In This Week’s Star

- NASA Selects Companies to Develop Human Landing System

- NASA Commits to Future Artemis Missions with More SLS Rocket Engines

- Mission Success is in My Hands: Gwen Artis

- Centennial Challenges Gets Green Light for Development of New Challenge Managed by Marshall

- Marshall Summer Internships Will Be Virtual

- John Brunson, Mark Prill, Josh Stiles Honored as ‘HEO HErO’

- Marshall Launches ‘We Are Artemis’ Digital Campaign

- Redstone Arsenal Road Projects Ramp Up During Reduced Traffic

- Alabama High School Student Names Future Mars Helicopter, Highlighted on ‘This Week @NASA’

- This Week in NASA History: LAGEOS Launches – May 4, 1976

NASA Selects Companies to Develop Human Landing System

By Taylor Goodwin

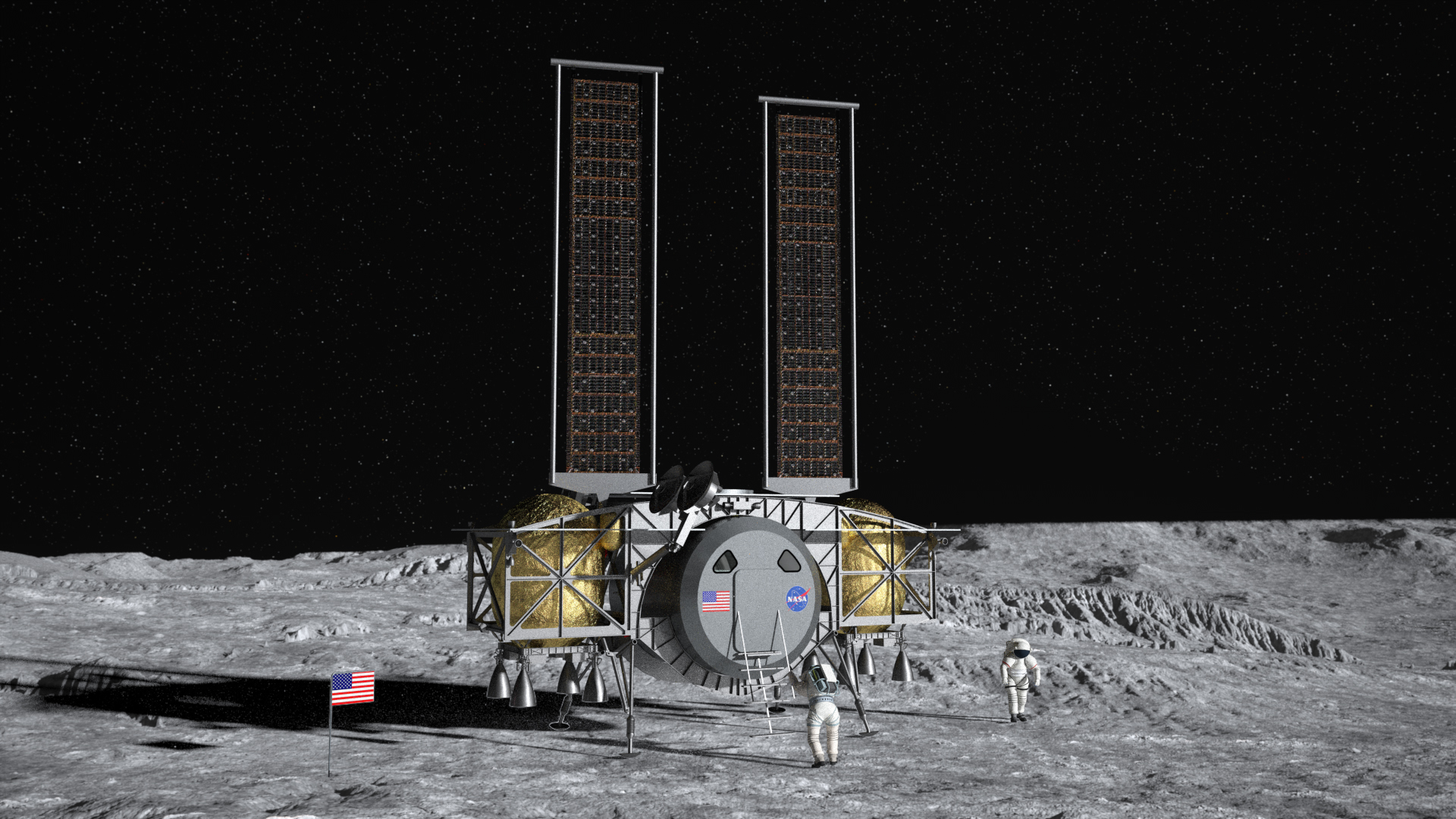

On April 30, NASA announced three U.S. companies to design and develop human landing systems for the agency’s Artemis program.

