In March, NASA researchers employed a new camera system to capture data imagery of the interaction between Firefly Aerospace Blue Ghost Mission-1 lander’s engine plumes and the lunar surface.

Through NASA’s Artemis campaign, this data will help researchers understand the hazards that may occur when a lander’s engine plumes blast away at the lunar dust, soil, and rocks.

The data also will be used by NASA’s commercial partners as they develop their human landing systems to safely transport astronauts from lunar orbit to the Moon’s surface and back, beginning with Artemis III.

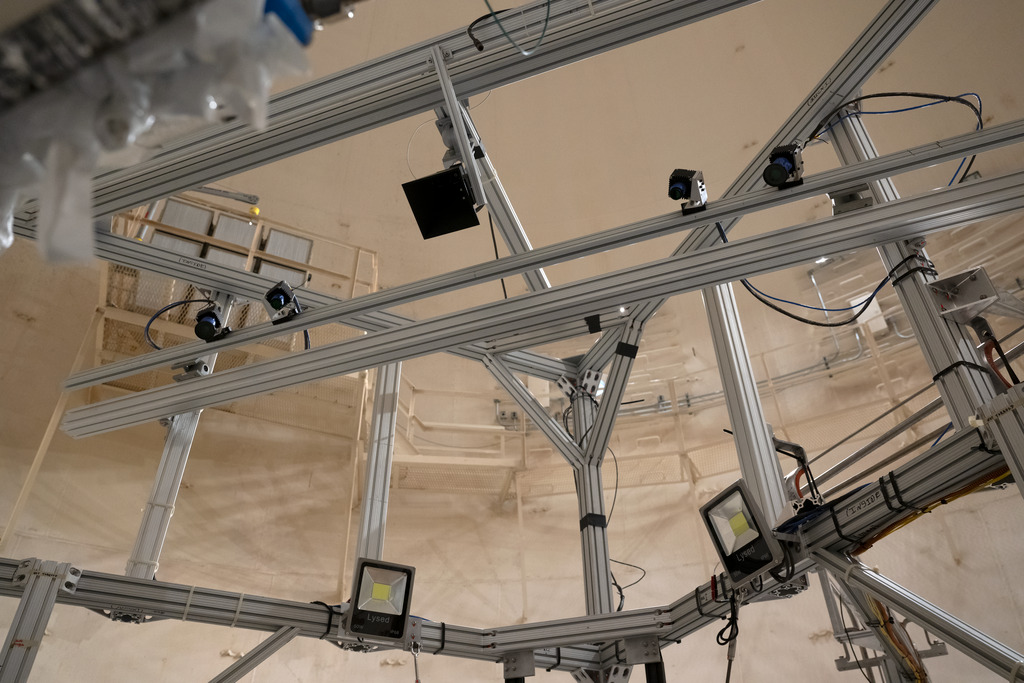

To better understand the science of lunar landings, a team at NASA’s Langley Research Center in Hampton, Virginia, has initiated a series of plume-surface interaction tests inside a massive 60-foot spherical vacuum chamber.

This plume-surface interaction ground test is the most complex test of its kind to be undertaken in a vacuum chamber

Ashley Korzun

PSI Testing Lead at NASA Langley

“This plume-surface interaction ground test is the most complex test of its kind to be undertaken in a vacuum chamber,” said Ashley Korzun, testing lead at NASA Langley. “If I’m in a spacecraft and I’m going to move all that regolith while landing, some of that’s going to hit my lander. Some of it’s going to go out toward other things — payloads, science experiments, eventually rovers and other assets. Understanding those physics is pivotal to ensuring crew safety and mission success.”

The campaign, which will run through spring of 2026, should provide an absolute treasure trove of data that researchers will be able to use to improve predictive models and influence the design of space hardware. As Korzun mentioned, it’s a big undertaking, and it involves multiple NASA centers, academic institutions, and commercial entities both small and large.

Korzun’ s team will test two types of propulsion systems in the vacuum sphere. For the first round of tests this fall, they are using an ethane plume simulation system designed by NASA’s Stennis Space Center near Bay St. Louis, Mississippi, and built and operated by Purdue University in West Lafayette, Indiana. The ethane system generates a maximum of about 100 pounds of thrust — imagine the force necessary to lift or support a 100-pound person. It heats up but doesn’t burn.

After completing the ethane tests, the second round of tests will involve a 14-inch, 3D-printed hybrid rocket motor developed at Utah State University in Logan, Utah, and recently tested at NASA’s Marshall Space Flight Center in Huntsville, Alabama. It produces around 35 pounds of thrust, igniting both solid propellant and a stream of gaseous oxygen to create a hot, powerful stream of rocket exhaust, simulating a real rocket engine but at smaller scale for this test series.

