burns has been appointed to the Senior Executive Service position of deputy, Space Systems Department, in Marshall’s Engineering Directorate.

The Space Systems Department is responsible for designing, developing, assembling, integrating, testing and delivering flight, ground, prototype and development products for human spaceflight programs, science investigations and exploration initiatives.

Reporting to the Space Systems director, Burns will assist in the supervision of an annual budget of over $110 million and the management of a diverse, highly technical workforce of approximately 560 civil service and contractor employees located in six divisions and 18 branches.

Burns joins the Marshall workforce after eight years with the U.S. Department of Defense Missile Defense Agency, where he served as the director of Science and Technology. He led the teams that managed the agency’s directed energy programs, conducted university and small business innovative research and modeled the impact of new missile defense capabilities.

Prior to his time with MDA, Burns was a senior leader in private industry. From April 2006 to May 2008, he was founder and chief executive officer of Dielectric Blue Inc. of Lacey’s Springs, Alabama, which specialized in the design and manufacture of anti-tamper sensors for military and commercial applications.

Burns retired from the U.S. Air Force in August 2003 after 20 years of active duty. His Air Force career included assignments in the Pentagon, multiple product centers, and London. In London, he was technical director of the European Office of Aerospace Research and Development. After retiring from the Air Force, he worked as the Science Applications International Corporation’s lead engineer, manager and supervisor for the Armed Robotic Vehicle-Heavy, a $2.6 billion element of the Army’s Future Combat System.

Burns holds a doctorate in electrical engineering from the Air Force Institute of Technology, a master’s degree in electrical engineering from the University of Dayton, Ohio, and a bachelor’s degree in electrical engineering from the Air Force Academy.

He is also a graduate of the Harvard Kennedy School of Government Senior Executive Fellows Program. He and his wife Cheryl have four children and reside in Huntsville.

Astronaut Kjell Lindgren Credits Marshall for Successful Mission

NASA astronaut Kjell Lindgren, visiting NASA’s Marshall Space Flight Center on April 14, talks with the workforce and sharing his experiences during his five-month stay on the International Space Station last year. “We worked every day with the dedicated professionals in the Payload Operations Integration Center, and it’s that partnership that makes science on orbit successful,” Lindgren said, referring to the flight controllers in NASA’s mission control for science in Building 4663. (NASA/MSFC/Emmett Given)

During his visit, Lindgren speaks with students who were at Marshall for NASA Student Launch, including Midshipman Zenas Yun of the U.S. Naval Academy in Annapolis, Maryland. Lindgren encouraged students to continue their journey of aerospace education, saying a member of the audience could be the first person to walk on the surface of Mars. (NASA/MSFC/Emmett Given)

‘Greening’ of Marshall Continues: Center Operations Teams Move Into Building 4260

By Rick Smith

NASA Marshall Space Flight Center’s latest green facility opens for business this month, as Building 4260 on Rideout Road becomes home to roughly 100 Office of Center Operations team members. Their move is expected to be complete by the end of May.

Building 4260 project manager Shannon Fulenwider said the new facility offers similar high-tech benefits used in Building 4220 and other new structures: state-of-the-art heating, ventilation and air conditioning; water-saving plumbing fixtures; and a retention pond to assist in stormwater quality control. The new building also will include two electric-vehicle charging stations for government vehicles — a pilot program to help meet new government emissions restrictions. It will also offer special parking for certified, low-emission personal vehicles.

“That’s another new incentive to encourage our team to think in sustainable, green terms,” Fulenwider said.

Introducing a human touch

Fulenwider is particularly proud of the new building’s aesthetics — the built-in “human touches,” such as the exposed ceiling and insulated glazing which bring natural light into the structure. She also points to the building’s strikingly curved exterior, mirrored by similar design touches throughout which lend warmth and personality to the lobby, meeting areas and break room.

“Trying to raise morale via pleasing yet cost-effective elements of these new facilities is part of our new guiding principles for the next 10 years,” said Melvin McKinstry, Marshall’s master planner in the Planning & Facilities Utilization Office. “Morale, health and fitness are as conducive to a successful workplace as energy efficiency and a reduced environmental footprint.”

