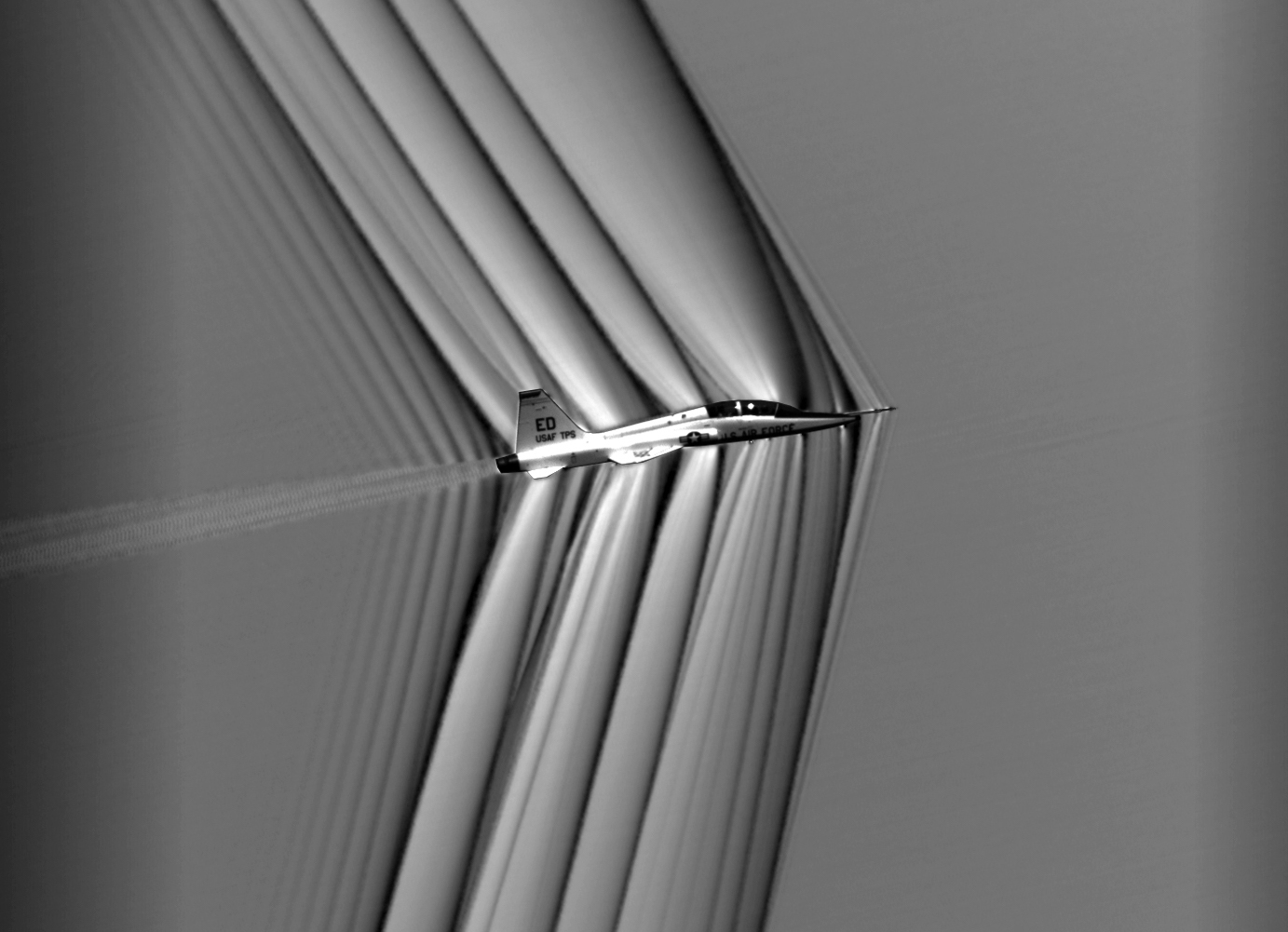

NASA has conducted a series of flights investigating the benefits of twistable, flexible wing flaps to improve flight efficiency.

