There’s a new collaborative space at NASA’s Langley Research Center – and it’s full of high-tech machines where the only limit is the imagination.

The Larkworks MakerSpace is a new facility that is open for the workforce of Langley, and is designed to spark imagination by providing a welcoming environment where staff can use a variety of tools, equipment and resources to be creative, develop new ideas and solve tough problems.

The MakerSpace combines small-scale manufacturing tools, community and education to enable its members to design, prototype and create in new and exciting ways. Available equipment includes a wide variety of 3D printers, electronics parts and robotics kits, a laser-cutting room, computer numerical control mills, a virtual reality station, as well as more sophisticated tools catered specifically to the needs of Langley researchers.

Aerospace technologist engineer Garry Qualls was giving tours of the facility to visitors at the MakerSpace open house. He was happy with the turnout and steady streams of guests, given the time spent moving equipment into the space.

“We’ve gotten a great response from everyone here at Langley, from the individual researchers all the way up to the top managers at the center” he said. “At this point, more than two dozen projects have used the MakerSpace and their feedback has been extremely positive.”

Qualls said a wide variety of projects have been made at the new space already.

“Larkworks MakerSpace users have made thousands of things since they started to get access to the equipment,” Qualls said. “We’ve seen everything from small plastic brackets, to very large parts, to functional models that users have made to help explain their work to others.” He added that the 3D printers have used more than 20 miles of filament, so far.

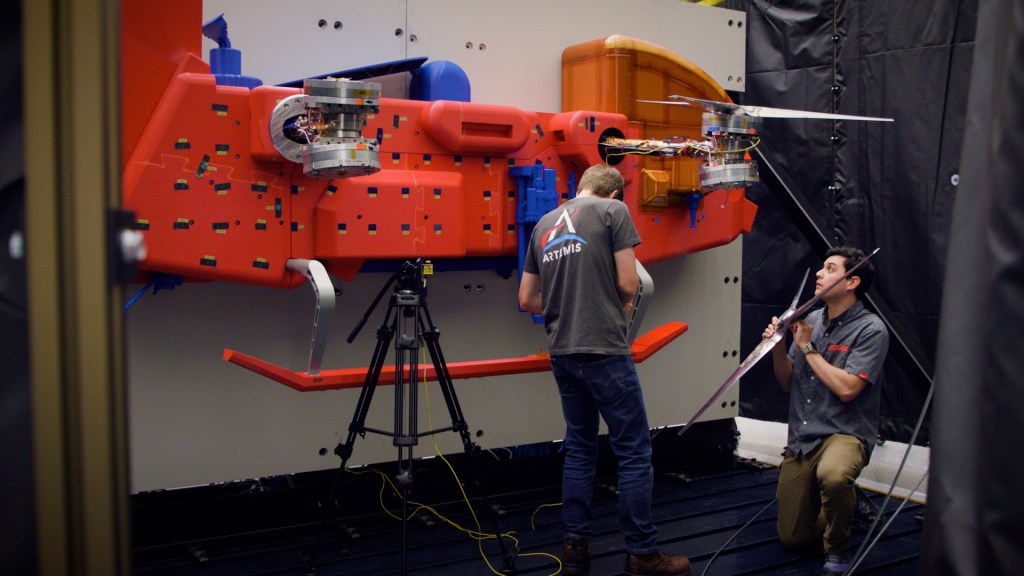

Aerospace engineer Brandon Litherland of Langley’s Aeronautics Systems Analysis Branch has worked on blades for a full-scale model of a motor of the X-57 Maxwell electric propulsion airplane using the 3D printing machines at the MakerSpace to great effect. He raved about the MakerSpace and its capabilities.

“We’ve learned tons of information,” he said, adding that the process has been easier, faster and cheaper to print parts, saving many man-hours but still providing high quality.

“It’s highly accurate,” he said.

Qualls can attest to the quality of the MakerSpace as he has used the machines himself to integrate some expensive radio equipment for his drone project.

“I’ve built a 6-axis robot arm using 3D-printed nylon parts that will be used for automated drone inspections,” he said.

Beyond the technical capabilities of the new facility, it’s the collaborative energy that can make the MakerSpace a coveted place for the Langley workforce.

“We’re seeing a lot of cross-pollination between different efforts as they help each other fix problems with the MakerSpace equipment or they help troubleshoot each other’s problems,” he said. “Building and reinforcing this sense of community is central to making Larkworks a success.”

Eric Gillard

NASA Langley Research Center