5.1 Product Implementation

5.2 Product Integration

5.3 Product Verification

5.4 Product Validation

5.5 Product Transition

The Product Transition Process is used to transition a verified and validated end product that has been generated by product implementation or product integration to the customer at the next level in the system structure for integration into an end product or, for the top-level end product, transitioned to the intended end user. The form of the product transitioned will be a function of the product life cycle phase success criteria and the location within the system structure of the WBS model in which the end product exists. The systems engineer involvement in this process includes ensuring the product being transitioned has been properly tested and verified/validated prior to being shipped to the next level stakeholder/customer.

Product transition occurs during all phases of the life cycle. During the early phases, the technical team’s products are documents, models, studies, and reports. As the project moves through the life cycle, these paper or soft products are transformed through implementation and integration processes into hardware and software solutions to meet the stakeholder expectations. They are repeated with different degrees of rigor throughout the life cycle. The Product Transition Process includes product transitions from one level of the system architecture upward. The Product Transition Process is the last of the product realization processes, and it is a bridge from one level of the system to the next higher level.

The Product Transition Process is the key to bridge from one activity, subsystem, or element to the overall engineered system. As the system development nears completion, the Product Transition Process is again applied for the end product, but with much more rigor since now the transition objective is delivery of the system-level end product to the actual end user. Depending on the kind or category of system developed, this may involve a Center or the Agency and impact thousands of individuals storing, handling, and transporting multiple end products; preparing user sites; training operators and maintenance personnel; and installing and sustaining, as applicable. Examples are transitioning the external tank, solid rocket boosters, and orbiter to Kennedy Space Center (KSC) for integration and flight. Another example is the transition of a software subsystem for integration into a combined hardware/software system.

