ARTEMIS I

WE ARE GOING

BACK TO THE MOON

ABOUT THE MISSION

Artemis I

All eyes will be on the historic Launch Complex 39B when the Orion spacecraft and the Space Launch System (SLS) rocket lift off for the first time from NASA’s modernized Kennedy Space Center in Florida.

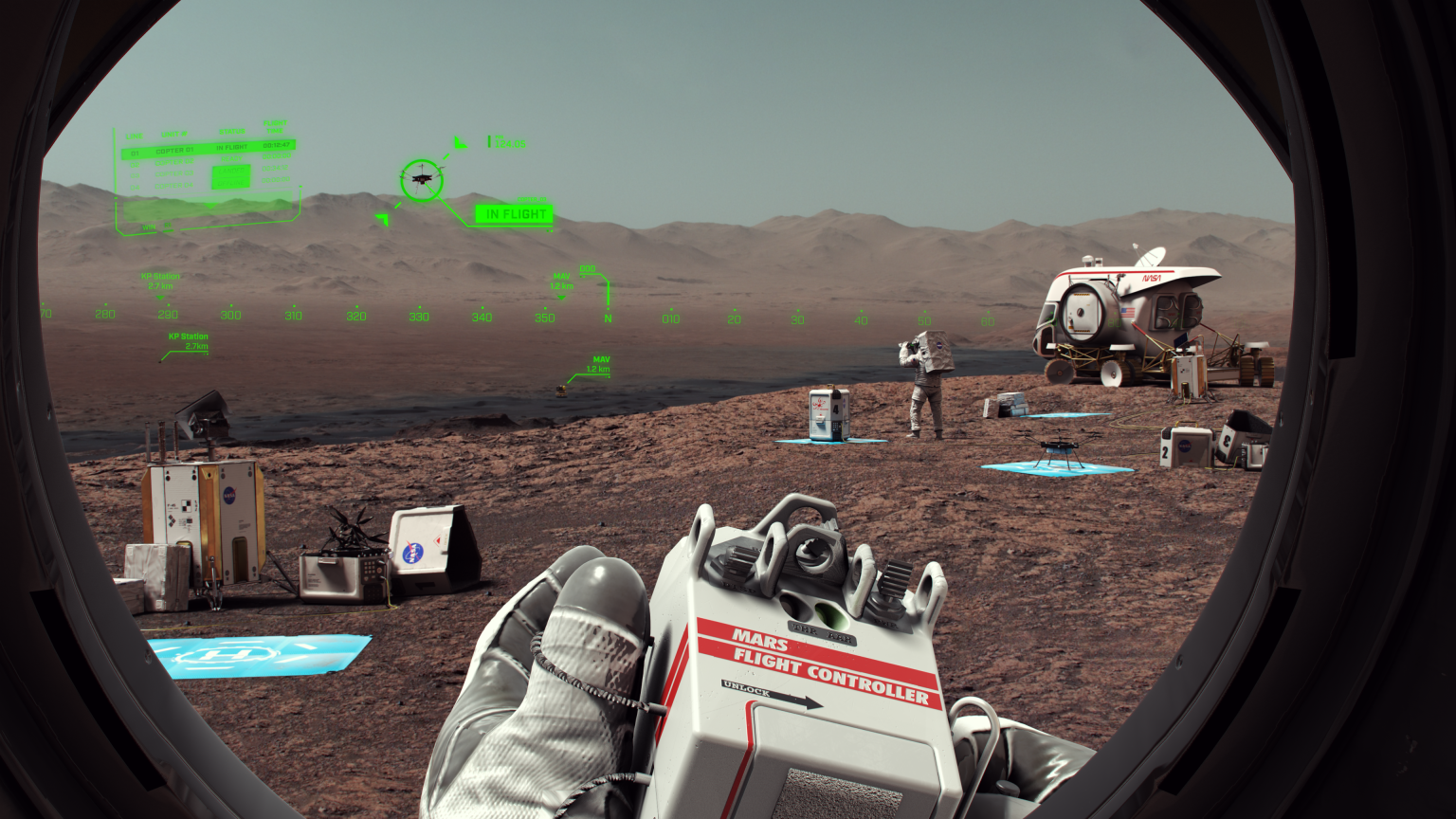

Artemis I will be the first in a series of increasingly complex missions to build a long-term human presence at the Moon for decades to come.

