“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center, the home of human spaceflight, stationed in Houston, Texas. We bring space right to you! On this podcast, you’ll learn from some of the brightest minds of America’s space agency as they discuss topics in engineering, science, technology and more. You’ll hear firsthand from astronauts what it’s like to launch atop a rocket, live in space and re-enter the Earth’s atmosphere. And you’ll listen in to the more human side of space as our guests tell stories of behind-the-scenes moments never heard before.

For Episode 83 spacewalk experts Tara Jochim and Art Thomason discuss the intense planning over months and sometimes years that goes into the complicated choreography of a spacewalk. This episode was recorded on September 6, 2018.

Transcript

Gary Jordan (Host) Houston, We Have a Podcast. Welcome to the official podcast of the NASA and Johnson Space Center, Episode 83, How to Plan a Spacewalk. I’m Gary Jordan, and I’ll be your host today. On this podcast, we bring in the experts, NASA scientists, engineers, and astronauts, all to let you know the coolest information about what’s going on right here at NASA. So if you’re familiar with us, you may know that NASA is full of acronyms and abbreviations. We try really hard to stay away from as many as we can, but sometimes it’s just really hard to avoid. Here’s one that we use all the time here, EVA. You may have heard it before. It stands for extravehicular activity. Broken down, it’s literally just working outside of a spacecraft. Astronauts get in space suits and go outside to work on different things. They’ve done EVAs on the moon, and now they’re going to perform EVAs for maintenance and upgrades on the International Space Station. They’re still doing it now. Today’s EVAs are planned months or sometimes years in advance for a six and a half hour run. Activities are well coordinated and jam packed into that time, and it’s a long day for the astronauts including the time before and after that run.

So, today, we’re exploring what goes on to plan a spacewalk. With me is Tara Jochim and Art Thomason. Tara is the project manager for the Alpha Magnetic Spectrometer EVA repair. This is a big deal, and we’ll get into some of it. Art is an EVA flight controller and instructor, one of the guys sitting in mission control during a spacewalk that knows the intricate procedures of every move. So with no further delay, let’s jump right ahead to our talk with Mrs. Tara Jochim and Mr. Art Thomason. Enjoy.

[ Music ]

Host: Tara and Art, thank you so much for coming on the podcast today to talk about what it takes to plan a spacewalk. It’s not an easy thing, right? Whenever you watch the movies, you kind of see them just kind of go out, and I’m sure, I’m sure from spacewalk planning perspective you are pretty aggravated, because they always seem to go out without tethers and just sort of float around and make it up along the way, but these things are highly coordinated and planned well in advance, right?

Tara Jochim: They are. It’s a very, very intricate process they go through to design the EVA, so to speak. We like to call it a big puzzle, and we fit all the different pieces together and figure out how the flow is going to work from the beginning to the end.

Host: Okay. So let’s kind of back up just a second and talk about what is a spacewalk to begin with. We’re going to talk about EVAs. This is going to be an acronym that is just bound to come up. We always say EVA because it’s part of this vernacular. It’s a spacewalk, but what is that, what is a spacewalk?

Art Thomason: A spacewalk is technically any time you’re going out in the vacuum of space, and when you’re going out into the vacuum of space, you’re in your own personal spacecraft, that suit. It looks like a suit to everyone else, like maybe, you know, a jacket you put on, but it’s really a spacecraft that has a complete life support system just like any spacecraft, except, you know, the thing that moves it around is you, your arms, and if you’re in a microgravity EVA by translating on hand rails.

Host: Yeah, I’ve kind of described it in the past as a spacecraft shaped like a human body. It’s just perfectly shaped right.

Tara Jochim: That’s good, yeah.

Art Thomason: Yeah, that’s true.

Host: So, what are they doing outside?

Art Thomason: Well, right now, you know, the biggest thing that you’re seeing is maintenance, upgrades, installing payload, those kind of things. Spacewalks are also used to build space stations, so, you know, hundreds of spacewalks were done to make all that happen. You know, as far as just a specific task that you’re going to see, it’s pretty simple things, driving bolts, many electrical connectors, data connections, fluid connections, those kinds of things. They design the hardware so that the crew member can unbolt a box that has all the equipment in it that’s needed to make something happen and, you know, change that out, put a new one in, so that it’s easier for the crew member because it’s pretty tough to work in that environment and in that suit.

Host: Yeah. So, you know, needless to say, whenever you’re, for example, assembling, right, whenever you’re building something in space, you can put them together, but ultimately you’re going to need some guys to go outside and connect some things, turn a few bolts, and do some other stuff. Just that hands-on perspective really really helps to make it successful.

Art Thomason: That’s true.

Tara Jochim: Right. The hardware was designed quite a few years back, and we were very busy within that time period, heling the hardware designers design for EVA. So there’s all kinds of requirements that the hardware designers have to meet. Things can’t be sharp. It can’t be too difficult for the crew to turn or push or pull or do whatever action it is that they need to do because they’re in this big white puffy space suite, right, and it gets very fatiguing for their hands to do a lot of these different actions. So there’s different ways they have to design the hardware. It seems easy on the ground. You go look at it. You go to your car and you fix your car. It’s very different when you’re in the spacesuit outside in a microgravity environment to be able to do those same actions.

Host: Yeah. That’s right. You don’t want them working with like needles or anything outside, not only for just the, you know, sharpness, but also how fine that skill is, because the gloves are pretty tough, right. You want things that they can actually interact with and don’t have to really squeeze on those gloves. Because that could be strenuous for the crew, right? And that’s something that we’ll get into later when we talk about executing a spacewalk, because I know like one of the things is, you know, you’re checking the gloves all the time, that’s one of the things when you’re actually going through, and there’s a reason for that.

Art Thomason: In talking about the difficult with gloves–

Host: Yeah.

Art Thomason: I kind of think about it like ski gloves.

Host: Okay.

Art Thomason: So if anyone’s ever gone skiing and something as simple as getting out your wallet to get a credit card is really tough to do that kind of thing in ski gloves. So working in the EMU is very similar, you know, the Extravehicular Mobility Unit is what the acronym stands for.

Host: Yeah, there you go. No, even myself, I have done that so many times, right. You have it in your jacket, your ski jacket, you pull it out and your ski gloves, you’re trying to buy something at the stand, but you just can’t get it out, so what do you do? You take off your gloves and just deal with the cold for a little bit. Not something that you can do in space, right.

Art Thomason: Exactly.

Tara Jochim: Definitely not.

Host: But you’re talking about, you said, EVA requirements, just whenever you are doing something that needs to be done on the outside, it needs to be designed specifically so that people can interact with it, and not just the equipment themselves, but also the tools that they’re using too, right.

Tara Jochim: Absolutely. We’ve got kind of a generic set of tools, just like you have in your garage that you’re going to go off and be able to work on different things. So, the hardware that is designed to be able to work with that generic set of tools that we already have. If there is a specific task that we have to go off and design and build a new tool for, we can do that, but we kind of like to stay within our tool chest of items that we already have.

Host: Sure.

Tara Jochim: Because then the crew already knows how to use those tools. They’ve been trained a lot with that and can go up and do that on an orbit. We really would prefer to not go EVA, right. We prefer hardware to be designed so that it doesn’t require EVA to go out there and change things out robotically or just stay outside on station and not have to go be worked with. But there are those cases where we do. It requires EVA to go off and do something with that piece of hardware. The car we’re driving is getting old.

Host: Yeah.

