Toxicology

Toxicology is critical in human spaceflight to assess and mitigate the potential health risks posed by exposure to various environmental factors, substances, or contaminants, ensuring the well-being and safety of astronauts during extended space missions. In order to maintain sustained occupation in space on the International Space Station (ISS), JSC experts assess toxicological risks and manage them within the context of isolation, continuous exposures, reuse of air and water, limited rescue options, and the need to use highly toxic compounds for propulsion and other purposes. As we begin to explore other celestial bodies, in situ toxicological risks, such as inhalation of reactive mineral dusts, must also be managed. JSC’s uniquely skilled team serves as the NASA-wide resource for space toxicology by assessing chemical toxicity to establish spacecraft maximum allowable concentrations (SMACs), spacecraft water exposure guidelines (SWEGs), assigning toxicity hazard levels to all compounds that could enter the habitable area of a spacecraft, performing offgas testing of flight hardware and whole modules, and monitoring and analyzing air quality in human space vehicles. We invite customers to leverage our expertise and unique facilities, ensuring the highest standards of safety and well-being for space travelers. Join us in pioneering the future of human spaceflight by harnessing our comprehensive toxicology resources.

Odor & Offgas Flight Acceptance and Standard Testing (FAST)

White Sands Test Facility conducts odor testing and offgas testing. The facilities detect, identify, and quantify all gaseous compounds and odors released from a material or article under human habitable atmospheric conditions. Human evaluation of odors can also be performed. Four trained and certified analytical chemists identify and quantify all offgassed products.

Analytical Capabilities

- Two Gas Chromatographs (GC) equipped with Fourier transform infrared (FTIR) detectors and mass spectrometers (MS) for detecting and quantifying offgassed inorganic and organic compounds

- One GC equipped with a Flame Ionization Detector (FID) for detecting and quantifying offgassed organic compounds

- One GC equipped with a methanizer coupled to a FID for detecting and quantifying carbon monoxide and methane

- One GC equipped with a thermal conductivity detector (TCD) for detecting and quantifying hydrogen

- Simulated-use testing conducted in two airtight gloveboxes

- Handling of electrostatic discharge (ESD) components. Class 1 ESD protective workstation available.

- Test small to very large materials and components. A large array of offgassing chambers to fit most any size material or test article (2 L through 86700 L) are maintained for testing. Our largest offgassing chamber is the CVI® self-heating cylindrical offgassing chamber. This chamber is 1.83 m (6 ft) in diameter and 2.74 m (9 ft) long. This chamber can achieve vacuums as low as 1.33 Pa (1 × 10-2 torr), with a temperature range from ambient ~ 21 to 93°C (70 to 200°F).

- Thermal conditioning capabilities range from ~21 to 316 °C (~70 to 600°F). Five thermal conditioning ovens (incorporating multiple temperature measurement systems) are connected to an automatic alarm system to notify personnel of power outages and/or temperature nonconformities. Ovens can handle the entire size range of sample chambers.

- Odor Test Panel maintained and tested for odor testing (Test 6). An “Odor Mission” is conducted by five certified odor panel members under the direction of an Odor Panel Test Conductor. These five odor panel members are selected randomly out of a pool of all odor panel members and their sense of smell tested to ensure sensitivity.

- On-site state-of-the-art test article/material preparation and analytical laboratories with full sample preparation, measurement, thermal conditioning, and chemical analysis capabilities are maintained

- A secure, limited-access storage area for spaceflight items and other high cost/importance items is utilized

- Direct test data entry and storage into a secure, laboratory information and tracking system that automatically generates the reports for review and transmittal is maintained

- Materials and equipment to handle heavy and bulky articles up to 909 Kg (2000 lb.) (heavier with prior notification), are available. In addition to a full rack, sized to hold test articles in the 3 m (10 ft) by 1.8 m (6 ft) chamber.

Toxicology and Risk Assessment

Toxicological and other environmental risks are assessed and managed within the context of isolation, continuous exposures, reuse of air and water, limited rescue options, and the need to use highly toxic/biohazardous compounds in payloads, for propulsion, and other purposes.

- Establish limits for air and water pollutants

- Spacecraft Maximum Allowable Concentration (SMACs)

- Spacecraft Water Exposure Guidelines (SWEGs)

- Assess chemical hazards for flight

- Data interpretation and trend analysis

Pharmacotherapeutics Laboratory

Pharmacotherapeutics Laboratory’s capabilities include access to expertise in pharmaceutical, toxicology, regulatory sciences and research, investigational and clinical pharmacy consultation, dosage form design, delivery, and performance, and pharmaceutical stability analyses and assessments. The Pharmacotherapeutics Laboratory also offers access to a variety of analytical workspace and state-of-the-art equipment options including environmentally controlled drug storage chambers, liquid chromatography systems (HPLC, UPLC), Mass Spectrometers, Friability and Hardness Testers, and a variety of other laboratory supplies and bench-top equipment.