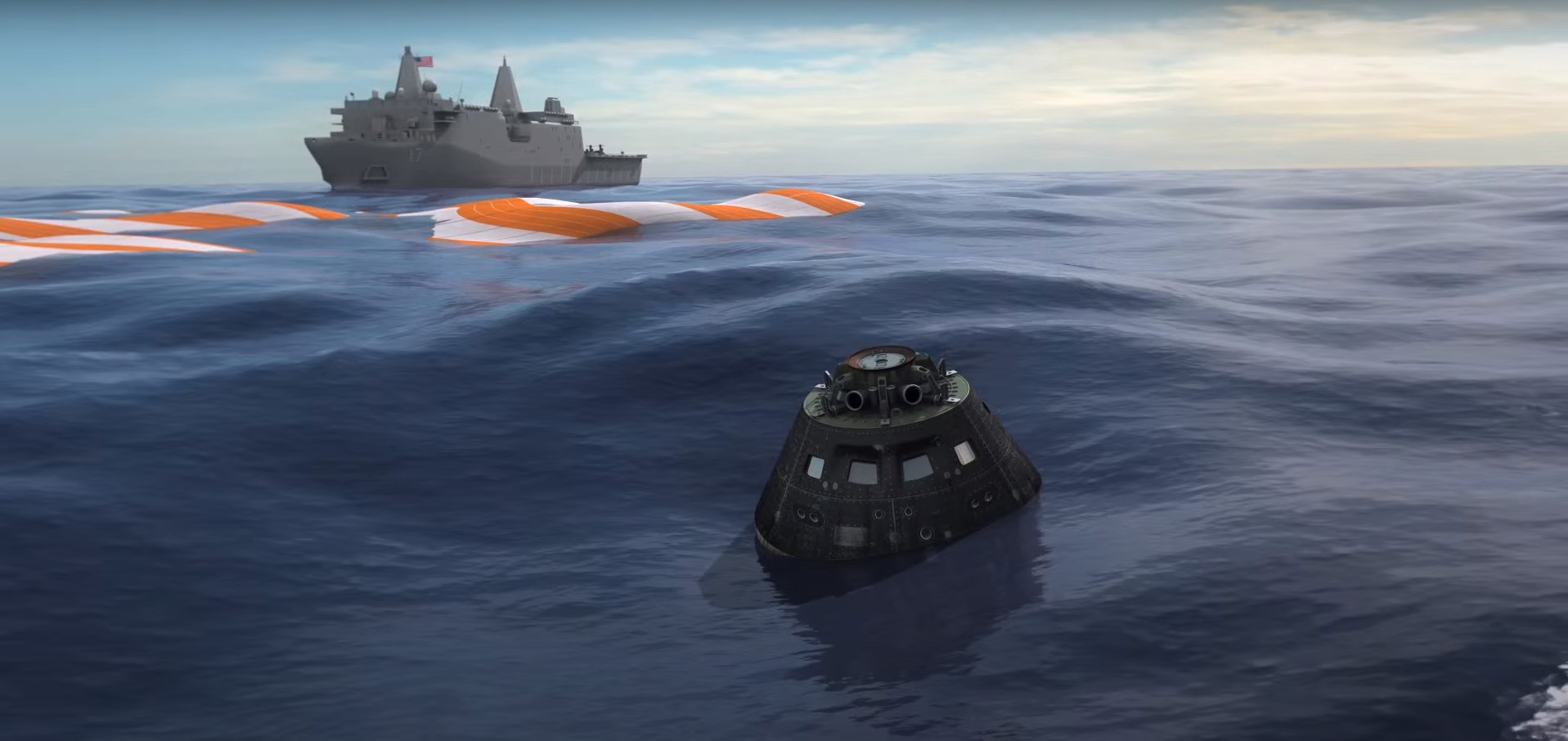

The primary goals for Artemis I are to demonstrate Orion’s systems in a spaceflight environment and ensure a safe re-entry, descent, splashdown, and recovery prior to the first flight with crew on Artemis II.

