In This Week’s Star

- NASA Completes Welding on Massive Fuel Tank for First Flight of SLS Rocket

- Work Underway on Hardware that will do Double Duty on First SLS Flight

- NASA’s Asteroid-Bound Spacecraft Aces Instrument Check

- Faces of SLS: Vito Neal

- The Doctor Is In: Dr. Sanjay Gupta Discusses NASA and Studying Twins in Space

- Free Event to Celebrate International Observe the Moon Night Oct. 8

- ‘Mission Success is in Our Hands’ Promotes Safety and Success of NASA Missions

- Show Some Love: Participate in CFC Bus Tours and Service Days

- This Week in NASA History: Space Shuttle Program’s First Mated Vertical Ground Vibration Test Performed at Marshall — Oct. 4, 1978

- Obituaries

NASA Completes Welding on Massive Fuel Tank for First Flight of SLS Rocket

Welding is complete on the largest piece of the core stage that will provide the fuel for the first flight of NASA’s new rocket, the Space Launch System, with the Orion spacecraft in 2018. The core stage liquid hydrogen tank has completed welding on the Vertical Assembly Center at NASA’s Michoud Assembly Facility. Standing more than 130 feet tall, the liquid hydrogen tank is the largest cryogenic fuel tanks for a rocket in the world. The liquid hydrogen tank and liquid oxygen tank are part of the core stage — the “backbone” of the SLS rocket that will stand at more than 200 feet tall. Together, the tanks will hold 733,000 gallons of propellant and feed the vehicle’s four RS-25 engines to produce a total of 2 million pounds of thrust. This is the second major piece of core stage flight hardware to finish full welding on the Vertical Assembly Center. The core stage flight engine section completed welding in April. More than 1.7 miles of welds have been completed for core stage hardware at Michoud. Traveling to deep space requires a large rocket that can carry huge payloads, and SLS will have the payload capacity needed to carry crew and cargo for future exploration missions, including to Mars. (NASA/MAF/Steven Seipel)

Work Underway on Hardware that will do Double Duty on First SLS Flight

David Osborne, an Aerie Aerospace LLC machinist at NASA’s Marshall Space Flight Center, takes measurements prior to the start of precision machining of the Orion stage adapter for NASA’s new rocket, the Space Launch System. The adapter will connect the Orion spacecraft to the interim cryogenic propulsion stage for the first flight of SLS with Orion in late 2018. The ICPS is the liquid oxygen/liquid hydrogen-based system that will give Orion the big, in-space push needed to fly beyond the moon before it returns to Earth. The adapter also will carry 13 CubeSats to perform science and technology investigations that will help pave the way for future human exploration in deep space, including to Mars. The adapter’s top surface will be machined completely flat on a seven-axis mill turntable before hundreds of holes are drilled in it for bolting to the rest of the rocket. To complete the same work on the other side of the adapter, the hardware will later be flipped using a Posi-Turner load rotation device and an assembly jig, the ring that connects the Posi-Turner to the bottom of the adapter and rotates it. The adapter will then undergo inspections, and a special coating will be added to the top and bottom of the structure to make it more corrosion resistant. Engineers also are installing brackets on the adapter for the small secondary payload satellites. (NASA/MSFC/Emmett Given)

NASA’s Asteroid-Bound Spacecraft Aces Instrument Check

Its science instruments have been powered on, and NASA’s OSIRIS-REx spacecraft continues on its journey to an asteroid. The spacecraft has passed its initial instrument check with flying colors as it speeds toward a 2018 rendezvous with the asteroid Bennu.

NASA’s spacecraft designed to collect a sample of an asteroid recently ran the first check of its onboard instruments. Starting on Sept. 19, engineers controlling the Origins, Spectral Interpretation, Resource Identification, Security-Regolith Explorer, OSIRIS-REx, spacecraft powered on and operated the mission’s five science instruments and one of its navigational instruments. The data received from the checkout indicate that the spacecraft and its instruments are all healthy.

Instrument testing commenced with the OSIRIS-REx Camera Suite, OCAMS, provided by the University of Arizona, in Tuscon. On Sept. 19, OCAMS executed its power-on and test sequence with no issues. The cameras recorded a star field in Taurus north of the constellation Orion along with Orion’s bright red star Betelgeuse. The three OCAMS cameras performed flawlessly during the test.

On Sept. 19 and Sept. 21, the OSIRIS-REx Laser Altimeter, OLA, contributed by the Canadian Space Agency, conducted its test sequences, which included a firing of its laser. All telemetry received from the instrument was as expected.

