Editor’s note: This project has concluded. This content is being kept online for historical purposes, but is no longer being updated.

NASA is addressing improved methods, tools, and protocols to reduce the development and certification timeline for composite materials and structures. It is inevitable that composite structures will see increased application due to the pressure to develop more efficient, sustainable vehicles. The present approach for the development and certification of composites is primarily based on testing. It is time-consuming, and expensive but does provide results that have been rigorously validated. NASA will focus on the development and use of high fidelity and rigorous computational methods, improved test protocols, standardized inspection techniques, and manufacturing process simulation to shorten the timeline to bring innovative composite materials and structures to market. NASA will engage key players from Government (FAA and DoD), industry, and academia to mature and verify the methodology, to ensure effective transition to industry, and to assure safety through certification authorities such as the FAA. To achieve the goal of reducing the current 5-10 year development and certification timeline by 30%, NASA will:

- Develop analytical methods and rapid-design tools to reduce structural design cycle time and testing effort during development and certification;

- Develop quantitative and practical inspection methods, data management methods, models, and tools that will increase inspection throughput; and

- Develop process models to predict defects that occur in automated manufacturing, improve quality control for co-bond and co-cured interfaces, and develop cure process models to prevent defect formation during matrix cure.

TECHNICAL CHALLENGES

Accurate Strength and Life Prediction

Develop validated strength and life prediction tools with known accuracy for complex composite structures and standardized procedures for their reliable use.

Rapid Inspection and Characterization

Develop and demonstrate NDE systems and enabling technologies to fully inspect and rapidly disposition findings in complex composite structures.

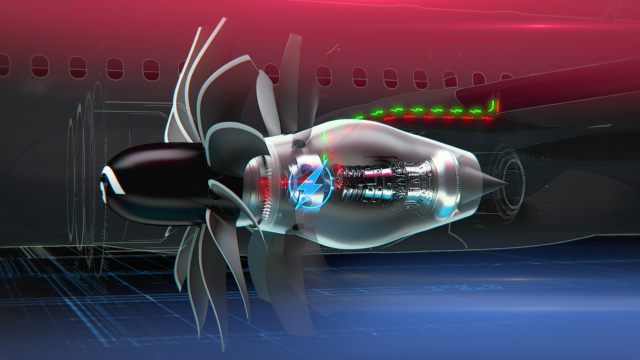

Efficient Manufacturing Process Development

Develop and demonstrate new computational methods to relate manufacturing parameters to defect formation, and connect to commercial design and analysis software to allow structural optimization while resolving predicted manufacturing issues.