“With the new elements in Building 4260, we’re well ahead of the curve,” Fulenwider added.

For their part, Roy Malone and Robert Devlin, manager and deputy manager of the Office of Center Operations, are excited to take up residence in the new facility. “It allows us to co-locate a number of Center Operations personnel currently spread out around the campus, improving communications and collaboration,” Malone said. “More importantly, it’s another step in Marshall’s master plan, increasing our efficiency as an organization while improving our overall energy efficiency.”

Setting the green standard

Reactions to Marshall’s new generation of environmentally friendly buildings have been similarly positive for a decade now — beginning with the construction in 2003 of Building 4600, NASA’s first-ever green facility and the anchor of Marshall’s new engineering complex. Since then, Marshall has erected six more award-winning, high-efficiency facilities — all of them achieving the U.S. Green Building Council‘s Leadership in Energy and Environmental Design certification.

Building 4260, Marshall’s eighth such facility, is under consideration for LEED certification. Like all major government construction projects, it must be designed to LEED silver status or better. The voluntary national standard assesses sustainable design principles in new, high-performance structures, including maximized use of environmentally sound fabrication, maintenance and cleaning techniques, materials and products; minimization of non-renewable energy consumption; and optimal protection and conservation of water and power.

For Marshall, the ultimate goal is to become leaner and more efficient, Devlin said. Between 2005 and 2019, Marshall will have demolished approximately a quarter of its existing square footage, dramatically reducing its environmental footprint and streamlining operations, making offices, laboratories and other workspaces more comfortable, healthy and conducive to collaboration. They’ll also be far more energy efficient, reducing operating and maintenance costs by 65 percent and lowering utility costs by up to 40 percent.

McKinstry and Fulenwider’s pride in their team for these accomplishments — and in the visually appealing new building opening this month on Rideout Road — is self-evident. “We’re thrilled to take another step forward with Marshall’s master plan, creating exciting places in which to perform our work,” McKinstry said.

For Malone and his Center Operations team, the bottom line is even simpler. “Less expensive buildings and infrastructure preserves dollars to put toward programs,” he said. “At the end of the day, accomplishing our missions in space is our chief measure of success.”

Building 4260 was designed by the Nashville-based architectural firm of Barge, Waggoner, Sumner & Cannon Inc. Baggette Construction Inc. of Decatur, Alabama, built the facility.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

