Contents

- Propulsion Subsystems

- Human-Rated Spacecraft Propulsion Systems

- Propulsion Subsystems DDTE

- Propulsion System Concept, Mission, & Architecture Trade Study

- Propulsion System & Component Design and Test

- Propulsion Fluid System Design, Analysis and Test

- Propulsion System Technology Advanced Development and In-space Flight Demonstration

- Propulsion Testing

- Oxygen Systems Testing and Analysis

- Propellants and Aerospace Fluids Testing and Analysis

- Composite Overwrapped Pressure Vessels

- Valve Repair and Refurbishment

- Precision Cleaning

- Related Patents

- Connect With Us

Propulsion Subsystems

Johnson Space Center (JSC) leads the development and certification of many of NASA’s human spacecraft propulsion systems and is actively engaged in the development and demonstration of advanced propulsion system technologies. Spacecraft propulsion subsystems are crucial for maneuvering and navigating in space. Expertise is available to support development of cold / warm gas, monopropellant, bi-propellant, and cryogenic propulsion systems over the full life cycle of a project, from concept definition to flight. This experience and knowledge is captured from the Mercury and Apollo Programs through to the Orion and Commercial Crew Programs.

NASA White Sands Test Facility (WSTF) offers numerous ambient pressure and altitude simulation stands to test rocket propulsion systems, as well as single rocket engines. WSTF has extensive experience testing with hypergolic and liquid oxygen / hydrocarbon propellants over a wide range of operating conditions. Because of its remote location and long history of supporting NASA, DoD, and commercial aerospace programs, WSTF is the only NASA facility, and one of only a few government or private industry locations in the country capable of testing rockets with hypergolic rocket propellants. WSTF can dispatch propellant handling teams to support projects at any location or can provide hands-on training to customer personnel in handling hypergolic propellants, oxygen, and hydrogen.

The Johnson Propulsion Systems team supports the development and certification of human-rated spacecraft propulsion systems and EVA/IVA equipment. They provide spacecraft propulsion system and vehicle integration, design, development, certification, integration, test, and operational support for human-rated systems, including advanced development activities to implement new technologies that are critical to improving human spaceflight.

We invite our partners to utilize our unique capabilities and expertise in human-rated spacecraft propulsion systems to enable their own spaceflight endeavors, expanding humanity’s presence across our solar system.

Human-Rated Spacecraft Propulsion Systems

The Johnson Propulsion Systems team provides expertise in human-rated spacecraft propulsion, covering systems for in-space vehicles, landers, refueling, and EVA support. This expertise has been applied to major programs including the Orion Crew Module and Service Module, Commercial Crew Vehicles, and various ISS visiting vehicles.

- Primary & auxiliary propulsion for in-space vehicles

- Descent and ascent propulsion systems for landers

- Propellant transfer and refueling

- Hypergolic and cryogenic propulsion system integration

- EVA/IVA support propulsion (typically cold/warm gas)

Propulsion Subsystems DDTE

NASA Johnson’s Propulsion Systems team provides propulsion subsystem design, development, test and evaluation (DDTE), as well as mission engineering support and technical authority responsibilities.

- System certification and hazard analysis for human rating

- Independent technical assessment of flight readiness

- JSC-67723 Control of Catastrophic Hazards in Spacecraft Propulsion Systems

- Application of design and construction standards

- Independent verification and validation activities

- Real-time flight operations support

- Rapid response for anomaly resolution and corrective actions

- Lesson learned knowledge capture from 60+ years of spacecraft flight experience from Mercury, Gemini, Apollo, Shuttle, Orion, Commercial Crew Program, etc.

Propulsion System Concept, Mission, & Architecture Trade Study

The Johnson Propulsion Systems team conducts trade studies on spacecraft propulsion concepts, missions, and architectures. The expertise includes vehicle integration with other subsystems, performance modeling, system sizing and mass estimation using tools like ENVISION (in-house developed) Exploration Vehicle System Estimation tool, and developing propellant refueling system architectures, drawing on experience from studies like the First Lunar Outpost and non-toxic OMGS and RCS propellant trade studies.