Tara Jochim: Right, it’s been on orbit for a long time, and so now we’re starting to see that maintenance time period come up, and we go out and, you know, fix things that maybe have some issues or go install new science payloads for, you know, new science to get completed on Space Station. So there’s a lot of neat stuff that EVA gets to be involved with.

Host: Yeah, not just kind of maintaining but also, you know, that new installing payloads. I know just not too long ago at the time of this recording on a Russian spacewalk they installed an experiment that was like an animal tracking sort of GPS thing on the outside and that can actually look at animals tagged on the Earth with GPS, with like little receivers. It was pretty cool to actually research and read about. But like you said, we’re in this period of maintenance right now when we’re talking spacewalks, spacewalks mainly, well, exclusively now on the International Space Station, but spacewalking itself is just going outside of a vehicle, like you said, Art. So even spacewalking, that was like the moon landings, someone getting out in a space suit. That was spacewalking, right?

Art Thomason: That’s right.

Host: It required a little bit of different hardware and procedures, but that was also spacewalking.

Art Thomason: That’s right.

Host: Now, the difference there was they were trying to figure stuff out, really, right. They don’t really have, they didn’t get to go into like their moon gravity room, flip a switch, and all right, here’s how we’re going to, here’s how we’re going to do it. They had to figure stuff along the way.

Art Thomason: Yeah.

Host: How about now. In microgravity, are we, you said that we’ve already done a couple hundred, just for space station assembly and maintenance, how are we now? Do we have things mostly figured out, or are there still things we’re learning?

Art Thomason: I think we have things figured out as far as how we operate.

Host: Okay.

Art Thomason: Each EVA is different.

Host: Yeah.

Art Thomason: And so like Tara mentioned earlier, it is kind of like a puzzle.

Host: Yeah.

Art Thomason: So we have a lot of tasks that we need to do. Sometimes there is one big major task that takes most of the EVA, and sometimes there’s, you know, 15 small tasks, and trying to fit those together in order of priorities but also in order of efficiency. So, if I’m going to be at one location and there’s three things in that area, even though they all may not be the highest priority, it may be more efficient to get those things done. So there’s definitely a puzzle factor that comes in, and it’s fun to play around with that and try to get as efficient as you can.

Host: Yeah.

Tara Jochim: Definitely. And Art’s team has learned a lot over the years on how to fit those puzzle together and to work with the Space Station program now and figure out, okay, here are our priorities. Here are all the things we can do in a six and a half hour EVA. This is how we would like to timeline all this out, and that community has just really become professionals on fitting as much as they do into these EVAs and safely completing the activities.

Host: Yeah. Okay, so let’s go right into it. Now, let’s say we have a task that we want to complete. At what point do you start planning for an EVA?

Art Thomason: Well, that’s a tough one. It really, it really depends, I would say, generically it’s probably a year or more out and so—

Host: Wow.

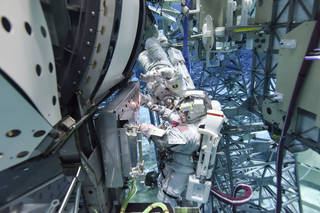

Art Thomason: You know, the first thing that we like to do, and we don’t always get the chance to do this, but is to do development runs on the hardware. So what that means is get a mock-up built of, if it’s something new that’s going to come to Space Station, we get the drawings for it early, put it in the Neutral Buoyancy Lab, get a mockup built, and get crew members to assess it. So make sure it has all the right interfaces. We can access all the bolts we need to access, handle it. It has right hand rails that we need, and we can affect the design, if there’s something that we need to change. So, if we can catch it early enough, then that’s great to get that input in and get something that is easier for us to use on orbit. So that’s kind of the first phase. From there, we wait until we get a little bit closer in as to where that’s going to be integrated into a specific EVA. Usually that’s more on the time frame of maybe six months out when we would start really putting all the pieces together exactly, the order of things, you know, what we’re going to be able to fit into this next EVA.

Host: And this, is this when you start considering everything that’s going to take place during this six and a half hours? So if you have a single task, you know, I know, I notice even you have this time, right, six and a half hours, and there’s a reason for that, so you want to use it to the fullest extent. Are you considering what else can we do during this time?

Art Thomason: Definitely.

Host: Yeah. Actually, what is the reason behind six and a half hours?

Art Thomason: Well, so, it’s basically the consumables on the suit.

Host: Oh, okay.

Art Thomason: Yeah, so. You know, the main things that we have to think about are oxygen, so, you know, you have an oxygen tank, and there’s limited amount of oxygen in there. You’ve got battery power. You’ve got water for cooling. So that water, there’s a sublimator, basically an ice pack that built on the suit, and so you do lose some water to that ice pack, so over the course of the EVA, you deplete water out of the system. And then the one that limits us the most is the CO2 scrubbing capability. So, you know, the oxygen that you breathe out is, or the air that you breathe out is still reused and it goes back through a CO2 scrubbed because, you know, you don’t want that CO2 to build up in the suit. So, that CO2 scrubber works great until you get close to the end of the EVA, and you’ll start to see CO2 levels start to increase a little bit, and that’s when you know that the CO2 scrubber is kind of used up.

Host: Yeah.

Tara Jochim: And our history on that, you know, tells us around six and a half hours is the time that we want to plan for. So the teams then go off and figure out all those tasks and all those puzzle pieces and how do we fit them into that six and a half hours. And it’s not all six and a half hours of doing EVA. Right. So, the crew has to get out the door, get out of the air lock, get out the door, acclimate themselves to being outside, you know. A lot of, as our newer astronauts are being flown, they’ve never done spacewalks, so it takes a few minutes of getting out there and really getting your space legs, I guess, so to speak. You know, being able to translate walking in space with their hands, figuring out how to do that. They have to set up the area that they’re going to go work in. So, sometimes areas don’t have a place to stand on, so they set up special foot restraints. So the crew member in this suit can then go and stand in that location and have both their hands available for them to use their tools or to take their photographs or whatever it is they need to do. So, there’s lots of things that go into that six and a half hour time period.

Host: Right. Because, yeah, it’s not just, you know, okay you’re going to go over and you’re going to turn this bolt, right. You have to get the drill. You have to get the little foot stand so you can put it into the right place so you can get to the spot so you can use the drill. There’s a lot of different steps that happen.

Tara Jochim: Right. And to get just to that point, the flight operations team and the hardware developers and the astronauts on the ground have spent a lot of hours developing how long that’s really going to take and the exact position of how that foot restraint is going to be when they get out there, what the handrails are that they’re going to use to get to that spot, and how they’re going to turn that bolt. So, there’s a lot of work that goes into that seemingly simple task of just going out and turning the bolt.

Art Thomason: And even things like the torque value of the bolt. If the hardware provider says that this is going to require a lot of torque, then you really want to have your feet in something so you can react to that torque, but if it’s, hey, this is a very light amount of torque, I can hold onto a handrail with one hand and drive it with my cordless drill, so there’s a lot of those things that factor into how we want to approach a task.

Host: Yeah, that’s true. Huh? I guess I wouldn’t think about that. Every action has an equal and opposite reaction. So the drill, if you need to turn it too hard, you’re going to go with it if you don’t have enough restraint.

Tara Jochim: Right.