Mission Facts:

- Launch date: Nov. 16, 2022

- Mission duration: 25 days, 10 hours, 53 minutes

- Total distance traveled: 1.4 miIlion miles

- Re-entry speed: 24,581 mph (Mach 32)

- Splashdown: Dec. 11, 2022

The mission patch for Artemis I showcases several elements within the design that carry symbolic meaning for this historic flight including the triangular shape and the colors of silver, orange, red, white, and blue.

– EXPLORE THE SYSTEM –

EXPLORE THE SYSTEM

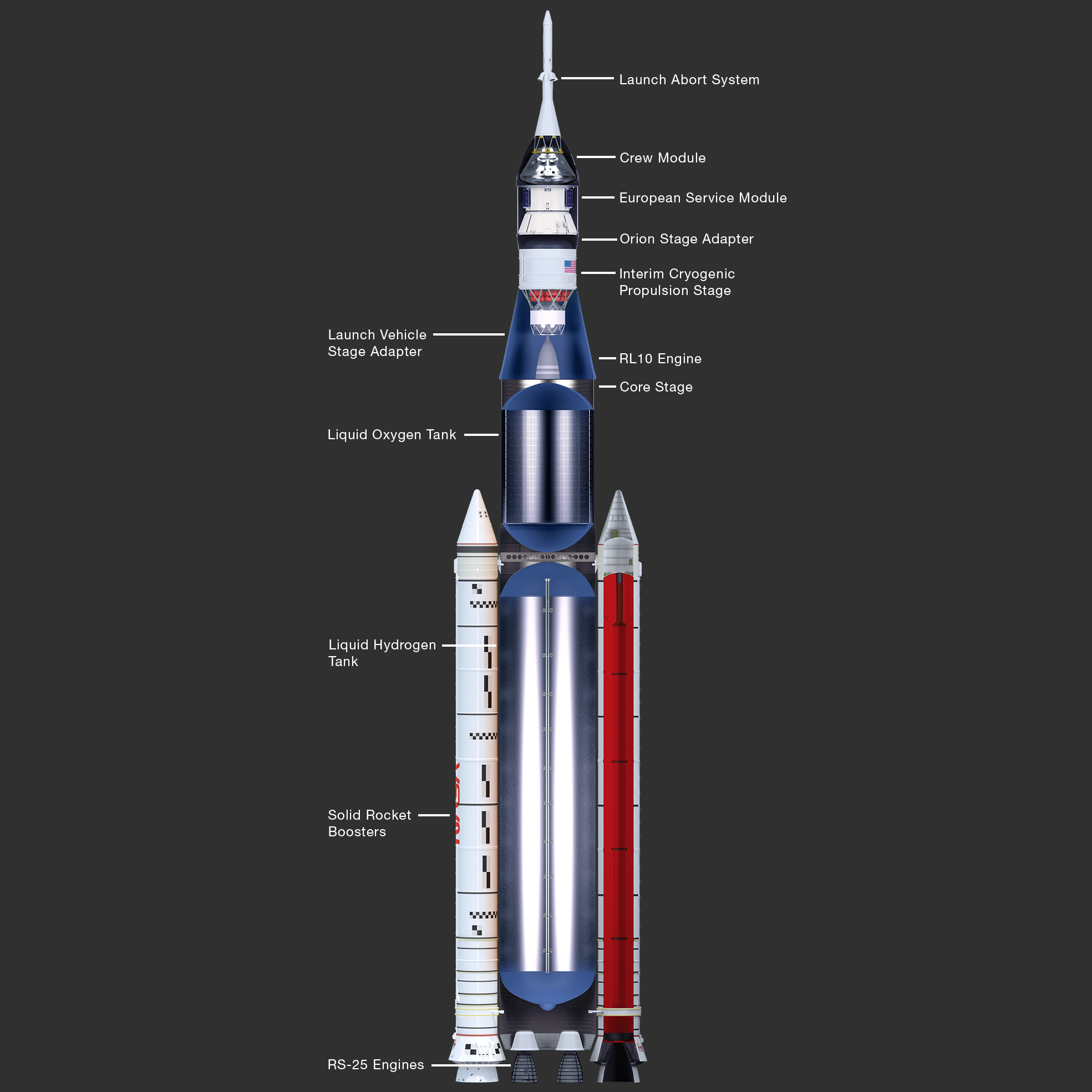

Launch Abort System

The launch abort system is positioned atop the Orion crew module. On crewed missions, it can activate in milliseconds to pull the spacecraft away from the rocket if a problem arises during launch or ascent. The system’s powerful abort motor can accelerate from zero to 500 mph in two seconds if needed during an emergency.

Crew Module

The crew module is the pressurized part of the Orion spacecraft, sometimes referred to as the capsule, where astronauts will live and work on crewed missions to the Moon and back. It can accommodate four crew members for up to 21 days, and contains advanced life support, avionics, and power systems.

European Service Module

Orion’s European Service Module, provided by ESA (European Space Agency), is the powerhouse that fuels and propels the spacecraft in space. It provides propulsion, thermal control, and electrical power generated by solar arrays. On missions with astronauts, the service module will also provide life support systems for the crew including water, oxygen, and nitrogen.

Orion Stage Adapter

The Orion Stage Adapter connects Orion to the rocket. It will carry several CubeSats as secondary payloads on Artemis I that will be deployed for their own technology demonstrations and science missions in deep space.

Interim Cryogenic Propulsion Stage

