In This Week’s Star

- Center Continuity Management Team Leads Marshall’s COVID-19 Response

- Payload Operations Continue While Marshall is at Stage 4

- NASA @ WORK Seeks Creative Solutions for Coronavirus Pandemic

- Marshall Ground, Marine Teams Integral to Moving SLS Rocket

- SpaceX Dragon Returns From Space Station With Findings From Marshall Research Partnership, More

- Chandra Data Tests ‘Theory of Everything’

- NASA Brings the Universe ‘Home’

- This Week in NASA History: STS-131 Launches – April 5, 2010

Center Continuity Management Team Leads Marshall’s COVID-19 Response

By Kristen Conner Hill

“Good afternoon everybody, welcome. We have a lot to get to today for the COOP,” said Steve Miley, associate director of NASA’s Marshall Space Flight Center, as he kicked off a Continuity of Operations — better known as COOP – meeting with the Center Continuity Management Team. The team has been meeting frequently since Marshall moved to initiate mandatory telework for the majority on the workforce on March 13 in response to the global coronavirus pandemic.

The Center Continuity Management Team, a network of Marshall leaders trained to respond to emergencies, operates under a regularly updated readiness plan for how NASA and its centers organize and tackle crises. When Marshall faces a situation that may trigger operational changes and is unable to open as normal, the COOP offers a framework for before, during and after a situation like the spread of the coronavirus. The team actively plans for severe weather, natural disasters and emergencies that could impact NASA operations. And when disasters loom, that planning turns to immediate action.

Miley leads this effort, delegated by Marshall Director Jody Singer. During this time of mandatory telework and social distancing because of the coronavirus, direct reports, deputies and key officials essential to center communications and operations participate from home offices. They come prepared to share what their employees and organizations need and can contribute to maintain the safety of the workforce and continuity of critical functions.

On this particular call, as Miley leads a discussion about the accessibility of the NASAPeople website subsections of Marshall and NASA’s Michoud Assembly Facility to employees outside the NASA firewall, a loud and low howl cuts through his words. That’s his beagle, Maggie, making herself known to colleagues that might otherwise never have met her.

“Sorry guys,” Miley says, as Singer makes a joke and a chorus of chuckling ensues. “Oh, it’s good we can laugh,” he notes before getting back to business.

For this group, COOP work has surged. The frequency of calls in the past few weeks has increased markedly from weekly to daily, and sometimes even more often if needed. It is amazing, Miley noted, how quickly the group can assemble with seemingly a moment’s notice, allowing for rapid information sharing and decision-making.

“The pace of the COOP meetings is demand-driven and event-driven,” Miley said. “We could have 50 people on a conference call in 15-30 minutes. We have done that numerous times. We are very flexible and responsive to urgent needs.”

“That’s just a testament to how seriously we are taking this,” said Carole Valenti, Marshall’s Emergency Management director and the center COOP coordinator. “Everybody has come together to jump into this. There are no egos here. Everybody understands there are no stupid questions and we help each other seamlessly. We work hard, we get a lot done.”

Valenti is in charge of updating the Marshall Continuity of Operations Plan every year in concert with national and NASA emergency management updates and best practices. It allows Marshall to react swiftly as its capabilities evolve to save time and potentially lives during a crisis situation.

“For a car to work, you have to have gas, mechanics,” Valenti said. “You can’t go out there with just one tire. You have to have all the parts and they all have to play their role at the correct time. With our COOP, we know what everyone else is doing and we are talking to each other. This calms any fears and provides an avenue to who is coming on center, what buildings are open and every office’s operations during an event like this.”

Marshall’s workforce may not see the response team in action, but everyone is affected by the decisions that are made, which are often rapidly communicated to the workforce. For example, during the March 13 COOP call, Miley coordinated a focused discussion prompted by David Thaxton, Marshall occupational health officer, providing insights about a potential case of COVID-19 among the Marshall workforce. While maintaining privacy, the group evaluated the best course of action to protect employees and limit any further risk on-site.

A short time later, Singer sent notification to all Marshall employees about the then-confirmed case and moved the center to Stage 3 in the NASA Response Framework. After numerous team meetings in the following weeks, Marshall moved to and remains at Stage 4 of that framework.

Thaxton said he believes the heavy decisions Singer makes based on communication with the team have made a huge difference in the health and safety of the Marshall workforce. “I think we have done the right things to keep people safe,” he said.

