In This Week’s Star

- Katherine Van Hooser Named Manager of Marshall’s Chief Engineer’s Office

- Precision Meets Progress in Welding on SLS Liquid Oxygen Tank Hardware

- New Crew and Science Payloads Arrive at Space Station

- Europa Project Manager Barry Goldstein Visits Huntsville

- NASA Data Used to Track Groundwater in Pakistan

- Rousing Robot Success During Alabama’s Newest FIRST Robotic Competition

- This Week in NASA History: Construction Continues on Marshall’s S-IC Static Test Stand — March 29, 1963

Katherine Van Hooser Named Manager of Marshall’s Chief Engineer’s Office

Katherine Van Hooser, a native of Madisonville, Kentucky, has been appointed to the Senior Executive Service position of manager of the Chief Engineer’s Office at NASA’s Marshall Space Flight Center.

Van Hooser will assure the technical excellence and success of all Marshall-assigned spacecraft, propulsion, science payload, life support and mission systems, with oversight of some 149 NASA civil servants and contractors. She will provide expert technical leadership in planning and execution of research and technology; ground and flight systems design and development; and production, integration and sustaining engineering for the Space Launch System Program, the Flight Programs and Partnerships Office, the Science and Technology Office and other projects within NASA’s Human Exploration and Operations and Science Mission directorates.

The Senior Executive Service is the personnel system that covers most of the top managerial, supervisory and policy positions in the executive branch of the federal government.

She has served as deputy director of Marshall’s Materials and Processes Laboratory since February 2015, helping to manage science, technology and engineering endeavors related to materials, processes and products for use in space vehicles and related applications. She also was responsible for managing a number of research and development efforts in world-class facilities, including the National Center for Advanced Manufacturing.

Van Hooser began her NASA career in 1991 as a turbomachinery engineer, steadily progressing to turbomachinery team lead and, within months, turbomachinery branch chief. There, she was responsible for managing the design, development, testing, evaluation, certification, production and flight of liquid rocket engine turbomachinery for use in space vehicle applications.

She was named space shuttle main engine assistant chief engineer in 2005, and chief engineer for the same project in 2008, leading a multi-disciplined group of engineers and other professional and support personnel in every aspect of the space shuttle main engine project during the last 21 space shuttle flights. In 2011, she was named chief engineer for the Space Launch System Liquid Engines Element, overseeing engineering activities and the successful design and adaptation of the J-2X and RS-25 engines.

In 2012, Van Hooser accepted a five-month assignment as SLS acting deputy chief engineer, assisting the SLS chief engineer in leading overall engineering support. She accepted another Engineering Directorate detail in 2013 as acting associate director of engineering for technical management. During that 15-month assignment, she helped lead an organization of approximately 2,600 civil service and support contractors and served as a member of the overall strategic planning staff. She also was coordinator for all engineering activities supporting NASA’s Technical Capability Assessment Team.

Van Hooser received a bachelor of science degree in aerospace engineering from the University of Tennessee in Knoxville in 1991. In 2011, she was awarded the NASA Distinguished Service Medal, the highest honor the agency confers, and in 2010 received the NASA astronaut corps’ Silver Snoopy award for outstanding achievements supporting human spaceflight and mission success. She also received the NASA Exceptional Engineering Achievement Medal in 2008, NASA’s Software of the Year Award in 2001 — recognizing her role in developing cutting-edge software to model turbomachinery fluid flow — and numerous special service and group achievement awards. She is the author of numerous technical papers and has been involved in session planning for American Institute of Aeronautics and Astronautics and Joint Army-Navy-NASA-Air Force conferences.

Precision Meets Progress in Welding on SLS Liquid Oxygen Tank Hardware

A liquid oxygen tank confidence article for NASA’s new rocket, the Space Launch System, completes final welding on the Vertical Assembly Center at Michoud Assembly Facility. This is the first glimpse of what one of the two tanks will look like that make up the SLS core stage. Towering more than 200 feet tall with a diameter of 27.6 feet, the core stage will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines. Confidence hardware verifies weld procedures are working as planned and tooling-to-hardware interfaces are correct. It will also be used in developing the application process for the thermal protection system, which is the insulation foam that gives the tank its orange color. The liquid oxygen tank is the smaller of the two tanks in the core stage. Components of the liquid hydrogen tank confidence article completed welding in February at Michoud. All welding for the SLS core stage for the Block I configuration of the rocket — including confidence, qualification and flight hardware — will be done this summer in preparation for its first flight with NASA’s Orion spacecraft in 2018. (NASA/Michoud/Steven Seipel)

New Crew and Science Payloads Arrive at Space Station

Within the space of a week, the International Space Station doubled its number of crew members to six and received dozens more science payloads, making for a very busy seven days on the orbiting laboratory.