Measuring 45 ft (13.7 m) tall and 16.7-foot (5.1 m) in diameter, the Interim Cryogenic Propulsion Stage is a single-engine liquid hydrogen and liquid oxygen-based system that provides in-space propulsion after the solid rocket boosters and core stage put SLS into an Earth orbit.

Launch Vehicle Stage Adapter

The Launch Vehicle Stage Adapter covers the RL10 engine during launch and connects the Interim Cryogenic Propulsion Stage to the core stage.

RL10 Engine

During the Artemis I uncrewed test flight, a single liquid hydrogen and liquid oxygen-fed RL10B-2 engine producing 24,750 pounds (110kN) of thrust will serve as the main propulsion for the Interim Cryogenic Propulsion Stage that will send the Orion spacecraft to the Moon.

Core Stage

The core stage is the backbone of SLS and includes two propellant tanks, flight computers, and four RS-25 rocket engines. Towering 212 feet, the SLS core stage feeds the engines about 1,500 gallons of propellant each second for eight minutes, which is how long it takes SLS to reach Earth orbit.

Liquid Oxygen Tank

The SLS liquid oxygen tank in the core stage holds 196,000 gallons of liquid oxygen, cooled to -297 degrees F. Liquid oxygen is the oxidizer in the combustion reaction that fuels the RS-25 main engines.

Liquid Hydrogen Tank

The fuel for the SLS RS-25 rocket engines is liquid hydrogen. The liquid hydrogen tank holds 537,000 gallons of liquid hydrogen cooled to -423 degrees F.

Solid Rocket Boosters

The SLS has two solid rocket boosters that burn approximately six tons of solid propellant each second to help lift the enormous rocket off the launch pad and send it soaring to space. Their job is finished in two minutes.

Engines

The four RS-25 rocket engines accelerate the rocket to more than 17,000 mph during the first 8 minutes of flight. Thanks to supercool propellant and hot combustion gases, these rocket engines withstand temperatures ranging from -423 degrees F to more than 6,000 degrees F.

FAST FACTS

SPACE LAUNCH SYSTEM ROCKET

The most powerful rocket in the world, designed to send humans to deep space.

