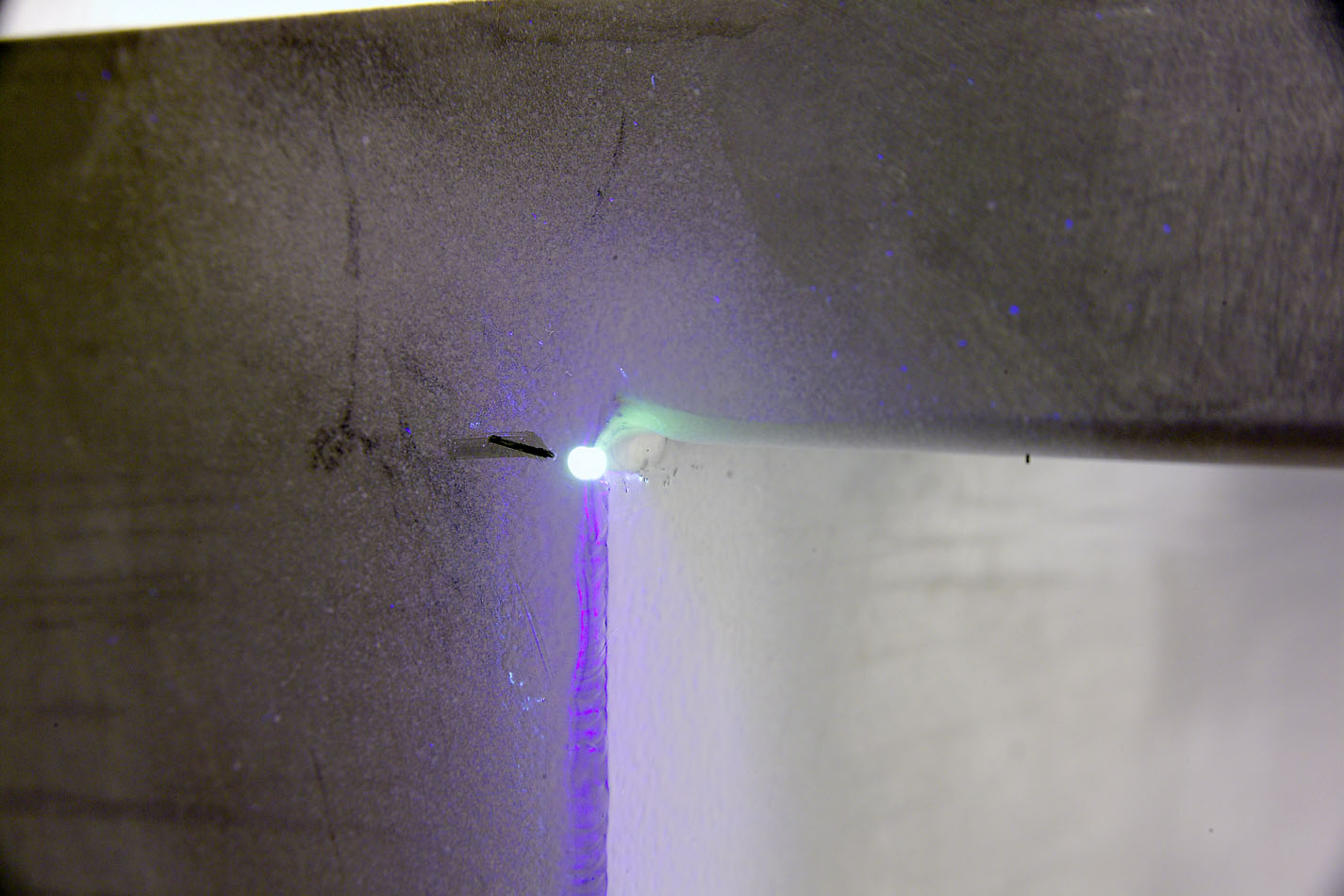

To meet the tight tolerances, quick turnaround times, and superior quality required for NASA, aerospace, defense and commercial industry, White Sands Test Facility maintains certification of hardware in accordance with industry standards for quality assurance inspections.

Quality Assurance and Quality Control

- Routine in-house and third party Quality Assurance inspections

- In-house testing including:

- Non-destructive Evaluation (NDE)

- Failure Analysis, and

- Calibration of inspection equipment.

