Making metal alloys can sometimes seem like baking. A little bit of “this,” a dash of “that;” mix it up, heat it and let it cool for that perfect metal alloy. Small amounts of different ingredients can make a big impact on the strength and characteristics of your metal.

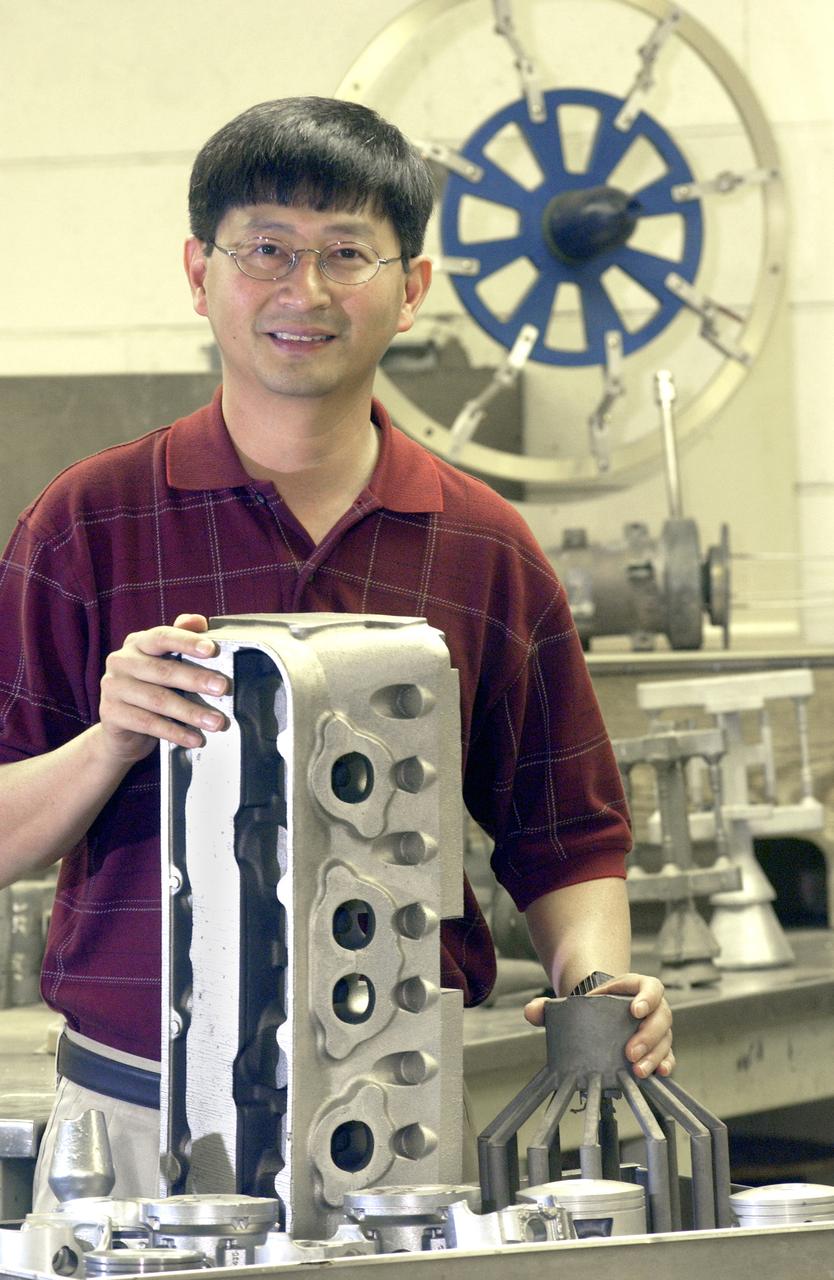

At NASA’s Marshall Space Flight Center in Huntsville, Alabama, there are many “bakers” of materials, and two of those alloy creators, Jonathan Lee and Po Chen, were inducted — along with their alloy, NASA 398 — into the Space Foundation’s Space Technology Hall of Fame during the 34th annual Space Symposium in Colorado Springs, Colorado, on April 19.

“The induction of the NASA 398 alloy into the Space Technology Hall of Fame means that our innovation has been recognized worldwide as one of the life-changing technologies to significantly improve the quality of life on Earth,” Lee said.

The Marshall Center and Sammy Nabors, manager of Marshall technology licensing and commercialization, were also recognized, as was Evinrude/BRP of Sturtevant, Wisconsin. Over 700,000 Evinrude E-Tec outboard boat engines contain the lightweight, high-strength aluminum alloy developed at Marshall.

The creation of NASA 398 started in 1993 when Lee and Chen were involved in the Partnership for Next Generation Vehicles, also known as PNGV. The goal at the time was to create a lightweight alloy for combustion engine pistons capable of withstanding high temperatures and pressures to enable the engines to run more efficiently with reduced emissions.

Using aluminum as the base metal, Lee and Chen added small amounts of other elements — including silicon, titanium and vanadium — making the naturally weak metal stronger and more resistant to wear.

“Prior to the PNGV involvement, Dr. Po Chen and I had some experience in developing high-temperature, nickel-based super alloys for NASA’s rocket propulsion hardware,” Lee said. “Naturally, we decided to take advantage of this material design knowledge to create a better aluminum alloy by modifying the compositions from a conventional alloy and its heat treatment process, in order to drastically improve its mechanical properties at high temperatures.”

Once the alloy was developed, tested and patented, the inventors went through the process of commercialization with Marshall’s Technology Transfer Office and Nabors, who set out to find companies interested in licensing the patented technology.

“We have to make industry aware of what is available for licensing,” Nabors said. “NASA has over 1,400 patents available for licensing. It is Technology Transfer’s responsibility to market these technologies to industry partners. One way we do that is participating in conferences and trade shows.”

One company interested in the alloy was Bombardier Recreational Products (BRP) of Valcourt, Quebec, Canada. They found application of the technology and use it in the Evinrude E-Tec outboard engine. Nabors’ efforts to commercialize the technology were recognized by the Space Foundation, and he received a Commendation from the organization.

Boat engines, though, are not the only place the alloy has found use.

“Over the years, we had several commercial applications for the NASA 398 alloy,” said Lee. “However, what has surprised me the most is its current potential application for making high-temperature bicycle brake rotors! This has been the most challenging application to meet so far, and we are working closely with our client to see if it can be done.”

The alloy is also a component in large fans for underground streets and traffic tunnels that pull in fresh air during emergency situations, potentially to help save lives.

The alloy has proven its mettle and now, along with its inventors, Marshall and Evinrude/BRP, found another home in the Space Technology Hall of Fame.