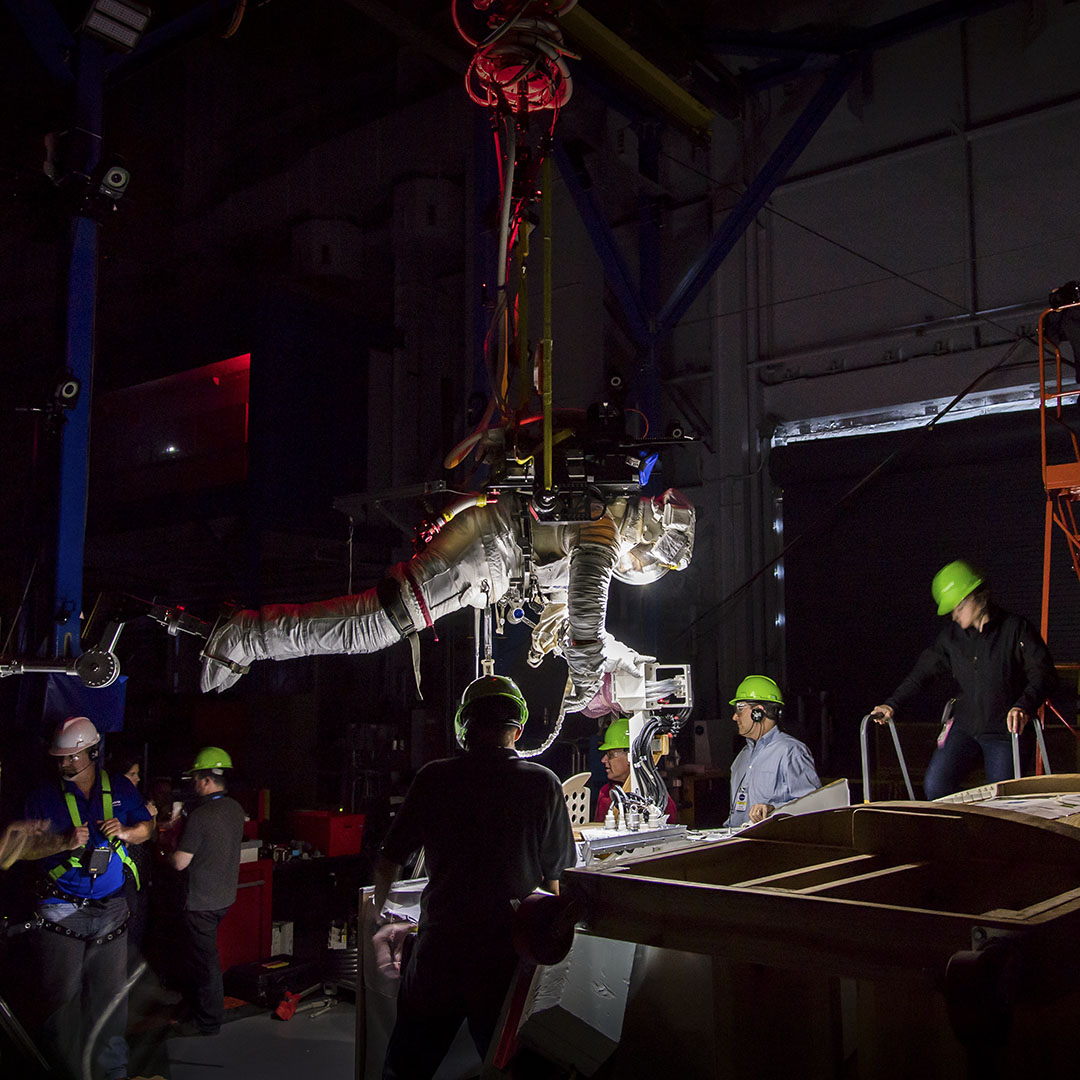

Art Thomason: That’s right. And, you know, that’s one of the training facilities we have on the ground is something called POGO. So it’s basically a system that suspends you, and we do that over in the mockup facility over here in building 9. And it’s great because people, it’s eye opening when you see someone do it for the first time. When they start to drive a bolt, they spin around if they’re not holding onto anything, so that’s kind of the first experience they get with that. You have to react to that torque, even if it’s small.

Host: Yeah, so the astronauts themselves are preparing for a spacewalk here on the ground with different, I guess, ways to practice, POGO being one of them, right? Suspends you above the ground. The one we talk about a lot here is the Neutral Buoyance Laboratory, right? So, what are they doing there? Do they practice these specific runs, or are they just gaining basic skills? What are they doing there?

Art Thomason: A little bit of both.

Tara Jochim: Little bit of both.

Host: Oh, okay.

Tara Jochim: Really.

Host: Cool.

Art Thomason: So, as far as the generic flow that each astronaut is going to go through before they go to Space Station, we try to develop a skills-based training program. So we have a set of runs that they should be able to see all the skills that they need to perform any spacewalk that we can conceive might happen. So, a lot of it is for critical contingency EVAs, which are failures on station, which would leave us to where we’re, you know, the next failure makes it to where we have to de-man stations. So those are the important ones. So we make sure they see all of those.

Host: Yeah.

Art Thomason: And with that, we also make sure that they have all the skills. So if they’ve changed out, you know, one big box that has two bolts on it, and there’s two other boxes that do something totally different but have the same interfaces, then we really don’t need to show them all of those. They know how to change out a box with two bolts on it. So, we try to minimize the training and make sure they’ve seen kind of every type of hardware that they may run into.

Host: Yeah, that’s right. It makes total sense. And one of the basic skills you want to have in your repertoire is if something goes wrong, you want to be able to turn something around real quick.

Art Thomason: Yeah, right.

Tara Jochim: Exactly.

Host: So a lot of these spacewalks are planned, like you said, a year, maybe more in advance, but if something goes wrong, you want those skills right on hand so they can go right out the door.

Tara Jochim: Right, since you have people living on Space Station 24 hours a day, every day of the year, they’ve got to be able to go out and take care of themselves effectively. Whereas before in the shuttle era, the shuttle would, you know, we would train. They would launch. They’d be on orbit for maybe two weeks, and then they’d come home. And they would have their skillset built up around what they were specifically doing on that mission. For Space Station, that’s such a broader picture. So, operationally, we had to figure out, gosh, how do we train these crews to go off and do all these different tasks? So, Operations had to come up with this kind of generic set of tasks that cover this broad range of activities. So where we used to train shuttle crews specifically for this very specific, very choreographed, six and a half hours for an EVA, now they get a lot more general training of, you know, we think these are the activities that are going to come about when you’re up on orbit. So we’re going to show you these as you go through your training flow. They may never actually see the whole six and a half hour EVA on the ground before they go perform it in space.

Host: But they have those basic skills?

Tara Jochim: Absolutely.

Host: How to move, how to use certain tools, how to position and hold yourself so that you’re not turning with the bolt, right, like we said before.

Art Thomason: That’s right

Host: There’s a lot of these skills that are super important. You know, on the topic of tools and designing some things, I’m trying to figure out, trying to imagine, we’re talking about a drill, but I know there’s a lot of other things that they can use. What are some examples of tools that are designed specifically for a spacewalker to interact with, like you said EVA certified, or the requirements outside?

Tara Jochim: Got that?

Art Thomason: Well, yeah, we have a lot of tools. Actually, I mean most of them are things pretty similar to what you’d find in your garage. I mean–

Host: Really?

Art Thomason: The cordless drill or what we call the pistol-grip tool is what we use probably the most. That’s what we use to drive bolts. It’s really handy that you can program in a torque and the RPMs that you want it to turn at. And so that’s great from a, you know, hardware standpoint, because hardware has different requirements, so that’s a lot easier than setting a torque wrench or something along those lines.

Host: Yeah.