HEIGHT — 322 feet

MASS AT LIFTOFF — 5.75 million pounds

THRUST AT LIFTOFF — 8.8 million pounds

PAYLOAD TO THE MOON — 59,000 pounds

ORION SPACECRAFT

Next generation spacecraft, designed for the demands of human missions to deep space.

CREW AND SERVICE MODULE HEIGHT — 26 feet

PRESSURIZED VOLUME — 690.6 ft3

MASS TO THE MOON — 53,000 pounds

RETURN MASS AT LANDING — 18,200 pounds

TAKE A 360 TOUR

GET INVOLVED

Get Involved

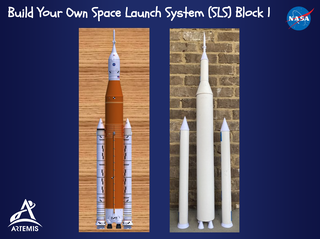

Learn how to build your own Space Launch System rocket from supplies at home, put together your own Moon kit, and more.

Send Your Name

Sign up to send your name around the Moon on a flash drive that will fly aboard Artemis I and get your boarding pass.

Draw Artemis

Learn to draw a fleet of sophisticated space hardware for Artemis missions.

Register for a Watch Party

Join Artemis I! Register to be a virtual participant or host a watch-party, and add-on the Artemis I STEM Learning Pathway!