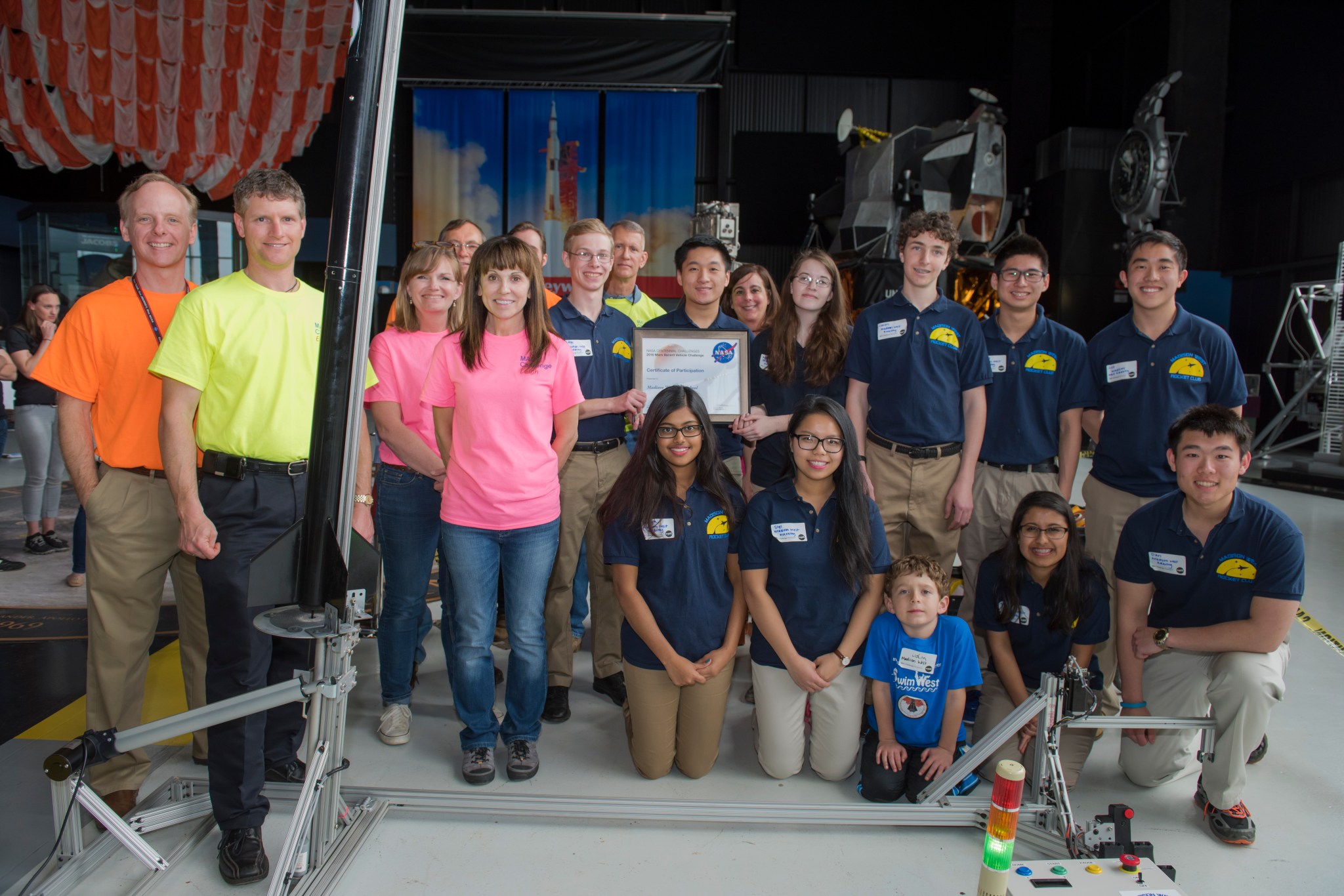

NASA Announces Preliminary Winners of Student Launch, Winners of Mars Ascent Challenge

By Christopher Blair

After the smoke cleared from a long day of high-powered rocket launches April 16, NASA announced the preliminary award winners for the 2016 NASA Student Launch Challenge and the final award winners of the Mars Ascent Vehicle Challenge. The events were held April 13-16 near NASA’s Marshall Space Flight Center.

Hundreds of students spent the past eight months building and testing rockets designed to fly to an altitude of one mile, deploy an automated parachute system, and land safely enough for reuse. Several teams also designed scientific payloads to collect data during flight, while others, participating in the MAV challenge, developed separate autonomous ground support systems, capable of retrieving and loading a mock Martian sample into their rocket.

Student Launch — now in its 16th year — included an astronaut visit with Kjell Lindgren of the Expedition 44/45 to the International Space Station; a presentation by four-time space shuttle astronaut Charlie Precourt; a rocket fair, where students gave formal presentations about their designs to team members of NASA and longtime corporate sponsor Orbital ATK Aerospace Group of Promontory, Utah; a behind-the-scenes tour of Marshall and much more.

Preliminary award winners for Student Launch were announced during an awards ceremony at the U.S. Space & Rocket Center. The overall winners will be announced in early May, after the Orbital ATK team sifts through final flight data for accuracy. Award winners will include the top three teams and the rookie award winner. The first-place winner will receive $5,000 from Orbital ATK.

“Our company is proud to have sponsored Student Launch since 2007,” said Precourt, vice president and general manager of Orbital ATK. “For nine years we have been the sole corporate sponsor, and it’s great to see teams return year-after-year. Student Launch really brings out the best in our future rocket scientists.”

