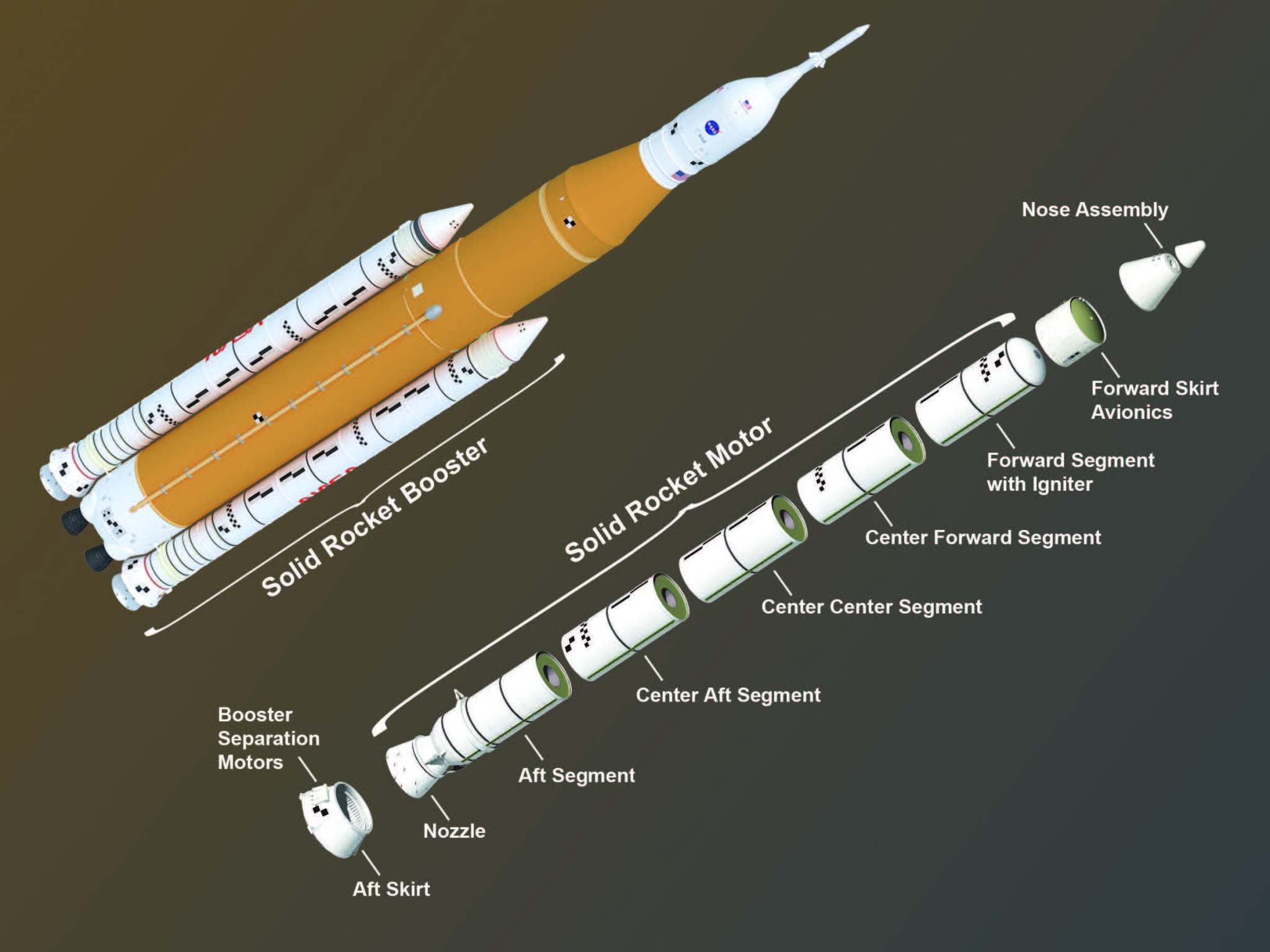

Space Launch System Solid Rocket Booster

NASA’s Space Launch System (SLS) solid rocket booster is based on three decades of knowledge and experience gained with the space shuttle booster, and improved with the latest technology.

NASA’s new rocket, the Space Launch System, is the only rocket that can send the Orion spacecraft, astronauts and a large cargo to the Moon on a single mission.

The boosters contribute to the power that SLS needs to launch payloads with more mass and volume to deep space than any rocket ever built. This makes it possible to send astronauts to distant destinations including Mars.

