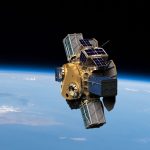

With support from a Tipping Point Award managed by NASA’s Flight Opportunities program and in collaboration with NASA’s Marshall Space Flight Center, UP Aerospace developed the Spyder hypersonic launch system as a low-cost vehicle to enable enhanced suborbital missions and planetary re-entry test environments. Spyder’s maiden flight took place on June 13, 2025, at White Sands Missile Range, which provided the photo above.

This flight test was to advance re-entry capsules by enabling evaluation of stability, control, and thermal management systems during hypersonic flight. During the flight, Spyder reached the hypersonic speed threshold and successfully deployed the Los Alamos National Laboratory’s payload test vehicle.

NASA has been a key player in helping not only bring the Spyder vehicle to life but also enabling a small U.S. business to put forth a new platform for testing technologies for space exploration and national security.

flight provider

UP Aerospace

flight test platform

Sounding rocket

flight date

June 13, 2025

location

White Sands Missile Range, New Mexico

Advancing Safer Re-Entry with Spyder Hypersonic Rocket

Through two ACO (Announcement of Collaborative Opportunity) partnerships as well as a 2017 Tipping Point Award, UP Aerospace and NASA Marshall have collaborated to develop Spyder’s enhanced mass-lifting and speed-performance capabilities that support suborbital testing of thermal protection systems and re-entry vehicles.

During the collaboration, researchers at the company and NASA demonstrated seven different technologies to reduce development risk for Spyder, including a guidance, navigation, and control system; a nose-fairing separation system; and a lightweight staging system, among others.

In addition, NASA Marshall engineers worked closely with UP on the design, development, and manufacturing of the various stages of Spyder’s solid rocket motor. The teams also collaborated on ground testing as well as flight tested some of the jointly developed technologies on a SpaceLoft flight. NASA support also helped UP Aerospace establish its own solid rocket motor manufacturing facility for Spyder’s motor propellant casting and hot-fire testing.

Spyder’s high-efficiency upper-stage solid rocket motors are designed to increase performance and support a bigger rocket, enabling heavier payloads to go higher and faster. Compared to the company’s SpaceLoft sounding rocket, which can carry a 60-pound payload to altitudes of 100-120 km (about 70 miles high) with 3 minutes of microgravity, Spyder can carry 400 pounds with increased diameters while providing the same amount of microgravity time.

As UP Aerospace continues development of its new sounding rocket, Spyder’s next mission will integrate guidance and control systems. Future Spyder developments include a maximum performance booster motor and multiple upper-stage variants capable of achieving altitudes approaching 300 km to support a wide variety of hypersonic mission objectives.