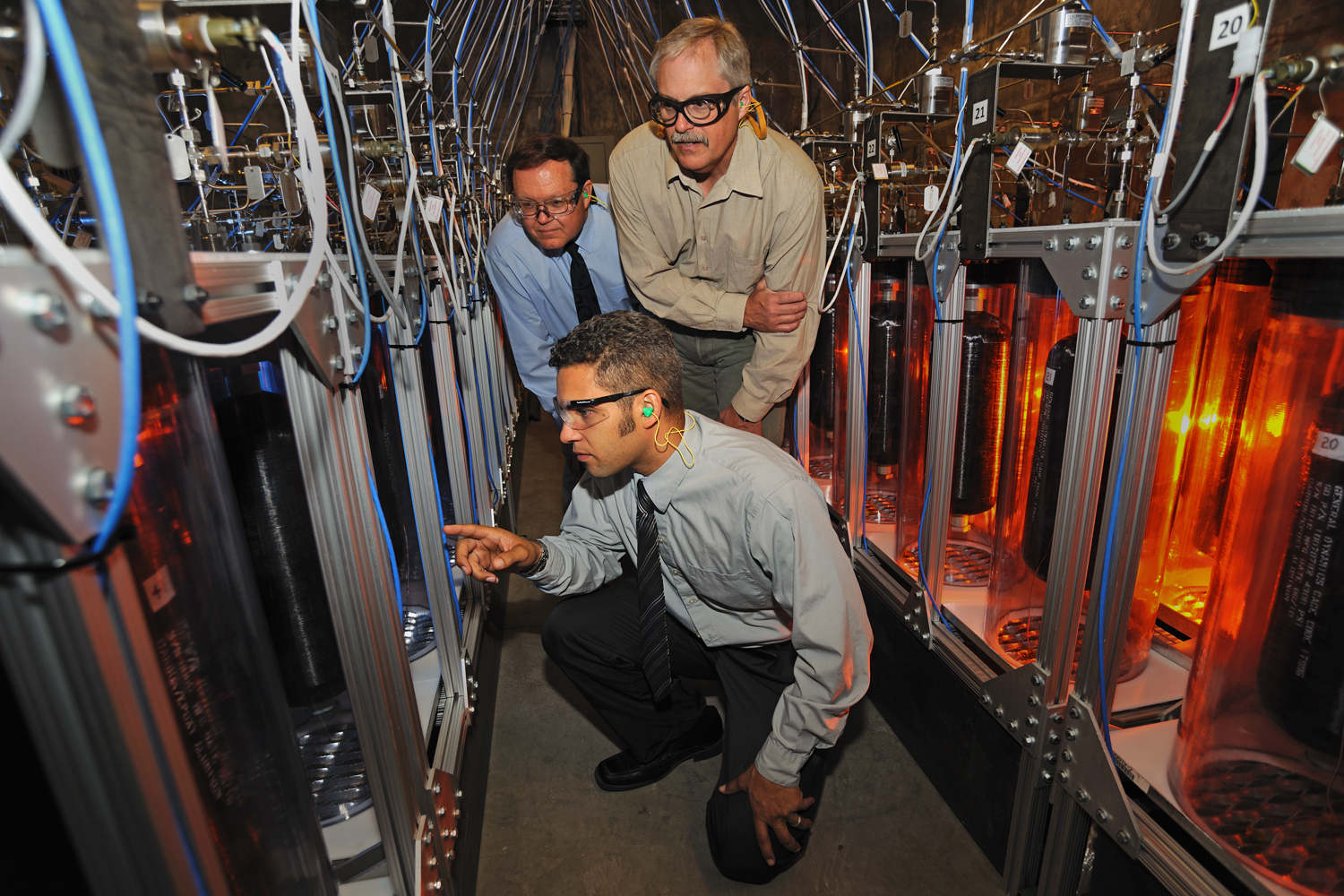

Pressure testing is a highly accurate way to test pressure vessels for quality. Once your test vessel is filled and pressurized, our Composite Overwrap Pressure Vessel (COPV) team employs nondestructive evaluation (NDE) techniques to evaluate the vessel for stress response, strength, leaks, and overall integrity.

Pressure Cycling

Pressure fluctuation and mission duty cycles are an inherent part of operations of pressurized system and, over time, can cause pressure cycle induced fatigue leading to potential growth of flaws. Our team can provide pressure cycling profiles and integrity assessments to help minimize these fluctuations. Additionally, custom pressure profiles can be provided. The variety of NDE and health monitoring techniques can be applied throughout the duration of testing.

Autofrettage/Proof Cycling

The Autofrettage/Proof cycle is an important procedure for components exposed to high and ultra-high pressures and White Sands Test Facility is uniquely qualified to provide autofrettage data. Autofrettage/proof cycling is essential for the reduction of operating stresses and the extension of the vessels life time use. The pressure vessel is exposed to enormous pressures up to 1.5X the service pressure which causes internal portions of the vessel to yield plastically increasing fatigue performance. Our engineers evaluate and analyze the resulting internal compressive residual stresses and volume hysteresis after the test is complete.

Long-term Sustained Load

Pressure vessels subjected to high pressure for prolonged periods can lose strength and result in failure. Determining when, where, and how quickly yielding occurs allows for system understanding and the ability of timely detection. The facility has the capability of placing up to 30 COPV’s in a hydraulic system. The system is capable of bringing a bank of pressure vessel test articles up to a desired pressure and then maintaining the pressure for a sustained period of time. The system is controlled by fast-acting valves that close before venting the surviving COPV, thus reducing the variation of multiple cycles. This system monitors the behavior of the test articles as creep and long-term use begin to affect the test article.

The system is designed to tightly control the stress ratio caused by creep and any diurnal temperature excursions.

Custom Testing

Our skilled COPV team coordinates with customers who have unique requirements. The team has significant experience working with and designing custom experiments with our customers to achieve relative data that meets their desired need.