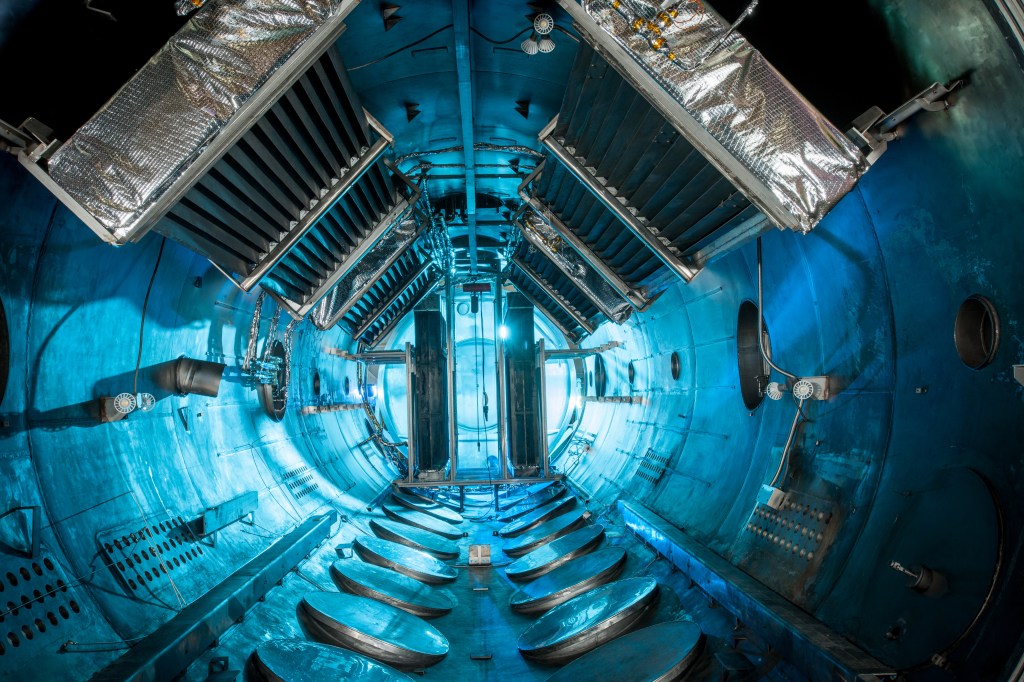

X-Ray and Cryogenic Facility

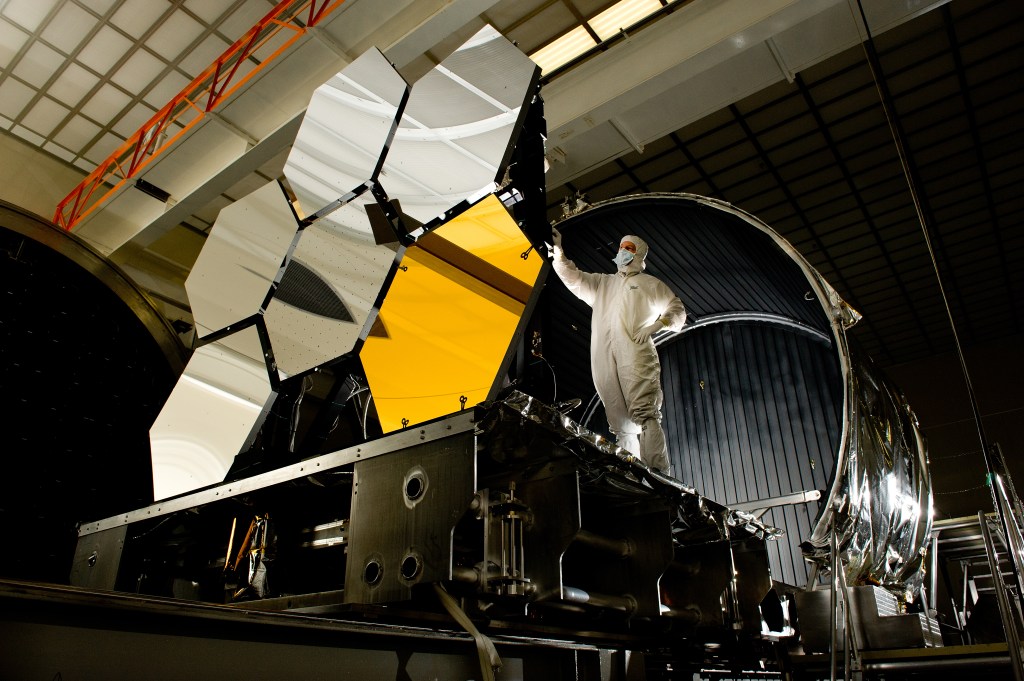

NASA’s X-Ray and Cryogenic Facility (XRCF) is an adaptable space environment simulation facility that has been enabling technology development and pre-flight verification of space missions since 1991. As the Agency’s premier cryogenic optical test facility, the XRCF enables the development and pre-flight evaluation of large direct-incidence telescope mirrors and structures in relevant thermal environments. Most recently, the facility hosted development and verification activities for the James Webb Space Telescope.

As the world’s largest X-ray optical test facility, the XRCF also enables development, performance, and calibration testing of grazing-incidence X-ray optics, detectors and telescopes. Technology evaluation and readiness demonstrations have been performed on advanced X-ray mirrors, composite cryogenic structures, advanced video guidance systems, solar thermal propulsion inflatable structures, and advanced ultraviolet-optical-infrared mirrors.

XRCF Testing Labs

4-Foot Cryo Chamber

In addition to its large vacuum chamber, this facility has a smaller cryogenic optical testing chamber. The helium-cooled test volume in the small chamber is a horizontal cylinder 40 inches in diameter and 88 inches deep. This chamber achieves test pressures and temperatures comparable to those of the large chamber in approximately one-tenth the time. It uses control and data acquisition systems similar to those of the larger chamber, and accommodates the same interferometer systems. More than 30 cryogenic test operations have been completed in the small chamber since it was commissioned in 2001.

4-Foot Preconditioning Chamber

Hardware pre-conditioning takes place in a 4-foot wide by 8-foot long horizontal cylinder

equipped with lamps and a cold plate. This chamber is used for time and temperature bake-outs up to 300°F to ensure contamination control requirements can be satisfied.

Containment Evaluation and Monitoring Chamber

Control and monitoring of vacuum system cleanliness is critical for facility operations. Controls in this chamber include preconditioning hardware, material evaluation/testing, use of an LN2 getter panel, and controlled repress rates. Monitoring in a vacuum environment can include active or passive plates or wafers. Portable particle counters for non-vacuum applications are also available.

Clean Rooms

XRCF clean rooms provide temperature, humidity, pressure, and particle control. Critical clean rooms include the Receiving Clean Room Class 10K (ISO 7), the Instrument Chamber Clean Room Class 1K (ISO 6), and the Equipment Clean-up Area Class 10K (ISO 7).