NASA and its industry partners have been working to disprove an aeronautical version of the notion that you can’t have your cake and eat it too – and it may appear that indeed you can.

The challenge is to figure out how to design an airplane wing so that it can provide high lift during takeoff and landing, yet still be able to cruise at altitude such that the air is moving absolutely smoothly across the wing – a concept called laminar flow.

Achieving this goal would enable an airplane to fly more efficiently throughout its flight, and that in turn could result in significant fuel savings that reduce both operating costs and noxious engine emissions.

This important work is part of NASA’s overall effort to explore and develop technologies enabling revolutionary improvements in energy efficiency, and noise and emissions reduction for future transport aircraft.

RICH WAHLS

NASA’s Fixed Wing Project Scientist at the Langley Research Center in Virginia

Laminar flow is particularly tough because the flaps and slats that are extended out from behind and ahead of the wing to create high lift during takeoff and landing, when retracted during cruise, leave small steps and gaps in the wing’s surface.

These disruptions in the smooth surface of the wing cause some amount of turbulence as the air moves across the wing. This turbulence increases drag and reduces efficiency.

“Transport aircraft require high lift at the beginning and end of a flight – the challenge is figuring out how to do it in a way that still allows laminar flow at cruise,” said Michael Rogers, NASA’s technical lead for the Aerodynamic Efficiency Subproject of NASA’s Fixed Wing Project at the Ames Research Center in California.

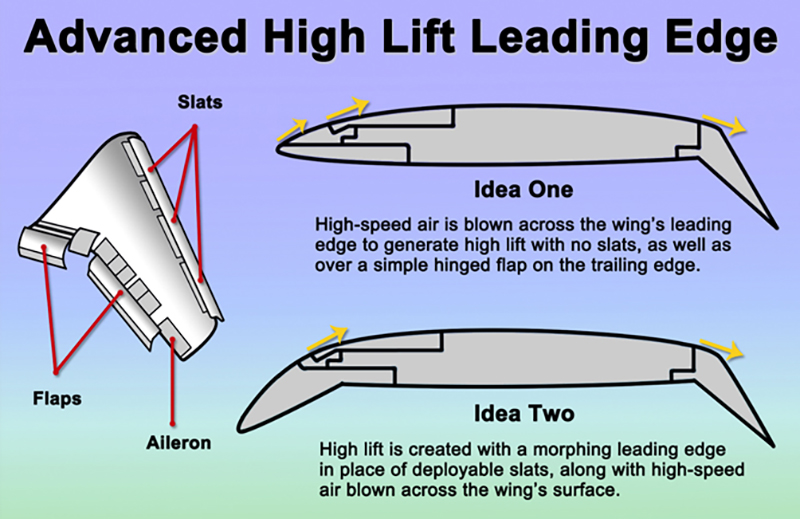

So to help solve the conundrum, NASA worked with a team led by Northrop Grumman on an Advanced High-Lift Leading-Edge system for laminar flow wings, developing and testing two ideas that might do the job and that could be integrated into future airliner designs flying during the 2030s.

The first idea was to design a wing section already proved to have a shape and surface conducive to laminar flow at cruise, but built with none of the slats that normally would extend from the leading edge to provide high lift during takeoff and landing.

Instead, high-speed air would be blown across the wing’s leading edge to artificially generate high lift. The pressurized air would be bled off from the jet engines and piped within the wing to be released through tiny slots near the front of the wing.

As the expelled air passes over the wing it creates extra lift, in place of the slats, through its interaction with the air already moving over the wing resulting from the airplane’s forward momentum – a process called active flow control.

Active flow control also is used near the wing’s trailing edge, where a simple, hinged flap is made possible instead of using a more mechanically complex, slotted flap often seen on airliners.

“We’ve used active flow control instead of moving slats and mechanically complex flaps to accomplish the high lift we need for takeoff and landing. And the good thing is that by using this alternative approach you’ve made it possible to maintain the laminar flow at cruise,” said John Lin, NASA’s technical monitor for Advanced High Lift Leading Edge study at the Langley Research Center in Virginia.

The second idea was to take that same wing section with good laminar flow at cruise but this time test a wing capable of seamlessly changing its shape by drooping down its leading edge – in effect, by morphing.

The morphed leading edge of the wing would enable the same high-lift effect that deploying slats would accomplish. The second idea also incorporated the slots for blowing air, like in the first idea, to further enhance its high-lift capability.

By not using the panels for slats on the front of the wings, the resulting gaps, steps and seams from the retracted slats would disappear and maintain the otherwise smooth wing surface needed for laminar flow.

The result: the wing can change its shape as needed depending on what part of the flight the airplane is in, and never lose the advantages of having high lift at the beginning or end, or the non-turbulent, fuel-efficient flow of air over the wing during cruise.

Incidentally, the point of these tests with Northrop Grumman wasn’t to develop or test actual morphing technology, which is being studied by others within the aviation community.

“In this case we weren’t trying to prove out any drooping technology; how it’s done or what materials to use. Instead, we just set out to show that if it could be done, would there be significant benefits enough to make it worth pursuing?” Lin said.

The two ideas were assessed, developed and validated during a 13-month period that ended in 2012 after a series of tests using Northrop Grumman’s 7 x10-foot wind tunnel in Hawthorne, Calif.

Both ideas exceeded all expectations and met all the goals for the study, which means the technology is far enough along to be optimistic about its use in the future, although it’s too early to say exactly what this would do in terms of fuel savings and reduced emissions or expenses.

“There is a lot of work that still needs to be done before this technology would be ready for prime time on a commercial airliner, or even a smaller business jet,” Rogers said.

For example, the Advanced High Lift Leading Edge study only used a small rectangle-shaped section of a wing airfoil. To fully evaluate these two ideas, a full-sized swept wing would have to be built and tested in a wind tunnel.

Moreover, in the case of the active flow control with its blowing air over the wing, all the plumbing and delivery systems running from the jet engines – or some other source – still has to be developed, tested and certified safe to use.

“So there’s a lot of plumbing to figure out and ensure that it will be reliable enough so that if one of the pipes clogs up for some reason, your airplane won’t fall out of the sky because it can’t generate enough lift, especially so close to the ground,” Rogers said.

But new technologies that can someday provide great benefits have to start somewhere. NASA’s Fixed Wing Project will continue to conduct research in this very important technical area.

It is envisioned that there will be further studies using a large-scale wind tunnel model of a modern transport wing, incorporating technologies such as the ones studied in this effort and other active flow control concept for seamless, mechanically simple, high-lift systems.

NASA’s work with Northrop Grumman is part of the agency’s Aeronautics Research Mission Directorate and managed by the Fundamental Aeronautics Program’s Fixed Wing Project.