Art Thomason: And we also have ratchet wrenches, and it works just like the one that you have in your garage. Those are, I think, two of the tools that we use the most. Aside from that, bags are a huge thing. So a way to carry a bunch of tools to a worksite. You know, so there may be a case where were removing a bunch of caps or those kind of things. So, if we can take everything that we need to do the worksite in one bag as opposed to carrying a bunch of little things that are going to kind of float around and get into your field of view and potentially get lost, and that helps a lot. And there’s been a lot, you know, cable routing is something that we also do. So we’ve developed some bags specifically for cable routings that kind of have shelves, if you will, or layers, so that we can keep all the bundles of cables separate so they don’t get tangled together.

Host: Oh, yeah. Okay.

Tara Jochim: Kind of like going behind your TV, and you pull out this big wad of cabling. You know, you don’t want to do that. You don’t want to go to your EVA bag and pull out this giant wad and think, okay, where does this connector go.

Host: Yeah.

Tara Jochim: So they do a really nice job of keeping it very neat and organized. So if they have to go and install a new power cord or a new data cable or anything like that, they can lay it out smoothly and lay it on station to use in the future.

Host: I’m imagining the frustration of looking behind the TV and thinking, oh, no, this is something I’m going to have to deal with now. I can imagine being in a space suit now and you’re already, you know, a couple hours into this EVA, and all of a sudden, oh my gosh, I have to untangle all of these. Yeah, that would be, that would be pretty bad.

Tara Jochim: One other thing that I think people forget about when you’re doing spacewalks that’s different than just being on the ground is everything you use has to be connected to you or to Space Station.

Host: That’s right.

Tara Jochim: So, you yourself and the big white spacesuit has to be connected to Space Station with what we call a safety tether. So, they’re always positively attached. So in case they were to let go of their hand rail or have some problem, they’re still attached to Space Station. Same thing for all the tools that we use, all the hardware, all the bags, all these things have to be connected up. So every time you go reach for that wrench, it’s connected to a tether. You go use that wrench, and you have to leave it on the tether, and you go put it back in the bag. It may require you to change that tether from you to the bag. So there’s all these extra actions that you have to do as you go off and perform this simple turning of a bolt kind of activity.

Host: Wow. How detailed are these actions? Do you literally have, okay, now step one, take tether, move here. Step two, move over to this side. Step three. Is it get into that level of detail?

Art Thomason: Yeah, it definitely does.

Host: Wow.

Art Thomason:You know, when you’re in a spacesuit, there’s a lot of stuff that you have to think about, and you kind of have a tunnel vision in a way that, I mean, you can’t turn your head and look, yet. You really can see what’s right in front of you, and if I tell you to go somewhere, you know, that’s ten feet away, it may not be obvious what that path is by just turning and looking there. So, by us telling them, okay, you’re going to look for this handrail and then, you know, head up to your left or your right from here, that helps them know where they need to go. Also, you know, by having detailed steps, and we do, like you said, have detailed steps, get this tool out of the bag. Drive this bolt for this many turns at this torque, and we tell them when to do it. There’s also things that are happening behind the scenes on the ground that we may have to power down a connection before they pull this box out or they’re going to be demating a hot connector. So, that we have to verify on the ground that that happens before we give them the go to do that. So, you know, we try to give them very detailed instructions so that there’s less things that they have to think about on their end, and they can just do the work.

Host: Wow.

Tara Jochim: Then it gets even crazier when there’s a problem. The team on the ground has to have thought about what are all the problems that could happen if they go to turn this bolt. Do they need a higher torque. Do we need to turn it more times? You know, what are our options? So they have all those options figured out, because again, you only have six and a half hours that you’re outside. You can’t wait around for an hour for the ground to come back and say, oh, let’s do it this way.

Host: Let’s do an assessment, yeah.

Tara Jochim: Right. So all those things have to be thought about ahead of time and figured out and documented in your procedures to say if part A doesn’t work, then let’s go to part B and move from here. So, lots of work ahead of time just to do that simple six and a half hour EVA.

Host: Not only are there detailed procedures, but there’s little branches off of every section, okay. Okay, if at this point something goes wrong, you can do this, you can do this, you can do this. Basically a list of troubleshooting things too.

Tara Jochim: Right.

Art Thomason: That’s right, yeah. And, you know, it’s one thing for us to come up with ideas, but a lot of times our plans will affect a lot of other things.

Host: Yeah.

Art Thomason: So, that’s why we have these meetings ahead of time. Okay, if we did this as our backup plan, what does that do to these other systems, and they’ll have inputs, and we’ll kind of have to all work together to come up with an agreed to plan so that we don’t have to have, you know, this meeting that took us an hour in real-time. We already have agreed to work around for that and can tell the crew what they need to do.

Host: Wow.

Tara Jochim: And that they already have the tools with them.

Art Thomason: That’s true.

Tara Jochim: They took them with them outside to be able to go do that plan B. So, lots of choreography.

Host: So tell me about the team that’s actually working through this. How big is the team? Who is approving everything? How are we going through all the steps? What’s going on there?

Tara Jochim: It’s a very large community with lots of different groups that all play different roles.

Host: Okay.

Tara Jochim: I’ve often likened it to a movie production. You’ve got your astronauts are kind of your actors, and they’re the ones who are going off and performing the activity that’s going on. And you have your flight operations group. They’re the directors telling the actors, hey, this is how you need to go off and do this. And then you have a group of management so to speak, and some other offices that help with the production side, right. They make sure that all the tools are there and the spacesuit is there and the directors and the actors have all the things that they need to safely go off and complete the EVA. So there’s a large group of people that get involved in the different activities. It takes quite a while, a lot of interaction, and definitely a group effort.

Host: Wow. Yeah, yeah, it takes a whole movie production. I’m actually, that was a great analogy, because I was imagining all of that. That’s fantastic. But I’m sure, you know, there’s the creative side of the, you know, movie world, and then there’s our highly technical, acronym-driven world, world of NASA. I do a commentary for EVA sometimes, and it is, it’s is very difficult to keep up, and it takes a lot of studying beforehand to know what I’m talking about, because my job is to translate to everyone else. Hi, this is what they’re talking about when they say EVA, PCB, LOL, you know, that kind of thing.

Art Thomason: Yeah.

Host: Okay, so let’s jump to day of. Now, we’re getting ready. Everything is set. Who is supporting the team in mission control and behind the scenes helping out, getting ready to get everyone ready for the day?

Art Thomason: Well, so getting ready, I mean the way that the console works is we have three shifts. So what we call is in orbit one and orbit two and in orbit three. So, typically, the orbit one shift is the one that’s there when the crew is getting ready. So that means they’re getting in the suit. They’re doing their prebreathe, which is, you know, hours long. They need to breathe 100 percent oxygen on a mask. Then they get in the suit, do more prebreathe and exercise, and this all happens before they go out the door for a six and a half hour EVA. So that’s kind of the orbit one shift, and so, you know, we’ve obviously got EVA team there, which would be a front-room EVA person as well as some backroom people that are also, you know, looking at data, looking at the details. And we’ve got a flight director. The flight director is in charge of the vehicle, so they’re the ones that make the ultimate decisions, but we’re kind of experts on the EVA piece of the system, so we’re the one advising the flight director on what’s going on. So, you know, we’re keeping up with what’s going on and looking at data. You know, as long as everything goes well, it’s just a matter of kind of keeping pace with them and looking ahead. And then we get to the orbit two timeframe. So that’s right about the time they’re getting ready to depress the airlock and go out the door. So, at that point, the execute team, is what we call it, comes on.