5.5.1 Process Description

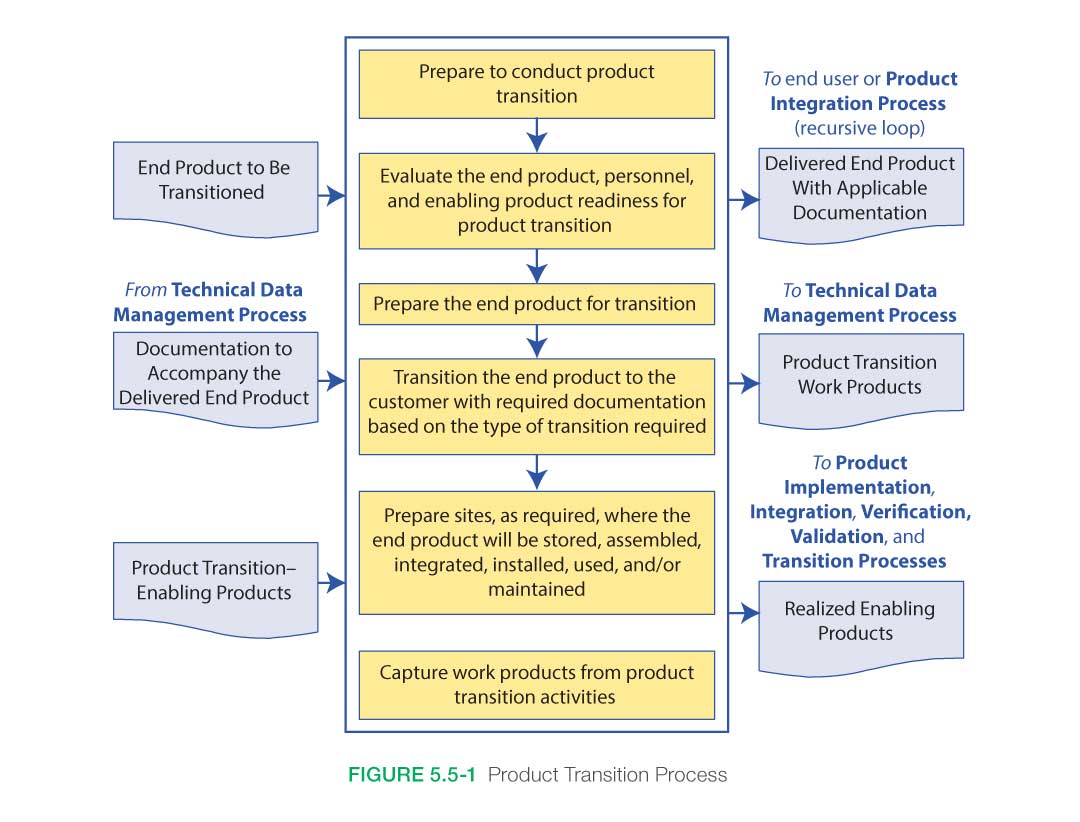

Figure 5.5-1 provides a typical flow diagram for the Product Transition Process and identifies typical inputs, outputs, and activities to consider in addressing product transition.

5.5.1.1 Inputs

Inputs to the Product Transition Process depend primarily on the transition requirements, the product that is being transitioned, the form of the product transition that is taking place, and the location to which the product is transitioning. Typical inputs are shown in Figure 5.5-1 and described below.

- The end product or products to be transitioned (from the Product Validation Process): The product to be transitioned can take several forms. It can be a subsystem component, system assembly, or top-level end product. It can be hardware, analytical models, or software. It can be newly built, purchased, or reused. A product can transition from a lower system product to a higher one by being integrated with other transitioned products. This process may be repeated until the final end product is achieved. Each succeeding transition requires unique input considerations when preparing the validated product for transition to the next level.

Early phase products can take the form of information or data generated from basic or applied research using analytical or physical models and are often in paper or electronic form. In fact, the end product for many NASA research projects or science activities is a report, paper, model, or even an oral presentation. In a sense, the dissemination of information gathered through NASA research and development is an important form of product transition.

- Documentation including manuals, procedures, and processes that accompany the end product (from the Technical Data Management Process): The documentation required for the Product Transition Process depends on the specific end product; its current location within the system structure; and the requirements identified in various agreements, plans, or requirements documents. Typically, a product has a unique identification (i.e., serial or version number) and may have a pedigree (documentation) that specifies its heritage and current state. Pertinent information may be controlled using a configuration control process or work order system as well as design drawings and test reports. Documentation often includes proof of verification and validation conformance. A COTS product would typically contain a manufacturer’s specification or fact sheet. Documentation may include operations manuals, installation instructions, and other information.

The documentation level of detail is dependent upon where the product is within the product hierarchy and the life cycle. Early in the life cycle, this documentation may be conceptual or preliminary in nature. Later in the life cycle, the documentation may be detailed design documents, user manuals, drawings, or other work products. Documentation that is gathered during the input process for the transition phase may require editing, assembling, or repackaging to ensure it is in the required condition for acceptance by the customer.

Special consideration should be given to safety, including clearly identifiable tags and markings that identify the use of hazardous materials, special handling instructions, and storage requirements.

- Product transition-enabling products, including packaging materials; containers; handling equipment; and storage, receiving, and shipping facilities (from existing resources or the Product Transition Process for enabling product realization): Product transition-enabling products may be required to facilitate the implementation, integration, evaluation, transition, training, operations, support, and/or retirement of the transition product at its next higher level or for the transition of the final end product. Some or all of the enabling products may be defined in transition-related agreements, system requirements documents, or project plans. In some cases, product transition-enabling products are developed during the realization of the product itself or may be required to be developed during the transition stage.

As a product is developed, special containers, holders, or other devices may also be developed to aid in the storing and transporting of the product through development and realization. These may be temporary accommodations that do not satisfy all the transition requirements, but allow the product to be initiated into the transition process. In such cases, the temporary accommodations will have to be modified or new accommodations will need to be designed and built or procured to meet specific transportation, handling, storage, and shipping requirements.

Sensitive or hazardous products may require special enabling products such as monitoring equipment, security features, inspection devices, safety devices, and personnel training to ensure adequate safety and environmental requirements are achieved and maintained.

5.5.1.2 Process Activities

Transitioning the product can take one of two forms:

- The delivery of lower system end products to higher ones for integration into another end product; or

- The delivery of the final end product to the customer or user that will use it in its operational environment.

