By Jim Cawley

NASA’s John F. Kennedy Space Center

Technicians and engineers are working around the clock at the NASA’s Kennedy Space Center in Florida to prepare the Artemis I rocket and spacecraft for flight. The Space Launch System rocket – taller than the Statue of Liberty and capable of producing 15% more thrust than the Saturn V – will soon launch the Orion spacecraft on its mission around the Moon.

Going to the Moon is not an easy feat. During processing, Exploration Ground Systems (EGS) Senior Technical Integration Manager Phil Weber and his team are working to make sure all of the complicated Artemis I systems work seamlessly together. When they need outside help with any of the equipment – big or small – the 30-plus-year NASA veteran has a key resource on center, and he doesn’t hesitate to call.

“Don’t be shy about raising your hand and asking for help if you need it, especially if you don’t know the exact path through the woods,” Weber said. “That’s kind of the ‘bat signal’ you send up – ask Bob and his team to look at it.”

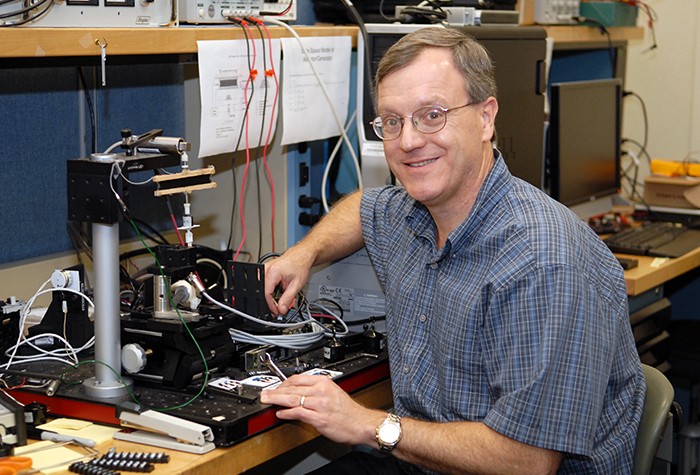

“Bob” is Dr. Bob Youngquist, the Applied Physics Lab lead, who has worked with civil servant and contractor engineers and others in the Applied Chemistry Lab and Exploration Research and Technology Programs to offer new ideas and help refine or develop new processes.

Some of the process improvements and new approaches resulting from these collaborations on the mega-Moon rocket include:

- Orion window structured light inspection tool involves guiding light through a fiber bundle to the device. Allows for an easier inspection at the pad before launch, ensuring no defects in Orion’s windows.

- Acoustic emission system. Used to locate the source of an unknown popping sound and vibration in the mobile launcher crew access arm. Sound receptors revealed a minor issue the team resolved, avoiding a potential significant work stoppage. It also was used to locate the source of a suspicious sound on the mobile launcher platform surface.

- Fire detector optics. Extended the range of ultraviolet (UV) fire detectors, which helps better detect and monitor hydrogen flames, improving safety for the crews working on Artemis.

- Ultrasonic leak detection capabilities. The lab’s patented ultrasonic leak detector was used to locate two leaks in the Exploration Flight Test-1 Orion spacecraft.

- UV hydrogen flame simulator tool. Prototype handheld “selfie stick” device that can be held in front of the new UV hydrogen fire detectors to validate the performance in the field.

“It’s exciting when they come to the lab and say, ‘Here’s something we can’t solve, but we think you can’ – that gives you something new you can dig your teeth into,” Youngquist said. “And if you come up with a new approach for it, you can make a big impact.”

Weber and Youngquist met during the Space Shuttle Program, during which time Weber developed a deep respect for his colleague’s capabilities. Those unique talents have proven to be just as helpful in resolving a variety of challenges that invariably arise when assembling and processing new launch vehicles and spacecraft that are capable of human deep-space missions.

“A lot of our team has unique skill sets for processing and testing the hardware, but we don’t get exposed to a lot of the things that Bob and his team do,” Weber said. “That’s the secret sauce to innovation – having people from different backgrounds engaged in figuring out solutions.”

Youngquist, a 2020 NASA Inventors Hall of Fame inductee, views it as a personal challenge to find a new process or develop a new tool or prototype. Weber has come to rely on that resoluteness.

“It’s difficult to envision our processing world without that kind of help,” Weber said.

“When EGS calls, we step right in and offer help to the best of our abilities; it’s the attitude we’ve had in the lab over the years,” Youngquist said. “It’s incredibly satisfying to see these systems operational, inspected, and working properly so we can safely launch astronauts to space.”

Artemis is the first step in the next era of human exploration. Together with commercial and international partners, NASA will aim to land the first woman and first person of color on the Moon to establish a long-term presence in preparation for missions to Mars.