On March 19, NASA astronaut Jeff Williams became the first three-time, long-term American resident of the space station when he arrived there with Roscosmos cosmonauts Alexey Ovchinin and Oleg Skripochka, where they will continue important research that advances NASA’s journey to Mars.

The trio launched aboard a Soyuz spacecraft from the Baikonur Cosmodrome in Kazakhstan on March 18, and orbited Earth four times before docking at the station.

Just before midnight on March 22, Orbital ATK launched its fifth resupply mission to the station on a United Launch Alliance Atlas V rocket from NASA’s Kennedy Space Center. The Cygnus capsule arrived at the station March 26 and was opened the following day. It carried a variety of investigations including one to study fire scenarios on a spacecraft; another enabling the first space-based observations of meteors entering Earth’s atmosphere from space; explorations of how regolith, or soil, behaves and moves in microgravity; testing a gecko-inspired adhesive gripping device that can stick on command in the harsh environment of space; and a new 3-D printer which builds on earlier work with 3-D printers on the station that was managed by NASA’s Marshall Space Flight Center.

“The printer is very important to the space station and future exploration,” said Rick Rodriguez, a payload operations manager for Expeditions 47 and 48, guiding the ground-based science support team from the Payload Operations Integration Center at Marshall. “Manufacturing spare parts and tools in orbit so we don’t need to bring them along from Earth is critical and saves mass for other items, especially on those long voyages away from Earth when we can’t easily send a resupply vessel.”

For 15 years, Marshall has been the science command post for the space station. Experts in disciplines including engineering, math, science, logistics, computer programming and communications manage and monitor investigations around the clock, 365 days a year. Every day, they collaborate with astronauts and cosmonauts and hundreds of scientists around the globe to make discoveries that benefit life on Earth.

The three new crew members joined Expedition 47 Commander Tim Kopra of NASA and Flight Engineers Tim Peake of the European Space Agency and Yuri Malenchenko of Roscosmos. The Expedition 47 crew members will spend five months conducting more than 250 science investigations in fields that benefit all of humanity, such as biology, Earth science, human research, physical sciences and technology development.

During his six-month mission, Williams will become the American record holder for cumulative days in space — 534 — surpassing Expedition 46 Commander Scott Kelly, who wrapped up his one-year mission March 1.

Humans have been living continuously aboard the space station for more than 15 years, advancing scientific knowledge and demonstrating new technologies, making research breakthroughs not possible on Earth to enable long-duration human and robotic exploration into deep space. A truly global endeavor, more than 200 people from 15 countries have visited the unique microgravity laboratory that has hosted more than 1,700 research investigations from researchers in more than 80 countries.

