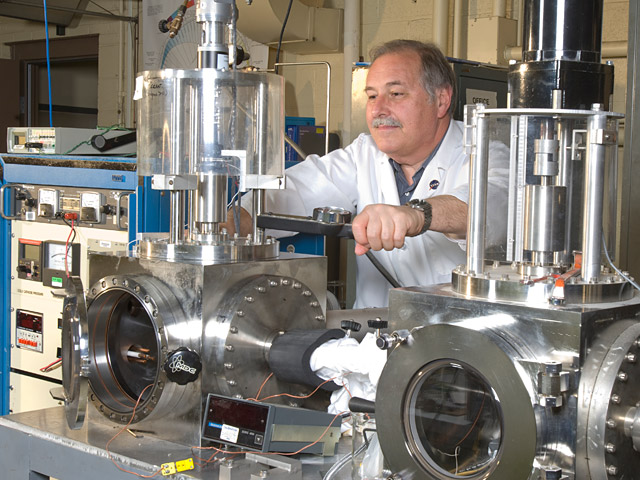

The Engine Research Building (ERB) supports research in all aspects of engine development, providing superior testing of turbomachinery, aerodynamics flow, physics, aeropropulsion heat transfer, mechanical components, and combustor facilities.

Facility Overview

The Engine Research Building (ERB) is the largest and most adaptable test facility complex at NASA Glenn, with 152,235 square feet of floor space housing more than 60 test rigs. Most aspects of engine development can be studied here, with numerous facilities specializing in turbomachinery, tribology, flow physics, combustion, aerochemistry, mechanical components, and heat transfer.

Fundamental and applied research is conducted in the following test facilities:

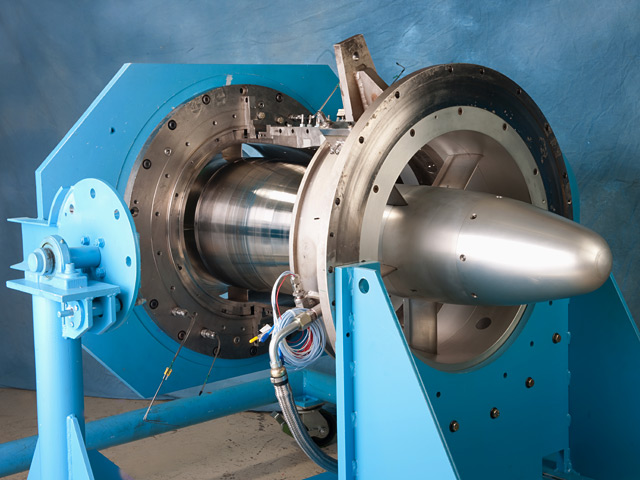

- Compressor and turbine research is conducted in the turbomachinery facilities to advance new technology for components of aeronautical gas turbine engines. Glenn Research Center is NASA’s Center of Excellence in turbomachinery.