On Sept. 20, both the OSIRIS-REx Visible and Infrared Spectrometer provided by NASA’s Goddard Space Flight Center, and the OSIRIS-REx Thermal Emissions Spectrometer provided by Arizona State University in Tempe, were separately powered on for tests. Data from both during the checkout showed that the instruments were healthy. The science measurements acquired from the OSIRIS-REx Thermal Emissions Spectrometer exceeded the instrument’s performance requirements.

On Sept. 21, the student experiment from the Massachusetts Institute of Technology in Cambridge, the Regolith X-ray Imaging Spectrometer, executed its functional test with no problems. And on Sept. 22, the Touch and Go Camera System navigational camera was powered on and tested, and it operated as expected. As part of its checkout, the camera system took an image of the spacecraft’s Sample Return Capsule.

The downlink of the test data continued through the weekend via the spacecraft’s low gain antenna, which transmitted at 40 kbps to NASA’s Deep Space Network.

Goddard provides overall mission management, systems engineering and the safety and mission assurance for OSIRIS-REx. Dante Lauretta of the University of Arizona is the principal investigator. Lockheed Martin Space Systems in Denver built the spacecraft and is providing spacecraft flight operations. OSIRIS-REx is the third mission in NASA’s New Frontiers Program, which is managed by NASA’s Marshall Space Flight Center for NASA’s Science Mission Directorate.

Faces of SLS: Vito Neal

This Louisiana native and lifelong fisherman is “casting” his skills to build the world’s most powerful rocket, NASA’s Space Launch System, for missions to deep space. Meet Vito Neal, a Boeing certified fusion welder at NASA’s Michoud Assembly Facility.

I’m an enthusiastic, lifelong fisherman in just about every good water hole in Louisiana, but my favorite stories to share are about my role building the giant rocket for the journey to Mars.

Born and raised right here in Slidell, Louisiana, it’s a tremendous opportunity to work at NASA’s Michoud Assembly Facility and help build America’s rocket, the Space Launch System. I’ve always liked building things, and after spending a few years in the Army and working with Multiple Launch Rocket System rockets, it gave me even more of an appreciation for the work being done for SLS at Michoud. Those past experiences, as well as on-the-job training, helped strengthen my welding expertise. I was ready when the chance to work on SLS came up.

The work here is important, and I take it very seriously as the only certified fusion welder at Michoud. I also do other types of welding, including friction-stir-weld plug welding. Once a tank or dome is completed on the world’s largest welding tool, the Vertical Assembly Center, there are holes left from the weld head. My job is to fill those holes, and maintain the integrity and strength of the overall weld.

It’s an art form that relies on precision. When you’re building rockets for human spaceflight, your work has to be flawless. Astronauts in NASA’s Orion spacecraft will ride on the rocket, and we’re doing everything right to ensure a perfect launch. It’s a lot of responsibility, and I’m proud to tell my son and daughter what I do every day.

NASA’s Marshall Space Flight Center manages the SLS Program and the Michoud Assembly Facility.

The Doctor Is In: Dr. Sanjay Gupta Discusses NASA and Studying Twins in Space

A video crew from NASA’s Marshall Space Flight Center recently caught up with Dr. Sanjay Gupta, a surgeon and the medical correspondent for CNN, at the 2016 International Space Station R&D Conference in San Diego. Gupta discussed why he feels the space station is such an important resource for science and whether he would go to space himself. A keynote speaker at the event, Gupta led a discussion with veteran NASA astronauts and identical twins Mark and Scott Kelly about NASA’s Twins Study. The investigation collected samples from Scott, who spent nearly a year on the space station, and Mark, who underwent many of the same tests and exercises as his brother on Earth. Scientists will compare the data from the genetically identical twins to help identify the changes the body experiences in space. For more information on ISS science, click here.