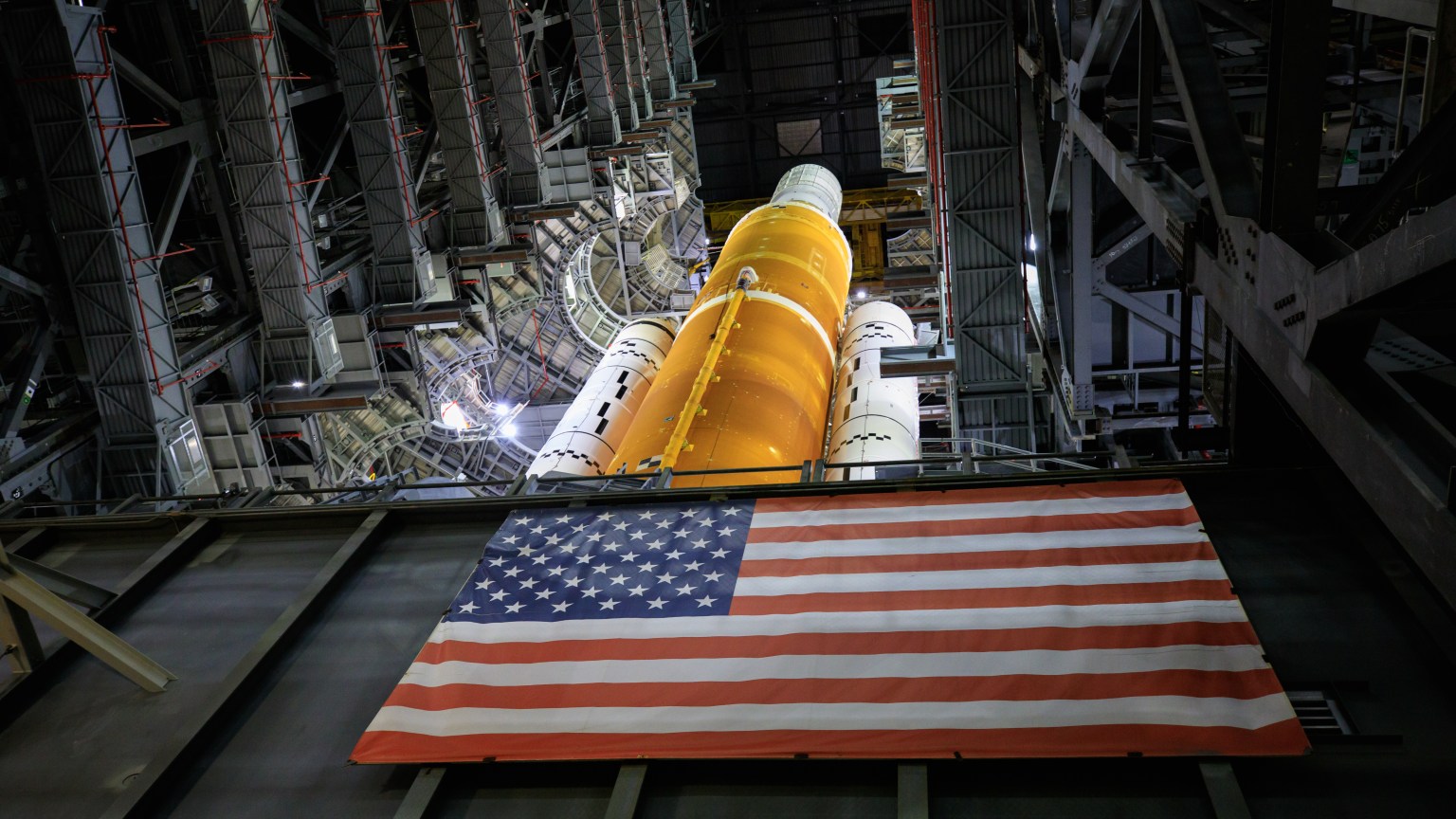

BUILDING AND TESTING

Building Artemis

Every state in America has contributed to building Artemis, with companies hard at work to build the systems that will help establish a long-term human presence at the Moon. Contributions from men and women across America and in Europe are critical to the space economy, fueling new industries and technologies, supporting job growth, and furthering the demand for a highly skilled workforce.

Orion Environmental Testing

Testing at NASA’s Neil A. Armstrong Test Facility in Ohio confirmed the Orion spacecraft’s systems performed as designed for Artemis missions. A thermal vacuum test simulated flying in and out of sunlight and shadow in space, and an electromagnetic interference and compatibility test ensured the spacecraft’s electronics work properly when operated at the same time.

Parachute Testing in Arizona

Testing at the U.S. Army’s Yuma Proving Ground in Arizona included eight tests to qualify Orion’s parachute system under a variety of landing scenarios and aerodynamic conditions. Eleven parachutes will slow Orion from about 325 mph to about 20 mph in about 10 minutes as Orion descends through Earth’s atmosphere for splashdown into the ocean.

Launch Abort System Testing

Orion’s launch abort system was tested in a pad abort test from a launch pad, as well as in an ascent abort scenario to validate the system when the spacecraft faces the greatest aerodynamic forces during ascent. The system is designed to carry the crew module to safety in the event of an emergency during launch or ascent atop the SLS rocket.

Water Impact Tests

Water impact testing in the hydro impact basin at the Landing and Impact Research Facility at NASA's Langley Research Center in Hampton, Virginia, provides high fidelity data of the forces that the Orion spacecraft structure and its astronaut crew would experience during a water landing after its mission around the Moon.

Orion Structural Testing

Structural testing in Denver confirmed Orion’s design is sound and the spacecraft is ready for deep-space missions. Tests ensured the spacecraft structures can withstand intense loads and vibrational forces at launch and entry, as well as the powerful pyrotechnic blasts needed for critical separation events, and even potential lightning strikes.

SLS Structural Testing

The structural testing campaign for the SLS rocket at NASA’s Marshall Space Flight Center in Huntsville, Alabama verified the structures of the core stage and upper part of the rocket can survive flight. Test cases included baseline tests to simulate forces expected during flight and tests to determine the design limits and breaking point of the fuel tanks.

SLS RS-25 Engine Testing

Tests at NASA’s Stennis Space Center near Bay St. Louis, Mississippi, confirmed the RS-25 engines can perform at the power level needed to launch the super heavy-lift SLS rocket. Tests with development engines also evaluated new parts for future engines made with advanced manufacturing techniques to increase reliability and sustainability of the engines.