Solid Rocket Booster Details

- Length: 177 feet

- Diameter: 12 feet

- Weight: 1.6 million pounds each

- Propellant: polybutadiene acrylonitrile (PBAN)

- Thrust: 3.6 million pounds each

- Operational time: 126 seconds

Five Segment Solid Rocket Booster

The SLS booster is the largest, most powerful solid propellant booster ever built for flight. Standing 17 stories tall and burning approximately six tons of propellant every second, each booster generates more thrust than 14 four-engine jumbo commercial airliners. Together, the SLS twin boosters provide more than 75 percent of the total SLS thrust at launch.

The major physical difference between the shuttle and SLS boosters is the addition of a fifth propellant segment to the four-segment shuttle booster, allowing NASA’s new launch-er to lift more weight than the shuttle. Additionally, the SLS booster will be optimized for a single use, while the shuttle booster was designed to be reused. Though based on the shuttle booster, the SLS booster benefits from severaldesign, process, and testing improvements for greater performance, safety, and affordability.

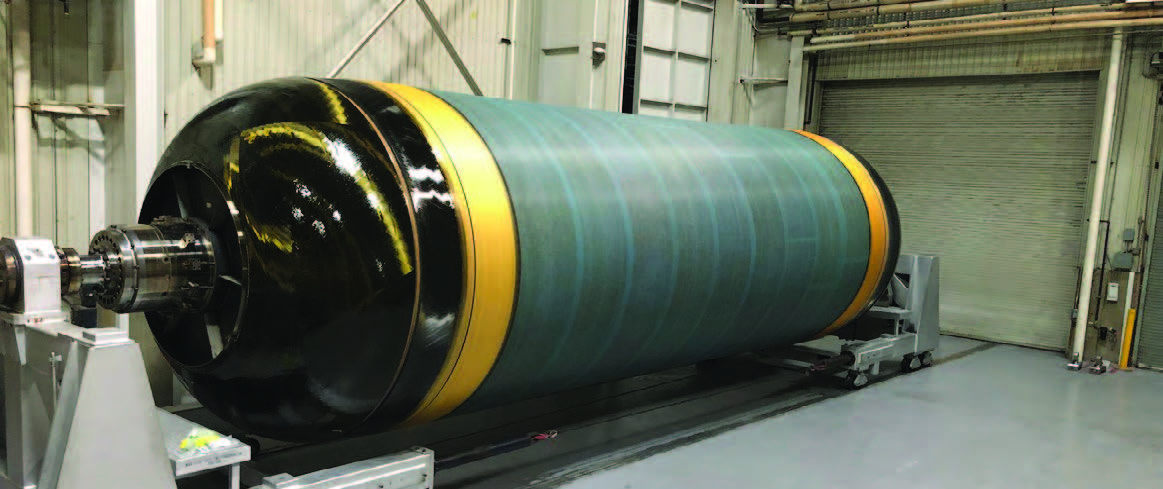

All booster components use steel cases repurposed from cases used on prior space shuttle flights.The five booster motors are manufactured by Northrop Grumman in Utah. The motors that include the propellant are the largest single component of each booster. They undergo a rigorous nondestructive inspection process to confirm each motor’s readiness for flight.

Solid Rocket Booster Improvements

- 25 percent more propellant

- New nozzle design

- New asbestos-free insulation

- New liner configuration

- New avionics

- Improved nondestructive evaluation processes

The other booster components are assembled in the Booster Fabrication Facility at Kennedy.

The booster forward skirt houses booster avionics that communicate with the SLS avionics to monitor booster conditions and steer the booster exhaust nozzle.

The aft skirt contains the thrust vector control system that steers the nozzle based on commands from the booster avionics. The frustum and nose cone serve as the aerodynamic fairing for the booster.

Trains transport booster motors to Kennedy where they are stacked and prepared for launch. The boosters are the first SLS element stacked on the Mobile Launcher. After stacking, each booster is mated to the SLS core stage by braces on the forward and aft booster segments.

On the launch pad, the boosters carry the entire weight of the fueled SLS launch vehicle. After launch, the boosters operate for about two minutes before separating from the core stage and landing in the Atlantic Ocean

For more information about SLS, visit:

https://www.nasa.gov/artemis

https://www.nasa.gov/sls

http://www.twitter.com/NASA_SLS

http://www.facebook.com/NASASLS

http://www.instagram.com/exploreNASA