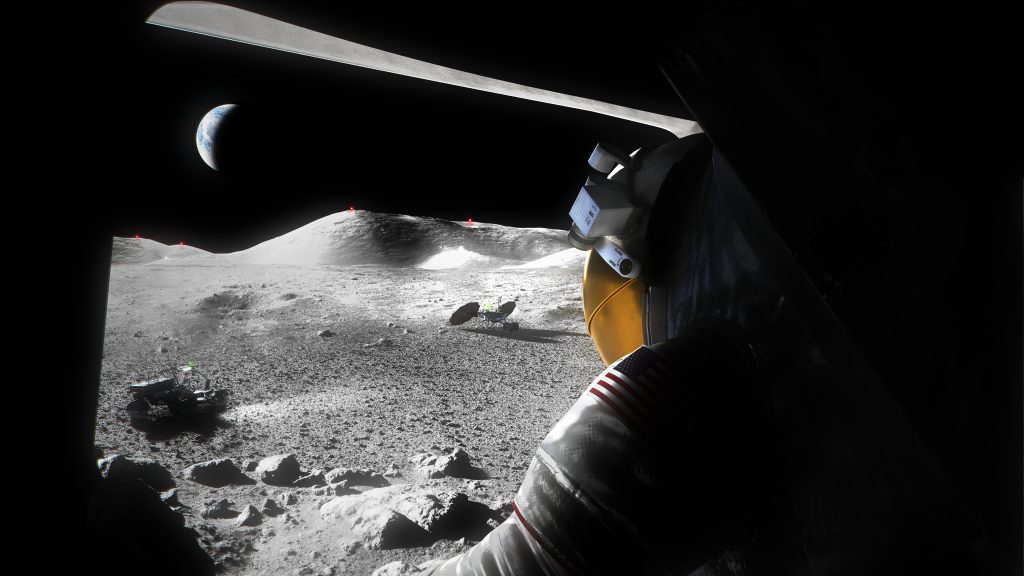

Free Event to Celebrate International Observe the Moon Night Oct. 8

The public is invited to celebrate International Observe the Moon Night Oct. 8 from 5:30-9 p.m. at the U.S. Space & Rocket Center in Huntsville. The free event will include moon-related and solar system exhibits and hands-on activities for children and adults. Activities will include an out-of-this-world photo booth, airbrush tattoo station and a meet and greet with Janet Ivey from PBS’s “Janet’s Planet.” Several large amateur telescopes will be set up to view the moon, stars and visible planets. Visitors can also take a virtual 3-D trip to the moon with the astronomy van, offering a magnified, command-module-like view of the lunar surface. Live music will be provided by DJ Shell and the family movie “Home” will begin at dusk. A panel discussion, “Planets, Moons & Meteorites Oh My!”, will begin at 7:15 p.m. in the National Geographic Theater and will feature NASA Marshall Space Flight Center scientists Mitzi Adams, a NASA solar physicist; Barbara Cohen, a NASA planetary scientist; Bill Cooke, manager of NASA’s Meteoroid Environments Office at Marshall; and Renee Weber, a NASA planetary scientist. For more information about the event, click here. (NASA/MSFC/Emmett Given)

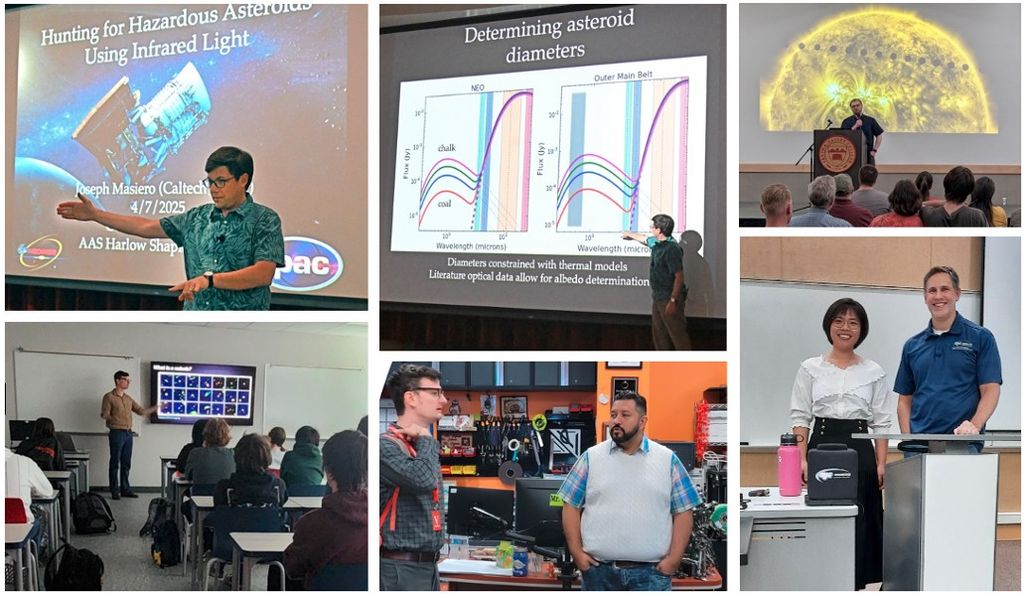

‘Mission Success is in Our Hands’ Promotes Safety and Success of NASA Missions

By Brian C. Massey

At NASA’s Marshall Space Flight Center, safety is paramount. Every team member has a role in ensuring safety and the success of the agency’s missions.