Propulsion System & Component Design and Test

The Johnson Propulsion Systems team provides propulsion system and component design, qualification and acceptance testing of spacecraft propulsion systems and their individual components. The expertise covers everything from system-level test plans for human-rated spacecraft to the in-house design, development test, operation and maintenance of entire propulsion systems like Morpheus, SAFER (Simplified Aid for EVA Rescue) and the Orbital Resupply System.

- System level test plans and test article engineering

- Subject matter expertise for human-rated spacecraft propulsion systems encompassing: tanks, feed systems, valves, pressure-fed engines for hypergolic and cryogenic applications

- Refueling systems including couplings and transfer lines

- Component test plans and test article engineers for tests at ESTA, WSTF, and MSFC. Examples include: Fluid connectors and seal-saver test, Ti-NTO test and analysis; Pressure Spike Effect testing; MMH/NTO and RP1 leak detection testing

- Capability for in-house design, development, test, operating, and maintaining propulsion systems. Examples include: Morpheus, Safer, Orbital Resupply System (ORS)

Propulsion Fluid System Design, Analysis and Test

NASA JSC has expertise in the design, fabrication, build, and testing of vehicle-level fluid integrated fluid systems. The balance of plant design, fabrication, assembly, and operation, including the following:

- Fluid dynamics & thermal (Engine ignition and manifold priming analysis)

- Propulsion feed system dynamic and thermal analysis capabilities to assess waterhammer, priming surge, etc. (Easy5X – transient simulation, Sinda/Fluint – Two phase flow simulation, Ansys CFD, Thermal Desktop and FLOCAD)

- Tank and feed system test plans and test article engineering and interface to NASA and external test organizations

Propulsion System Technology Advanced Development and In-space Flight Demonstration

At Johnson, we advance propulsion technologies to meet human spaceflight needs. We take advanced systems and components from TRL 3 to TRL 7+ to be ready for flight implementation for human missions. We demonstrate advanced development systems with in-space flight tests through partnerships that lead to human rated systems. Examples include:

- Cubesat (Seeker) propulsion in-flight demonstration of 3D printed parts

- Hybrid motors for EDL demonstrations

- Morpheus LOX/LCH4 propulsion system vehicle-level flight tests for future human lunar and Mars application

- High performance pressure-fed systems

- High performance helium system using helium heat exchangers

- Isothermal GHe Tank for rapid use pressurization systems to reduce mass

- Engine nozzle wall HEX to heat the helium

- Coil-on-Plug Reliable Ignition Systems

- Engine-level testing vacuum chambers

- Oxygen/methane (or hydrogen) RCS/ignitor

- Modal propellant gauge (MPG) – non-intrusive, propellant agnostic mass gauge for hypergolics and cryogenics