For Miley, that’s what it’s all about. “It goes back to Jody’s management priorities: mission, people and partnerships,” he said. “We want to get it right. We want to get people and partners out of harm’s way if we can — get them home, quarantined, or otherwise protected so when the pandemic is over, everyone is healthy and can come back full-speed on our mission.”

When a return to the center is authorized, the team will also monitor that process to maintain an order transition. Then comes documenting lessons learned and updating the center’s pandemic plans for the next time the COOP will be activated. With the new age of telework and the ways Marshall employees have proven their agility and ability to adapt to new technology, Marshall leaders have seen how missions can continue even when employees are challenged to work in new ways.

Wrapping up his COOP call, Miley asks the group for final comments. “We will be back in touch,” he says to close. “Everybody, take care.” And you can tell he means it.

Hill, an LSINC Corp. employee, supports the Office of Strategic Analysis & Communications.

Payload Operations Continue While Marshall is at Stage 4

By Janet Anderson

In the immediate aftermath of the tragic April 2011 tornadoes that wreaked havoc across North Alabama, the Payload Operations Integration Center team at NASA’s Marshall Space Flight Center came together and continued to manage science operations for the International Space Station. Today, in the face of the coronavirus pandemic, operations continue to enable ongoing research on the space station.

On March 29, as Marshall began transitioning operations to Stage 4 in the NASA response framework, the real-time links between the space station crew and scientists around the world continued.

“We’ve not missed a beat, operationally,” said Mike Shell, Increment 62 payload operations manager. “We have maintained a nominal science and crew schedule without any change to our science plan due to the COVID-19 event.”

The payload operations team achieved about 46 hours of science the week of March 16 and continued with 50 hours the week of March 23, all within the average number of hours for science operations. These hours include operations for NASA and its international partners. Additionally, the team delivered 33,115 commands to operate science payloads on the station the week of March 23. According to Shell, the team downlinked an average of 1,052GB per day of science data for the weeks of March 16 and 23 — almost 15TB.

“Our payload operations facility is the nerve center for all the science that occurs daily on the space station,” said Joseph Pelfrey, acting payload operations cost account manager and deputy manager for the Human Exploration Development & Operations Office. “We are mission-critical in the agency’s execution of science research and I am proud of the team for continuing to rise to the challenge during this time.”

Marshall’s move to Stage 4 reduced the number of employees supporting payload operations from 30 flight and ground control team members, scheduled over three daily shifts, to 24 team members. Other team members are available on an on-call basis. To help the crew in orbit conduct record amounts of scientific study, the operations center is staffed 24 hours a day, 365 days a year.

“Our payload operations group already has that team mentality and they believe in it,” said Bobby Watkins, manager of the Human Exploration Development & Operations Office. “Their team mentality is essential to mission success at Marshall.”

Anderson is a public affairs officer in the Office of Strategic Analysis & Communications.

NASA @ WORK Seeks Creative Solutions for Coronavirus Pandemic

By Will Bryan

No one is unaffected by the ongoing coronavirus pandemic. Whether fighting the disease, knowing someone who is, or someone working from home with kids and pets wanting attention, for everyone everyday life has changed.

In an effort to understand the impacts of COVID-19 and help in the battle, NASA is employing its internal, innovation challenge platform NASA @ WORK to collect ideas from the agency’s workforce. All NASA civil servants, contractors and interns are encouraged to participate by submitting ideas or simply voting on those ideas that are submitted. If contractors have questions or concerns about participation, they should speak with their management.

Released April 1, the new challenge seeks to help with the response to COVID-19. Submissions are due by April 15 and should fall into one of three specific areas or the fourth, open-ended category. Following are brief descriptions of those areas:

- Novel approaches to enable rapid, effective personal protective equipment: Includes ideas for development of self-sanitizing personal protective equipment, new applications for fast, robust and inexpensive sterilization for personal protective equipment reuse and novel approaches for repurposing personal protective equipment.

- Rapid design and prototyping of innovative ventilation devices: Includes solutions that contain segmented-use ventilation devices designed for rapid prototyping that can move quickly through the regulatory approval process and that can be rapidly manufactured at scale.

- Forecast COVID-19’s spread and its impact to society and Earth system: Ideas that will help researchers understand how the virus spreads, forecast the spread and determine what the impacts of the virus will be to the planet and humans. Innovative approaches to data mining and predictions using that data will help with preparation and execution of counter measures and recovery efforts.

- Other NASA-specific contributions to COVID-19-related needs: Includes, but is not limited to, telemedicine, digital tools to help healthcare workers monitor patients, telerobotics and lessons and applications about social isolation and blended work-home environments learned from human space exploration.