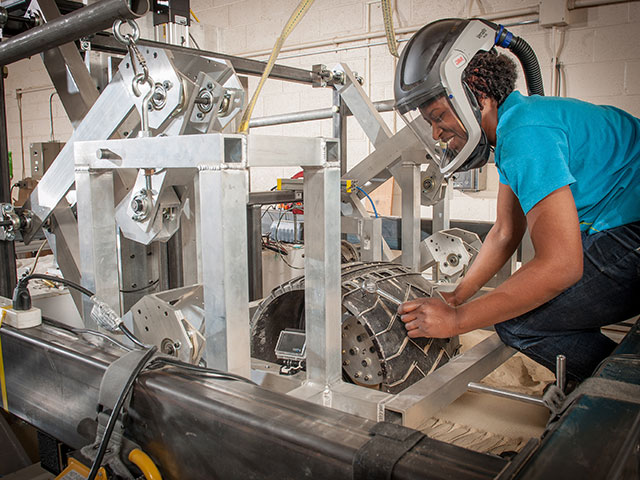

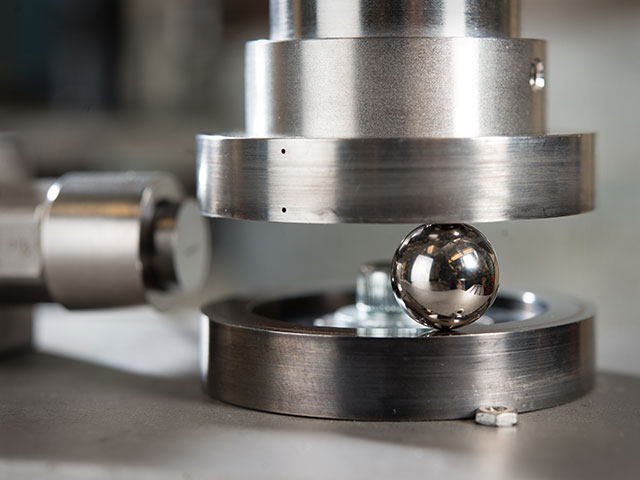

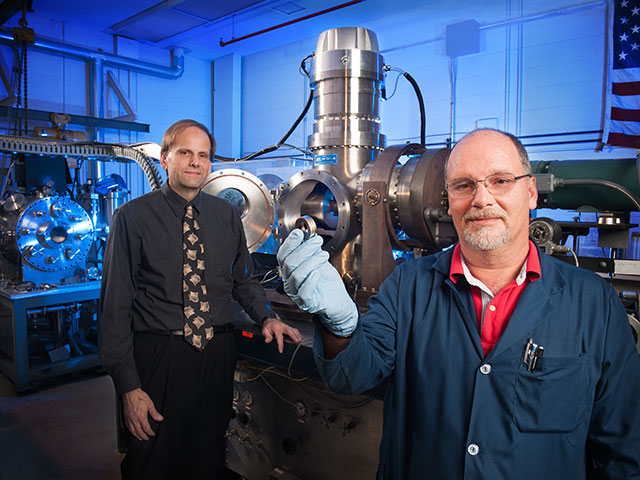

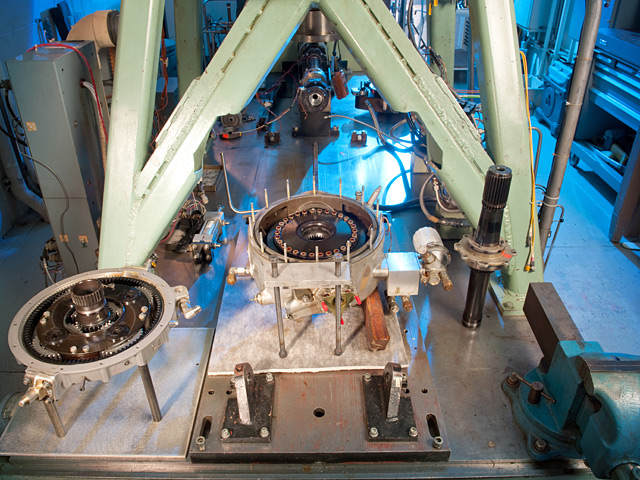

- Advanced lubricants, oil-free bearings, and other components are tested in the tribology facilities to develop clean, fuel-efficient engine technologies requiring less maintenance.

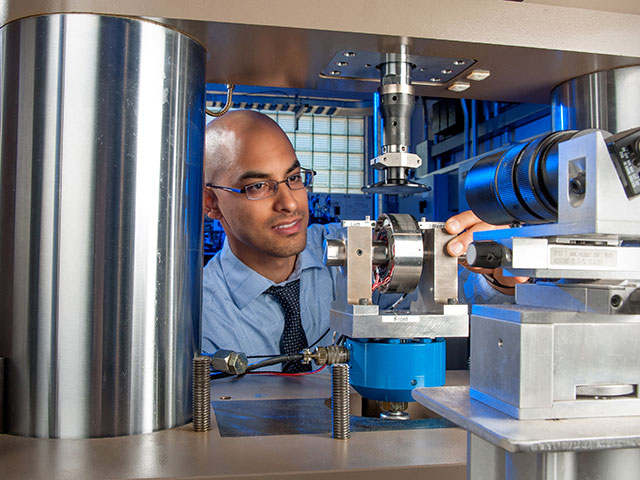

- Work to develop and validate computational fluid flow codes, and the subsonic to supersonic flow physics phenomena fundamental to ducted wall-bound flows, is conducted in the aerodynamic flow physics facilities.