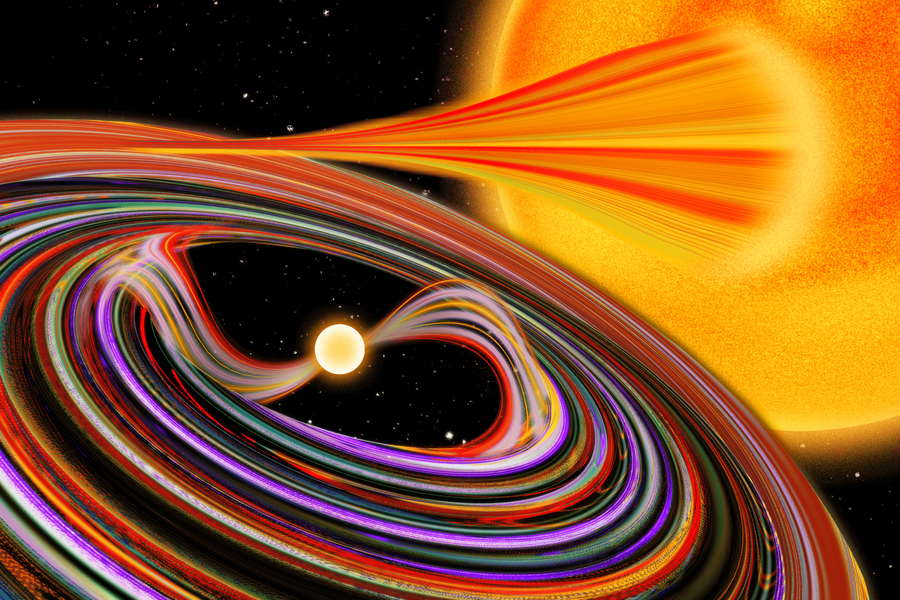

Europa Project Manager Barry Goldstein Visits Huntsville

Barry Goldstein, Europa project manager at NASA’s Jet Propulsion Lab, speaks with scientists and engineers March 16 at the National Space Science and Technology Center on the campus of the University of Alabama in Huntsville about NASA’s planned mission to Jupiter’s moon. The mission will investigate Europa to determine if it could possibly harbor primitive life under its icy shell. The mission plan calls for a spacecraft to be launched to Jupiter in the 2020s, arriving in the planet’s orbit after a journey of several years. The spacecraft would orbit the gas giant every two weeks, providing many opportunities to image the moon’s surface at high resolution and investigate its composition and structure. During his visit to Huntsville, Goldstein also spoke to the Space Launch System team and gave a public lecture at the local chapter of the National Space Society, HAL5. (NASA/MSFC/Ryan Connelly)