More details about each area, along with submission requirements, judging criteria and the evaluation process can be found on the challenge’s page at the NASA @ Work site.

Problems in the realm of space exploration often need creative solutions. The platform enables the NASA team to issue challenges, have discussions and develop viable answers to the difficulties faced.

Since its inception in 2011, NASA @ WORK has hosted 176 challenges, including 160 successes; 158 of those successes have been implemented or are planned for implementation and 150 have resulted in cost savings. NASA @ WORK is managed by the agency’s Center of Excellence for Collaborative Innovation.

Bryan, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Ground, Marine Teams Integral to Moving SLS Rocket

By Corinne Edmiston and Jonathan Stinson

As NASA prepares for the launch of Artemis I, the first mission of the agency’s Space Launch System rocket and Orion spacecraft to the Moon, one team will be there every step of the way: the aptly nicknamed “SLS Move Team.”

The team, based out of NASA’s Marshall Space Flight Center, ensures all the flight hardware for the SLS rocket’s core stage is safely and efficiently transported from the site where it was manufactured to various test facilities and — ultimately — to its future launch site.

“Marshall’s Ground and Marine Transportation teams are responsible for the handling and transportation of the SLS rocket’s core stage, which is the largest rocket stage NASA has assembled, tested and transported since the Apollo Program,” said Robert Rutherford, transportation and logistics engineering group lead at Marshall. “We started logistics planning for both the moves of structural test articles of the individual elements and for the entire Artemis I core stage early on in the program.”

While the full team is divided between ground and marine activities, they typically operate together as one cohesive unit to successfully transport the large hardware for the megarocket’s 212-foot-tall core stage. The huge stage includes two giant propellant tanks and four RS-25 engines, each the size of a compact car.

The teams’ coordination and efforts were prominently displayed as the first SLS rocket core stage was rolled out from NASA’s Michoud Assembly Facility to the agency’s Pegasus barge Jan. 8, then transported to nearby NASA’s Stennis Space Center for the core stage Green Run test series. Once the barge and flight hardware arrived at Stennis, the Ground Operations team was again at work, helping to prepare, lift and install the flight hardware into the B-2 Test Stand for the test campaign.

“The effort to move the SLS rocket’s core stage from Michoud to Stennis and installing it into the B-2 Test Stand is a result of extensive preparation,” said Bryan Jones, logistics engineering and ground transportation team lead at Marshall. “It was a true team effort. Without the support of all parties that play a part in the operations, we would not be successful.”

Both ground and marine teams prepared for the move of actual flight hardware by transporting four SLS structural test articles from Michoud to Marshall for structural testing. During the spring and summer of 2019, the move team transported the SLS core stage pathfinder, a full-scale replica of the stage itself, to Stennis and NASA’s Kennedy Space Center.

Teams spend months meticulously planning and developing detailed transportation move procedures to ensure test articles and flight hardware alike are delivered without a mishap. They use a myriad of specialized equipment, including transporters specifically designed to accommodate and hold the hardware, and Pegasus.

“Each member of the team understands the privilege and responsibility that NASA’s ground and marine transportation teams have been given in handling hardware that will enable the United States to send American astronauts to the Moon and on to Mars,” said Alan Murphy, team lead of marine operations for Pegasus. “The size of the SLS core stage pathfinder and the flight hardware core stage, although massive, did not intimidate the Pegasus crew as we leaned on our experience from shipping the four structural test articles.”

Marshall’s Ground and Marine Transportation teams coordinate their efforts with other NASA organizations and dozens of agencies, including the Tennessee Valley Authority, Army Corps of Engineers, Coast Guard, National Oceanic and Atmospheric Administration and Redstone Arsenal.

Kristoffer Leatherman, a project manager with the U.S. Army civil engineer in Redstone’s Garrison Headquarters, assisted with the transportation of the structural test article of the SLS liquid hydrogen tank it to the test stand at Marshall. One of his first big projects was in January 2019, helping NASA navigate the arsenal’s roads with its specialized equipment. The test tank had to be moved from Pegasus, docked along the Tennessee River, to Test Stand 4693.

Arsenal and Marshall teams evaluated the width of the roadways and bridge structures as well as the basic route, which includes hills and curves. Leatherman said it took significant construction to mold roads into pathways that could handle the machine.

“This is the stuff they are going to use to potentially go to Mars,” Leatherman said. “So, this was my little contribution to it.”