- System and tank-level testing of avionics and MPG system

- Microgravity testing in partnership with industry and universities

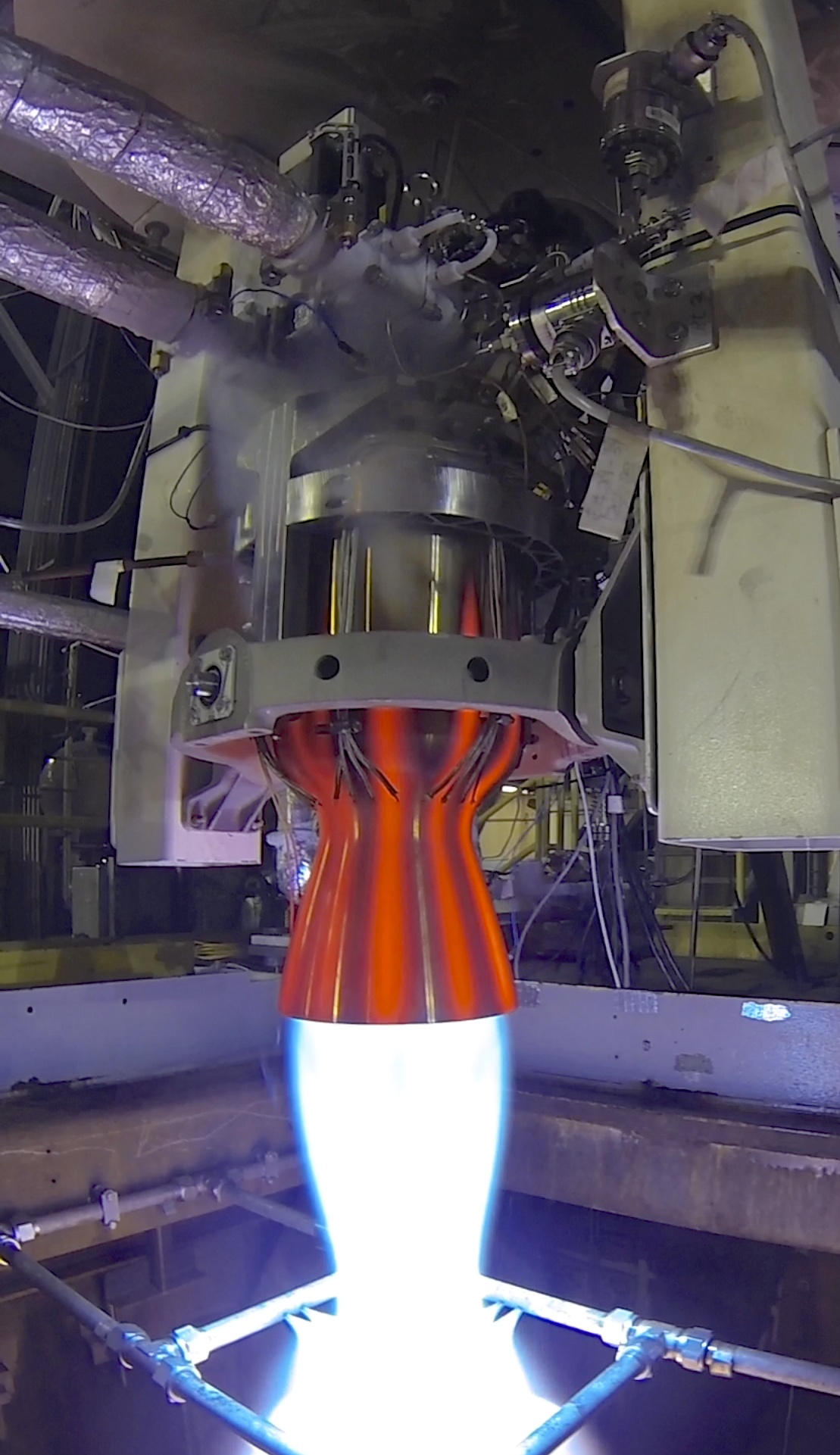

Propulsion Testing

White Sands Test Facility (WSTF) offers numerous ambient pressure and altitude simulation stands to test rocket propulsion systems, as well as single rocket engines. These facilities maintain extensive experience testing with hypergolic and liquid oxygen/hydrocarbon propellants over a wide range of operating conditions. Further information may be found at: https://www.nasa.gov/directorates/space-operations/rpt/propulsion-test-capabilities/

Altitude Testing: WSTF has six test stands that provide simulated altitude greater than 100,000 ft for engines and engine systems with thrust levels up to 25,000 pound-force (lbf). Horizontal and vertical firing configurations are available.

Ambient Testing: Three test stands at WSTF support ambient firing at 5000 ft (1500 m) above sea level. Rocket engines with thrust levels up to 60,000 lbf. (270 kN) can be tested. Horizontal and vertical firing configurations are available.

