The design and construction of the Combined Effects Chamber at NASA’s Neil Armstrong Test Facility in Sandusky, Ohio, allows large-scale liquid hydrogen (LH2) experiments to be conducted safely. Control systems are located in a separate, remote building.

Facility Overview

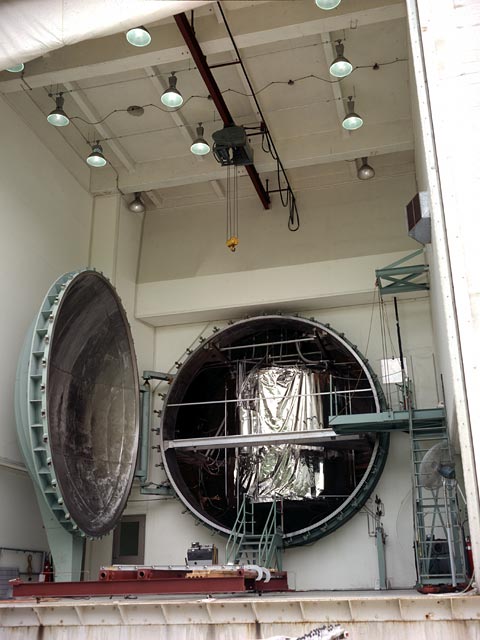

The Combined Effects Chamber (CEC) is a space-environment test chamber 25 feet in diameter with a 20-foot-diameter door. The design and construction of this facility allows large-scale liquid hydrogen (LH2) experiments to be conducted safely. Control and data systems are located in a separate, remote building, and electrical control systems include explosion-proof hardware.

Other features of CEC include a removable LH2/LN2 cryogenic cold wall that can simulate deep space temperatures down to –423 degrees Fahreinheit, vacuum-jacketed LH2 piping and chamber penetrations, a hydraulic shaker system, a vacuum-jacketed LH2 dump line, and a burn-off stack to handle accidental LH2 spills inside the chamber.

The CEC plays an essential role in the development of advanced insulation systems and on-orbit fluid transfer techniques for flight-weight cryogenic fuel tanks and insulation systems.

The CEC is currently being considered for use as a Planetary Surface Simulation Test Facility due to the chamber’s size and ease of access through the 20-foot hatch.

Quick Facts

| Test Chamber | 25-foot diameter, spherical space environment | |

| Temperature | Down to -423°F | |

| Vacuum | Capable of 5 x 10-7 torr |

Capabilities

- 1,200-foot LH2 exclusion zone

- Remotely located test control building

- 25-foot-diameter spherical space-environment test chamber certified for LH2 testing

- Capable of vacuum to 5×10-7torr

- Removable cryogenic cold wall with LH2 or LN2 capability

- Equipped with hydraulic shaker system for LH2 tank slosh testing inside of chamber

- Designed for development and certification of flight-weight cryogenic fuel tanks and insulation systems, cryogenic valves, pumps, and actuators

Contact

Combined Effects Chamber

Facility Manager: Hal Weaver

419-621-2219

Harold.F.Weaver@nasa.gov

NASA’s Neil Armstrong Test Facility

Deputy Director: David Taylor

419-621-2101

David.E.Taylor@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center in Cleveland provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

/Hubble%20Space%20Telescope%20(A).png)