In its second year, the Mars Ascent Vehicle Challenge — sponsored by NASA’s Centennial Challenges Program — awarded $50,000 in prize money to the top three teams in its competition. Eighteen teams representing 17 universities, one high school and 14 states competed in the MAV Prize competition.

“The MAV prize is one element of the larger story of how technology will enable our future exploration,” said Dennis Andrucyk, NASA’s deputy associate administrator of the Space Technology Mission Directorate. “Citizen prize competitions allow NASA to bring diverse minds to the table and I am impressed with the innovation, enthusiasm and spirit these young teams have delivered.”

To view a complete list of winners, plus learn more about Student Launch, click here.

For more information about the Centennial Challenges MAV Challenge, click here.

Archived launch-day footage is available on the Marshall’s Ustream channel.

Blair, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Tests Earthquake Mitigation System at the University of Alabama in Tuscaloosa

Rob Berry, an engineer at NASA’s Marshall Space Flight Center and the principal investigator for the disruptive tuned mass system, addresses media before tests at the Large Scale Structures Laboratory at the University of Alabama in Tuscaloosa. NASA and University of Alabama engineers tested a disruptive tuned mass system April 14 to demonstrate the technology’s ability to mitigate a building’s response to earthquakes. Originally developed to solve vibration issues encountered during a rocket launch, the disruptive tuned mass system has potential applications across multiple industries to improve damper systems on ships, automobiles, airplanes, helicopters, bridges and much more. The university’s high-performance, uniaxial, 12-foot-by-13-foot table is designed to handle a two-story building with a maximum payload of 20 tons. Working with computers, the table shakes the test article to simulate the seismic effects on a building. Marshall’s Technology Transfer Office supports the commercialization and transfer of the disruptive tuned mass system. NASA’s Technology Transfer Program ensures that technologies developed for missions in exploration and discovery are broadly available to the public, maximizing the benefit to the nation. (NASA/MSFC/Brian C. Massey)

I Will Launch America: Launch Vehicle Deputy Manager Dayna Ise

By Brian C. Massey

American-built rockets will soon once again launch astronauts from American soil, and Dayna Ise, an engineer at NASA’s Marshall Space Flight Center, is excited to be part of the program making this possible.

Ise, deputy manager of the Launch Vehicle Office in NASA’s Commercial Crew Program, said working at the dawn of a new generation of human spaceflight brings intensity in a number of areas.

“Of all the projects I have been part of with NASA in my 15 years, this is easily the work I am most proud of,” said Ise, who started her career working on space shuttle main engines. “I joined the team early on, almost five years ago, and it’s been fun to see it grow. It’s exciting to be part of program that will launch astronauts to the space station from American soil and allow NASA more resources for exploration deeper into our solar system.”

NASA’s ultimate goal with the Commercial Crew Program is to establish reliable and cost-effective human access to space. In the Launch Vehicle Office, Ise works with industry partners to ensure all launch vehicle requirements and standards are met before launching astronauts for the agency. SpaceX will launch its Crew Dragon spacecraft on a Falcon 9 rocket, while Boeing will launch its CST-100 Starliner spacecraft on a United Launch Alliance Atlas V rocket.

Unlike previous human spaceflight programs, NASA did not design the spacecraft and rockets and will not own and operate them. The companies will do that. NASA is lending its expertise in developing the systems and will certify the launch vehicles, spacecraft and related hardware and operations once they meet all requirements for flight.

“NASA has spent a lot of time sending people into low-Earth orbit,” said Ise. “We know how to do it, and now it’s time to turn over that knowledge and capability to commercial companies so that they can figure out how to do it cheaper and more efficiently, while maintaining crew safety requirements.”

Commercial crew transportation to and from the station will provide expanded utility of the International Space Station, including additional crew time dedicated to research on the orbiting laboratory. The station is a critical test bed for NASA to understand and overcome the challenges of long-duration spaceflight necessary for the journey to Mars.

“Low-Earth orbit provides us a foundation for deep space exploration,” said Ise. “People living on the space station are teaching us what to expect on long-duration missions, like those to Mars.”

Commercial partners transporting astronauts to and from the space station will allow NASA to focus on other areas of exploration, namely deep space.