Marshall’s Safety and Mission Assurance Directorate, with partner Jacobs Engineering of Huntsville, promotes and strengthens the center’s focus on mission, hardware and crew safety through the “Mission Success is in Our Hands” campaign.

The campaign aims to help team members make meaningful connections between their jobs and the safety and success of NASA missions. Two ways this is accomplished is through the Golden Eagle Award and the “Shared Experiences” forum.

“The Golden Eagle Award promotes awareness and appreciation for the connections between team members’ everyday work, the success of NASA and Marshall missions and the safety of our astronauts,” said Sheryl Kittredge, SMA technical assistant. “The award recognizes individuals who have made significant contributions to flight safety and mission assurance.”

Jennifer Spurgeon, a quality assurance engineer at Marshall, was awarded the first Golden Eagle Award in July 2015 for her leadership in quality assurance activities for NASA’s Space Launch System Program. Since then, the campaign has recognized three more Marshall team members with the award.

Jeff Dilg

Jeff Dilg, cheif engineer for the SLS Spacecraft Payload Integration and Evolution Office at Marshall, was recognized for his performance in support of SLS in leading a risk based gap assessment to allow the program to accept the prime vendor’s design and construction standards without an in-depth knowledge of the vendor’s processes and controls.

Joel Hobbs

Hobbs, an engineer in Marshall’s Materials and Processes Laboratory, was recognized for his performance in the development of automated finite element analysis evaluations for the large number of NASA’s aging non-code, layered pressure vessels to ensure the safety of personnel and hardware.

Lisa Waddell

Waddell, an analyst in Marshall’s Engineering Directorate, was recognized for her role in the recognition of a crack in the structural test equipment intertank load test tower’s base support, and ensuring proper weld inspections were performed to certify the structure would not fail during testing.

The recipients received their awards at presentations during the program’s Shared Experiences forum. The bi-monthly speaker series features personal stories from trusted practitioners that draw connections between their experiences and work being performed today at Marshall.

The next Shared Experiences forum, featuring former Spacelab Program Manager John Thomas, will be held at 11:30 a.m. Oct. 20 in Building 4203, Room 1201. Thomas will share his experiences covering over a half century, including his work with the Saturn Program, Skylab, Spacelab, the Space Shuttle Program and SLS, with a perspective from inside NASA and the aerospace industry.

For more information about Thomas’ Shared Experiences presentation, click here.

All Marshall team members are eligible for the Golden Eagle Award. To nominate someone for consideration, click here.

For more information about Mission Success is in Our Hands, click here.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

Show Some Love: Participate in CFC Bus Tours and Service Days

NASA’s Marshall Space Flight Center team members can be part of the huge impact of the Combined Federal Campaign — the largest and most successful federal government workplace fundraising campaign in the world — by touring local charities and volunteering for community service days.

Community service days provide opportunities for Marshall team members to volunteer their time and talents to help local nonprofit organizations. These service opportunities range from escorting athletes participating in the Special Olympics, to building wheelchair ramps for CASA of Madison County, to helping the Salvation Army with angel tree preparations.

Each civil service employee may take up to four hours of excused leave for the hours worked on a CFC community service day project. For more information about community service days, contact Leah Fox or Labreesha Batey. To sign up for a community service day, click here.

In addition to volunteering, Marshall team members can participate in bus tours to learn how their CFC contributions help nonprofit organizations change lives in the local community. Upcoming bus tours include the Huntsville-Madison County Senior Center, Downtown Rescue Mission, Centers for the Developmentally Disabled and many more. For more information about CFC bus tours, contact Lindsey Ingram or Sylvester Dorsey. To sign up for a bus tour, click here.

For more information about Marshall’s CFC efforts, click here.

This Week in NASA History: Space Shuttle Program’s First Mated Vertical Ground Vibration Test Performed at Marshall — Oct. 4, 1978

This week in 1978, space shuttle Enterprise underwent a Mated Vertical Ground Vibration Test at NASA Marshall Space Flight Center’s Dynamic Test Stand. The test marked the first time all shuttle elements — an orbiter, external tank and two solid rocket boosters — were vertically mated. The test verified that the shuttle performed as expected in its launch configuration. The first shuttle mission launched in April 1981, and for the next 30 years the program’s five spacecraft carried people into orbit repeatedly, allowing crew to launch, recover and repair satellites, conduct cutting-edge research and build the largest structure in space, the International Space Station. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the History Program’s webpage. (NASA)

Obituaries

Jack A. Jones, 81, of Asheville, North Carolina, died Sept. 28. He retired from the Marshall Center in 1997 as an aerospace engineer. He is survived by his wife, Katherine Armitage.