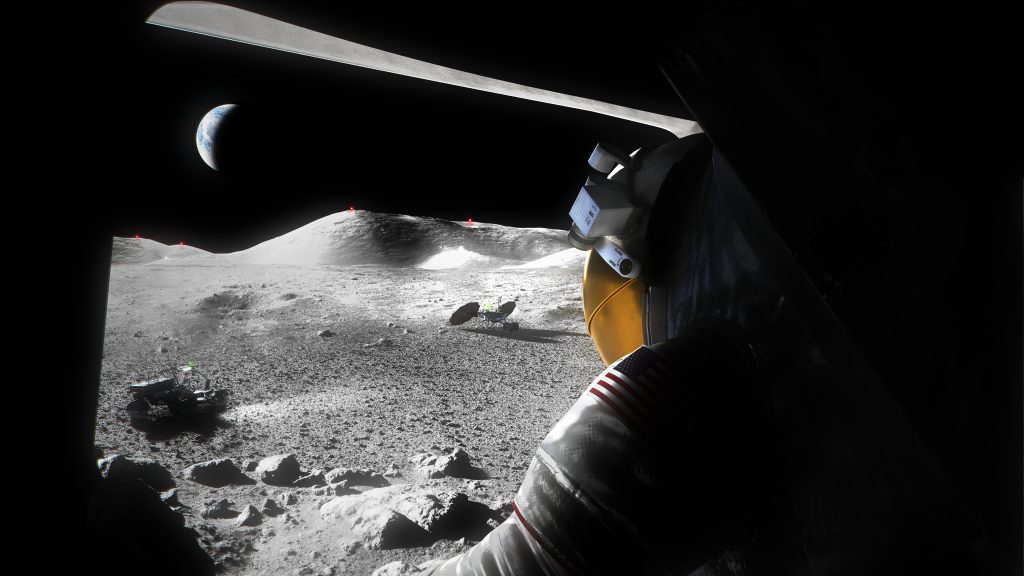

A liquid hydrogen tank weld confidence article, at left, for the core stage of NASA’s new rocket, the Space Launch System, recently was completed on the Vertical Assembly Center at Michoud Assembly Facility in New Orleans. The completed confidence article, consisting of a dome and two barrels, verifies weld procedures are working as planned and tooling-to-hardware interfaces are correct. It also gives the weld team experience in bringing all aspects of hardware, tooling and software together to create a tank. Once a confidence article is completed, the structural qualification article is welded, which closely replicates flight hardware and processing procedures. The structural qualification article will be rigorously tested as part of the design verification process for the core stage. The Vertical Assembly Center is the largest spacecraft welding tool in the world and is part of six state-of-the-art tools designed to weld the core stage of SLS. More than 50 pieces of flight and qualification hardware for the core stage liquid oxygen and liquid hydrogen tanks have been completed and are ready for welding in the Vertical Assembly Center at Michoud. A fish-eye lens was used to capture the scale of the machinery.

Image credit: NASA/Michoud/Steven Seipel