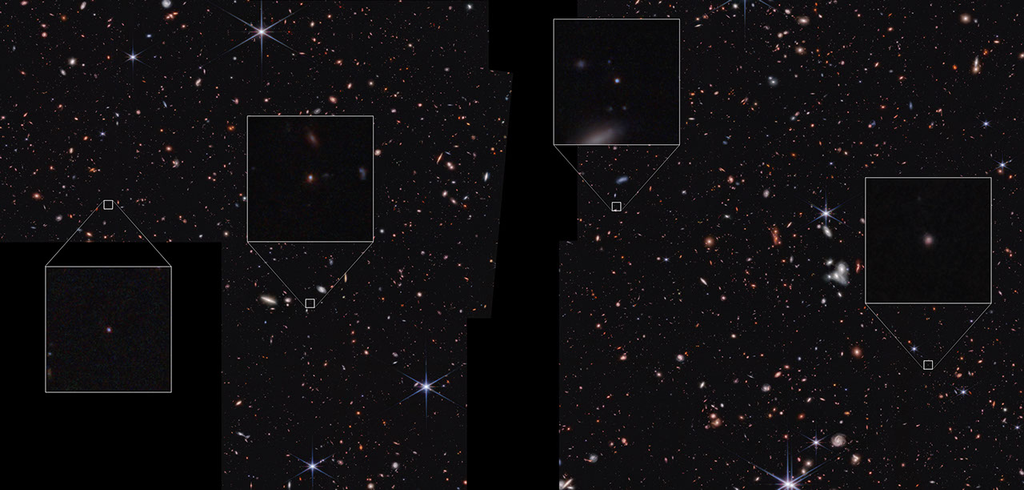

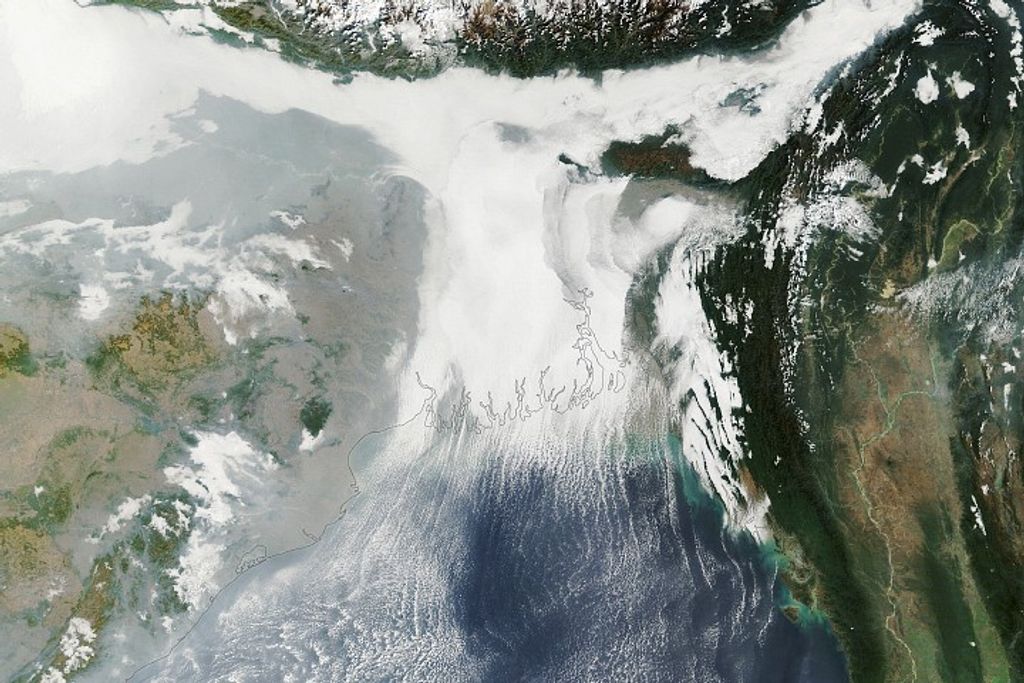

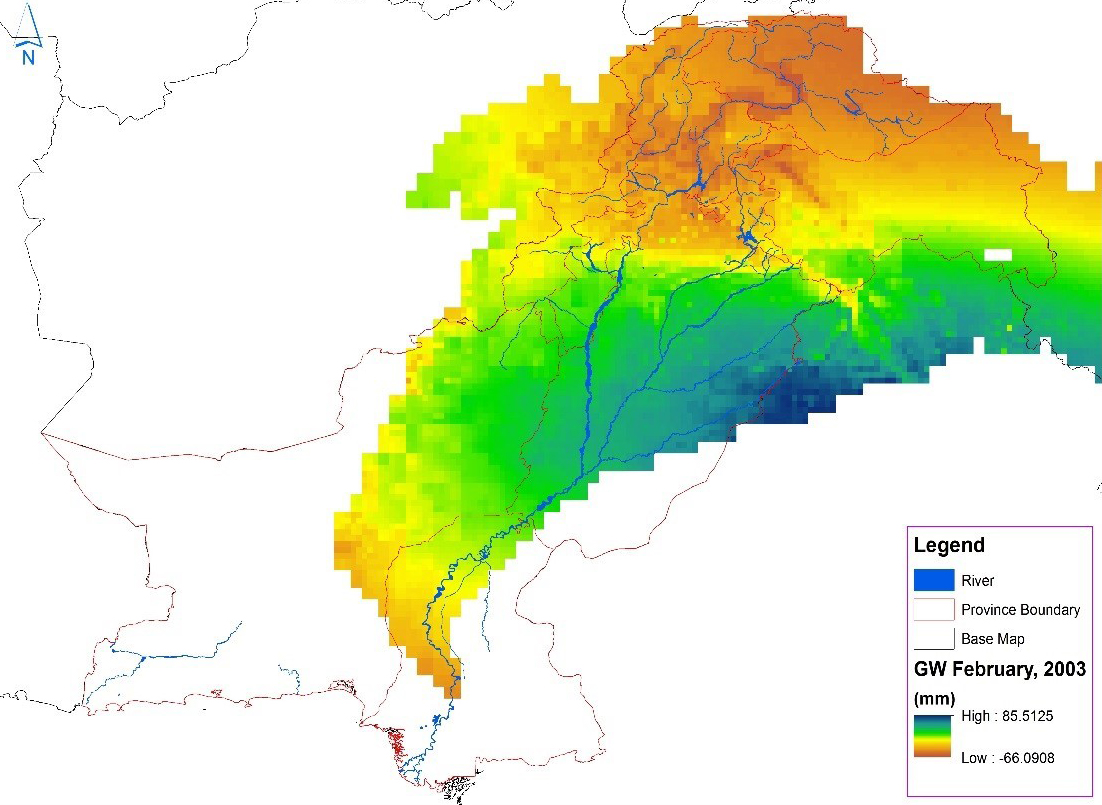

NASA Data Used to Track Groundwater in Pakistan

The vast farmlands of Pakistan — a country with an economy based on agriculture — rely on one of the largest continuous irrigation systems in the world. Pakistani farmers were once able to depend solely on rivers and man-made canals fed by glaciers and rain.

