Quick Facts

Year Built: 1945

Historic Eligibility: Contributing Resource to Historic District

Year Demolished: 2008

History

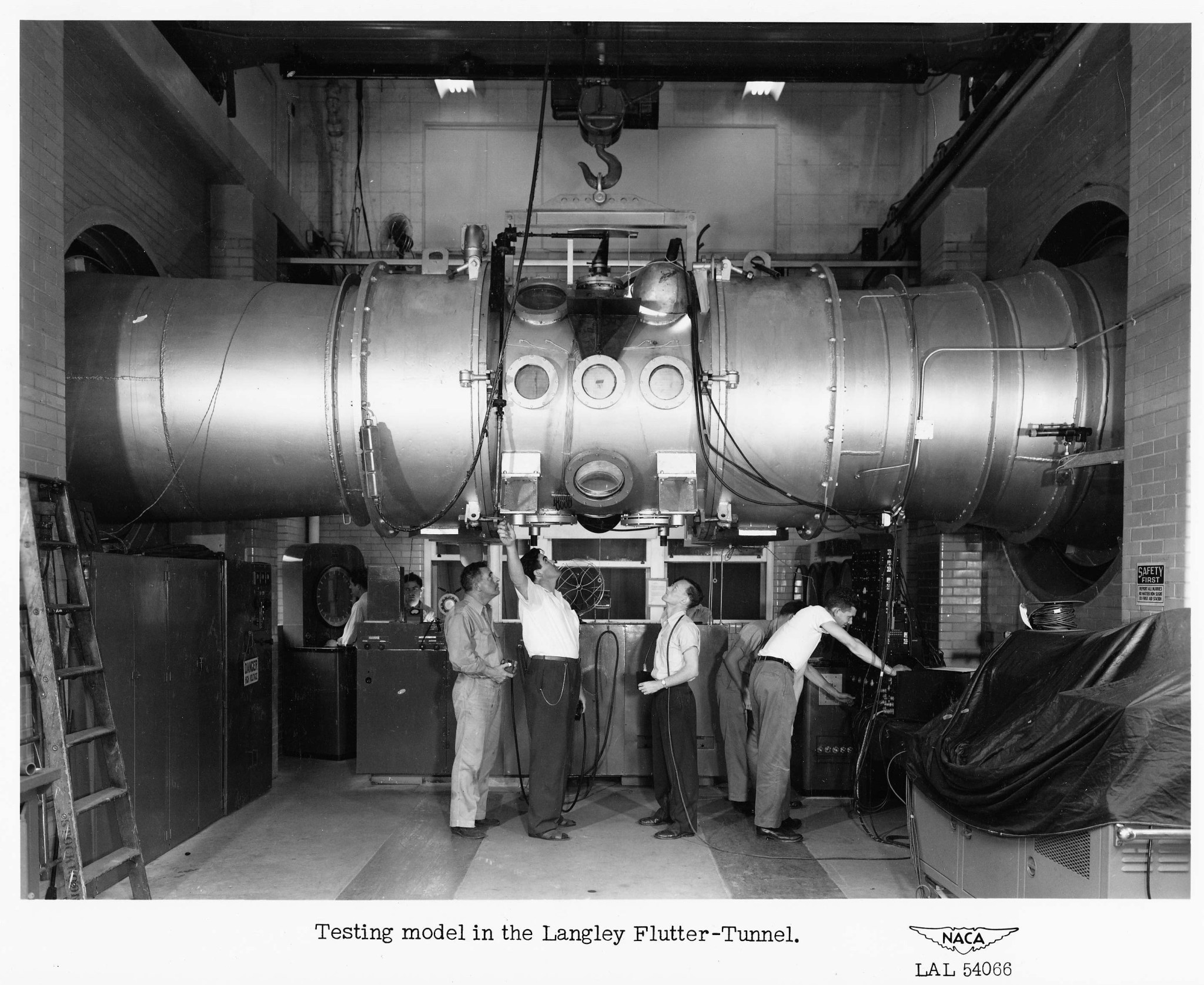

As the maximum speed of aircraft approached transonic conditions near the end of World War II, the onset of compressibility further aggravated aeroelastic phenomena associated with potentially catastrophic flutter of wings and control surfaces.

In addition, the design trend toward thinner wing structures resulted in an urgent need to develop a specialized wind tunnel to provide design information for future aircraft and to evaluate the flutter susceptibility of emerging designs. Accordingly, the NACA constructed a transonic tunnel which became operational in September of 1945 in Building 1229A.

The Langley Flutter Tunnel was a single-return, closed-throat tunnel with unique flutter testing capability including pressurization of up to 1.8 atmospheres and the use of air or Freon-12 as a test medium. Its test section was 4-feet 6-inches in diameter with interchangeable test sections and a maximum speed of Mach 1.

Researcher accomplishments in the Flutter Tunnel firmly established Langley’s leadership in the field of flutter. Major contributions to the studies of propeller and rotor blade flutter were conducted there, and growing interest in adapting the Langley 19-foot Tunnel in the East Area for testing of airplane configurations as well as management of Langley’s flutter research were centered in Building 1229.