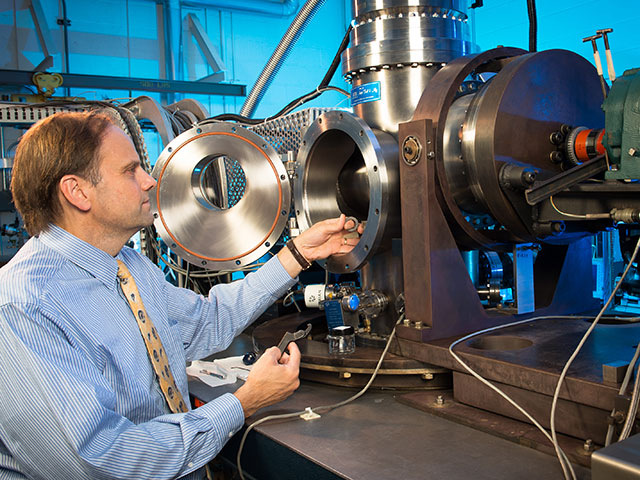

- The combustion processes of aeronautical gas turbine engines, including chemical reactions and combustion flow physics to develop gas turbine combustor technology, are conducted in the combustion and aerochemistry facilities.

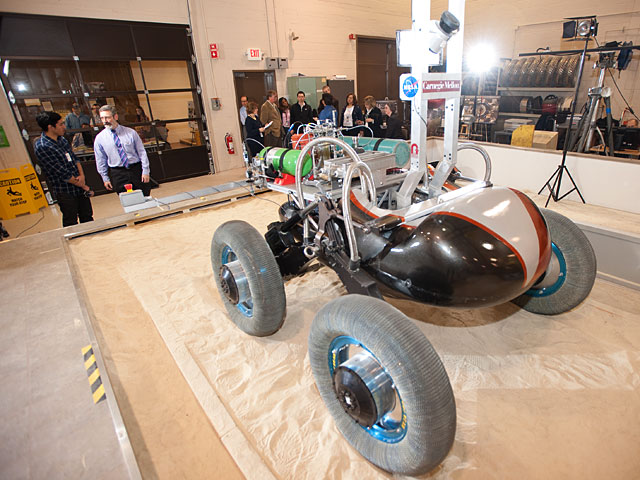

- Components for gas turbine engines, rotorcraft, space propulsion, and space mechanisms are developed in the mechanical components facilities.

- Gas path heat transfer with an emphasis on advanced materials is explored in the aeropropulsion heat transfer facilities.

Quick Facts

Almost half of the rigs support aeronautics programs in four general areas of research: turbomachinery, combustion and aerochemistry, aeropropulsion, and aerodynamic fluid flow.

| Name | Engine Research Building |

| Testing Capabilities | Aerodynamic Flow Physics, Aeropropulsion Heat Transfer Combustion, and Aerochemistry Mechanical Components Tribology Turbomachinery |

| Area | 152,235 ft2 |

- The ERB has over 60 test rigs supporting research in all aspects of engine development.

- The ERB provides superior testing of turbomachinery, aerodynamics flow physics, aeropropulsion heat transfer, mechanical components, and combustor facilities.

- There are 15 combustor and aerochemistry technology test facilities and laboratories. Fundamental and applied research is aimed at advancing the technology of the combustion processes of aeronautical gas turbine engines and advanced space transportation concepts.

- The ERB has 10 turbomachinery facilities and laboratories that specialize in conducting fundamental and applied research of aeronautical gas turbine engines.

- There are seven aerodynamic flow physics technology facilities that conduct research advancing the understanding of subsonic to supersonic flow physics phenomena fundamental to ducted wallbound flows.

Capabilities

Turbomachinery Facilities

- Small Engine Components Compressor Test Facility (CE-18)

- Low Speed Compressor Facility (W-1A)

- Single Spool Turbine Facility (W-6A)

- High Speed Multistage Compressor Facility (W-7)

- Single-Stage Axial Compressor Facility (W-8)

Combustor Facilities

There are seven combustor and aerochemistry technology test facilities and laboratories within the ERB. Fundamental and applied research is aimed at advancing the technology of the combustion processes of aeronautical gas turbine engines and advanced space transportation concepts. Research is focused on providing improved understanding of chemical kinetics of reacting flows, heat transfer phenomena, advanced high-temperature materials, low NOx combustion, and code development and validation.