But as population and urbanization boomed in recent decades, the country turned to groundwater to keep up with demand. Today, more than 60 percent of Pakistan’s water is pumped from natural underground reservoirs, with no limits placed on how many wells can be drilled or how much water anyone can take.

Now — thanks to a collaboration led by the University of Washington with the University of Houston, Ohio State University, SERVIR, and NASA Applied Sciences Program Water Resources application area — Pakistan’s water managers are using NASA satellites to help them more effectively monitor and manage the precious resource.

SERVIR — which is managed by NASA’s Marshall Space Flight Center — is a joint initiative of NASA and the U.S. Agency for International Development to use the vast amount of data and observations collected by Earth-orbiting satellites for greater good.

“This is a great example of free and open NASA data being used by countries around the world to address their development needs — and ultimately improve their water and food security,” said Dan Irwin, director of Marshall’s SERVIR Coordination Office.

“Satellites up in space looking at how much water we have underground, in rivers or in the atmosphere are providing routine observations that can help policymakers and on-the-ground managers make informed decisions,” said Faisal Hossain, a member of SERVIR’s Applied Sciences Team and associate professor of civil and environmental engineering at the University of Washington. “From offering improved flood forecasting to indicating areas where groundwater resources are threatened, freely available satellite data can be an invaluable resource, particularly in developing countries.”

After training at the University of Washington and the Pakistan Council of Research in Water Resources in Islamabad, Pakistani officials in January 2016 began using satellite data from NASA’s Gravity Recovery and Climate Experiment, or GRACE, mission to achieve a first-ever, basin-wide view of their water resources. They now create monthly updates on groundwater storage changes, allowing them to see where groundwater supplies are being depleted and where they are being adequately recharged. Like all NASA satellite data, GRACE data are freely available for download from open NASA data centers.

The research was funded through the NASA Applied Sciences Program‘s Water Resources application area and the SERVIR Applied Sciences Team.