Blue Origin of Kent, Washington; Dynetics, a Leidos company of Huntsville, Alabama; and SpaceX of Hawthorne, California, each proposed unique lander designs — one of which will deliver the first woman and next man to the lunar surface by 2024. With this development, NASA is on track — for the first time in history — for sustainable human exploration of the Moon.

Charged with returning to the Moon in the next four years, NASA’s Artemis program will reveal new knowledge about the Moon, Earth and our origins in the solar system. The Human Landing System is a vital part of NASA’s deep space exploration plans, along with the Space Launch System rocket, Orion spacecraft and Gateway.

“When I say this is historic,” NASA Administrator Jim Bridenstine said, “I mean that in the year 2020, Congress gave us a bipartisan budget that included funding for a human landing system — something we as an agency and as a country have not had since 1972. Today we’re going under contract with three companies that are going to take us all the way to the Moon.”

The human landing system awards under the Next Space Technologies for Exploration Partnerships Appendix H Broad Agency Announcement are firm-fixed price, milestone-based contracts. The total combined value for all awarded contracts is $967 million for the 10-month base period.

Blue Origin is the prime contractor for the National Team — which includes Lockheed Martin of Bethesda, Maryland; Northrop Grumman of Falls Church, Virginia; and Draper of Cambridge, Massachusetts. The team is developing an Integrated Lander Vehicle — a three-stage lander to be launched on its own New Glenn rocket and United Launch Alliance Vulcan rocket.

Dynetics proposed a team with more than 25 subcontractors specializing in both larger elements and the smaller system-level components of the Dynetics Human Landing System — a single structure providing the ascent and descent capabilities that will launch on the Vulcan.

