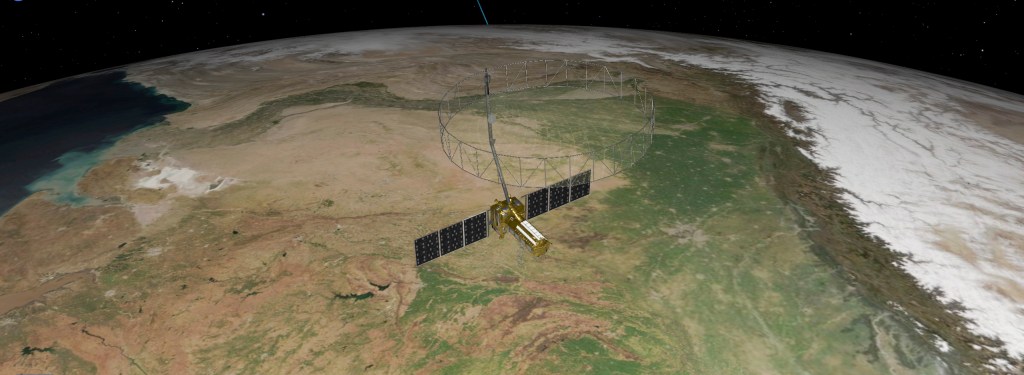

Media are invited to NASA’s rocket factory, the Michoud Assembly Facility in New Orleans, Friday morning Dec. 14, to view the largest piece of structural test hardware for America’s new deep space rocket, the Space Launch System. SLS will enable a new era of exploration beyond Earth’s orbit, launching astronauts in NASA’s Orion spacecraft on deep space exploration missions to the Moon and beyond.

Media will have the opportunity to interview NASA experts and view a 149-foot-long structural test version of the SLS liquid hydrogen tank as it is moved for loading onto NASA’s barge Pegasus to be shipped to the Marshall Space Flight Center in Huntsville, Alabama, where it will undergo critical testing. The core stage test article consisting of the rocket’s liquid hydrogen tank and two attached simulators is the largest SLS test article and is almost as long as the entire space shuttle external tank.

Interested media should contact Tracy McMahan at tracy.mcmahan@nasa.gov or 256-682-5326 or Janet Anderson at janet.l.anderson@nasa.gov or 256-544-0034 no later than 12:00 p.m. CST Thursday, Dec. 13, to provide information for badging. To attend, media will need to report at 7 a.m., Friday, Dec. 14, to the parking lot in front of Michoud’s Building 350 at 13800 Old Gentilly Road for badging. Participating media must be U.S. citizens with valid media credentials and a government-issued photo ID. Long pants and closed-toe shoes with heels smaller than two inches are required.

The testing at Marshall will help ensure the rocket can safely send astronauts to the Moon. The liquid hydrogen tank structural test article, which is structurally identical to the flight tank, will undergo extensive structural testing to verify the rocket can withstand the extreme forces expected during launch and flight. During space missions, the liquid hydrogen tank will hold 537,000 gallons of liquid hydrogen cooled to minus 423 degrees Fahrenheit. The hydrogen and liquid oxygen tanks provide propellant for the stage’s four RS-25 engines that produce two million pounds of thrust to help launch the rocket.

The delivery of the liquid hydrogen test article marks progress toward Exploration Mission-1, where SLS will send an Orion spacecraft around the Moon and back to test critical capabilities needed to carry astronauts farther in space than ever before. On Exploration Mission-2, SLS will carry astronauts aboard Orion on a return to deep space.

Tracy McMahan

Marshall Space Flight Center, Huntsville, Alabama

256-544-0034

tracy.mcmahan@nasa.gov