Standards

- SAE and EAAI standard AS 9001 Quality Management System – The international management system standard for the Aircraft, Space and Defense (AS&D) industry

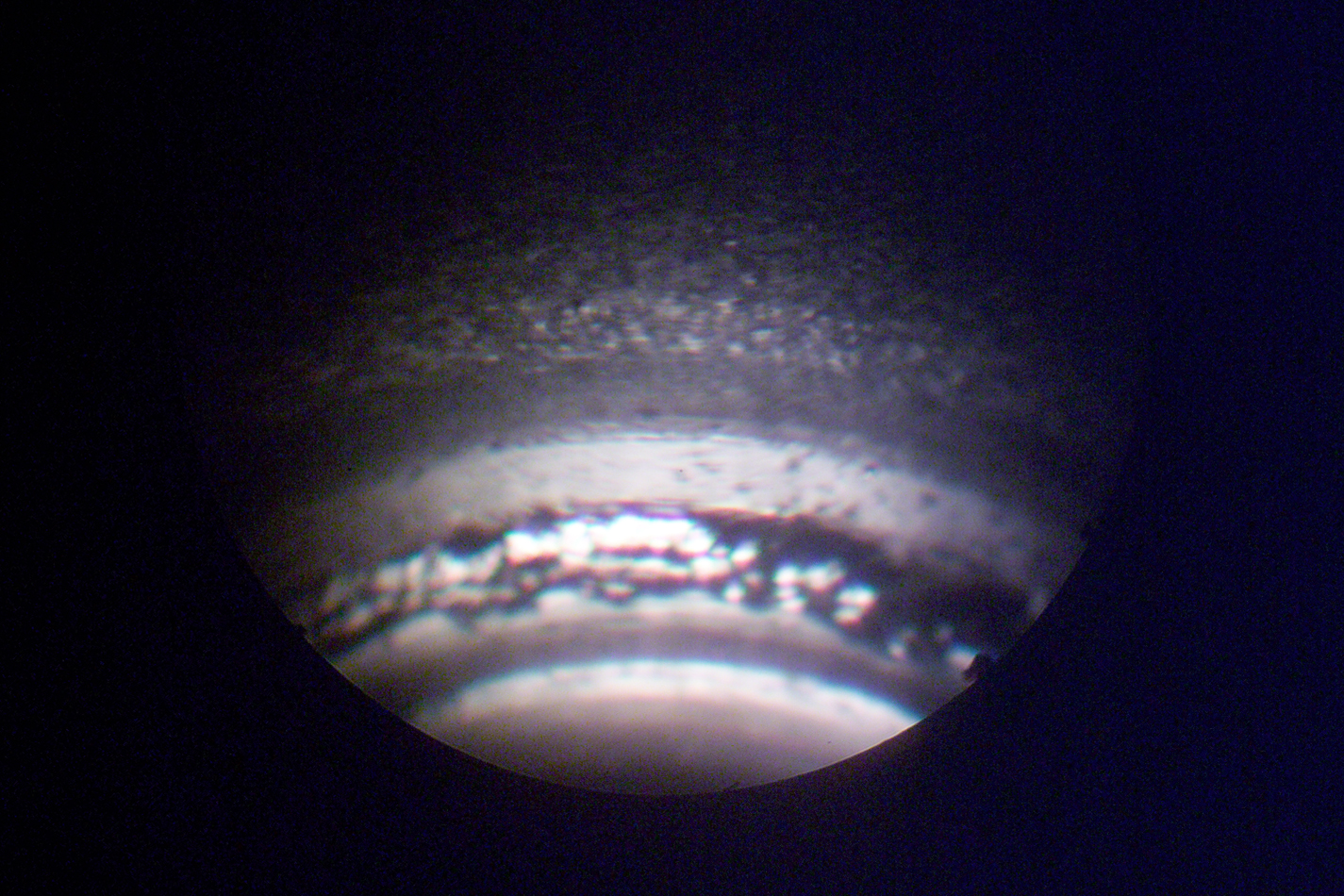

- SAE standard AMS STD-1595 – Qualification of Aircraft, Missile and Aerospace Fusion Welders

- ASME Boiler and Pressure Vessel Code (BPVC) Section IX – Welding and Brazing Qualifications

- American Welding Society standard AWS B2.1 Standard – Base Metal Grouping for Welding Procedure and Performance Qualification Standard