By Linda Herridge

NASA’s John F. Kennedy Space Center

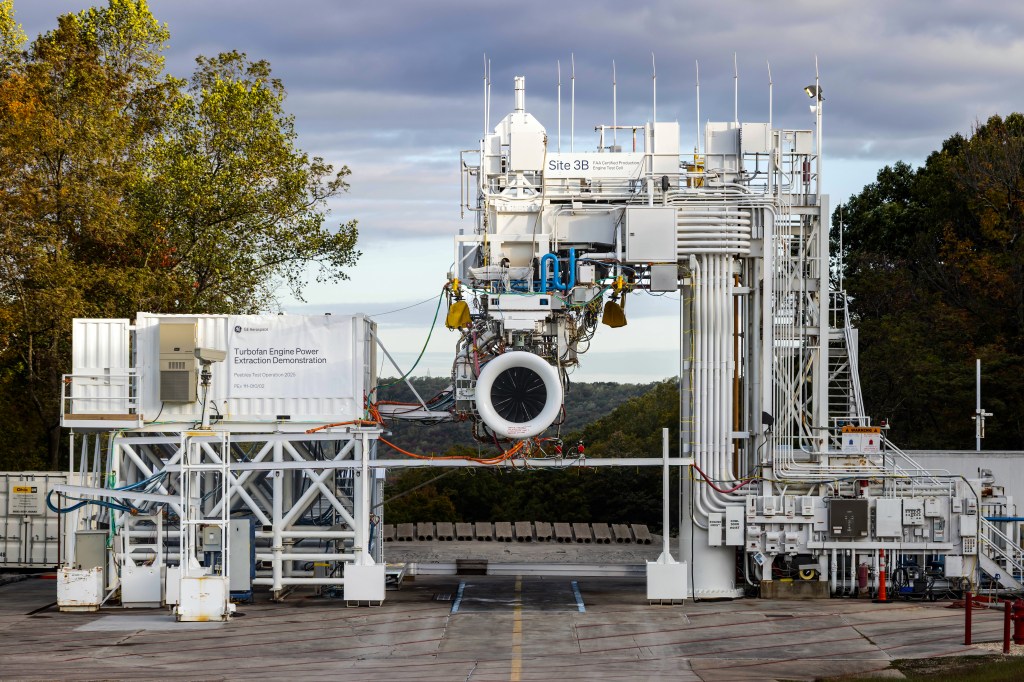

While flight hardware for NASA’s Orion crew module is undergoing work in Florida, near-identical structural test articles for the spacecraft are coming together in a test facility across the country in Colorado. Engineers at Lockheed Martin’s Waterton facility in Denver will conduct a series of tests to confirm Orion’s design is structurally sound and ensure the spacecraft is ready for deep-space missions.

“Testing is integral to demonstrating events and collecting data used to validate the spacecraft design for Orion’s next flight,” said Dan Qvale, the Orion mechanical test engineering manager with Lockheed Martin.

Orion’s structural test article is comprised of three main elements: a crew module, service module and the launch abort system. Unlike the flight hardware, Orion’s structural test articles lack electronics or propulsion systems, except the electronics needed to support testing. During the next few months, the test articles will undergo load, acoustic, vibration, shock and lightning tests. Some tests are done on individual parts, and other parts are tested together to expose the system to stresses expected in flight.

“The load tests, for example, will create the forces on Orion that the spacecraft needs to withstand during launch and landing events,” Qvale said.

Acoustic testing will simulate the sound the rocket produces and will be used to measure the vibration from the sound to test how it affects Orion. A series of shock tests will ensure shock levels don’t exceed what the components have been designed to survive. Simulated lightning tests will monitor how Orion reacts to close or nearby lightning strikes.

“All of these tests, except the lightning test, will help engineers validate the vibration and shock levels that Orion has been designed to withstand throughout the mission,” Qvale said.

NASA is testing Orion to ensure it is ready for its first integrated mission with the agency’s new Space Launch System rocket in 2019. During that uncrewed flight test, known as Exploration Mission-1, Orion will travel tens of thousands of miles beyond the moon and return home with a splashdown in the Pacific Ocean.