In the first case, the end product is one of perhaps several other pieces that will ultimately be integrated together to form the item. In the second case, the end product is for final delivery to the customer. For example, the end product might be one of several circuit cards that will be integrated together to form the final unit that is delivered. Or that unit might also be one of several units that have to be integrated together to form the final product.

The form of the product transitioned is not only a function of the location of that product within the system product hierarchy, but also a function of the life cycle phase. Early life cycle phase products may be in the form of paper, electronic files, physical models, or technology demonstration prototypes. Later phase products may be preproduction prototypes (engineering models), the final study report, or the flight units.

Figure 5.5-1 shows what kind of inputs, outputs, and activities are performed during product transition regardless of where in the product hierarchy or life cycle the product is. These activities include preparing to conduct the transition; making sure the end product, all personnel, and any enabling products are ready for transitioning; preparing the site; and performing the transition including capturing and documenting all work products.

How these activities are performed and what form the documentation takes depends on where the end items are in the product hierarchy and the life cycle phase.

5.5.1.2.1 Prepare to Conduct Transition

The first task is to identify which of the two forms of transition is needed: (1) the delivery of lower system end products to higher ones for integration into another end product; or (2) the delivery of the final end product to the customer or user that will use the end product in its operational environment. The form of the product being transitioned affects transition planning and the kind of packaging, handling, storage, and transportation that is required. The customer and other stakeholder expectations, as well as the specific design solution, may indicate special transition procedures or enabling product needs for packaging, storage, handling, shipping/transporting, site preparation, installation, and/or sustainability. These requirements need to be reviewed during the preparation stage.

Other tasks in preparing to transition a product involve making sure the end product, personnel, and any enabling products are ready for that transition. This includes the availability of the documentation or models that will be sent with the end product, including proof of verification and validation conformance. The appropriateness of detail for that documentation depends upon where the product is within the product hierarchy and the life cycle. Early in the life cycle, this documentation may be preliminary in nature. Later in the life cycle, the documentation may be detailed design documents, user manuals, drawings, or other work products. Procedures necessary for conducting the transition should be reviewed and approved by this time.

Finally, the availability and skills of personnel needed to conduct the transition as well as the availability of any necessary packaging materials/containers, handling equipment, storage facilities, and shipping/transporter services should also be reviewed. Any special training necessary for the personnel to perform their tasks needs to be performed by this time.

5.5.1.2.2 Prepare the Site to Receive the Product

For either of the forms of product transition, the receiving site needs to be prepared to receive the product. Here the end product is stored, assembled, integrated, installed, used, and/or maintained as appropriate for the life cycle phase, position of the end product in the system structure, and customer agreement.

A vast number of key complex activities, many of them outside direct control of the technical team, need to be synchronized to ensure smooth transition to the end user. If transition activities are not carefully controlled, there can be impacts on schedule, cost, and safety of the end product.

A site survey may need to be performed to determine the issues and needs. This should address the adequacy of existing facilities to accept, store, and operate the new end product and identify any logistical-support-enabling products and services required but not planned for. Additionally, any modifications to existing facilities should be planned well in advance of fielding; therefore, the site survey should be made during an early phase in the product life cycle. These may include logistical enabling products and services to provide support for end-product use, operations, maintenance, and disposal. Training for users, operators, maintainers, and other support personnel may need to be conducted. National Environmental Policy Act documentation or approvals may need to be obtained prior to the receipt of the end product.

Prior to shipment or after receipt, the end product may need to be stored in suitable storage conditions to protect and secure the product and prevent damage or the deterioration of it. These conditions should have been identified early in the design life cycle.

5.5.1.2.3 Prepare the Product for Transition

Whether transitioning a product to the next room for integration into the next higher assembly, or for final transportation across the country to the customer, care should be taken to ensure the safe transportation of the product. The requirements for packaging, handling, storage, training, and transportation should have been identified during system design. Preparing the packaging for protection, security, and prevention of deterioration is critical for products placed in storage or when it is necessary to transport or ship between and within organizational facilities or between organizations by land, air, and/or water vehicles. Particular emphasis needs to be on protecting surfaces from physical damage, preventing corrosion, eliminating damage to electronic wiring or cabling, shock or stress damage, heat warping or cold fractures, moisture, and other particulate intrusion that could damage moving parts.