“Commercial Crew and the space station are important building blocks for moving beyond,” said Ise. “A quick, efficient way of sending people to low-Earth orbit will allow NASA to spend time and energy in other endeavors including missions to an asteroid and eventually to Mars.”

The Commercial Crew Program is primarily based at NASA’s Kennedy Space Center, but many NASA team members agency-wide work with the program. Almost half of those working with commercial crew are involved in the work at other NASA centers, including Marshall and NASA’s Johnson Space Center.

At Marshall, about 100 engineers support many aspects of the program, including launch vehicle, spacecraft and integrated performance. With Marshall supporting several fields, Ise also manages Marshall’s overall commercial crew work package for the agency in addition to her role as launch vehicle deputy manager.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

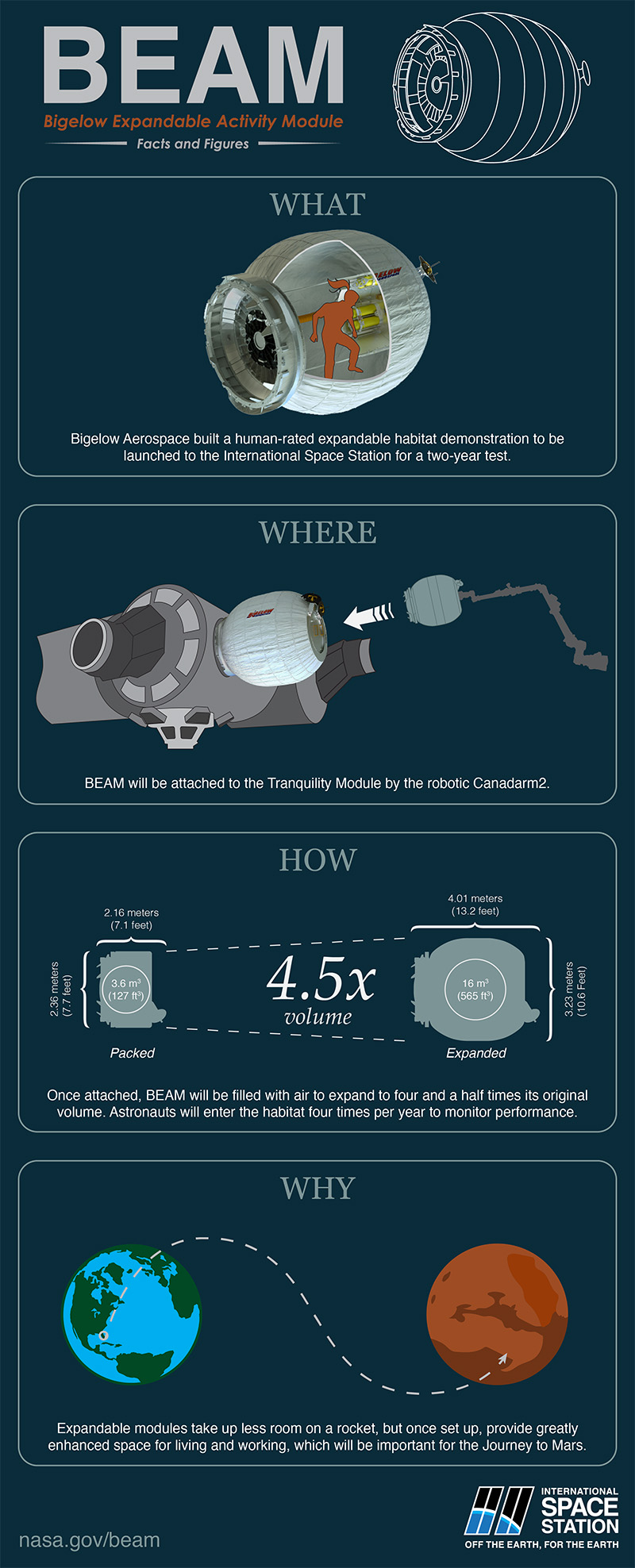

Space X and New Expandable Module Dock with International Space Station

By Bill Hubscher

With the successful berthing of the SpaceX Dragon capsule to the International Space Station on April 10, two commercial cargo craft are docked with the orbiting laboratory for the first time.