The SLS liquid hydrogen tank is the largest piece of hardware on the deep space rocket. To put that in perspective, the average double-wide trailer escorted on Interstate 65 is usually transported in two sections, which measure about 20 to 30 feet wide and 40 to 60 feet long, depending on how it’s split.

The SLS rocket hardware doesn’t split.

“Before NASA transports any hardware, teams meet to consider every aspect of the move — from the strength of the roadways to the weather the day of the move,” Rutherford said. “Because of the SLS core stage’s height, weight, width and length, special combinations and modifications had to be made to roads, docks, even power lines, and to the barge itself, to accommodate the total weight and width of the rocket hardware.”

While the core stage undergoes Green Run testing at Stennis, Marshall’s Ground and Marine Transportation teams will again be at work with arsenal leaders later this year to transport the launch vehicle stage adapter, the part of the rocket that connects the core stage to the upper part of the rocket. The hardware will move from Marshall, where it is manufactured, to Kennedy, where engineers will prepare it for integration to the rest of the rocket ahead of the launch of Artemis I.

Edmiston, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications. Stinson is assistant editor of Redstone Arsenal’s Redstone Rocket.

SpaceX Dragon Returns From Space Station With Findings From Marshall Research Partnership, More

By Erin Winick

A Dragon cargo spacecraft, which arrived March 9 at the International Space Station to deliver dozens of scientific experiments as part of SpaceX’s 20th cargo resupply mission, is home again. The Dragon undocked April 7 and successfully flew back to Earth, carrying samples, hardware and data from completed investigations — among them a noteworthy scientific study led by NASA’s Marshall Space Flight Center.

Here are details on some of the investigations returning to the ground for further analysis and reporting of results.