Host: Okay.

Art Thomason: So they’re the team that planned the EVA. They were the ones that spent the hours in the NBO runs and writing procedures and coordinating the plan with everyone. So they’re the experts on it. So they come out and are there for the crew when they’re outside.

Host: Okay.

Art Thomason: Performing the EVA. So then the crew comes back in, re-presses, and starts to get out of the suit. At that point, we transition to the orbit three team, they’re the team that helps, you know, get the crew out of the suit, any of the kind of the cleanup of the suit and maintenance after the fact. They support that. And then if there’s any kind of replanning to get ready for the next day, they’re there to do that. If there’s any anomalies or those kind of things, they log that data and make sure that all gets captured.

Host: Wow, okay.

Tara Jochim: Yeah, if you ever have a chance to listen to a spacewalk, any of the folks listening to this, it’s a really interesting process to watch and to listen to because it is such a well-oiled machine. The, you know, the flight director is in charge of the vehicle and everything that goes on there, and then there’s the capcom, who is generally another astronaut. There actually the one that speaks to the astronauts in space. So those are kind of the conversations you would hear, but there are so many people that support that in the back ground that are all commenting very quickly on what’s happening to that person in the front room. And there’s lots of other support from the EMU, the space suit specialist and the space tool specialist and the safety people, and, you know, all the other mechanical systems associated with the vehicle itself. So, there so many people in the background that we may not see on TV but are just an integral part of the whole process, being successful and running so smoothly as they do.

Host: Absolutely. Yeah, you were saying there’s someone right behind the flight director, just kind of watching over things, but then you have more people in other rooms listening in, and it takes a huge team to make this happen. That’s awesome. Going off of your point, Art, it sounds like, I mean that’s a long day for the EVA teams, right. You’re getting in early. You’re doing a lot of the prep. Then you have the actually execute team, the debrief team. A long day for the crew too. I was thinking about that, getting up and breathing for a few hours. We already talked, this is a six and a half EVA, then your day is not done. Then you have to do a lot of stuff afterwards. That’s a long day for the crew, how long does it actually add up to at the end of the day, do you know?

Art Thomason: I don’t have the exact crew dailies, but, you know, you spend about an hour on a mask where you’re breathing 100 percent oxygen.

Host: Yeah.

Art Thomason: Then you get into the suit, and that’s about three hours or so of just being in the suit and doing what we call light exercise, which is, you know, moving your legs. It’s just a way to kind of get the nitrogen bubbles out of your body so that doesn’t build up when you go to a lower pressure out in space. And, you know, then you depress for about 30 minutes, and you’ve got the six and a half hour EVA, and it takes you about 30 minutes to come back in and re-press and kind of get out of the suit. So, you can do the math, but a long time in the suite.

Host: Yeah, I mean I’m taking myself mentally through this day, and I’m just getting hungry just thinking about it–

Tara Jochim: Yes.

Host: Just not eating for that long.

Art Thomason: Yeah.

Host: When it comes actually down to going out the door, this is an interesting thing. I think it’s the official start of the six and a half hour day is not when they go out the hatch, right. It’s actually when they switch to battery power?

Art Thomason: That’s right.

Host: Why is that?

Art Thomason: Well, I can’t tell you exact reason for that. That’s just kind of when we start the EVA.

Host: Oh, okay.

Art Thomason: Yeah, so they’ll depress. They’ll go down to vacuum, still in airlock, and then they’ll be on vehicle power so that they can preserve battery power.

Host: Okay.

Art Thomason: And so at that point, once they are getting ready to go out of the hatch, they’ll go to battery power, and that’s just what we call the start of the EVA.

Host: Yeah.

Art Thomason: I guess, you know, there’s a history behind that, but it seems to work pretty well for us. So it’s really about the time that they are going to start doing work and, you know, doing the planned tasks for the EVA.

Host: Yeah. So how, the teams are looking at all the tasks, you know. We have computers, we have mission control, right. How was the crew kind of following along too? Is everything in their ears? Do they have some sort of checklist on their arm to follow along?

Art Thomason: Well, it’s pretty much just what we tell them. So, I mean, you know, they’re able to hear what mission control is saying. If for some reason the crew inside the Space Station needs to talk, everyone is on the same loop. They’re on space to ground one. So the crew in the suit is hot mic’d, so anything they say is going to go out on that space to ground one loop. They do, as far as checklists go, they do have what we call a cuff checklist that they wear on their wrist. This is primarily for emergencies. So, even if they lost comm or communication with us, and they get a message in their caution warning system on their suit, they can go to their cuff checklist page, and you know, if it, whatever the message is, there is a page for it, and it tells you how to respond to that.

Host: Okay.

Art Thomason: And so, you know, in most cases if they do get a message, we’ll see that on the ground, and we’ll be able to kind of talk them through that, but that cuff checklist page is there just for emergency. But they also have some blank pages. So if there are certain pictures or things that are going to help them along the way, they’ll put those in there as well as kind of memory joggers.

Host: Yeah, that makes sense. Because the last thing you need to do is drill and then flip to the right page and then, you know, where are you going to put the drill. Yeah, that makes a lot sense. So, besides actually the procedures themselves, you know, we’ve already talked about, they have step-by-step instructions. They know exactly the path of where they’re going to go and which handrails they’re going the grab onto, right. This is an important thing, handrails. And this is actually, you know, you can’t just design a tin can looking module. You got to install these things called handrails on the outside of them, because that’s how they move, right?

Tara Jochim: Right, right.

Host: Otherwise, what are they going to grab onto?

Tara Jochim: Right. And there’s all kinds of requirements associated with those handrails.

Host: Really?

Tara Jochim: You bet. How long they are, how much of a space can be between two handrails for the crew member to grab from one to the next, what the size of it going around it is, so that the crew member and their big snow mobile gloves can grab onto that handrail itself easily, right.

Host: Yeah.

Tara Jochim: Because we talked about those tactile things. You don’t want them to have to hunt and peck for a, you know, fingertip-type activities. They want to be able to easily move and work around their different worksites. So, yep, there’s all kinds of requirements. Sharp edges, that’s a big one that we deal with from a safety of crew perspective. You don’t want to put a cut in a glove, right.

Host: Yes.

Tara Jochim: We talked earlier about the crews throughout their EVAs have to check their gloves to make sure we don’t have any sharp edges. We found that the longer Space Station flies, the more opportunities we have to be hit by debris that’s flying in space, tiny little micro meteoroids. And sometimes that will hit pieces of metal, and when it does, it causes a rough edge or a burr to it, or has the opportunity to, and if the crew’s glove discovers one of those, we’ve found that it can put a little slice or a nick in the glove itself, so the crews now go off and take a look at their gloves every once in a while and give feedback down to ground to say, nope, my gloves look great. Or, hey, look at this little piece right over here. It’s torn in this area. The smart engineers go off that are experts in the gloves and take a look at that and say, no problem, keep going on. Or, you know what? We need to talk about this a little longer. Or, you know what? That’s the end of the EVA. We need to come inside for a safety reason.

Host: All right, yeah. That makes sense why you’re checking them so much, doing that analysis so the experts can make that decision. So you got all these little, you know, little, all right they predictable hazards or is it just you kind of have to kind of eyeball it, right.

Art Thomason: Well, we have both. So, yeah, I mean in some cases there’s hardware that doesn’t meet sharp edge requirements. A lot of times you’ll see that on certain payloads, that there’s, you know, maybe glass. You know, there’s a mirror or something, but it really has to be there for the payload to get the science that they need. So for those cases, we say you just need to stay away from it, if there’s a sharp edge.