On April 8, Space X launched its sixth resupply mission to the station from Cape Canaveral Air Force Station, loaded with 7,000 pounds of cargo, scientific gear, crew supplies and an expandable module demonstration. When it arrived two days later, the capsule was attached to the port next door to the Orbital ATK Cygnus commercial cargo vehicle, which was berthed to the Unity module on March 26. Although the SpaceX and Orbital ATK spacecraft have launched 12 times, this is the first time that the two vehicles, contracted by NASA and developed by private industry to resupply the station, have been connected to the space station at the same time.

“This makes things very busy for us,” said Ann Bathew, assistant payload operations manager in the Marshall Space Flight Center’s Payload Operations Integration Center, science mission control for the space station. “Both vehicles docked in such a short period of time means the crew is unloading a lot of new investigations that we need to get activated, installed or stowed. That’s a lot of scientific discovery we can look forward to.”

On April 16, less than a week after berthing to the space station, ground controllers in mission control at NASA’s Johnson Space Center removed the Bigelow Expandable Activity Module from the SpaceX Dragon. Using the robotic Canadarm2, controllers moved BEAM into its installation position at Tranquility’s aft port for its attachment to the station.

NASA is investigating concepts for habitats that can keep astronauts healthy during space exploration. Expandable habitats are one such concept under consideration — they require less payload volume on the rocket than traditional rigid structures, and expand after being deployed in space to provide additional room for astronauts to live and work inside. BEAM will be the first test of such a module attached to the space station. It will allow investigators to gauge how well it performs overall, and how it protects against solar radiation, space debris and the temperature extremes of space.

In late May, BEAM will be filled with air and expanded to its full size. Astronauts will enter BEAM occasionally to conduct tests to validate the module’s overall performance and the capability of expandable habitats. It will remain attached to station for a two-year test period. Then it will be released from the station to eventually burn up harmlessly in Earth’s atmosphere.

Hubscher, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

This Week in NASA History: Apollo 16 Lands on Moon — April 21, 1972

This week in 1972, Apollo 16’s John W. Young, mission commander, and Charles M. Duke Jr., lunar module pilot, began their three-day stay on the moon. Above, Young salutes the American flag with the lunar module and lunar roving vehicle in the background. The lunar roving vehicle — which was developed by NASA’s Marshall Space Flight Center — was used for collecting rocks and data on the lunar highlands. The NASA History Program documents and preserves NASA’s remarkable history through a variety of products — photos, press kits, press releases, mission transcripts and administrators’ speeches. For more pictures like this one and to connect to NASA’s history, visit the History Program’s Web page. (NASA)

Student Rocket Launches and Mars Sample Challenge Featured on ‘This Week @NASA’

NASA’s Student Launch, along with the Mars Ascent Vehicle Prize competition, are both featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

In its 16th year, Student Launch featured nearly 50 teams from 22 states competing for awards and prizes by designing, building and launching single-stage rockets.

Throughout their eight-month-long build season, teams worked to design a rocket capable of meeting specific goals in altitude and recovery, as well as provide quality results in project management, safety strategies and outreach activities.

MAV Prize — sponsored by NASA’s Centennial Challenges Program and running parallel with Student Launch — was held at the U.S. Space & Rocket Center on April 13, where 18 teams from 14 states competed for a share of $50,000 in prize money. Participating teams demonstrated their designs for autonomous robotic systems capable of retrieving and storing mock Martian samples into a rocket.

Both events are designed to engage students across the country in NASA’s journey to Mars through hands-on activities in the STEM field of science, technology, engineering and math.

The Academic Affairs Office at NASA’s Marshall Space Flight Center manages Student Launch, with funding and leadership also provided by NASA’s Office of Education, the Human Exploration and Operations Mission Directorate and Orbital ATK’s Propulsion Systems Division of Promontory, Utah. The Centennial Challenges Program is managed at Marshall and supported by NASA’s Space Technology Mission Directorate.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.