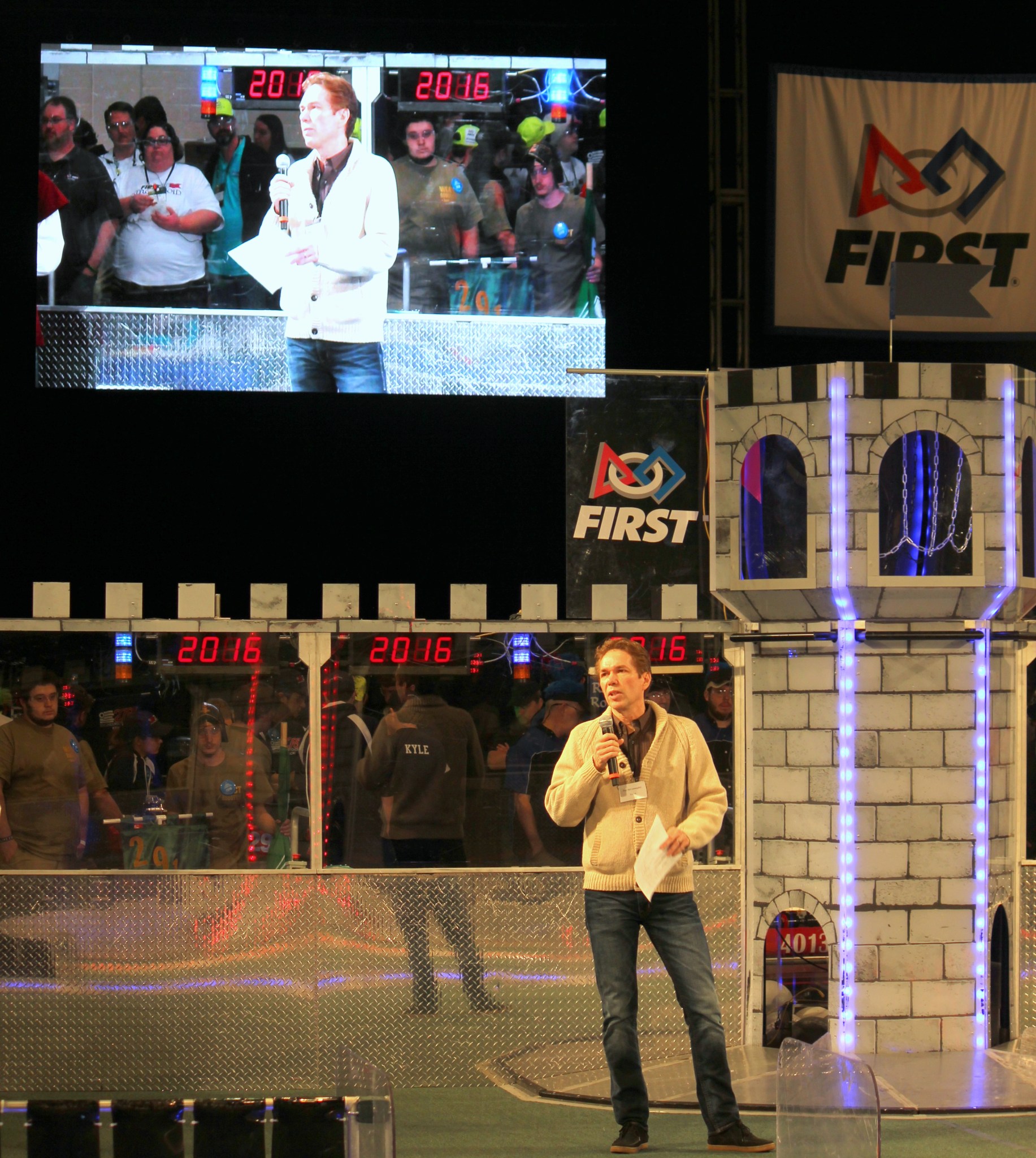

Rousing Robot Success During Alabama’s Newest FIRST Robotic Competition

Student members of Team 442, Redstone Robotics, gather at the control console behind safety glass to control their robot during the inaugural Rocket City Regional at the Von Braun Center March 24-26. Nearly 1,500 students from 11 states competed during the event, which is part of FIRST Robotics, a worldwide program for students in grades 9-12 to gain real-world experiences in the STEM fields of science, technology, engineering and math in a fun and competitive way. The competition offered teams a chance to qualify for the 2016 FIRST Championship in St. Louis on April 27-30. Several area schools participated in the regional, including The Mad Rockers, with students from Bob Jones and James Clemens high schools in Madison; Morgan County Mech Tech, comprised of students from A.P. Brewer, Priceville, Danville, Falkville and West Morgan high schools in Morgan County; and Team G.R.E.A.T. from Grissom High School in Huntsville. FIRST — For Inspiration and Recognition of Science and Technology — was founded in 1989 to inspire young people’s interest and participation in science and technology. For a list of winners from the Rocket City Regional, click here. (NASA/MSFC/Ryan Connelly)

During the March 26 opening ceremony of the Rocket City Regional competition, Paul K. McConnaughey, Marshall’s associate director, technical, greets students with words of encouragement, enthusiasm and praise for their hard work and dedication toward becoming the next generation of scientists, engineers and explorers. (NASA/MSFC/Christopher Blair)

This Week in NASA History: Construction Continues on Marshall’s S-IC Static Test Stand — March 29, 1963

This week in 1963, crews continued the construction of the S-IC Static Test Stand in NASA Marshall Space Flight Center’s west test area. Designed to test the first stage of the Saturn V rocket, the test stand was completed in 1964. The Saturn V S-IC first stage, or booster stage, weighed 280,000 pounds and was 138 feet long and 33 feet wide. This photograph, taken March 29, 1963, shows two of the test stand’s four growing towers. The NASA History Program documents and preserves NASA’s remarkable history through a variety of products — photos, press kits, press releases, mission transcripts and administrators’ speeches. For more pictures like this one and to connect to NASA’s history, visit the History Program’s Web page. (NASA)