Host: Makes sense.

Art Thomason: So that’s something that we would know about. But then there’s also cases where we have debris hits on the outside of station or handrails, and we get a lot of good pictures where we see those things, and so we know about some of them to warn the crew about, but there’s other ones that we don’t have photos for, and so, you know, that’s part of their job to kind of look ahead and be aware of their surroundings.

Host: Yeah, so you’re talking about translation, right, moving from one place to the other, using these handrails, are they– I’m guessing they are definitely designed ahead of time, right?

Tara Jochim: Right.

Host: You know exactly where you’re going. Are they designed as the fastest route, or is there kind of sensitive stuff along the way that you want to avoid?

Tara Jochim: A little bit of both.

Art Thomason: Yeah, it’s both, for sure, yeah.

Tara Jochim: Yeah, yeah.

Host: I’m asking the right questions.

Tara Jochim: You’re hitting it, right. All right. And again, it was a long time ago that a lot of these items were designed around the other hardware that was already in this piece of structure. Is there something that EVA has to go out and fix? Are there batteries out there or other items that an EVA crew member would have to go and change out? If so, then we have to provide a worksite for them. There has to be handrails there. The ability for the crew to position themselves in the worksite to do whatever that work, whatever that job is that they’ve got to go do. So, and the other thing that, you know, we didn’t talk about is it has to be able to, the structure has to be strong enough to take a person in a space suite carrying a bunch of other tools on them. It’s quite a large mess. So, if they’re going to be maneuvering themselves and using this handrail, that handrail and the structure that it’s attached to has to be able to take that load that that crew member is putting into it. So lots of that analysis in review, and data gets done ahead of time so that the crew member knows that we can be in this area safely.

Host: Yeah. I’m loving this topic so far because we’re going through, you know, how to plan a spacewalk. It’s just all these little things you have to think about throughout the whole time.

Art Thomason: And one thing that we do send up to the crew before they do an EVA is, and a lot of times it’s a, there’s a few different tools we have, and I’ll get into that.

Host: Yeah.

Art Thomason: But we have a plan for their translation path.

Host: Ok.

Art Thomason: So, you know, some of it will just be a picture of Space Station and will light up the handrails that they were going to use to get out there, so they can see, okay, this is where I’m going to go. And, you know, I’ve talked to some crew members, who if they have a good window view they’ll go and look. Okay, yeah, that’s where I’m going to be doing. So they can look, you know, days ahead of time to see if there’s anything that’s, you know, unusual or different than they expected and get familiar with that translation path.

Host: Okay. Now, besides, you know, beside the procedures themselves, the step-by-step instructions, what are the teams looking at to make that everything is going smoothly? You already mentioned consumables. That’s one of the reasons that it is six and a half hours. What else are you looking for along the way?

Art Thomason: Well, so, we’re definitely looking at the clock as far as, you know, what we have planned for the spacewalk and are they still going to be able to fit it into the six and a half hours. You know, so that’s one of our biggest challenges sometimes is if they’re running behind, and you know, sometimes you run into a problem or something that you didn’t expect that takes a little bit later, you know, you go through the crib sheet or the anomalies and, you know, you get the problem resolved, but now you’ve spent an extra 30 minutes. So, now is there some way to kind of make up that time? Can we go a little bit longer? Those are all the things that you kind of think about. And, you know, we think about those ahead of time so that we don’t get ourselves into a bad situation. We want to make sure that we at leave the Space Station in a good configuration. You know, we don’t take some critical power box out and then say, oh, now we’re out of time and don’t put something back in there. So, you know, we make sure that we have a plan for even if we are running behind, what do we do and how do we leave station in a good configuration and most importantly getting the crew back in safely.

Host: Yeah. So just based on your experience actually executing spacewalks takes so much energy to plan everything, and it actually works out, but when it comes down to it, how much real-time decision making is going on?

Tara Jochim: I think it really depends on the spacewalk and what the activity is, right, and how well it follows that timeline.

Host: Okay.

Tara Jochim: Sometimes, they go through very quickly and they’re able to accomplish things very smoothly and they’re ahead of the timeline. And then you have to figure out, you know, we have some extra tasks that we set aside. We call them get-ahead tasks. So if there’s time at the end, you know, we could fill in this open space with these get-ahead activities. You know. Is this the right time to plug that puzzle piece in and decide to go and finish that EVA and make it a whole 6, 30. Or, you know what? Do we come inside at six hours and consider it a success, we’ve gotten all of our main requirements done. So, some of those discussions happen real-time, as you’re stepping through the EVA. Boy, it’s the best group in the world doing this activity. They really got it down to a fine art watching it all happen.

Host: That’s right. So one of the first spacewalks that I did commentary on, I trained a lot. I got to sit in mission control, and here I go, you know, I’m just going to follow the procedures. It just happened to be the one where one of the shield on the outside of node three, I think that they were going to put, was inadvertently lost, and then you just see it kind of going away. This is one of my favorite spacewalks, even to this day, even though this was, again, my first, one of my first, so I was very nervous on air.

Tara Jochim: It was very memorable.

Host: It was extremely memorable, but can you kind of go over what happened and then how we fixed it real-time.

Art Thomason: Yeah, and so there was a lot of things that led up to this. So, for one, the shields were really large, and so it was going to be almost impossible to take all the shields out on one spacewalk to go and install them. So we planned ahead, saved some of the shields outside on an earlier spacewalk. So, they set outside for months, and then the crew went and picked those up. And so the way these shields were made is that they were folded in half, and then there’s a lot of other straps on it. So, there’s tether points, which is, that’s how you’re going to, you know, put your tether to, attach it to that so that you can translate to the worksite, keep the thing tethered all the time. So, the problem is what happened is one of the straps kind of got folded under, and so it looked like a tether point. And so the crew tethered to it, and it seemed to hold until they got to the worksite and put in a little bit of extra force, and it came undone, and so their hook just slid off the end of that strap. But, from, you know, and again, you kind of have tunnel vision in the space suit, so from their perspective, all they could see was that everything was working great, you know, until it started to float away.

So the kind of a perfect storm of how they lost it, but as far as the path to, you know, figure out what to do, we were kind of lucky in some ways that we had removed a thermal blanket earlier in the spacewalk from, you know, a different component of Space Station, and teams started thinking immediately, okay, you know, now that we’ve lost this shield, it was one out of four shields, what do we do to fill this quadrant that doesn’t have a shield? So, one thing that we do that I think is a great practice is in one of our back rooms we have as many tools as we possibly can. So we had the shields in the room, and we also had the other blanket that we had taken off. So we could lay those things out on the floor and see, okay, yeah, it looks like this blanket is going to fit there. And so that part of it was great, and we were able to use a model to show what handrails we could tie that blanket to and to tell the crew what to go to, but then there was also the piece of, is this blanket going to do the same thing as the shield. So there’s an engineering team that has to run the analysis, both thermal and from micrometeoroid. What’s going to happen? Is this actually going to do the job, or are we going to install this and realize we got to come back out later and fix it? So, it was great that they were able to do all that stuff real time and determine that, hey, this is going to meet our needs and we had the crew install it and, you know, it turned out to be a really successful EVA.

Host: Yeah, that was one of my favorite moments. You lost a shield but figured out a way on how to cover it and did all this analysis to make sure it was going to work, and if I’m not mistaken, I think everything on that EVA that was planned still got done, if I’m not mistaken.