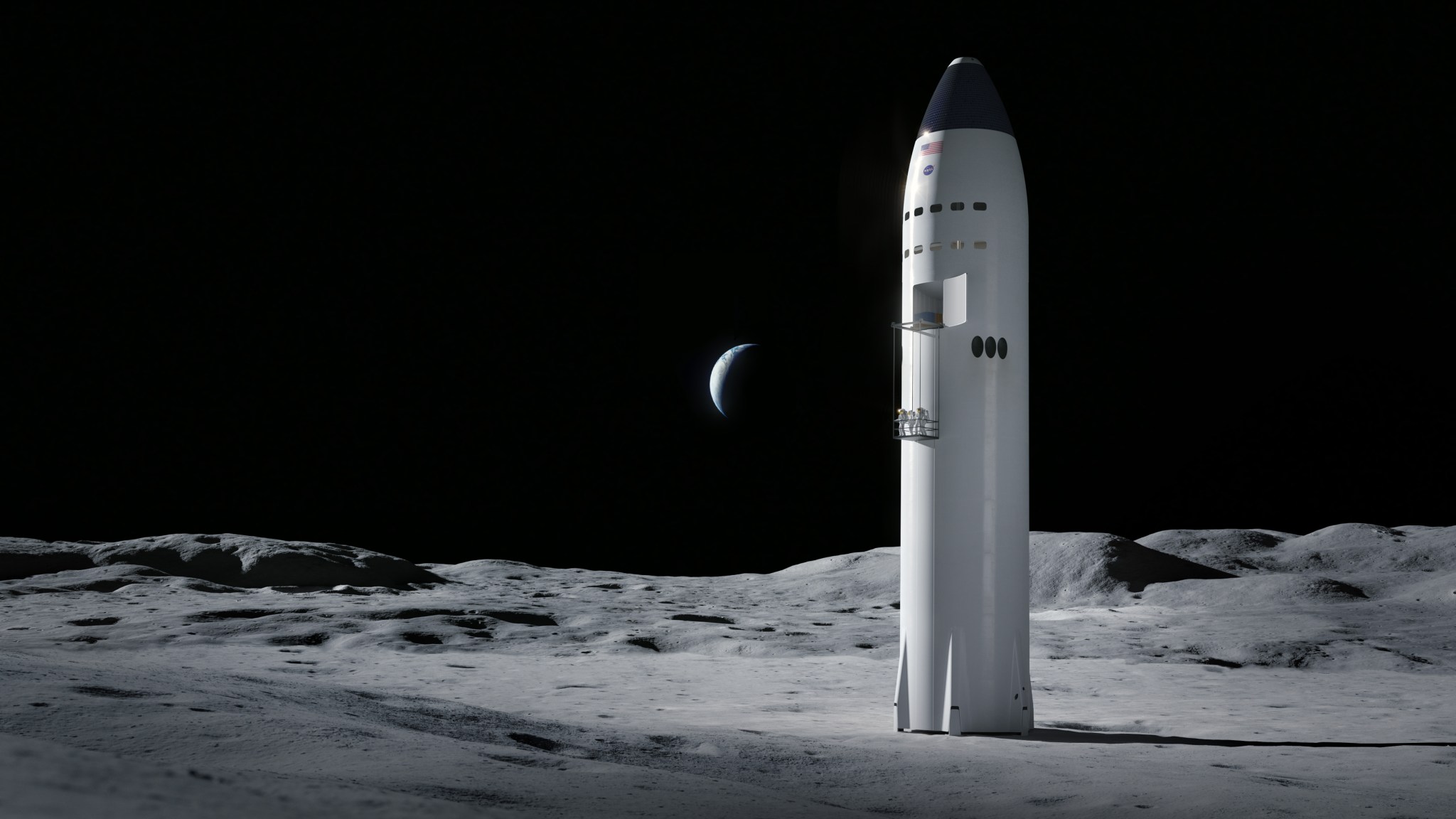

SpaceX is developing the Starship — a fully integrated lander that will use the SpaceX Super Heavy rocket.

“One thing we were striving for with the solicitations and announcements was to see what U.S. industry could bring us in respect to innovation,” said Lisa Watson-Morgan, Human Landing System program manager at NASA’s Marshall Space Flight Center, “and boy did they deliver. We have three notably different architectures — from a one-stage, a two-stage and a three-stage architecture. That achieves the innovation that we wanted.”

NASA’s commercial partners will refine their lander concepts through the contract base period ending in early 2021. During that time, the agency will evaluate which of the contractors will perform initial demonstration missions.

NASA will later select firms for development and maturation of sustainable lander systems followed by sustainable demonstration missions. NASA intends to procure transportation to the lunar surface as commercial space transportation services after these demonstrations are complete. During each phase of development, NASA and its partners will use critical lessons from earlier phases to hone the final concepts that will be used for future lunar commercial services.

NASA experts will work closely with the commercial partners building the next human landing systems, leveraging decades of human spaceflight experience and the speed of the commercial sector to achieve a Moon landing in 2024.

Watson-Morgan will assign NASA personnel to support the work of each contractor — providing direct, in-line expertise to the companies as requested in their proposals.

The Human Landing System Program will also perform advanced development and risk reduction activities, working in parallel to better inform the approach for the 2024 mission and the necessary maturation of systems for the future sustaining architecture.

“It’s important that our agency do this now,” Bridenstine said. “The whole world has been shaken by this coronavirus pandemic. Yet, we need to give people hope. We need to give them something they can look up to, to dream about. I think that’s what NASA does.”

Goodwin, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Commits to Future Artemis Missions with More SLS Rocket Engines

NASA has awarded a contract to Aerojet Rocketdyne to manufacture 18 additional Space Launch System RS-25 rocket engines to support Artemis missions to the Moon.

The follow-on contract is valued at $1.79 billion – which includes labor to build and test the engines, produce tooling and support SLS flights powered by the engines. This modifies the initial contract awarded in November 2015 to recertify and produce six new RS-25 engines and brings the total contract value to almost $3.5 billion with a period of performance through Sept. 30, 2029, and a total of 24 engines to support as many as six additional SLS flights.

“This contract allows NASA to work with Aerojet Rocketdyne to build the rocket engines needed for future missions,” said John Honeycutt, the SLS program manager at NASA’s Marshall Space Flight Center. “The same reliable engines that launched more than 100 space shuttle missions have been modified to be even more powerful to launch the next astronauts who will set foot on the lunar surface during the Artemis missions.”

Each SLS rocket uses four RS-25 engines, providing a total of 2 million pounds of thrust to send SLS to space. The SLS rocket leverages the assets, capabilities and experience of NASA’s Space Shuttle Program, using 16 existing RS-25 shuttle engines for the first four SLS missions. These engines were updated with new controllers — the brains that control the engine — and upgraded and tested to fly at the higher performance level necessary to launch the SLS, which is much larger and more powerful than the shuttle.