Propellants: Propellants available for testing at WSTF include liquid hydrogen, gaseous and liquid oxygen, hydrocarbon, hydrazine, Aerozine-50, monomethyl hydrazine (MMH), nitrogen tetroxide (N2O4), gaseous and liquid methane, and solid rocket propellants. Propellant saturation and temperature conditioning are available. Pressurants include nitrogen and helium.

Hypergolic Propellant Handling: WSTF can dispatch propellant handling teams to support projects at any location. Hypergolic propellants such as hydrazine, monomethyl hydrazine, nitrogen tetroxide, and unsymmetrical dimethylhydrazine have been used and stored at WSTF since 1964.

Oxygen Systems Testing and Analysis

The Oxygen Systems Engineering Group (OSEG) at White Sands Test Facility (WSTF) specializes in all aspects of the performance and safety of oxygen systems. OSEG assists in the design and optimization of these systems for all applications through comprehensive analysis, modeling and materials testing in spaceflight environments.

Analysis and Design Capabilities

- Oxygen Compatibility Assessments

- Material and Components Compatibility

- Systems Safety Analysis

- Failure investigation

- Design assistance

- White Sands Test Facility (WSTF) also offers oxygen system training courses for designers, operators, and maintainers of oxygen systems

Test System Capabilities

- High flow, high pressure particle impact ignition testing, (subsonic and supersonic velocities)

- Flowing Oxygen Promoted Combustion testing

- Friction Ignition testing

- Laser Promoted Ignition testing

- Ultra-High Pressure Promoted Combustion Testing (up to 30,000 psi)

- Ability to provide Liquid Oxygen (LOX) for pumps, turbopumps, immersion tests, and various other LOX applications

- Various low-pressure cloth/fabric flammability test chambers (upward and downward flame propagation)

- Arc/Spark ignition test system

Propellants and Aerospace Fluids Testing and Analysis

White Sands Test Facility (WSTF) performs testing that enables aerospace fluid and propulsion system designers to evaluate the risks and hazards associated with potential and existing materials, components, and system configurations.

The White Sands Test Facility (WSTF) performs laboratory-scale experiments and tests to determine and verify the properties of aerospace fluids. Tests include micro-calorimetry and accelerated rate calorimetry, flash point, fire point, differential scanning calorimetry, inductively coupled plasma-mass spectroscopy (ICP-MS), Fourier transform infrared spectroscopy (FTIR), adiabatic compression, and thermal runaway. Testing is performed on exposed and nonexposed materials per applicable NASA, military, and American Society for Testing and Materials (ASTM) standards to determine how fluid exposure affects the material’s properties. Testing can consist of exposure to any of the fluids and properties can vary depending on the type of material being evaluated (soft good, metal, ceramic, lubricant, or other materials). Testing includes tensile strength, flexure, compression set, and hardness. Composition and glass transition temperature are tested when polymers are the subject material. Posttest analysis of fluids is performed after exposure to determine how material exposure may affect fluid specifications and performance. WSTF designs free-field blast experiments up to 230-kilogram (kg) trinitrotoluene (TNT) equivalency and small-scale experiments to assess the hazards associated with a variety of high-energy release mechanisms. These energy releases can be the result of thermochemical reaction, such as with explosives and propellants; the rupture of gas or fluid storage vessels at high pressures, or both. WSTF hydrogen test facilities are designed to allow gaseous tests to be conducted at pressures up to 6,000 psi and at flow rates up to 5 pounds per second. Materials and component tests can be conducted with hydrogen in both the gaseous and liquid state. WSTF can provide in-person training to personnel handling hypergolic propellants, oxygen, and hydrogen medias. Classes are tailored to the individual audience and can vary from intense classroom discussions of new chemical analytical techniques to field training with Level-A, totally encapsulating suits (TES).

