NASA’s Orion spacecraft will carry astronauts on future Artemis missions to the Moon and return them safely to Earth. Orion will be home to the crew on these long-duration missions, which help prepare for future destinations like Mars.

The agency is working with industry and international partners to ensure the next-generation spacecraft is safe and successful for crew on their missions. This includes Lockheed Martin, NASA’s lead contractor for Orion, and ESA (European Space Agency), which oversees the development of Orion’s service module.

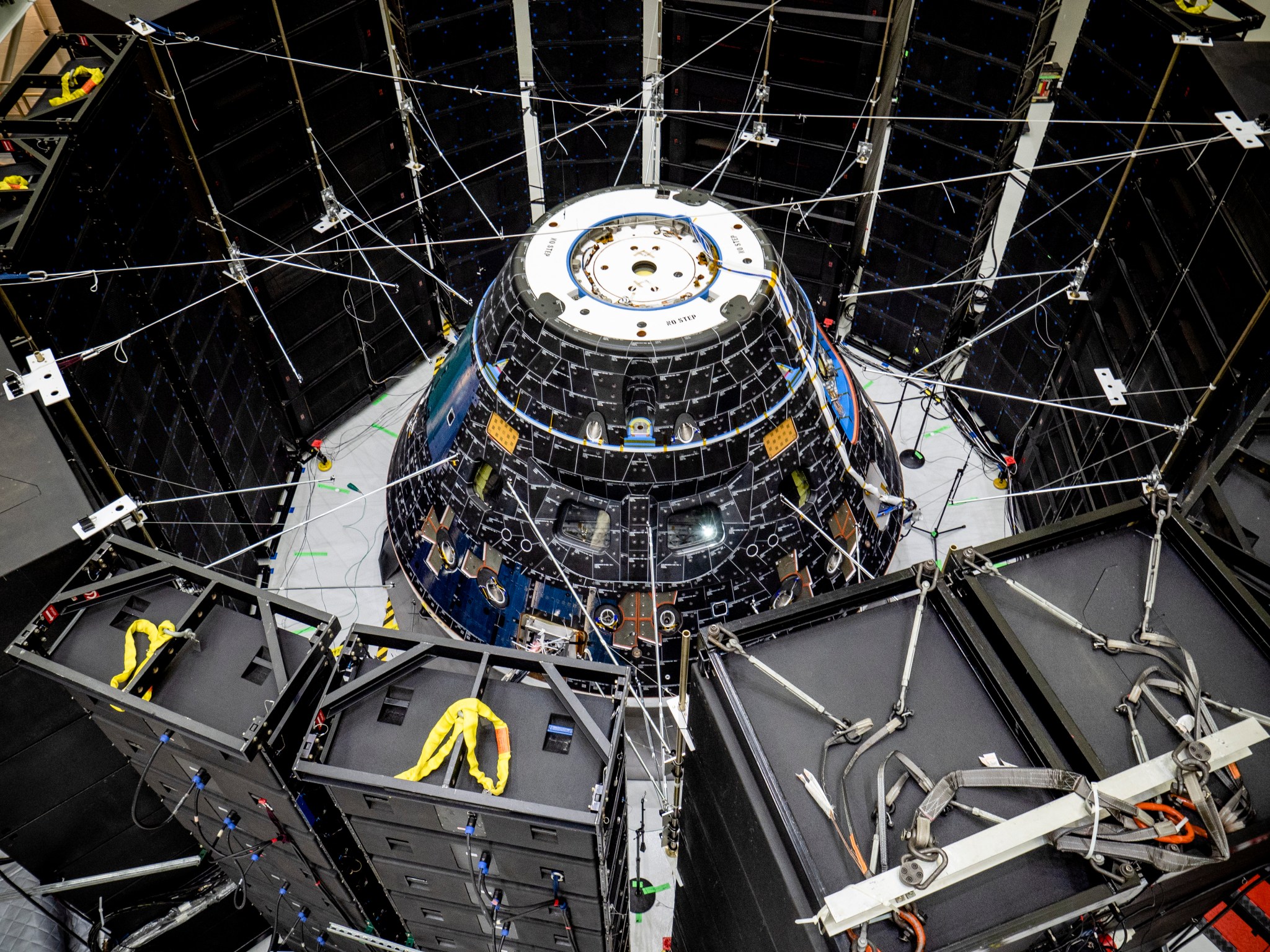

Previously, NASA highlighted a few people who work on Orion’s launch abort system (LAS), designed to carry the crew to safety in the event of an emergency during launch or ascent. Various teams also diligently work on Orion’s crew module, located below the LAS, where crew will live and work on their journey to the Moon and back.

The Way We Explore: The Crew Module

Orion’s pressurized crew module can accommodate four astronauts for up to 21 days, and provides a safe habitat through launch, on-orbit operations, landing, and recovery.

California-based subcontractor AMRO Fabricating Corp. makes several major components of the pressure vessel, the underlying structure of the crew module that provides the air-tight, habitable space for astronauts. Kevin Gonzalez, a quality engineer at AMRO’s South El Monte, California, facility, helps oversee quality inspection for crew module parts including the window panels, LAS hatch, and the motor adapter — all while completing his bachelor’s degree.

Gonzalez, a first-generation American from a Nicaraguan family, grew up in Hacienda Heights, California, and received his associate degree in mathematics from Arizona State University. He’s studying mechanical engineering at California State University, Fullerton, and said working on Orion has motivated him to take his education further.

“Working on this spacecraft has really inspired me,” said Gonzalez. “It’s inspired me to just get back in school and not only finish my bachelor’s, but take it another step and earn my master’s.”

Once the primary structure is built, people like NASA’s Josh Keely help make sure the crew module’s hardware and software are integrated and work together. That’s his primary role as software integration multidisciplinary, or SWIM, lead for the environmental control and life support system, which is essential for keeping astronauts alive in space.

That’s just one of several roles that Keely plays at NASA’s Johnson Space Center in Houston. He’s also the lead for the problem resolution team for the spacecraft’s valving and plumbing, known as the purge, vent and drain system, and the software integration lead for the Orion Life Support Integration Facility that tests and qualifies the environmental control and life support system for its first use with crew on Artemis II.

“Looking back at being in school, I had an idea of what an engineer does, but I just didn’t have any concept of the amount of specialties that I could explore,” said Keely, who’s from Curwensville, Pennsylvania.

He earned his bachelor’s in mechanical engineering, with a minor in English from Lafayette College in Easton, Pennsylvania. Keely then pursued his master’s in mechanical and aerospace engineering at the University of Virginia in Charlottesville for several years before coming to NASA.

“Working on Orion, I get to interact with multiple systems and help solve problems from a different perspective. I’m constantly learning,” he said.

Lockheed Martin’s Lashawn Boulware is constantly learning as a human factors design engineer in Houston. Boulware, who’s from Harvey, Louisiana, earned her bachelor’s in industrial systems engineering from North Carolina A&T State University and her master’s in industrial engineering with a concentration in human factors and ergonomics from Texas A&M University.

She now ensures that systems for the crew module, including display units and even the hygiene bay, also known as the toilet, are designed with comfort in mind for the astronauts who will use them. This means testing with humans inside the Orion mockup, a full-size model of the spacecraft at Johnson, to ensure both efficient design and ease of use by the astronauts.

“I listen to the astronauts, provide their feedback to the designers, and am an advocate and middleman for the two groups to ensure that we are meeting our shared goal to build the right spacecraft,” she said. “I feel like my purpose is to help people, and I get to live that by working on Orion.”

Find out more about the people bringing Orion to life at: https://www.nasa.gov/exploration/systems/orion/index.html