The rocket engines are mounted at the base of the 212-foot-tall core stage, which holds more than 700,000 gallons of propellant and provides the flight computers that control the rocket’s flight. The engines for the Artemis I mission to the Moon have already been assembled as part of the core stage, which is undergoing Green Run testing at NASA’s Stennis Space Center.

“We’ve already begun production on the first six new RS-25 engines,” said Johnny Heflin, the SLS engines manager. “Aerojet Rocketdyne has restarted the production lines, established a supplier base and is building engines using advanced techniques that reduce both the cost and time for manufacturing each engine.”

The engines are built at Aerojet Rocketdyne’s factory in Canoga Park, California. Working with NASA, Aerojet has implemented a plan to reduce the cost of the engines by as much as 30% by using more advanced manufacturing techniques to modify some of the rocket components. Some of these modified components have already been tested during engine tests that replicate the conditions of flight. The new digital controllers are built by Honeywell Aerospace in Clearwater, Florida, a major subcontractor to Aerojet Rocketdyne.

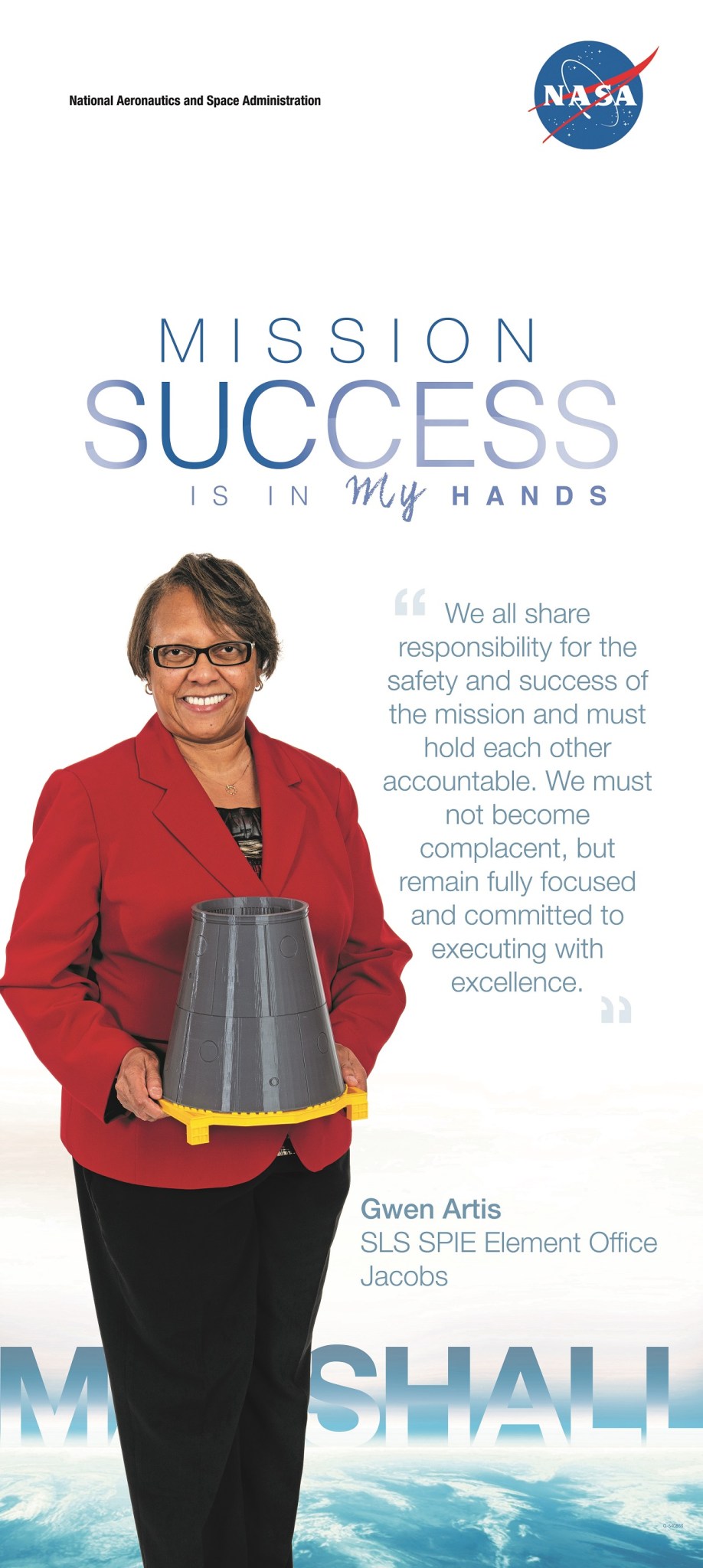

Mission Success is in My Hands: Gwen Artis

Editor’s note: This is the second in a series of articles spotlighting how eight team members at NASA’s Marshall Space Flight Center make meaningful connections between their jobs and the safety and success of NASA and Marshall missions. The Mission Success Is in Our Hands initiative is a centerwide campaign led by Marshall’s Safety and Mission Assurance Directorate and partner Jacobs Engineering of Huntsville that promotes and strengthens the center’s focus on mission, hardware and crew safety.

By Corinne Edmiston

When you are part of a team producing a key piece of hardware for NASA’s Artemis program, safety and communication go hand in hand.

NASA’s Marshall Space Flight Center’s Gwen Artis, a senior systems engineer, is cognizant of that. For more than 30 years, Artis has supported a variety of missions at Marshall, including NASA’s Chandra X-Ray Observatory and numerous payload operations missions. She is currently working with NASA’s Space Launch System Program, where she serves as the technical assistant for the launch vehicle stage adapter.

The launch vehicle stage adapter is a critical attachment point between the SLS rocket’s core stage and upper stage. It is the largest segment of the rocket manufactured at Marshall. The first completed launch vehicle stage adapter for flight on Artemis I, the first integrated mission of the SLS rocket and NASA’s Orion spacecraft, will be delivered to NASA’s Kennedy Space Center for launch preparations this summer.