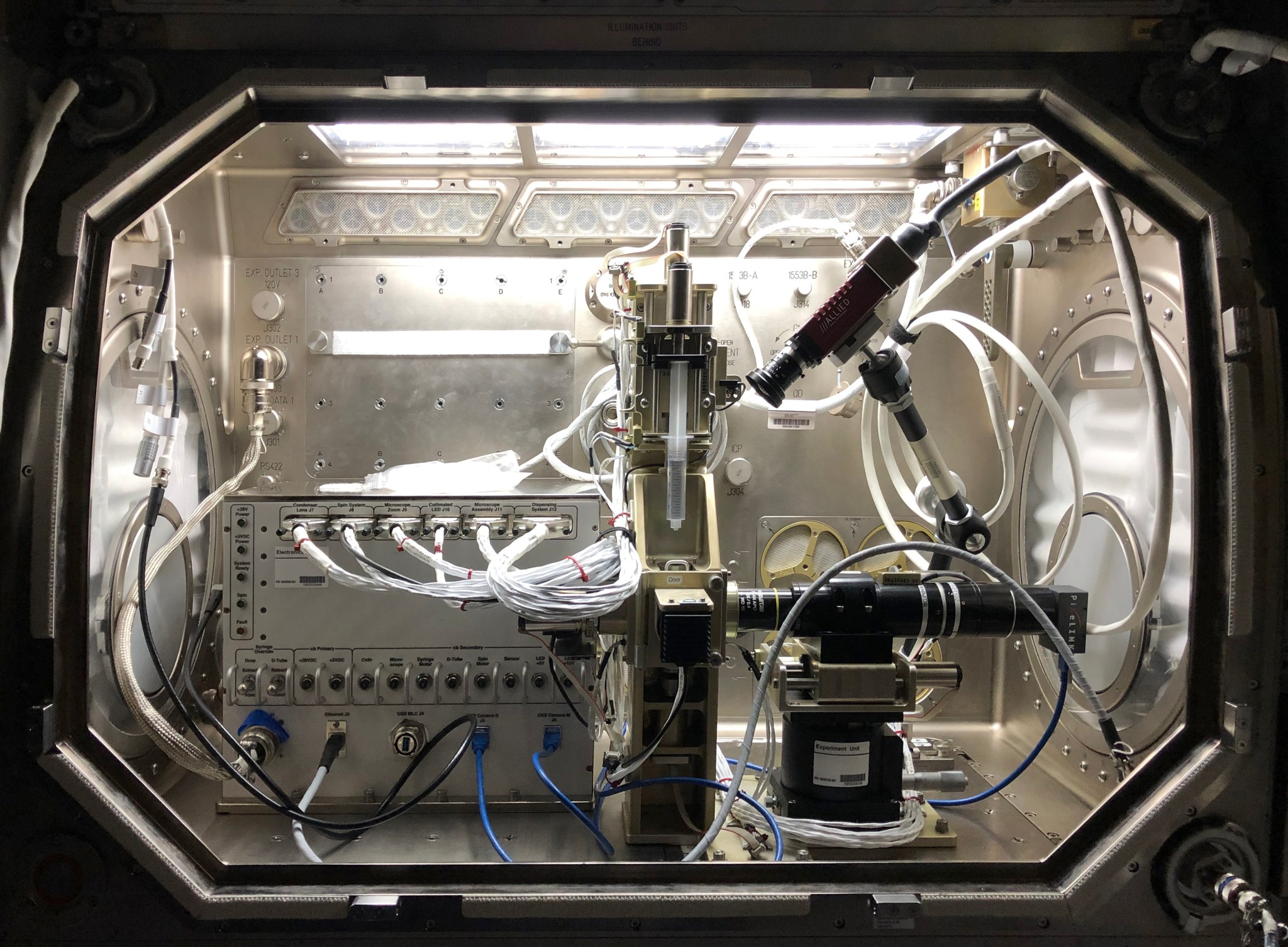

Examining amyloid formation in microgravity

The Ring-Sheared Drop investigation is an innovative experiment flown to the space station in July 2019 to help in the fight against aggressive neurodegenerative diseases, such as Alzheimer’s and Parkinson’s.

Developed by Teledyne Brown Engineering of Huntsville under contract to Marshall, the project takes advantage of the fact that fluids float in microgravity, allowing researchers to examine formation of amyloid fibrils in liquids held together by surface tension rather than by a container. Amyloids are abnormal fibrous deposits found in organs and tissues and are associated with neurodegenerative conditions. These proteins can lose characteristic properties and come out of solution. As they accumulate over time, they may disrupt the healthy function of tissues and organs.

Results from this experiment could contribute to a better understanding of and treatments for these neurodegenerative diseases, and the study findings could contribute to development of advanced materials for a variety of uses.

Generating nutritional meals

Planning ways to supply food for a multiyear mission on the Moon or Mars while keeping astronauts healthy on the long trip may require making fresh food and nutrients in space. BioNutrients, an investigation developed by scientists at NASA’s Ames Research Center, demonstrates a technology that enables on-demand production of nutrients needed during long-duration space missions.

The process uses microbes, such as baker’s yeast, expressly engineered to make fresh nutrients for human consumption starting from dry powdered media — food for the yeast — and water. The fresh nutrients can supplement potential vitamin losses from food stored for very long periods.

Over the five-year study, astronauts intermittently activate specially designed packets containing the yeast — or, in the future, other microorganisms — and their food. The crew warms the packets for two days to allow the yeast to do its job, growing and producing the desired nutrients, and then freeze them for return to Earth for analysis.

These tests will allow scientists to check how long their specially engineered yeast can be stored and still deliver fresh nutrients needed by humans to stay healthy in space. Though designed for space, the system also could help provide nutrition for people in remote areas of our planet.

Printing human organs in space

Biological printing of the tiny, complex structures found inside human organs, such as capillaries, has proven difficult in Earth’s gravity, which requires an initial support structure to form the desired shape of the tissue.

The BioFabrication Facility attempts to take the first steps toward printing human organs and tissues in microgravity using ultra-fine layers of bioink that may be several times smaller than the width of a human hair. This research is part of a long-term plan to manufacture whole human organs in space using refined biological 3D-printing techniques.

The facility has successfully proved its basic functionality in orbit, said John Vellinger, president of Techshot, the Greenville, Indiana, company which developed the facility with sponsorship from NASA and the U.S. National Laboratory. The team will review its findings and make upgrades to enable high throughput use when the facility is returned to the space station.

For daily updates on science aboard the space station, follow @ISS_Research on Twitter, or the International Space Station on Facebook. For more information, visit Space Station Research and Technology News or the ISS National Lab.

Winick, a writer for the International Space Station Program Research Office at NASA’s Johnson Space Center, authored the original, expanded feature story, which is available here.

