This weekend’s Academy Awards is probably the last place most people would look for NASA technology, but it’s there: the coveted Oscar trophy is coated in the same gold that helps telescopes glimpse distant galaxies.

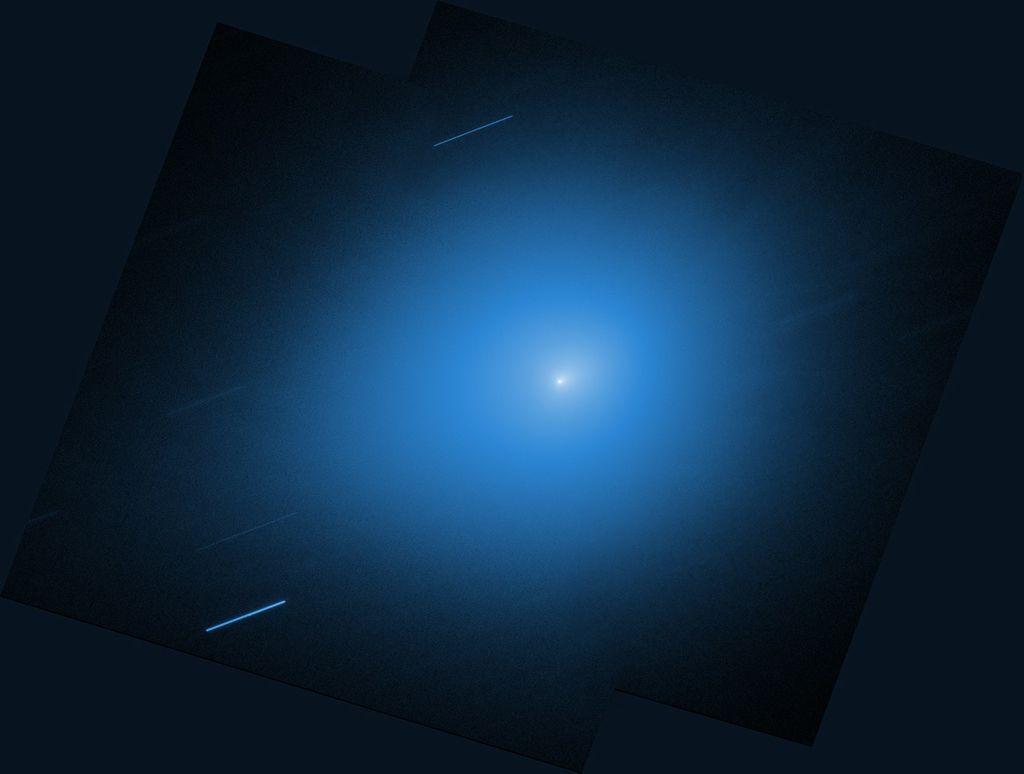

Gold is useful in space, because it is good at reflecting infrared wavelengths of light, which help to detect celestial objects from very far away. Even better, says Goddard Space Flight Center physicist Jim Tuttle, “gold is really inert. It doesn’t oxidize at all.” That means it won’t tarnish.

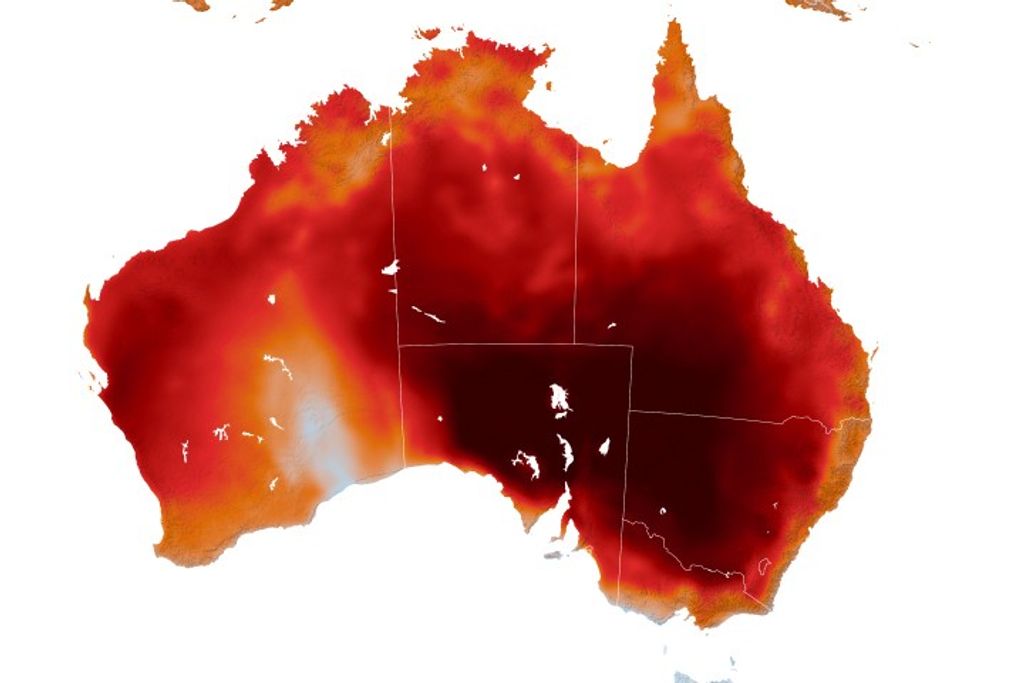

Because of both of those properties, gold is also a good way to block the absorption of radiant heat. That’s why the James Webb Space Telescope team chose gold to coat a 32-foot refrigerant tube that cools the Mid-Infrared Instrument, or MIRI.