Art Thomason: I think that’s right.

Host: Yeah. One of my absolute favorite moments. It was really cool. One of the big things we learned just from doing spacewalks, this is actually one of the recent things, I think it happened in 2013 when Luca Parmitano was on a spacewalk, and there was some water in his helmet. Can you describe what happened there and then how we fixed it and then what came from that?

Art Thomason: Yeah, so on the spacewalk, Luca reported that he started feeling some water kind of on the back of his neck, back of his head.

Host: Yeah.

Art Thomason: And, you know, we had seen similar things before where, you know, a drink bag– so they have a drink back, there’s 32 ounces in the suit, so if that leaks, you’re going to get a little bit of water there. You know, there’s maybe some other cases where you might get a small amount of water. So, initially, that’s not something that necessarily concerns us, but as time goes on and it has started to increase, it became a bigger deal, and the team quickly realized that we’re going to have to call this spacewalk and get him back inside. So, as he translated back, things seemed to be going well, but, you know, the way that water behaves in microgravity is a lot different than on Earth, so, and because of surface tension, it wants to hold together. So, as he turns the corner, the blob of water kind of went to his face, and so then it caused a lot more problems, so it made it to where it was, he couldn’t hear very well because of the water in his ear cups and the speakers that he has, and then we couldn’t hear him because it got onto the microphone as well. So, you know, it quickly turned into a really bad situation, but he was able to get back into the airlock, and Chris Cassidy was there with him and was able to get eyes on him and communicate with him, you know, by hand squeezes, and make sure that he was doing okay.

So they got him re-pressed as quickly as possible, and everything was, you know, turned out okay for that EVA. And what we did find out was there was, due to contaminated water, when the suit was filled on the ground, there was just very small particulate in there that clogged what we call a water separator, and so that’s something that kind of is designed to get the water out of the vent loop, but because of that failure it actually, it had the opposite effect, it had actually flooded the vent loop. So, you know, water from the water system was now able to come into the ventilation system, and that’s what we ran into. But, you know, since then, obviously we’re much more careful about what water goes into the suit as well, but we do different checks, so we do conductivity tests of the water, and so that kind of determines what the particulates are in the water. But then, you know, more, from a more simple standpoint, we have an absorbent, kind of like basically a diaper that goes in the back of their helmet.

Host: Right.

Art Thomason: So, if you did get a lot of water built up there, that diaper would soak the water up. And so we kind of have an idea of how much water we think we could get, and so that’s able to absorb most of that. They also have something called a snorkel, which is just a tube that’s up near their, by their chin, that goes down farther in the suit. So, if they did get water near their face, they could breathe in through that tube to get air from another place in the suit and then just exhale out into their helmet.

Host: There you go.

Tara Jochim: Yeah, that whole thing. I was on console as well–

Host: You were.

Tara Jochim: And it was just and awesome example of the team under pressure, working as a well-oiled machine. It was a—what could have been a very scary and terrifying moment was handled very professionally, and they got the crew back inside safely. And, you know, after that went down through the process of figuring out what the problem was to get us back out and we’re doing spacewalks again. And so it was just, it was a really great example of how well this community works through challenges that are thrown at them, especially real time.

Host: Oh, yeah. And this is why we do all this practicing, right. And a lot of what you train, even Art, you were saying, the things that they have in their arm are in case something goes wrong. You know, there’s a lot of things you got to consider ahead of time, and that’s why, that’s why we practice. It’s really an amazing feat.

Art Thomason: And, you know, the other thing is, this suit was made with ’70s technology. It’s been around a long time, but this was not something that was on our radar that it was a possibility to happen. And so, you know, since that’s happened, our cuff checklist, we’ve added a page about water in the helmet and how to deal with that, but it wasn’t something that, you know, initially at the time Luca didn’t have a page that addressed that.

Host: Right.

Art Thomason: So we’re continuing to learn even though, you know, stuff’s been around a while.

Host: Yeah, there’s a lot of cool stuff in the suit. I mean, besides these little things, just from this mishap, one of the things, I think is super interesting is I think called the Valsalva. It’s something you wouldn’t think about, but, you know, you’re in a suit. How do you itch your face? How do you pop your ears? It’s like this little nose cup, right, and you can itch, and you can–

Art Thomason: Yeah, so anyone that scuba dives is probably familiar with the need to Valsalva, and so, you know, some people can just kind of wiggle their ears, or you know, that kind of thing. But other people you have to hold your nose and kind of blow or apply pressure, and that clears your ears. So, you definitely need to do that when you’re coming back in from a spacewalk.

Host: Yeah. So, speaking of coming back in, we talked about going out, switch to battery power, that’s a start. What about coming back in? When does it end, and then what are you doing until final cleanup?

Art Thomason: So, the start of re-press is when we stop the clock on the link to the spacewalk.

Host: Okay. And then getting ready for, how do you, you know, take everything off and all that?

Art Thomason: Oh, yeah. So, you know, once they get back in and start the re-press, that’s something that’s, you know, surprisingly simple, which is great, because it’s something that you really have to be able to do. I mean of all the thing you do in a spacewalk, you have to be able to re-press.

Host: Yeah.

Art Thomason: That’s, you know, probably the most important thing. So, it’s basically just a valve that opens up a hole and let’s air from the station come back into the airlock and fill the airlock. So, the crew members do have the discretion of kind of throttling that valve if you will, so they can let their ears equalize, use the Valsalva, those kind of things. So, once they’re completely re-pressed, they can open the hatch, and then they come in and get out of the suit. At that point, it’s really the IV crew member, the person that’s inside helps them get out because it’s pretty touch to reach some of those interfaces and work them when you have gloves on your hand. But it’s, you know, a matter of de-pressing the suit. So the suit is, when you’re outside, it’s 4 PSI above ambient, but once you come back inside, you go down to about 1 PSI. So you still have to depressurize the suit. So you make sure that you’re equalized, and at that point you start taking the components off. We take the gloves off first, because if you took the helmet off first, you wouldn’t want there to be a little extra pressure held in the suit, and then, you know, hit your chin or your nose, those kind of thing.

Host: Okay.

Art Thomason: So we take the gloves off first, and once we know that we’re completely equalized, and they can take the helmet off, and then from that point they disconnect kind of the pants from the shirt area. And so, you know, where we call the heart upper torso, that’s a fiberglass piece of the suit, and so that, I think it’s not so much like, you know, putting a shirt on. It’s more like you’re climbing into this piece of equipment is the way that it feels, I think, when you’re getting in and out of it. So, yeah, to get out of it, it’s kind of a trick that, you know, you have to get your shoulders in the right position so that you can come out of the bottom.

Host: Yeah.

Art Thomason: And then, you know, from there, I think that’s the hard part, getting in and out of that hard upper torso is probably the most difficult part.

Host: How long until they get to have some food?

Art Thomason: Pretty much immediately after that.

Tara Jochim: Like right away.

Art Thomason: Yeah.

Host: I know I would. [laughter] That’s a long day. So, we were talking about on the outside having translation paths, dealing with, you know, sensitive equipment, watching out for payloads, things that you don’t really want to interact with. I think that’s a nice segue into this Alpha Magnetic Spectrometer spacewalk that we have coming up, because you’re talking about dealing with really sensitive equipment Literally that is the definition of the spacewalk, right.

Tara Jochim: Right. Right. Yeah, this is, this is really challenging one for us.

Host: Yeah.