Composite Overwrapped Pressure Vessels

White Sands Test Facility (WSTF) tests and evaluates composite overwrap pressure vessels (COPVs) and components through studying damage tolerance and stress rupture. It also offers leading expertise in both destructive and nondestructive evaluation, training, analysis, and development of life extension protocols for composite structures.

White Sands Test Facility (WSTF) offers leading expertise in the testing, nondestructive evaluation, training, and analysis of composite structures. WSTF engages in the test and evaluation of structures by performing mechanical damage tests, sustained load testing, material compatibility, and hydraulic and pneumatic burst tests to understand and evaluate environmental effects on pressurized systems.

Damage Detection Course

A two-day damage detection course is offered to qualify aerospace visual inspectors of flight composite pressure vessels and provides comprehensive working knowledge of composite overwrap pressure vessel (COPV) technology. The course focuses specifically on mechanical damage, safe life, sustained load, and propellant/fuel exposure effects on pressure vessels built using graphite/epoxy composite filament wound onto metallic liners.

Valve Repair and Refurbishment

White Sands Test Facility (WSTF) provides fluid component support to its customers through valve refurbishment, repair, and maintenance. Services provided follow the American National Standards Institute (ANSI) National Board Inspection Code (NBIC)/NB-23.

- Component Services workforce: disassembly, cleaning, maintenance, reassembly, refurbishment, and testing of pressure relief and pressure safety valves in compliance with the American National Standards Institute (ANSI) National Board Inspection Code (NBIC)/NB-23

- Operations: hardware precision cleaning, component assembly, and component calibration. With a full-service clean room and an American Society of Mechanical Engineers/ National Board Inspection Code (ASME/NBIC) certified Valve Repair (VR) Facility, this organization has extensive cleaning and refurbishing experience with numerous valve configurations, metal types, and elastomerics

- Unique VR facility: relief valve repairs and flow tests are performed in an oxygen-clean environment to service ASME code relief devices for use in oxygen systems

- The Fluid Components Laboratory: services on fluid components and systems, including manual valves, chemical pumps, compressors, vacuum pumps, and flight compressors on the ISS

- Refurbish and repair valves for oil, gas, chemical, propellant, and fuel use, as well as for components in liquid oxygen systems

- Reassembly and functional testing, cleanliness is maintained using a clean, Class 10,000 environment

Precision Cleaning

White Sands Test Facility (WSTF) provides contamination control support to its customers through cleaning and cleanliness verification, personal protection equipment, and clean room garments maintenance. The Contamination Control Laboratory provides standard processes for cleaning materials used in critical space applications and performs special processes including pickling and passivation.

The Contamination Control Laboratory at White Sands Test Facility (WSTF) provides standard processes for cleaning materials used in critical space applications. Some of the construction materials are titanium, stainless steel, aluminum, brass, and various plastics, and elastomers. Cleanliness is verified using a variety of fluids, including isopropyl alcohol, ultra-pure water, and hydrofluoro ether (HFE 7100) for a multitude of systems including oxygen, hypergolics, and nitrogen. Precision cleaned items are packaged in clean nylon or Teflon® bags, with an outer bag of polyethylene to protect the cleanliness of the hardware until ready for use. Special processes including pickling and passivation are also performed in the Contamination Control Laboratory. Among items processed through this laboratory are man-rated breathing apparatus for space flight, lubrication systems on large vacuum pumps, large oxygen tanks, and tube-bank trailers. Personal protective equipment (PPE) at WSTF is a critical part of testing aerospace hardware and systems. We test, maintain, and certify self-contained breathing apparatus (SCBA), totally encapsulating suits (TES) and standard splash gear. WSTF operates a clean room garment processing facility that cleans, samples, and packages uniforms for use in critical clean areas.

Related Patents

Connect With Us

Whether you are a public agency, private company, or academic institution, we look forward to hearing from you. Fill out the Statement of Interest form to submit your inquiry.