Artis assists with the oversight of the design and technical elements of manufacturing the launch vehicle stage adapter flight hardware at Marshall to ensure it is ready for integration activities at Kennedy.

“LVSA production and integration tasks at times require team members to work at high elevations, in confined spaces, around chemicals and operate large equipment,” she said. “I share the responsibility for making sure the team has the resources they need, that they are interfacing with the appropriate technical authorities to maintain awareness of any hazardous operations and subsequently implementing appropriate NASA and Marshall operation and safety procedures.”

The importance of safety and attentiveness was a lesson she learned early in her career.

“I was a co-op student when the Challenger accident occurred,” she said. “Up until that point, shuttle missions seemed routine. I learned that day and was reminded years later in 2005 when I almost died from a routine surgery, that no matter how monotonous a task or undertaking may be, never become complacent, remain focused and definitely make sure safety is the highest priority.”

She says team communication is key to the success of any mission, especially when a group is responsible for a piece of hardware that will help enable America’s return to the Moon.

“I try to make sure team members know they can speak up and are comfortable in doing so,” Artis said. “I encourage them by expecting them to speak up and voice concerns in any team meetings — by email, phone call or in person — and reinforcing the need to and by making sure they know it will be appreciated when they do.”

By giving team members the chance to participate in conversations related to safety and mission success, team members also gain a greater understanding of the broader aspects of the overall mission — not just their piece of it. Team members who participate in both the programmatic and technical aspects of their assignment contribute, from the outset, to the mission’s success in a uniquely important way, Artis said.

“We have a shared responsibility for the safety and success of the mission and must hold each other accountable,” Artis said. “We must not become complacent, but remain fully focused and committed to executing with excellence.”

For Artis and her team, the mission may begin at Marshall but their diligence will contribute to the successful launch of the first Artemis mission to the Moon from Kennedy, ushering in new era of lunar exploration as a result.

Edmiston, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Centennial Challenges Gets Green Light for Development of New Challenge Managed by Marshall