Flow Physics Facilities

Seven aerodynamic flow physics technology facilities are located in the ERB. These facilities are used to conduct research advancing the understanding of subsonic-to-supersonic flow physics phenomena fundamental to ducted wall-bound flows. Research involves the development, assessment, and application of computational fluid dynamics tools for ducted flows, and for the acquisition and analysis of experimental measurements of flows in inlets, ducts, and nozzles. Typically, testing is performed to define basic flow properties, to predict and validate component performance, and to investigate specific phenomena including shock systems, boundary layers, bleeds, diffusion, separated flows, heat transfer, cooling, spillage, acoustics, and stability.

Heat Transfer Technology

Four aeropropulsion heat transfer technology facilities are located in the ERB. These facilities provide testing capability for experiments to advance fundamental understanding of the heat transfer process and to contribute to the predictive capability for heat transfer in aeronautical and space propulsion systems. Research in these facilities centers on gas turbine-related heat transfer with special emphasis placed on gas path aero/heat transfer.

Data Acquisition

The ERB consists of many different test cells that each perform testing in one of four broad areas: turbomachinery, flow physics, combustion, and heat transfer. Each test cell uses one of two standardized steady-state data acquisition systems, and depending on the test cell and research requirements, may also have a scanned pressure system and/or a high-speed data acquisition system.

- Analog Steady-State Data Systems

- Escort – uses a DEC Alpha microprocessor to provide:

- An X windows based system

- Real-time acquisition of analog and digital signals

- Conversion of raw 10 Hz filtered digitized Neff data to engineering units

- Real-time calculations, which can be displayed in a variety of tabular and graphical formats

- Limit checking on channels

- 1 second update rate

- COBRA – uses a distributed PC topology to provide:

- Real-time acquisition of analog and digital signals

- Conversion of raw digitized data to engineering units

- Real-time calculations, which can be displayed in a variety of tabular and graphical formats

- Limit checking on channels

- Variable sampling rates of 12.5, 25, 50, 100, 200, 400, and 800 samples per second

- Display update rates of 12.5 updates per second

- Escort – uses a DEC Alpha microprocessor to provide:

Escort and COBRA can stand alone to meet all secure test requirements or can be connected to a central processing cluster, which facilitates software application development, downloading of software, uploading and storage of facility tables, post processing of data, and transmitting of data to a data collector for archival storage.

- Pressure Systems

- Electronically Scanned Pressure System (ESP)

- Multiple rack mounted modules with 32 or 16 ports each

- Ranges: ±1 PSID to ±500 PSID

- Check pressure on each module for functional check

- Calibrated in place every two hours using Pressure Calibration Unit (PCU)

- Overall system accuracy of ±0.05% of module full scale range

- Netscanner

- Multiple rack mounted modules with 16 ports each

- Ranges: ±1 PSID to ±500 PSID

- Check pressure on each module for functional check

- System validation only required at the beginning and end of each test day due to higher stability transducers

- Overall system accuracy of ±0.05% of module full scale range

- Electronically Scanned Pressure System (ESP)

- High-Speed Data System

Many ERB test cells have dedicated Dewesoft high-speed data acquisition systems for the purpose of recording transient data or performing spectral analysis of data. The high-speed data system provides multi-channel high-speed digitized acquisition of rapidly changing cyclic or non-periodic impulse type events. A typical portable system consists of:- A Precision Filters front end of anti-aliasing filters and signal conditioning

- Standalone PC to configure individual channel filtering, engineering unit conversions, calculations, and data analysis

- The ability to export the data to a file server to many standard file formats for post processing purposes

- Up to 64 channels with a 24-bit A/D per channel

- Simultaneous differential sampling rates up to 200 kS/sec

Contact

Engine Research Building (ERB)

Facility Manager: Gwynn Severt

216-433-8310

Gwynn.A.Severt@nasa.gov

Test Facility Management Branch

Acting Chief: Tony Doglio

216-433-2402

James.A.Doglio@nasa.gov

Using Our Facilities

NASA’s Glenn Research Center in Cleveland provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

/Hubble%20Space%20Telescope%20(A).png)