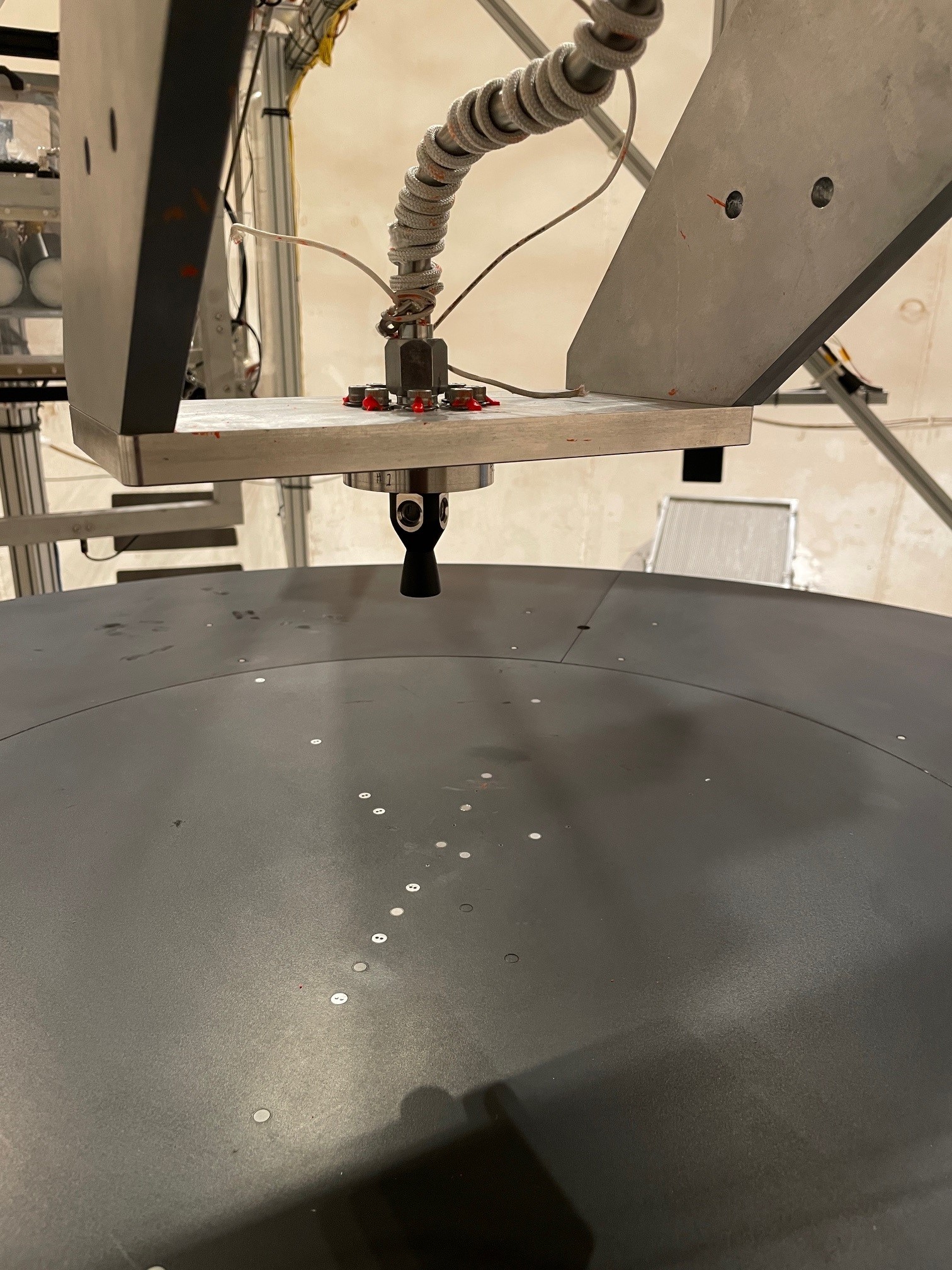

Researchers will test both propulsion systems at various heights, firing them into a roughly six-and-a-half-foot diameter, one-foot-deep bin of simulated lunar regolith, called Black Point-1 that has jagged, cohesive properties similar to lunar regolith.

“It gives us a huge range of test conditions,” Korzun said, “to be able to talk about spacecraft of all different kinds going to the Moon, and for us to understand what they’re going to do as they land or try to take back off from the surface.”

The data from these tests at NASA Langley will be critical in developing and validating models to predict the effects of plume surface interaction for landing on the Moon and even Mars, ensuring mission success for the HLS landers and the safety of our astronauts

Daniel Stubbs

Engineer with HLS Plume and Aero Environments Team at NASA Marshall

A number of different instruments, including a version of the specialized camera system that imaged the plume-surface interaction during the Blue Ghost landing, will capture data and imagery from the tests, which will only last about six seconds each. The instruments will measure crater formation, the speed and angle of ejecta particles, and the shapes of the engine plumes.

Korzun sees this test campaign as more than a one-shot, Moon-specific thing. The entire operation is modular by design and can also prepare NASA for missions to Mars. The lunar regolith simulant can be replaced with a Mars simulant that’s more like sand. Pieces of hardware and instrumentation can be unbolted and replaced to represent future Mars landers. Rather than take the vacuum sphere down to really low pressure like on the Moon, it can be adjusted to a pressure that simulates the atmosphere on the Red Planet. “Mars has always been in our road maps,” Korzun said.

But for now, the Moon looms large.

“This test campaign is one of the most flight-relevant and highly instrumented plume-surface interaction test series NASA has ever conducted,” said Daniel Stubbs, an engineer with the human landing systems plume and aero environments team at NASA Marshall. “The data from these tests at NASA Langley will be critical in developing and validating models to predict the effects of plume-surface interaction for landing on the Moon and even Mars, ensuring mission success for the human landing systems and the safety of our astronauts.”

Through the Artemis campaign, NASA will send astronauts to explore the Moon for scientific discovery, economic benefits, and to build upon our foundation for the first crewed missions to Mars – for the benefit of all.

For more information about Artemis, visit:

Joe Atkinson

NASA Langley Research Center