By Amanda M. Adams

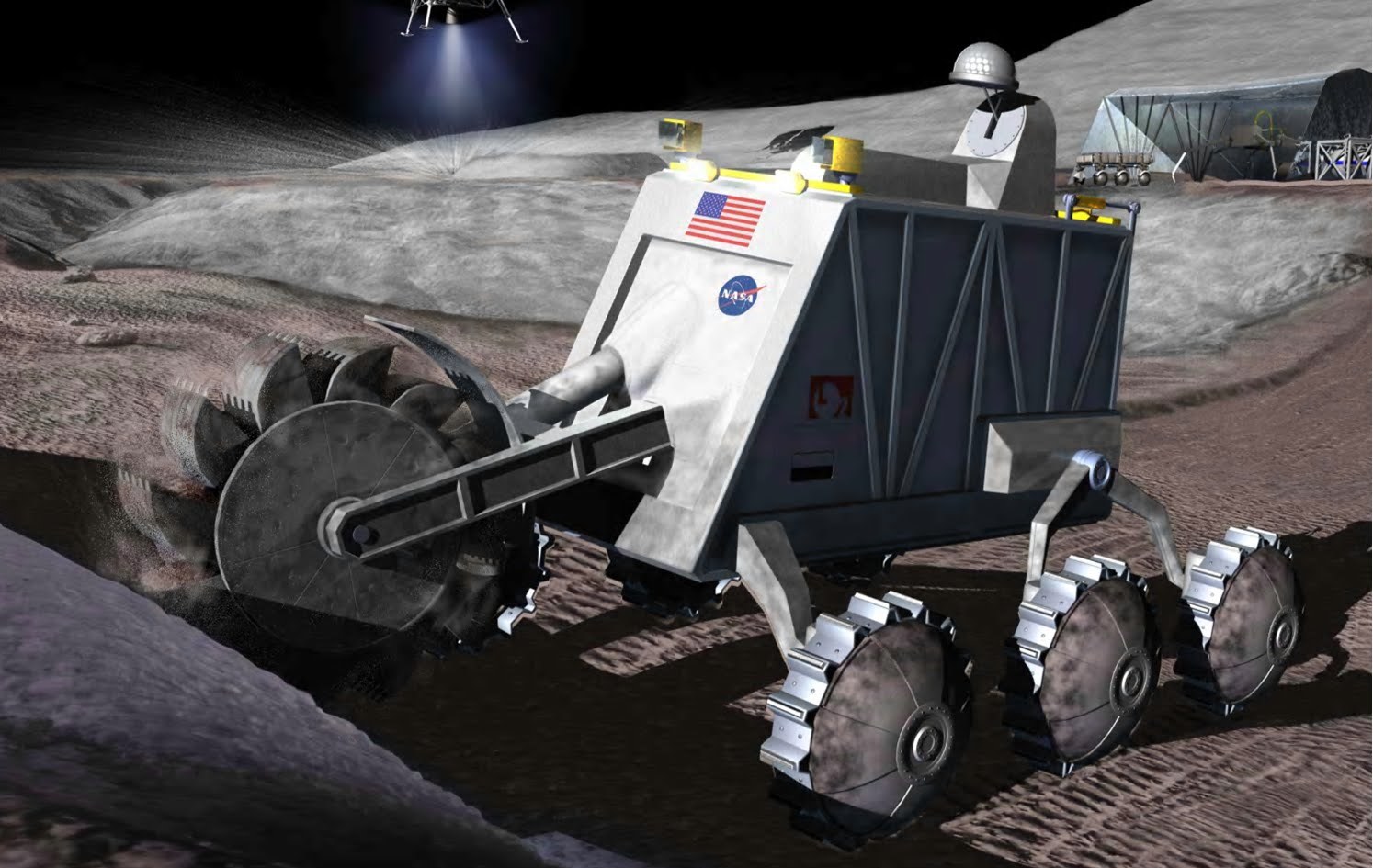

The Centennial Challenges program, managed by NASA’s Marshall Space Flight Center, was recently given a green light to develop a new challenge centered on excavation of lunar regolith to help the agency meet the goals of sustaining human presence on the Moon and eventually Mars. The challenge will be open to the public and co-managed by Marshall and NASA’s Kennedy Space Center.

“NASA is always looking for cutting-edge technologies that can be applied to current or future missions and Marshall is proud to co-lead this challenge that will further that goal,” said Preston Jones, associate director, technical, at Marshall. “The success of previous challenges is helping the agency advance technologies that will enable us land on the Moon and Mars. This challenge will explore areas that are crucial to deep space exploration and the Artemis program.”

Centennial Challenges offer incentive prizes to the public, academia and industry working to develop revolutionary solutions to problems of interest to NASA and the nation. This will be the first Centennial challenge to be managed by Marshall. The center, along with Kennedy, will provide subject matter experts and help develop official rules. Additionally, testing facilities at the two sites could be used in demonstrating the technologies developed by competing teams to aid in judging the competition.

The Centennial Challenges team presented the plan for the new challenge at the Space Technology Mission Directorate Program Management Council’s virtual meeting April 15, and received approval to proceed with development of the challenge. This allows the program to partner with academia and industry to finalize details of the competition. The three-phase challenge is expected to have a prize purse of up to $5 million and open for registration no earlier than November 2020.