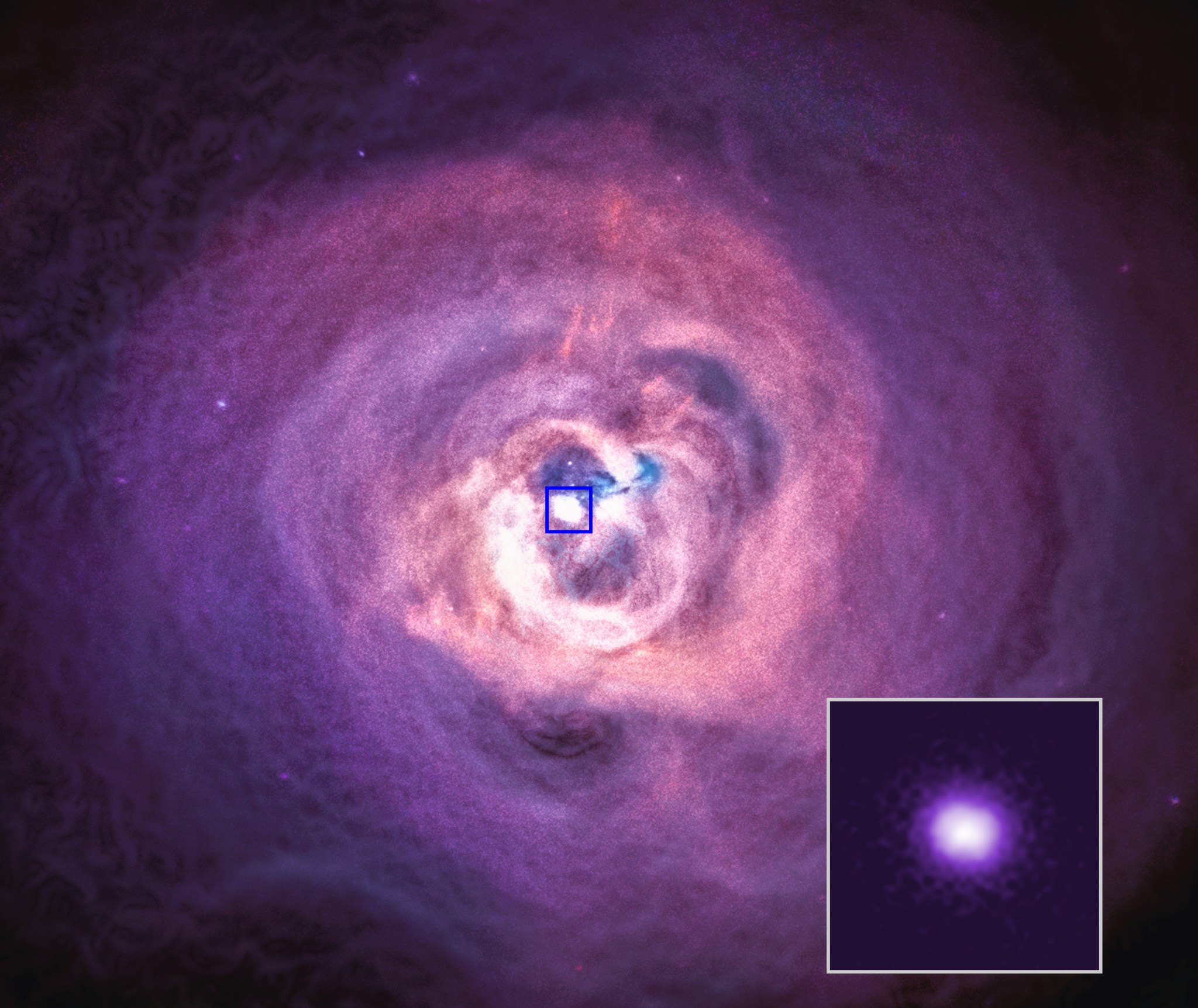

Chandra Data Tests ‘Theory of Everything’

By searching through galaxy clusters using NASA’s Chandra X-ray Observatory, astronomers recently made significant strides in the study of string theory — or the “theory of everything.”

One of the biggest ideas in physics is the possibility that all known forces, particles and interactions can be connected in one framework.

String theory is arguably the best-known proposal for a “theory of everything” that would tie together our understanding of the physical universe. Despite having many different versions of string theory circulating throughout the physics community for decades, there have been few experimental tests.

By using Chandra to search through galaxy clusters — the largest structures in the universe held together by gravity — researchers were able to hunt for a specific particle, known as an axion, that many models of string theory predict should exist. While the resulting lack of detection does not rule out string theory altogether, it does deliver a blow to certain models within that family of ideas.

“Until recently I had no idea just how much X-ray astronomers bring to the table when it comes to string theory, but we could play a major role,” said the leader of the study, Christopher Reynolds of the University of Cambridge in the United Kingdom. “If these particles are eventually detected it would change physics forever.”