The second series of Adaptive Compliant Trailing Edge flights, or ACTE II, was flown at NASA’s Armstrong Flight Research Center in Edwards, California, and continued three areas of research based on knowledge gained from the project’s first series, which flew in 2014 and 2015.

The ACTE project began as a joint effort between NASA and the U.S. Air Force Research Laboratory, or AFRL, to investigate the ability of shape-changing surfaces to determine if advanced flexible trailing-edge wing flaps can both improve aircraft aerodynamic efficiency and reduce airport-area noise generated during takeoffs and landings. In 2014, engineers replaced the conventional aluminum wing flap on NASA’s Gulfstream-III Subsonic Research Aircraft Testbed, or SCRAT, with a seamless, twistable flap, patented and built by FlexSys, Inc, of Ann Arbor, Michigan.

ACTE II advanced several steps from the project’s initial phase, including validation of the technology at higher speeds, investigation of the flap’s impact on drag, and the first ever flights of a twisted flap configuration.

The completion of a flight with a twisted flap configuration through ACTE II marks a major milestone for compliant structure technology. The flight featured the flap set in such a way that different areas of the flap were deflected in different positions. The purpose of this flight was to demonstrate the ability to fly with a twisted configuration.

To accomplish the twisted flap configuration, engineers deflected the inboard and outboard sections of the flap in opposite degrees. In this particular test series, the flap was arranged so that the inboard section was deflected 2.5 degrees down, while the outboard edge was deflected 2.5 degrees up.

The potential advantage of such a configuration is the ability to change where the center of lift is on the wing, such as how and where the wing responds to wind gusts. Accomplishing this can lead to future wing designs that are much lighter, making the aircraft more efficient, explains SCRAT chief engineer Ethan Baumann.

“We’re twisting the inboard and outboard sides of the flaps in order to show that we can move the center of lift inboard or outboard,” Baumann said. “You can use a technique like this for gust load alleviation. Wing structure is designed for a worst-case gust loading condition, so if you can quickly change the curve of your wing and respond to a gust, then you can theoretically get away with designing lighter wings.”

Initial flights with the ACTE flaps in a twisted configuration were limited to a maximum speed of 250 knots and 20,000 feet in order to demonstrate the concept in flight.

Another successful milestone of ACTE II was the completion of Mach extension flights, which allowed researchers to observe the ability of the technology to safely fly at speeds more accurately representing those of a commercial airliner. While flight tests in ACTE’s first phase were performed at a maximum speed of Mach .75, ACTE II, or approximately 570 miles per hour, saw that speed increase to Mach .85, which is the maximum cruise Mach number of the G-III.

This allowed researchers to observe the structural stability of the technology at common cruising speeds.

“In ACTE I, we were limited to Mach .75 due to structural concerns,” recalled Baumann. “Based on what we learned from those first sets of flights, we’ve extended out to Mach .85.”

The third area of investigation dealt with performance flights, for which the aircraft was instrumented to be able to monitor fuel flow. By comparing how much fuel the aircraft uses with the flap deflected at different angles, NASA researchers will be able to better understand how different flap deflections influence drag.

“With these flights, we were able to measure the flow of fuel through the engine, and we’ll be able to analyze that data to get accurate estimates on the drag of the aircraft at various speeds, altitudes and weights,” ACTE project manager Kevin Weinert said.

NASA researchers will now began data analysis on the fuel burn, which will provide better understanding of how twistable wing flaps may affect fuel efficiency.

“ACTE is a technology that, when incorporated with new wing designs, will make airplanes more efficient, quieter, and lighter weight, which helps reduce the overall fuel burn for future designs,” Weinert said.

ACTE II was flown as part of NASA’s Aeronautics Research Mission Directorate’s Flight Demonstrations and Capabilities project.