- Provide clinical pharmacy services

- Provide therapeutic drug monitoring

- Provide regulatory and compliance oversight

- Provide clinical trial protocol development, execution, and oversight

- Perform pharmaceutical dosage form design and storage

- Perform pharmaceutical stability assessment and design

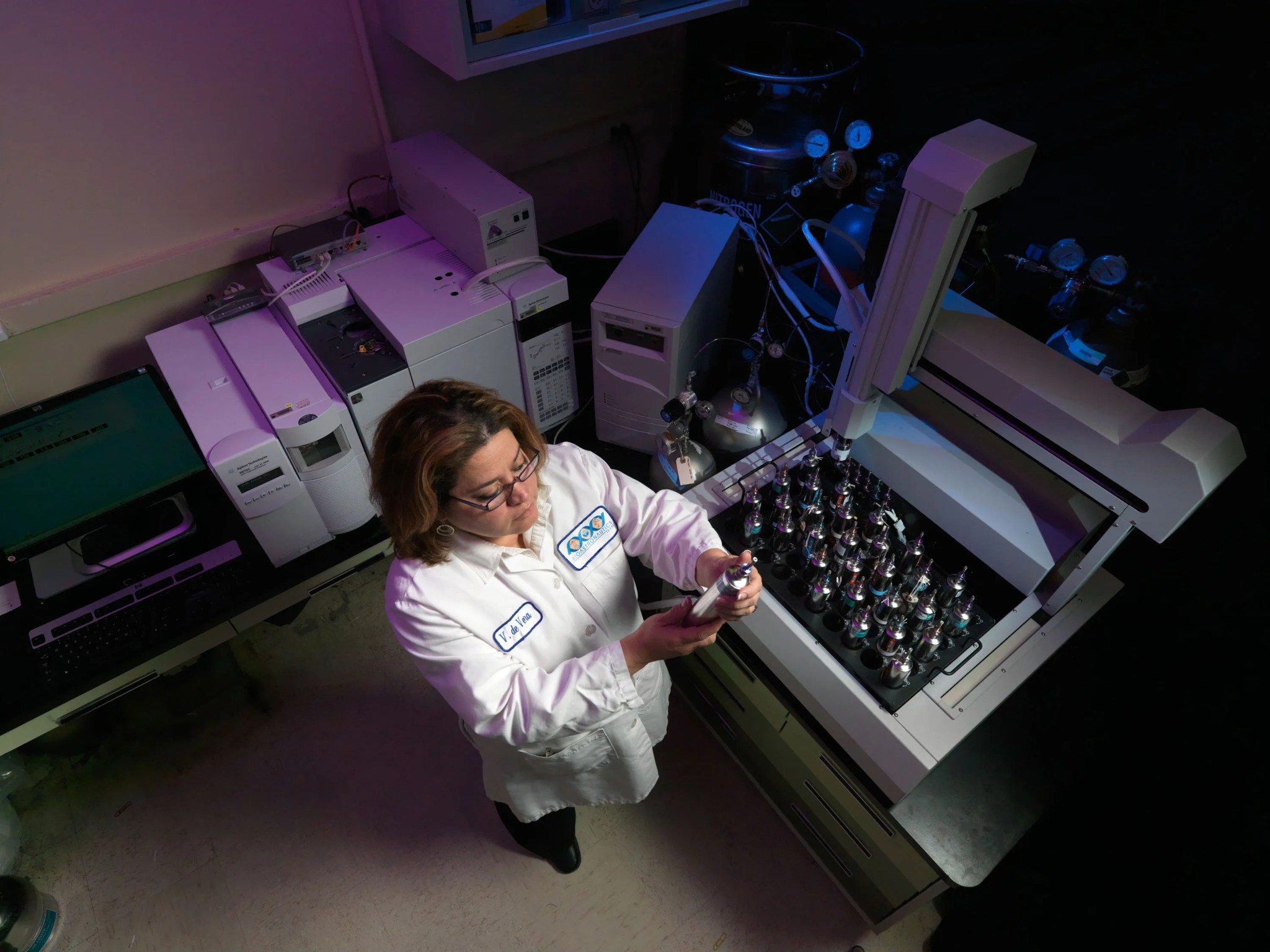

Environmental Chemistry Laboratory

The Environmental Chemistry Laboratory (ECL) has extensive experience analyzing environmental samples from crewed spacecraft and interpreting the results to ensure compliance with applicable standards. The ECL has the expertise to develop custom analytical methods to deal with complex sample matrices (wastewaters, preserved urines, urine brines) and to overcome the inherent challenges associated with spacecraft environmental monitoring (limited sample volumes, non-ideal storage conditions, etc.). The lab also works to identify and evaluate new environmental monitoring hardware, establishes monitoring requirements for new crewed spaceflight programs, and provides operational support for on-orbit monitoring and environmental control systems.

- Comprehensive analysis of air, water, and wastewater samples

- Interpretation of environmental data

- Development of custom analytical methods to overcome challenges created by complex matrices, limited sample volume, and unique/non-standard analyses

Related Patents

Corkscrew Filter Extracts Liquid From Air Charge