Tara Jochim: A few years back the AMS community has a lot of different sensors on their hardware and determined that some of their cooling system was having problems. So, they asked NASA, can you go off and repair this for us? So, for the last several years, the community here in Houston and some of the AMS collaboration around the world have been designing different parts of the hardware to go and bypass the cooling system that’s on this very large payload that’s outside. Whereas that’s a typical something we go off and do, go design a new spacewalk, this was unique in that the AMS was never designed to have EVA on it. So all these things we’ve been talking about, you know, the right requirements, having handrails and worksites and making sure it’s not sharp, making sure it can take loads. None of that was done for this area that we’re going to go work on. So there’s a lot of unique stuff that we had to go do in the last few years, lots of new tools, lots of new very specific EVA tools to go do these tasks. There’s a bunch of fasteners that usually when we go remove them on orbit during a spacewalk they stay captive.

They stay held onto whatever it is that you’re removing it from. Not here, not in this case. They’re very small fasteners, and we have to go and be able to capture them, make sure we don’t lose them and create debris. There are places with potential sharp edges that are out there. So there’s a lot of different stuff that we have to work around to create tools to help the astronaut in their big snowmobile suit and figure out how they can go and do these very challenging activities. So, it’s been a lot of fun these last few years, of really going off and designing something entirely new. I think what excites me the most about it is looking downstream into the future of EVA and thinking of future planetary spacewalks and those kinds of things. You know, at some point we’re going to have to go out and fix the habitat we live in, the cooling system that we’re in. Some of the stuff that we’re doing I think will definitely apply to those type of actions and activities that we have to do. We have to go in and cut stainless steel tubes and re-plumb a new system into it.

So we’re bypassing the old and installing a new system, and it’s stuff that we’ve never done on spacewalking. So, it’s really exciting. The new tools, pipe cutting tools, suage tools, all kinds of new stuff that we’ve had to go design. So, it’s been an exciting process.

Host: Wow.

Tara Jochim: Yeah.

Host: Yeah. It’s just, it’s just funny. I wanted to bring it up because you talk about how difficult this is to plan and all the intricate details, and then this is just you have to plan further back. You have to plan for a longer period of time, and then you have to do things with tools that you haven’t used before.

Tara Jochim: Absolutely. And so we’ve really had to come up with kind of new ways to train it as well. We have a facility where the neutral buoyancy lab, our water tank, is an awesome training facility for our spacewalking. It’s just fabulous. What we’ve had to do before we had the ability to get into the NBL, we had to go off and design our tools. That’s something that required really a different environment for us to get into. The Active Response Gravity Offload System, ARGOS, was a facility that was really just getting up and running here recently, and it’s something that we have used many times in the last two years to develop our tools. It’s similar to POGO in that you suspend a crew member over the top of a mock-up, and the crew then, when the crew puts a force into a motion that they’re doing, computer controls the astronaut and moves the astronaut in a method that would be similar to microgravity or whatever environment that they’re in. And it’s been a really awesome way for us to, we’d be able to go off and design a tool, 3D print it, go over to that ARGOS facility, put an astronaut in the spacesuit and test it. Have some updates to it and go through that process again very quickly. And it’s really been a benefit to the team to be able to go accomplish our tool designs, hopefully in a success manner.

Host: Wow. So not only do you have to design the tool, you have to test it out and make sure it works. And then, you know, after you finally designed the drill, you get into position, and you start drilling, and then you’re spinning. And you’re like, darn, we need a foot restraint.

Tara Jochim: That’s right, that’s right.

Host: Wow. It’s an amazing feat. It can’t wait to see it happen. Thinking ahead, and this is kind of a note that I kind of wanted to close on, is going through these procedures, what’s nice about the way that this is designed is it’s designed for real-time communication. You are talking to the crew the whole time, right. So you have this constant feedback. You have ground support that are solving things real time. You said they don’t even need a checklist because everything is fed to them in their ear. In what ways is it going to be different as we go further out into space? Moon, maybe will be a little bit easier because it’s not that delayed, but even, but especially Mars, when we have those really long communications delays.

Tara Jochim: Sure.

Host: What are we looking forward to for executing a spacewalk?

Tara Jochim: Sure, well I think there’s a ton of forward work that the operations communities need to go off and figure out exactly how to do that. We’re not quite that far yet, but I think some of the initial concepts are that they’re really going to have to be able to drive those EVAs themselves. Right. They’re going to have maybe an IV person that’s inside their habitat that’s communicating directly with them. And then when they need something from the Earth, you know, they’ll have to make a call and say, hey, this is going on. What is your input here? And that could take a really long time to get that communication back and forth, 12 minutes, up to 45 minutes. So you’re not sitting around waiting for Earth to respond back. So, it’ll definitely be a new way for us to be able to go and complete EVAs.

Art Thomason: And one thing we have seen on what we call analog missions, where we, you know, in some cases would go out to the desert and try to simulate this as best we could, is things like text messages seem to work better than maybe voice communication. That way you’re not talking over each other. You know, you just so happen to send something at the same time, and you say, oh wait, you know, we were talking at the same time you were. We didn’t hear you. Then you’ve got to wait another ten minutes before they respond with the answer. So, things like text messaging works a little bit better that you don’t get that kind of interference.

Host: Wow, that is going to be very challenging, but it is interesting. It’s not something I would have thought of. Now you’re not talking about ground support. You’re talking about someone from the inside, still having that real-time communication, but the expert is on the inside reading everything, they can still be listening.

Tara Jochim: Sure, so I think it’ll be a lot more communication prior to the EVA and really going through in detail what those activities are going to be, and hey, here is where you may see some difficulties or some issues. If you do, then you need to go to plan B, figure out, you know, how you’re going to take care of that real-time. So, you know, and maybe too that when you’re on a surface that you’re able to just come inside, radio back to Earth, and say, hey, this didn’t work. You know, plan for a few days, and then we’ll go back out again, and maybe that our time and abilities to do that will be easier and more capable than what we have nowadays.

Host: Absolutely fascinating. You know, Tara and Art, thank you so much for coming on and describing what it takes to plan a spacewalk. It’s a lot of work, and even executing real time, just a fascinating coordination of all of these people to go towards this task of completing a spacewalk. It’s really truly impressive. So I appreciate your time for describing it today.

Tara Jochim: You bet, thanks for having us.

Art Thomason: Thanks for having us.

[ Music ]

Host: Hey, thanks for sticking around. So, today we talked with Tara Jochim and Art Thomason about what it takes to plan and execute an EVA. We went into a lot of detail here. But the thing that they’re actually inside, and we described it on this episode, is literally a spacecraft shaped like a human body. It’s called a spacesuit. We went into detail about the spacesuit that they actually used to actually conduct the spacewalks on the International Space Station called the EMU, Extravehicular Mobility Unit. Check out Episode 16 to listen to that episode that goes into depth about spacesuits. Otherwise, you can see some of the things we’re doing on the International Space Station. Sometimes we actually broadcast some of these spacewalks live on Facebook. You can also check us out on Twitter and Instagram. If you have a question about any of this, just use the #AskNASA on your favorite platform and submit an idea for the show, mention Houston, We Have a Podcast, and we might bring it on here to answer or even make a whole episode out of it. So, this episode was recorded on September 6, 2018. Thanks to Alex Perryman, Bill Stafford, Pat Ryan, Kelly Humphries, Tim Hall, Stephanie Sipilia, and Jenny Knotts.

Thanks again to Mrs. Tara Jochim and Mr. Art Thomason for coming on the show. We’ll be back next week.