The design requirements should have already addressed the ease of handling or transporting the product such as component staking, addition of transportation hooks, crating, etc. The ease and safety of packing and unpacking the product should also have been addressed. Additional measures may also need to be implemented to show accountability and to securely track the product during transportation. In cases where hazardous materials are involved, special labeling or handling needs, including transportation routes, need to be in place.

5.5.1.2.4 Transition the Product

The end product is then transitioned (i.e., moved, transported, or shipped) with required documentation to the customer based on the type of transition required, e.g., to the next higher level item in the product hierarchy (often called the Product Breakdown Structure [PBS]) for product integration or to the end user. Documentation may include operations manuals, installation instructions, and other information.

The end product is finally installed into the next higher assembly or into the customer/user site using the preapproved installation procedures.

Confirm Ready to Support

After installation, whether into the next higher assembly or into the final customer site, functional and acceptance testing of the end product should be conducted. This ensures no damage from the shipping/handling process has occurred and that the product is ready for support. Any final transitional work products should be captured as well as documentation of product acceptance.

5.5.1.2.5 Capture Product Transition Work Products

Other work products generated during the transition process are captured and archived as appropriate. These may include site plans, special handling procedures, training, certifications, videos, inspections, or other products from these activities.

5.5.1.3 Outputs

- Delivered end product with applicable documentation: This may take one of two forms:

- Delivered end product for integration to next level up in system structure: This includes the appropriate documentation. The form of the end product and applicable documentation are a function of the life cycle phase and the placement within the system structure. (The form of the end product could be hardware, software, model, prototype, first article for test, or single operational article or multiple production articles.) Documentation includes applicable draft installation, operation, user, maintenance, or training manuals; applicable baseline documents (configuration baseline, specifications, and stakeholder expectations); and test results that reflect completion of verification and validation of the end product.

- Delivered operational end product for end users: The appropriate documentation is to accompany the delivered end product as well as the operational end product appropriately packaged. Documentation includes applicable final installation, operation, user, maintenance, or training manuals; applicable baseline documents (configuration baseline, specifications, stakeholder expectations); and test results that reflect completion of verification and validation of the end product. If the end user will perform end product validation, sufficient documentation to support end user validation activities is delivered with the end product.

- Work products from transition activities to technical data management: Work products could include the transition plan, site surveys, measures, training modules, procedures, decisions, lessons learned, corrective actions, etc.

- Realized enabling end products to appropriate life cycle support organization: Some of the enabling products that were developed during the various phases could include fabrication or integration specialized machines; tools; jigs; fabrication processes and manuals; integration processes and manuals; specialized inspection, analysis, demonstration, or test equipment; tools; test stands; specialized packaging materials and containers; handling equipment; storage-site environments; shipping or transportation vehicles or equipment; specialized courseware; instructional site environments; and delivery of the training instruction. For the later life cycle phases, enabling products that are to be delivered may include specialized mission control equipment; data collection equipment; data analysis equipment; operations manuals; specialized maintenance equipment, tools, manuals, and spare parts; specialized recovery equipment; disposal equipment; and readying recovery or disposal site environments.

The process is complete when the following activities have been accomplished:

- For deliveries to the integration path, the end product is delivered to intended usage sites in a condition suitable for integration with other end products or composites of end products. Procedures, decisions, assumptions, anomalies, corrective actions, lessons learned, etc., resulting from transition for integration are recorded.

- For delivery to the end user path, the end products are installed at the appropriate sites; appropriate acceptance and certification activities are completed; training of users, operators, maintainers, and other necessary personnel is completed; and delivery is closed out with appropriate acceptance documentation.

- Any realized enabling end products are also delivered as appropriate including procedures, decisions, assumptions, anomalies, corrective actions, lessons learned, etc., resulting from transition-enabling products.

5.5.2 Product Transition Guidance

Refer to Section 5.5.2 in the NASA Expanded Guidance for Systems Engineering at https://nen.nasa.gov/web/se/doc-repository for additional guidance on:

- additional product transition considerations and

- what’s next after product transition to the end user.