NASA research engineer Mahmooda Sultana has been named the 2017 “IRAD Innovator of the Year,” an award bestowed annually on those who achieve significant results creating technologies under the Goddard Space Flight Center’s Internal Research and Development, or IRAD, program.

Sultana received the award for her groundbreaking work advancing nanomaterials and processes to create small, potentially revolutionary detectors and devices for use in space.

The annual reward is presented by NASA Goddard’s Office of the Chief Technologist in Greenbelt, Maryland. The organization funds and manages the development of promising, potentially breakthrough technologies that could advance the agency’s scientific and exploration goals and benefit others.

“Mahmooda has distinguished herself as a tenacious, creative thinker, impressing virtually everyone with her technical acumen and drive,” said Goddard Chief Technologist Peter Hughes in his announcement.

“In her relatively short time here, she has successfully competed for 10 awards under our IRAD program, compiling an impressive list of accomplishments, including the creation of advanced sensors for which a patent is pending,” he continued. “Perhaps most notable is her emergence as one of NASA’s experts in nanotechnology. I can only imagine what she’ll do in the future. She embodies the very essence of innovation.”

Within a few months of joining NASA in 2010, Sultana had become the lead in the development of graphene-based sensors — efforts that led to the filing of a still-pending patent application. Graphene, which is just one atom thick and composed of carbon atoms arranged in tightly bound hexagons best visualized as atomic-scale chicken wire, is 200 times stronger than structural steel and highly sensitive and stable at extreme temperatures.

“When I came to NASA Goddard in 2010, no one at the center was doing substantial work on graphene, but there was a lot of excitement,” Sultana explained. “Everything was still at a very early stage; people around the world were coming up with new applications of graphene every day. I wanted to explore what graphene had to offer for space applications.”

She has since expanded her research interests.

Quantum Dots and 3-D Printing

She and her team currently are collaborating with the Massachusetts Institute of Technology, or MIT, to develop a prototype imaging spectrometer — an instrument used by virtually all scientific disciplines to measure the properties of light — based on the emerging quantum-dot technology that MIT researchers pioneered.

Quantum dots are a type of semiconductor nanocrystal discovered in the early 1980s. Invisible to the naked eye, the dots have proven in testing to absorb different wavelengths of light depending on their size, shape, and chemical composition. With her funding, Sultana is working to develop, qualify through thermal vacuum and vibration tests, and demonstrate a 20-by-20 quantum-dot array sensitive to visible wavelengths needed to image the Sun and the aurora.

In another collaboration involving Boston’s Northeastern University, Sultana and her team are experimenting with the university-created Nanoscale Offset Printing System to manufacture a multifunctional sensor platform made of different nanomaterials, including graphene, carbon nanotubes, and molybdenum disulfide.

The 3-D printing system is like offset printers used to produce money or newspapers, Sultana said. Instead of ink, however, this system applies nanomaterials to a mold through a process called electrophoresis, a standard laboratory technique by which charged molecules move through a solvent guided by an electrical field. With 3-D printing, the nanomaterials stick to certain parts of the mold when a voltage is applied, allowing technologists to custom design and quickly produce multiple copies of the sensor.

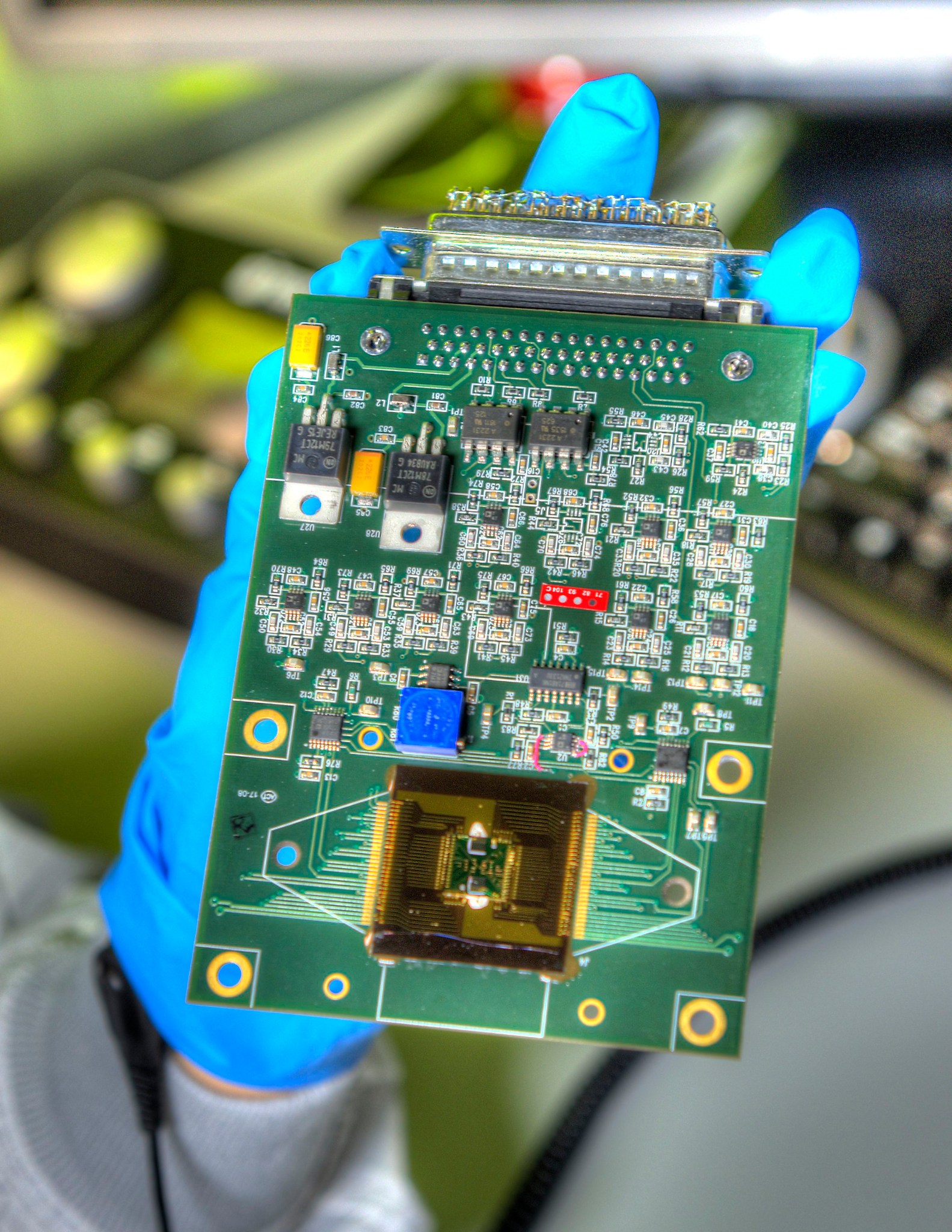

The goal is to use 3-D printing to fabricate a suite of sensors on the same platform. With this technique, she could apply different nanomaterials directly onto a daughter board, which she then could bond onto a printed circuit board. This could substantially simplify the assembly of sensors that typically require time-consuming hand work to wire together the components. With 3-D printing, these components would be laid down in one pass.

The consummate multi-tasker, Sultana now represents NASA on national and regional nanotech councils and is the recipient of many NASA awards and honors. She also has shown her mettle in management, recently being named as the associate branch head of Goddard’s Instrument Systems Branch — a position that will allow her to apply her detector expertise to the creation of next-generation instruments and missions.

“She is a real go-getter,” agreed Ted Swanson, senior technologist for strategic integration for Goddard’s Office of the Chief Technologist. “Mahmooda always has stayed current with new developments. She leverages the expertise of her colleagues, constantly looks for ways to advance the readiness of our technologies, and isn’t afraid to seek vehicles for financial support — the hallmark of a successful innovator.”

For more on this technology story and to view other stories in the Fall 2017 Cutting Edge, go to: https://www.nasa.gov/wp-content/uploads/2020/01/fall_2017_final_lowrez.pdf?emrc=381eff

By Lori Keesey

NASA’s Goddard Space Flight Center