These as-yet-undetected axions should have extraordinarily low masses. Some scientists think that axions could explain the mystery of dark matter — which accounts for the vast majority of matter in the universe.

One unusual property of these ultra-low-mass particles is that they might sometimes convert into photons — packets of light — as they pass through magnetic fields. The opposite may also hold true: Photons may also be converted into axions under certain conditions. How often this switch occurs depends on how easily they make this conversion — their “convertibility.”

Some scientists have proposed the existence of a broader class of ultra-low-mass particles with similar properties to axions, which would have a single convertibility value at each mass. But “axion-like particles” would have a range of convertibility at the same mass.

“While it may sound like a long shot to look for tiny particles like axions in gigantic structures like galaxy clusters, they are actually great places to look,” said co-author David Marsh of Stockholm University in Sweden. “Galaxy clusters contain magnetic fields over giant distances, and they also often contain bright X-ray sources. Together these properties enhance the chances that conversion of axion-like particles would be detectable.”

To look for signs of conversion by axion-like particles, the team of astronomers examined over five days the Chandra observations of X-rays from material falling toward the supermassive black hole in the center of the Perseus galaxy cluster. They studied the Chandra spectrum — the amount of X-ray emissions observed at different energies — of this source. The long observation and the bright X-ray source gave a spectrum with enough sensitivity to have shown distortions that scientists expected if axion-like particles were present.

The lack of detection of such distortions allowed the researchers to rule out the presence of most types of axion-like particles in the mass range their observations were sensitive to, below about a millionth of a billionth of an electron’s mass.

“Our research doesn’t rule out the existence of these particles, but it definitely doesn’t help their case,” said co-author Helen Russell of the University of Nottingham in the United Kingdom. “These constraints dig into the range of properties suggested by string theory and may help string theorists weed their theories.”

The latest result was about three to four times more sensitive than the previous best search for axion-like particles — which came from Chandra observations of the supermassive black hole in M87. The Perseus study is also about 100 times more powerful than current measurements that can be performed in laboratories on Earth for the range of masses that they have considered.

One possible interpretation of this work is that axion-like particles do not exist. Another explanation is that the particles have even lower convertibility values than this observation’s detection limit — and lower than some particle physicists have expected. They also could have higher masses than probed with the Chandra data.

A paper describing these results appeared in the Feb. 10, 2020, issue of The Astrophysical Journal and is available online.

NASA’s Marshall Space Flight Center manages the Chandra program. The Smithsonian Astrophysical Observatory’s Chandra X-ray Center controls science and flight operations from Cambridge and Burlington, Massachusetts.

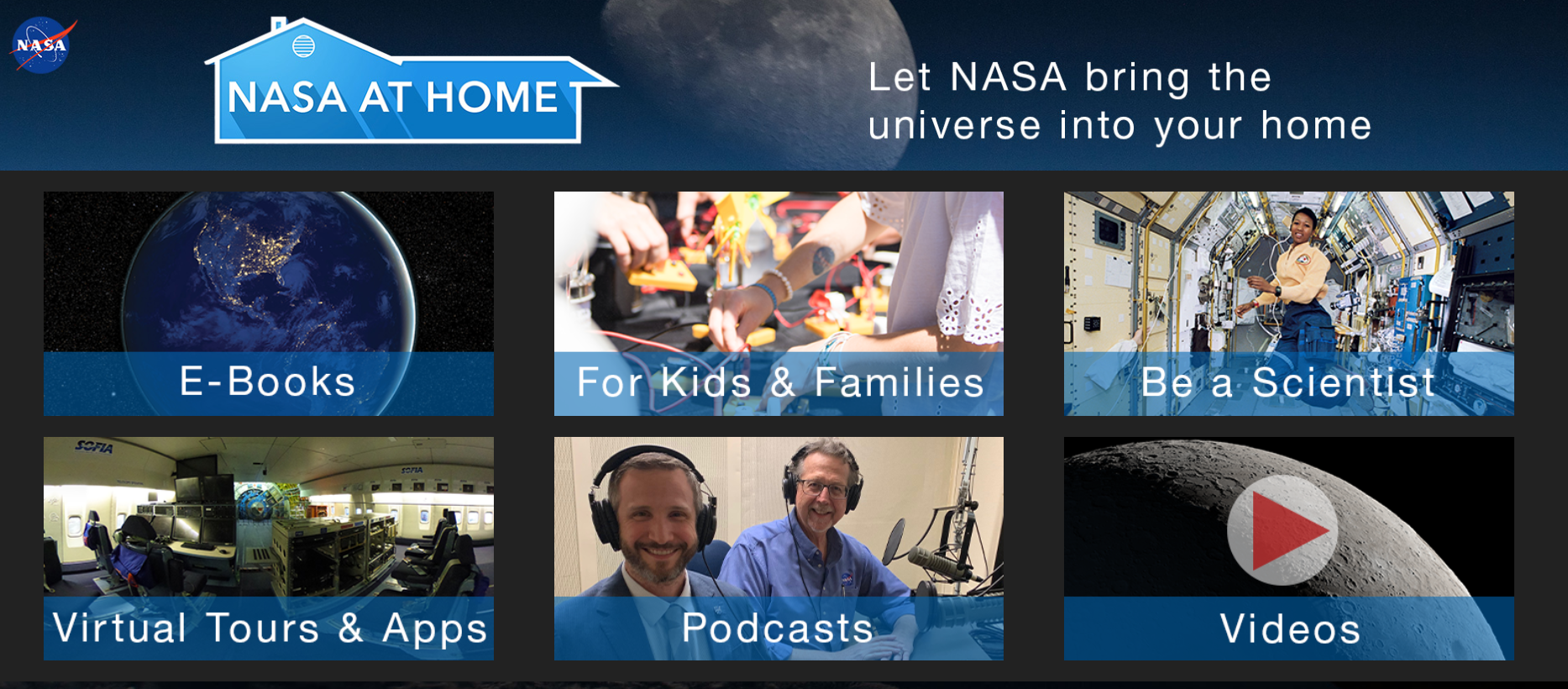

NASA Brings the Universe ‘Home’

NASA’s new website and social media campaign, NASA at Home, welcomes internet-browsing space enthusiasts and families to the agency’s beneficial discoveries, research endeavors and exploration initiatives — across the cosmos and right here on Earth — all from the comfort of their own homes.

NASA at Home serves as a one-stop repository of binge-worthy videos and podcasts, e-books on a variety of topics and do-it-yourself projects. There are also virtual and augmented reality tours for users to explore the International Space Station and NASA’s Hubble Space Telescope, and settle into the pilot’s seat of a NASA aircraft.

“We know people everywhere, especially students, are looking for ways to get out of the house without leaving their house,” said Bettina Inclán, associate administrator for NASA’s Office of Communications. “NASA has a way for them to see themselves in space with their feet planted safely on the ground — imaginations free to explore everywhere we go.”

The website also spotlights education and entertainment resources and activities for families, K-12 students and higher education students, including formal lesson plans and stories about how NASA science and exploration contribute to and benefit nearly every aspect of life on Earth.

NASA at Home offers ongoing opportunities to interact with agency experts such as astronaut Christina Koch, who served as space station flight engineer during Expeditions 59, 60 and 61. Koch, who set a record for the longest single spaceflight by a woman — 328 days — reads children’s books each weekday at 3 p.m. on Instagram live. The NASA program is designed to inspire students to pursue careers in the science, technology, engineering and mathematics fields.

For citizen scientists seeking ways to practice “safe science” at home during the COVID-19 pandemic, the site offers the opportunity to take part in real, ongoing research — from the far reaches of the solar system to one’s own backyard. Visitors to the site can help NASA climatologists track changes in clouds, water, plants and other Earth life; search for brown dwarfs and other planetoids in the outer solar system; or even help spot new exoplanets.

NASA at Home-themed programs also are available on NASA Television weekdays from 9 a.m. to 3 p.m., along with the agency’s regular lineup of around-the-clock mission coverage and news, conversations with astronauts on the space station, education spotlights on science, technology and exploration topics, and historical programs from NASA’s storied past.

This Week in NASA History: STS-131 Launches – April 5, 2010

This week in 2010, space shuttle Discovery, mission STS-131, launched from NASA’s Kennedy Space Center on the 33rd shuttle mission to the International Space Station. Discovery delivered a Multi-Purpose Logistics Module filled with science racks that were transferred to laboratories on the station. The modules were built by the Italian Space Agency and managed by NASA’s Marshall Space Flight Center. Today, the Payload Operations Integration Center at Marshall serves as “science central” for the space station, working 24/7, 365 days a year in support of the orbiting laboratory’s science experiments. After 20 years of continuous human presence, the space station remains the sole space-based proving ground and stepping stone toward achieving the goals of the Artemis program. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)