When deep space exploration missions launch, like NASA’s future Artemis missions to the Moon, they carry liquids with them for fuel and life support systems. These liquids are stored at cryogenic temperatures, which range from -243 to -423 degrees F, and to be usable, they need to remain cold and in a liquid state. But as the extreme environment of space warms a spacecraft, the fuels begin to evaporate or “boiloff.”

“As energy from the Sun, Earth, and even the Moon enters the cryogenic propellant tanks, the liquid has to absorb that energy, which causes it to boiloff,” explains Wesley Johnson, cryogenic fluid management technical lead at NASA’s Glenn Research Center in Cleveland. “Any propellant that evaporates can’t be used by the rocket and decreases the efficiency of the rocket.”

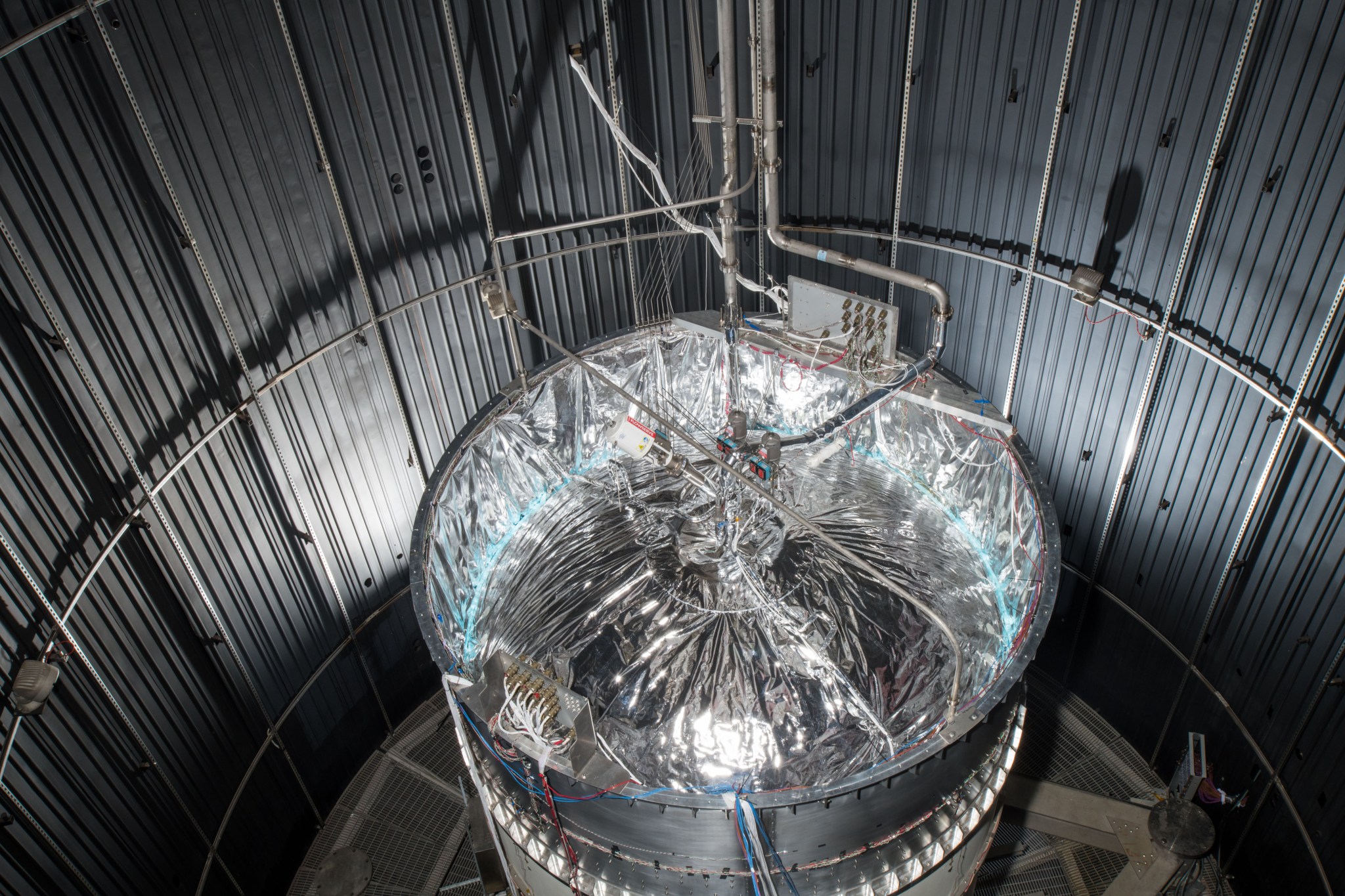

To combat boiloff, NASA’s eCryo project team is evaluating a series of technologies aimed at reducing the boiloff losses for human exploration missions. To test some of these new technologies at a relevant scale, the team built a large cryogenic propellant tank, which is more than 13 feet in diameter, called SHIIVER, or Structural Heat Intercept, Insulation and Vibration Evaluation Rig.

SHIIVER has reflective multilayer insulation as well as vapor cooling channels that minimize the heat going into the storage tank. It also uses a Radio Frequency Mass Gauge, a specialized tool designed at Glenn to accurately measure fluid levels in space. The gauge was recently demonstrated on the International Space Station.

“SHIIVER is the largest research tank NASA has ever built to test cryogenic technologies, and demonstrating the scalability is a critical aspect of infusion to in-space cryogenic propellant applications,” said Hans Hansen, eCryo project manager at Glenn.

In fall 2019, NASA engineers ran thermal vacuum tests on SHIIVER inside the In-Space Propulsion facility (ISP) located at NASA’s Plum Brook Station to assess the benefits of vapor-cooling and multilayer insulation performance for in-space conditions.

“The first vacuum test showed promising results, demonstrating total heat reduction of more than 55% compared to current system designs,” said Hansen. “The boiloff reduction varied based on the amount of fluid in the tank, but overall, the results have been positive and we’re seeing a significant reduction in boiloff.”

The SHIIVER team then used the world’s most powerful acoustic test chamber at the Space Environments Complex to simulate a dynamic launch environment, stressing the tank and thermal management features to make sure they are capable of surviving launch.

The final vacuum test, which assessed how its thermal management systems stood up to acoustic testing, was completed in January. The team is now looking for possible opportunities to demonstrate key cryogenic fluid management technologies in space.

SHIIVER is just one way NASA is improving upon state-of-the-art cryogenic propellant storage technologies, making them more energy, mass and cost-efficient. Once proven, these technologies could be used for future Artemis missions, including the large fuel tanks in the Space Launch System’s upper stage, nuclear thermal propulsion systems, future Mars transfer vehicles and cryogenic fuel depots.

Top Image: The SHIIVER tank sits inside the In-Space Propulsion Facility’s vacuum chamber at NASA’s Plum Brook Station. The tank was subjected to the extreme temperatures of space to ensure the new technologies on SHIIVER kept the propellants inside cold and in a liquid state.

Jimi Russell

NASA’s Glenn Research Center