The most common method for gold coating is by vapor deposit — the metal is heated in a vacuum until it becomes a gas, which then condenses in a thin layer across a surface.

The process is effective but has drawbacks. For one, the gold loses some of its reflectivity. Beyond that, the gold becomes extremely delicate.

“We’ve seen many times over the years, that somebody will put a nice gold coating on something, but as soon as you bend it, all of a sudden a whole layer of gold will peel up and flake off,” says Goddard engineer John Gygax. Not only does that lower reflectivity, but the flakes can interfere with sensitive instruments.

Good Enough for Mars

The telescope’s designers wanted a gold-plating method that would maintain the high reflectivity of solid gold and be extremely durable. For that, they turned to Brooklyn-based Epner Technology, which has been working with NASA since the 1970s and perfected its electroplating technique doing aerospace work in the 1990s.

Epner Technology claimed its gold would never flake off, but, says Gygax, “we were hesitant. That’s why we made them prove it to us — and they did.”

The company also boasted its gold plating was significantly more reflective than vapor-deposited gold. Again, the Goddard team wanted to be sure, so this time they turned to Tuttle, a cryogenics researcher who designed an experiment that showed the reflectance would be sufficient at its extremely low operating temperatures aboard Webb.

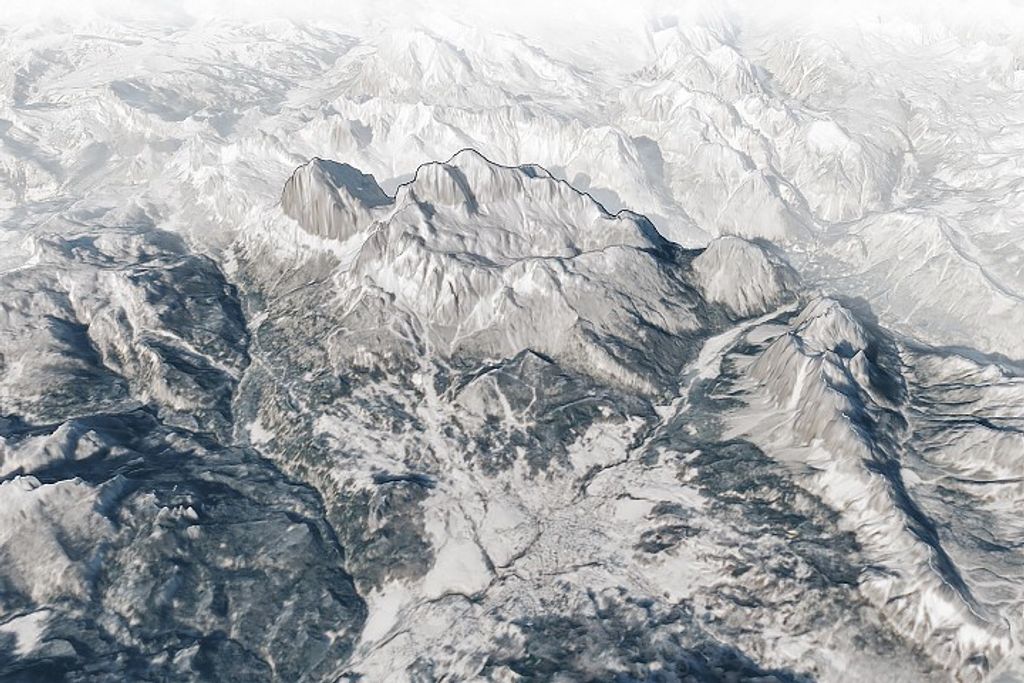

Epner uses an electroplating process it calls LaserGold. The resulting coating was already harder and more reflective than vapor-deposited gold, but both attributes have been further improved through the company’s NASA work. One key improvement came when NASA told Epner it needed better reflectivity on a gold-plated mirror for the Mars Orbiter Laser Altimeter, without losing strength.

At around the same time, the team building the Keck Observatory telescopes needed additional hardness to ensure its gold-plated secondary infrared mirror was cleanable without any scratching. (Keck was not a NASA mission, though the space agency later joined as a partner.)

In order to meet the needs of both aerospace projects, Epner tweaked its proprietary processes to ensure the highest possible reflectivity while also achieving a hardness triple that of pure gold. The trick, Epner explains, was in modifying the electric current to get a more tightly packed atom. Because the gold remains pure, the reflectivity remains extremely high.

And the Oscar Goes to . . .

Epner has been using the improved technique for its varied commercial clients ever since, from Braun ear thermometers to infrared carbon dioxide detectors to jewelry from gold-plated lace.

In 2016, Epner’s reputation for durable and brilliant gold coatings, built in part through its many years working for NASA, brought a new client: the Academy of Motion Picture Arts and Sciences. The Academy was awestruck that Epner Technology was giving them a plating technique that had been used for gold in space for 30, 35 years, company president David Epner recalls.

For more than three decades, a trophy manufacturer had been casting the Oscars in a tin alloy and then plated them with gold. They shone — but the coating wore off.

“We guaranteed that our gold coating will never come off,” Epner says. In fact, Epner has offered a lifetime guarantee to replate, for free, any Oscar that starts to show wear. “That’s something I’ll never have to make good on,” he says.

NASA has a long history of transferring technology to the private sector. Each year, the agency’s Spinoff publication profiles about 50 NASA technologies that have transformed into commercial products and services, demonstrating the wider benefits of America’s investment in its space program. Spinoff is a publication of the Technology Transfer Program in NASA’s Space Technology Mission Directorate.

To learn more about this NASA spinoff, read the original article from Spinoff 2018.

For more information on how NASA is bringing its technology down to Earth, visit: