NASA’s X-59 requires the use of creative and strategic supersonic technologies to control and soften the jarring sound that hits the ground as the aircraft flies faster than the speed of sound above. One of these creative technologies is the placement of the X-59 engine inlet.

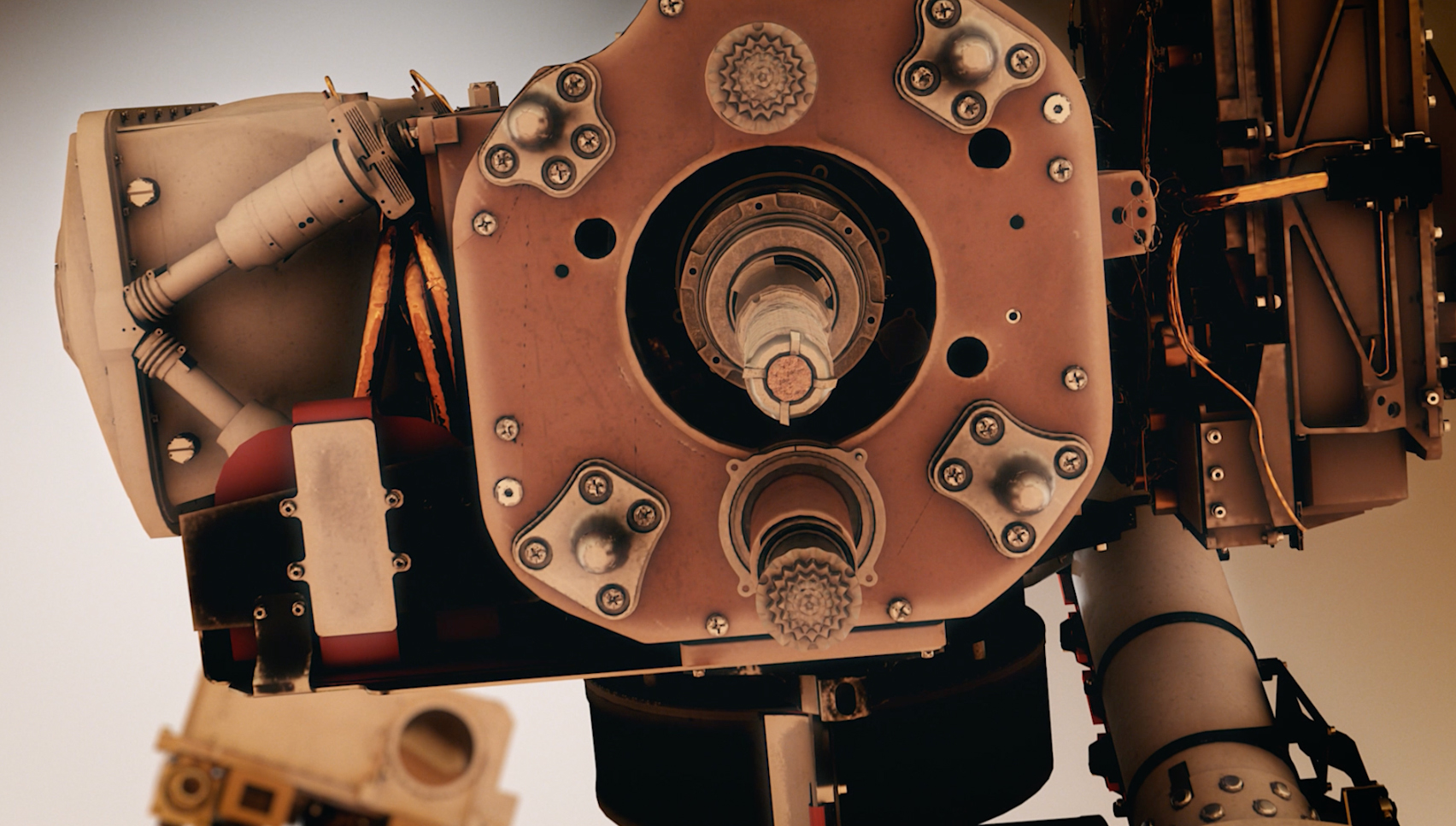

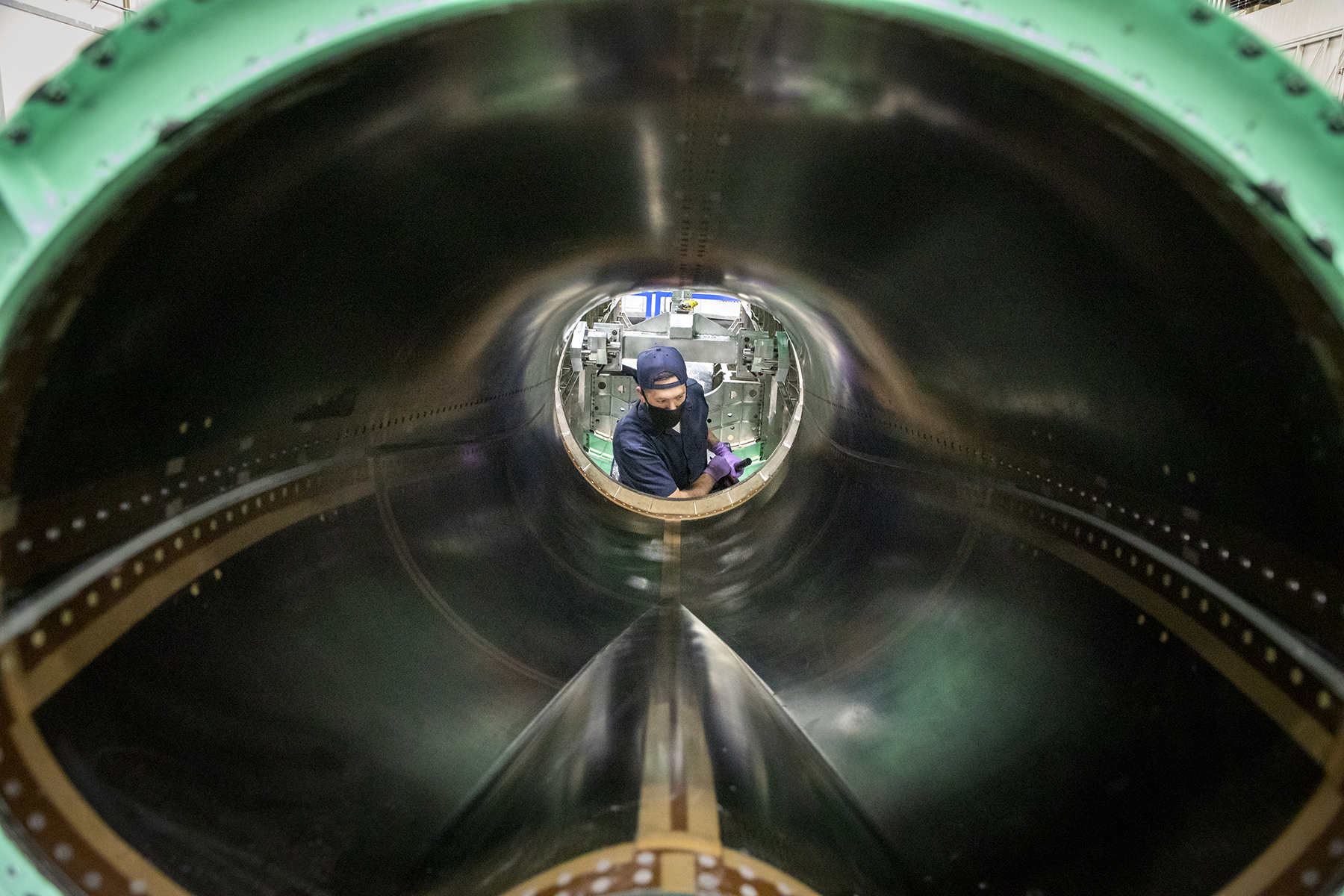

This visual is a closeup looking downstream inside of the X-59’s engine inlet where, later in the assembly process, the 13-foot GE F414 engine will be placed behind. The main purpose of the engine inlet is to condition or smooth out and slow down the air before it actually gets to the engine. Before the X-59 engine is installed, there will be pressure measurement sensors mounted to the inlet walls to help the team monitor the inlet air flow and flight test data for the X-59 aircraft.

Most of the time, the engine is placed on the bottom of an aircraft, but on the X-59, this section of the inlet and engine are mounted to the top of the plane. The reason for this is so the supersonic shock waves from the inlet and engine are shielded by the wing — one of the many ways that NASA reduces the sonic boom to a sonic thump. With the engine’s unique location on the plane in mind, the team conducts high-speed wind tunnel testing to increase confidence that the inlet will work as designed.

After proving the aircraft works as designed and can fly safely in the national airspace, NASA will fly the X-59 over several participating communities across the U.S. to understand their response to the X-59’s sonic thump. NASA will provide this data to federal and international regulators to enable them to consider setting new guidelines for the possibility of future supersonic commercial travel over land.

Image credit: Lockheed Martin