SLS Booster Testing

The SLS solid rocket boosters completed test firings in a horizontal position at Northrop Grumman’s facility in in Promontory, Utah. Teams have started testing small solid rocket motors that will help the agency build next-generation solid rocket boosters for future SLS flights.

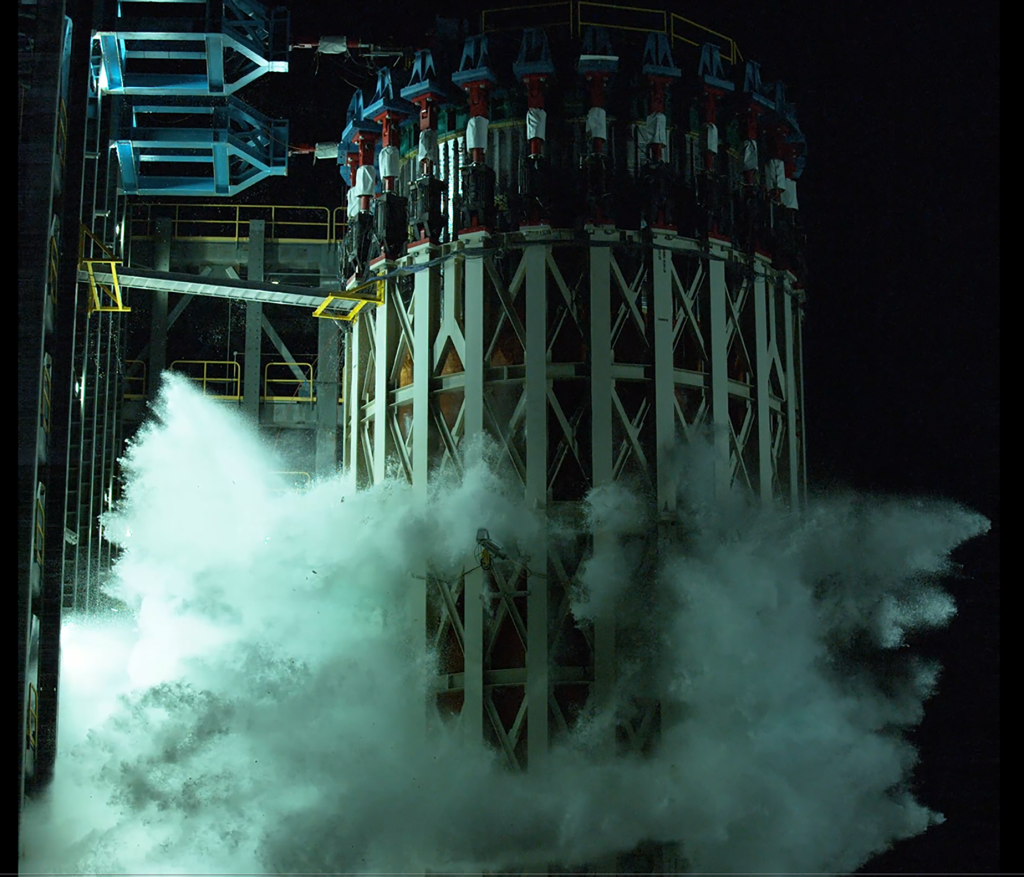

SLS Green Run Testing

Green Run testing at NASA’s Stennis Space Center near Bay St. Louis, Mississippi consisted of an eight-part test campaign to validate the integrated design of the core stage of the SLS rocket for flight. The test series culminated with all four RS-25 engines firing at the same time for more than eight minutes to simulate launch and ascent.

Verification and Validation of Mobile Launcher and Launch Pad 39B

The mobile launcher – the 380-foot-tall structure used to assemble, process and launch SLS – completed a series of tests in the Vehicle Assembly Building and at Launch Pad 39B. Testing included checks of the sound suppression system, cryogenic fuel system, and lines that provide power, environmental control, communication and more to the rocket and spacecraft.

FOLLOW OUR PROGRESS

It’s an exciting journey into the vastness of deep space. Follow along and we’ll take you there.