Due to the properties of regolith, and extreme environmental conditions present on the Moon, existing excavation technologies available on Earth are not viable options for the lunar surface. The goal of the competition is development of autonomous excavation technologies for near-term lunar missions that address key operational elements and environmental constraints. The technologies developed and demonstrated as part of the competition are expected to facilitate manufacturing and construction for lunar infrastructure that will be needed for future missions to the Moon and beyond.

“The challenge is an enabling and timely effort to expand lunar exploration and commercial enterprise in space,” said John Vickers, principal technologist for NASA’s Space Technology Mission Directorate. “These technologies are needed from the beginning to enable our capabilities for in-situ resource utilization and to prepare for a broad array of lunar surface infrastructure emplacement.”

Vickers will serve as the principal technologist and subject matter expert for the challenge and will lead the effort in establishing goals and success criteria for the competition.

To kick off the development of rules for the challenge, the Centennial Challenges team and experts from NASA will meet for a virtual workshop May 11-12. In February, the team hosted a two-day workshop at the U.S. Space & Rocket Center, where leaders from NASA, academia and industry participated in brainstorming activities to learn about and explore technology gaps related to the challenge.

Adams, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

Marshall Summer Internships Will Be Virtual

By Taylor Goodwin

NASA’s Marshall Space Flight Center typically welcomes hundreds of student interns annually. This year, the program is going virtual.

Out of an abundance of caution for the safety of the workforce and students in response to COVID-19, Marshall will provide telework opportunities for interns who would typically spend the summer on-site.

Out of thousands of competitive applicants, Marshall mentors selected the top candidates to participate in either research or other experiential learning under their guidance. The deadline to apply for the summer term has passed, and all offer letters were delivered by the end of April — giving students a month’s time to prepare for their role in NASA’s mission.

Though telework will not be possible for all candidates, those selected who are able to contribute to the mission virtually will be given the opportunity to do so for a minimum of eight weeks beginning June 15.

Marshall’s protective services and internet technology teams are working to ensure that students have the necessary equipment to fulfill their duties. Tentatively, interns will be shipped a laptop and a virtual private network token, allowing them to access the NASA network from their respective locations.

While the total number of interns will likely be significantly less than routine terms, Marshall’s Office of STEM Engagement is dedicated to giving students the most valuable experience possible.

“The agency’s main goals are to inspire and motivate students to pursue careers in science, technology, engineering and mathematics, and to engage the public in shaping and sharing the experience of exploration and discovery,” said Tracey Washington, NASA internships and fellowships lead in Marshall’s Office of STEM Engagement. “Even in an unconventional setting, we will do everything in our power to achieve that goal.”

Though many normalcies have been put on hold, the Office of STEM Engagement is planning for the future.

Individuals interested in applying for the fall term should submit their application no later than July 6. Full-time high school, college and graduate-level students with U.S. citizenship and a cumulative grade point average of 3.0 — on a 4.0 scale — meet the minimum qualifications to participate.

After the workforce can safely return on-site, the team hopes to resume job shadowing and volunteering opportunities.

“This is a constantly evolving situation, and nothing is set in stone,” Washington said, “but we have hopes to provide other summer opportunities for the students who want to contribute to Marshall.”

Mentors can find more information on Inside Marshall.

For more information on the NASA internship program, answers to frequently asked questions and access to applications, visit here.

Goodwin, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

John Brunson, Mark Prill, Josh Stiles Honored as ‘HEO HErO’

John Brunson, left, Mark Prill and Josh Stiles are the latest NASA’s Marshall Space Flight Center team members to be recognized as a “HEO HErO” in tweets by Douglas Loverro, NASA associate administrator for the Human Exploration and Operations Mission Directorate. Brunson and Prill helped prepare and perform the Space Launch System core stage’s move from NASA’s Michoud Assembly Facility to the agency’s Stennis Space Center. Stiles provides support for the Human Landing System Appendix H acquisition, specifically in contract pricing. Marshall manages the SLS and HLS programs for NASA. HEO HErOes from across the agency are shared on @DouglasLoverro. (NASA)

