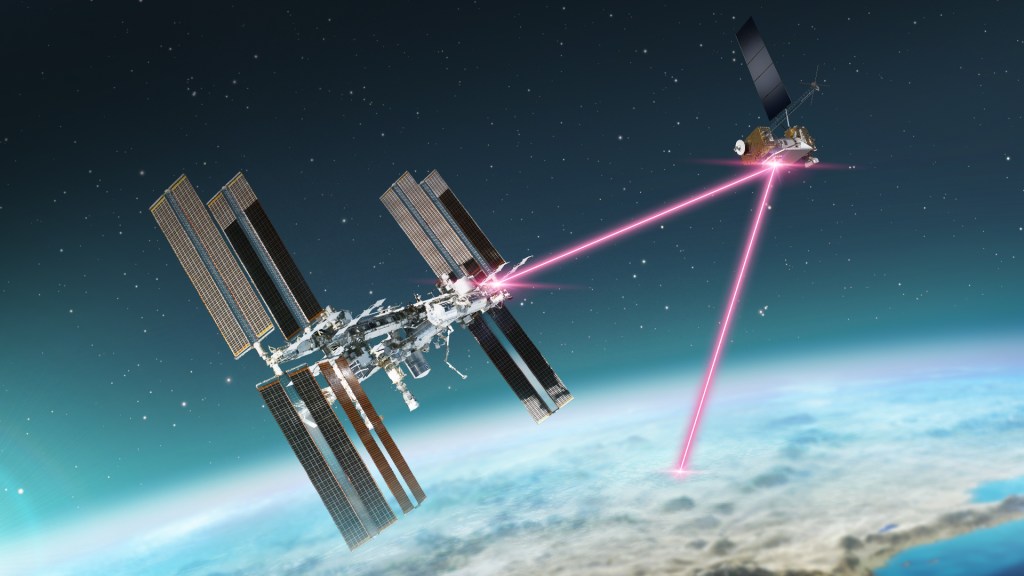

Art history, a travel agent’s advice, and inspiration from a tragedy were all part of NASA engineer Kristin Morgan’s journey to her role today of helping supply rocket engines for NASA’s powerful SLS (Space Launch System) rocket. The super heavy lift rocket – along with the Orion spacecraft, human landing systems, and the Gateway in orbit around the Moon – is part of the backbone of the agency’s Artemis deep space exploration program.

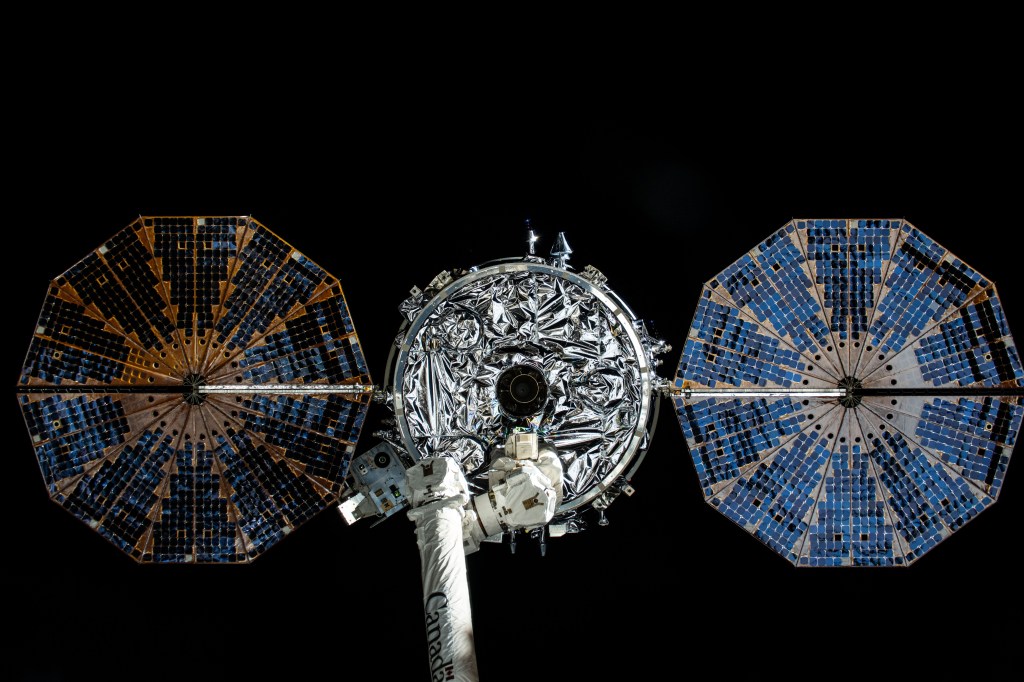

Morgan is the Contracting Officer’s Representative in the SLS Liquid Engines Office at NASA’s Marshall Space Flight Center. Since 2019, Morgan has managed contracts for the RS-25 and RL10 liquid-fueled engines. SLS is powered by a core stage with four RS-25 engines, as well as two solid-propellant boosters and an in-space stage powered by an RL10 engine, and will launch Orion, its crew, and large cargo into Earth orbit and on to the Moon.

Morgan started college as an art history major at the University of Florida in Gainesville. Despite her love of literature, art, and music, she began loading up on math courses and decided that engineering might provide more of the kinds of opportunities she wanted. Her mother, a travel agent, recommended materials engineering based on her business contacts. Morgan went on to earn both her bachelor’s and master’s degrees in materials science engineering.

Her first job after college was in durability, damage tolerance, and fleet maintenance supporting the F-16 fighter jet program at Lockheed Aeronautics in Fort Worth, Texas. Then the Space Shuttle Columbia accident happened, which drew her to the recovery effort.

She moved from the company’s Texas operation to its shuttle external tank operation at NASA’s Michoud Assembly Facility in New Orleans. There, she investigated the external tank foam insulation as part of the work to return the shuttle to flight. Later, she found a laboratory job at Marshall, testing materials for various projects, including the RS-25 engine that once powered the space shuttle and now is the main engine for SLS flights to deep space.

Seeking experience beyond her lab work, Morgan transferred to a Marshall group looking at the center’s strengths and where it should focus for the future. One of her projects was an early study of additive manufacturing and its possibilities for rocket engine development.

Having seen Marshall’s work from the lab and center-level, she wondered how those areas applied to a spaceflight project.

“How do these big projects get done?” she recalled thinking before joining the SLS Liquid Engines Office.

It’s challenging in that there’s lots of people, lots of stakeholders, lots of interests. Balancing them all is a challenge, and I like it.

Kristin Morgan

Contracting Officer’s Representative for the SLS Liquid Engine Office

She found the answer to her question as the Contracting Officer’s Representative for the SLS Liquid Engine Office, managing contracts for flight engines incorporating the additive manufacturing technology she helped nurture.

Currently, 24 new RS-25 engines are in production for missions beginning with Artemis V, employing additive manufacturing and other updated technologies and materials to make the engine 30% more affordable than the ones modified for use on earlier Artemis missions.

“I think I’m on the right path,” Morgan said. “I never know where that path is going to lead. To me this has been a natural progression. People throw around the word ‘passion,’ but I love working with NASA and the Space Launch System Program.”