Metal Cleaning Laboratory

After the Flutter Tunnel was dismantled, the facility became the Metal Cleaning Laboratory. Opened in 1998, the lab performed chemical and electro-chemical cleaning, etching, polishing and plating of metallic materials in support of center-wide research facilities.

The primary purpose of this facility was surface preparation of lightweight aluminum- and titanium-based alloys in support of forming and joining activities in the structures and materials research organizations.

Such studies included the manufacture of aerospace structures from foil and sheet gage materials which typically require multiple-step, surface treatment in both the pre- and post-processed condition. The Laboratory also performed work on a broad range of metallic materials in support of Wind Tunnel research and for other government agencies.

Specific surface preparation techniques which could be applied included chemical cleaning, etching and milling, electro-plating, passivating, polishing, anodizing and specialty products such as Iridite. Plating capabilities included the application of copper, gold, indium, nickel, platinum and silver for dimensional change or protection purposes.

An example of materials handled at this facility included alloys of aluminum, copper, iron, nickel, tantalum and titanium, a wide variety of steels and specialty products, such as Inconel and Vascomax. Most of these materials could be chemically cleaned, etched or plated, but implementation of other surface treatments was limited.

As with many of the buildings at Langley, this one had been modified throughout the years to serve a variety of purposes. The last of the buildings known as 1229A was demolished in 2008.

Search the NASA Technical Reports Server for additional information.

Related Materials

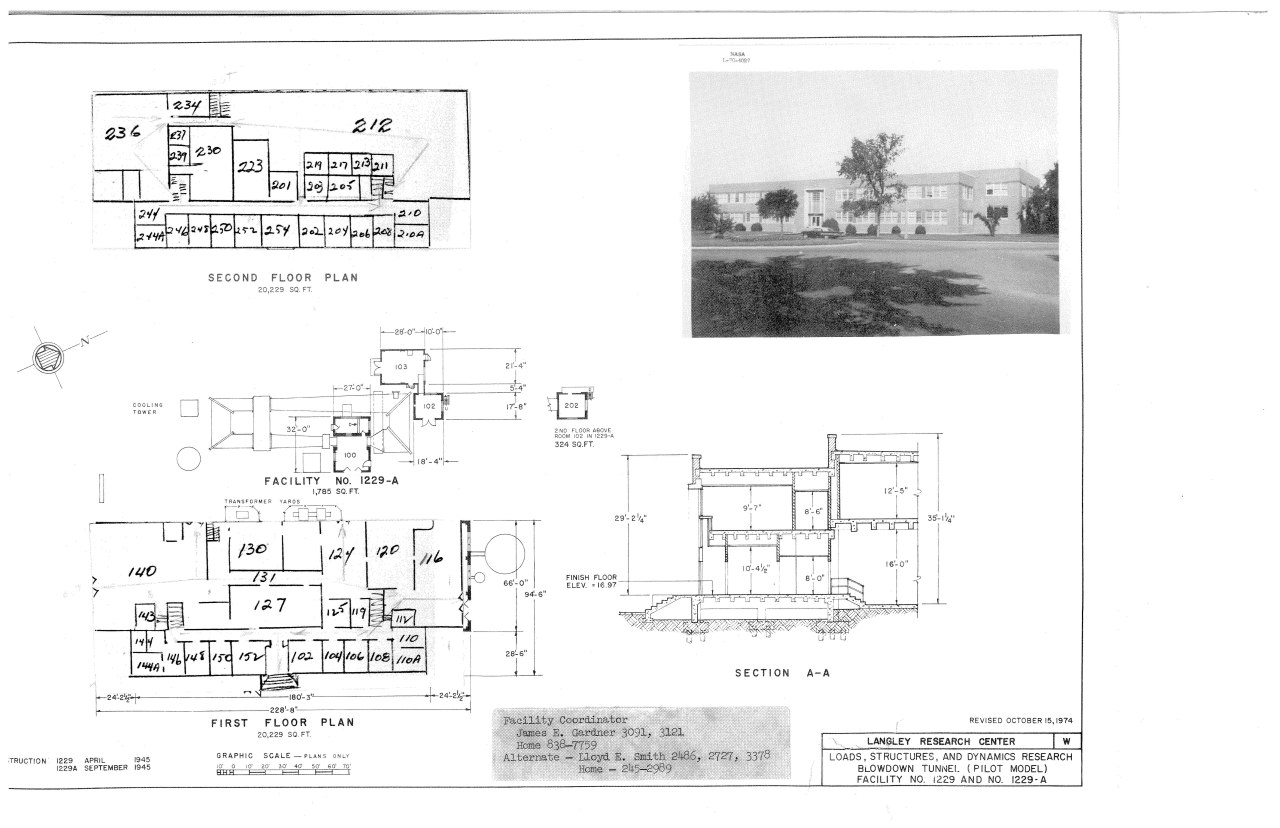

1974 Floor Plan with Tunnel

Physical Research

Researcher News article, June 1999