Marshall Launches ‘We Are Artemis’ Digital Campaign

As NASA’s Marshall Space Flight Center team members continue to work remotely in response to the COVID-19 pandemic, they are finding new ways to connect virtually. The Space Launch System Program team at Marshall is spearheading a new digital employee initiative — “We Are Artemis” — to highlight the men and women who are working to help ensure the success of the agency’s future Artemis lunar missions and landings. Marshall team members can participate in the campaign by downloading the “We Are Artemis” sign from the SLS ExplorNet page, taking a picture with the sign and uploading the image back to the SLS ExplorNet page, along with their name and position. To highlight the diversity and scope of the Artemis Generation, employees are encouraged to feature their children, spouse and even their pets. (NASA)

Redstone Arsenal Road Projects Ramp Up During Reduced Traffic

By Jonathan Stinson

Roughly 20% of Redstone Arsenal’s workforce is coming through the installation’s gates daily during the COVID-19 pandemic, which has allowed for a unique opportunity to make improvements to the commute that the remainder of workers will have when they return on-site.

“Our contractors have been very busy since the state’s stay-at-home order allowed construction to continue,” said Kathy Martin, director of engineering for the City of Huntsville. “It has been very important that we take advantage of the decrease in traffic throughout the city as well as at each arsenal gate.”

In early April, the Garrison shut down Gates 3 and 10.

“A positive result we did not anticipate when we placed the majority of our workforce on telework status to help fight the spread of COVID-19 was the ability to tackle much needed infrastructure improvements on and around Redstone,” said Col. Kelsey Smith, Garrison commander. “Our community partners and Directorate of Public Works realized the opportunity quickly, and have worked hard to get normally high-traffic roads surrounding Redstone improved with little to no impact on our reduced commuter population.”

According to Martin, this allowed roadwork contractors to extend their working hours at Gate 7 so they can work near the gate beyond 9 a.m. to 3 p.m., times when the gate didn’t experience heavy traffic. The contractor is installing new signals at the intersection in front of Gate 7.

At Gate 3, road contractors have adjusted their work sequence to focus on improvements to Redstone Road to take advantage of the lack of traffic, according to Martin. The plan is to reconfigure the roadway and install a new signal.

The ability to stripe permanent pavement markings at Gate 1 has saved money by turning a weekend project — which includes overtime pay — into a project workers can do during normal business hours, according to Kris Leatherman, of the Engineering Division in the Directorate of Public Works at the Garrison.

The overall decrease in traffic has also helped improve construction conditions beyond the gates.

“The decrease in traffic has had a positive effect on the progress of Research Park Boulevard widening due to less commuters using Gate 9 during this time,” Martin said. “As part of this project, the demolition of the Old Madison Pike bridge has been able to progress much better than previously expected due to less congestion and increased safety in the area.”

Also, with less traffic on Cecil Ashburn Drive – a heavily traveled commuter route from southeast Huntsville and Hampton Cove to and from the arsenal — the road contractor has been able to perform additional slope maintenance without significant disruption to the traffic flow.

The city has also been able to expedite some maintenance work like resurfacing Patton Road.

“Safety and traffic delays are always primary concerns when performing roadway improvement projects,” Martin said. “Being able to improve safety for the workers and to the motorists have proven to be real benefit during this time.”

Stinson is assistant editor of Redstone Arsenal’s Redstone Rocket.

Alabama High School Student Names Future Mars Helicopter, Highlighted on ‘This Week @NASA’

An Alabama high school student submitted the winning name for the Mars helicopter and is featured in “This Week @NASA,” a weekly video program broadcast on NASA-TV and posted online.

When NASA’s Mars 2020 Perseverance rover launches to the Red Planet later this year, it will carry with it a helicopter — named Ingenuity. Vaneeza Rupani, a junior at Tuscaloosa County High School in Northport, submitted the name as part of NASA’s “Name the Rover” essay contest. Her winning essay was among 28,000 submitted from every U.S. state and territory. Ingenuity is an experimental aircraft that could help add an aerial component to future Mars exploration missions.

View this and previous episodes at “This Week @NASA” on NASA’s YouTube page.

This Week in NASA History: LAGEOS Launches – May 4, 1976

This week in 1976, the LAser GEOdynamic Satellite was launched from Vandenberg Air Force Base in California. LAGEOS was the first spacecraft dedicated exclusively to high-precision laser ranging and provided the first opportunity to acquire laser-ranging data that were not degraded by errors originating in the satellite orbit or satellite array. Small deviations in the satellite’s orbit were used to develop early models of Earth’s gravitational field. With an aluminum shell and solid brass core weighing over 900 pounds, LAGEOS is a passive satellite with no power, communications or moving parts. NASA’s Marshall Space Flight Center was responsible for the design, development and launch of the satellite. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)