In This Week’s Star

- Todd May Named Deputy Director of NASA’s Marshall Space Flight Center

- Stennis Marks Milestone in Return to Deep-Space Missions

- Jerry Cook Named NASA’s Exploration Systems Development Chief Engineer

- NASA Deputy Administrator Newman Visits Michoud

- Five Questions for Marshall Master Planner Melvin McKinstry

- Green Propellant Infusion Mission Receives Propulsion System; On Track for 2016 Launch

- Marshall Team Invited to Retirement Reception Honoring Teresa Vanhooser

- New ‘Golden Eagle’ Award Showcases Artwork by Marshall Engineer

- This Week in NASA History: Discovery Makes Maiden Spaceflight — Aug. 30, 1984

Todd May Named Deputy Director of NASA’s Marshall Space Flight Center

By Kenneth Kesner

Todd May was appointed deputy director of NASA’s Marshall Space Flight Center on Aug. 25 by Director Patrick Scheuermann. May succeeds Teresa Vanhooser, who has been Marshall’s deputy director since November 2012 and is retiring this month after a 35-year NASA career.

Prior to being named deputy center director, May served as manager of the Space Launch System program since August 2011. SLS, now under development, is the most powerful rocket ever built, able to carry astronauts in NASA’s Orion spacecraft on deep space missions, including to an asteroid and ultimately to Mars. The program is managed at Marshall, and May has led the SLS program through a series of milestones, including engine tests and an in-depth critical design review in July.

As deputy director of Marshall, May will help manage one of NASA’s largest field installations, with nearly 6,000 on- and near-site civil service and contractor employees and an annual budget of approximately $2.5 billion.

“I’m confident that Todd will apply the excellent leadership skills he’s demonstrated as SLS manager to the entire spectrum of space exploration, science and technology missions Marshall manages or supports for NASA,” Scheuermann said. “With more than two decades of NASA experience, Todd is well prepared for this next assignment.”

May began his NASA career at Marshall in 1991 as an engineer in the Materials and Processes Laboratory. He has served in a variety of leadership and program and project management roles spanning all of NASA’s space-related mission directorates.

He relocated to NASA’s Johnson Space Center in 1994 to support the International Space Station Program as deputy manager of the Russian Integration Office. In 1998, he returned to Marshall to manage the successful integration, launch and commissioning of the space station’s “Quest” airlock. He then joined the team that launched the Gravity Probe B mission to test Einstein’s general theory of relativity.

In 2004, May assumed management of the Discovery and New Frontiers Programs, created to explore the solar system with frequent unmanned spacecraft missions. He joined the Constellation Program in 2006 as associate program manager, at the same time also serving as deputy director of Marshall’s Science and Mission Systems Office.

May was a deputy associate administrator in the Science Mission Directorate at NASA Headquarters from 2007 to 2008. Returning to Marshall in June 2008, he was named Marshall’s associate director, technical, a post he held until being named SLS program manager.

May earned a bachelor’s degree in materials engineering from Auburn University in Auburn, Alabama, in 1990. His many awards include NASA’s Exceptional Achievement Medal, the Presidential Rank Award of Meritorious Executive, NASA’s Outstanding Leadership Medal and the John W. Hager Award for professionalism in materials engineering. He has been named a Distinguished Engineer by his alma mater, Auburn University. In 2014, he received Aviation Week’s Program Excellence Award, as well as the Rotary National Award for Space Achievement Foundation’s Stellar Award in recognition of the SLS team’s many accomplishments.

May, a native of Fairhope, Alabama, and his wife, Kelly, have four children and reside in Huntsville.

Kesner, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Stennis Marks Milestone in Return to Deep-Space Missions

NASA moved 100 feet closer to its return to deep-space missions this month with the completion of a steel tower for tests of the world’s most powerful rocket, the Space Launch System. Engineers completed the addition of about 1 million pounds of structural steel work on the SLS core stage test frame on the B-2 test stand at the agency’s Stennis Space Center.

The distance may not sound like much, but completion of the steel work marks a major milestone as NASA prepares to test the core stage of the new SLS rocket, being developed to carry humans deeper into space than ever before, including to an asteroid and ultimately to Mars. NASA’s Marshall Space Flight Center manages the SLS Program for the agency.

“Every step brings us closer and closer to a new era of space exploration,” Stennis Director Rick Gilbrech said. “These are exciting days, and it is critical for Stennis to fulfill our test role on the frontlines. As has been said time and again, the return to deep space goes right through Stennis and south Mississippi.”

The addition of the structural framework to the historic test stand is needed to support the height and weight of the massive rocket’s core stage while allowing test teams access and providing for thrust takeout, which will hold the core stage in place during testing. The new core stage tanking and hot engine firing framework alters the Stennis skyline and moves NASA closer to the day when an SLS flight core stage is installed on the stand for testing.

For the testing, the actual core stage that will fly on the first SLS mission, including four RS-25 engines, will be installed on the stand. The core stage will be loaded with more than 733,000 gallons of liquid hydrogen and liquid oxygen, then all four engines will be fired simultaneously, creating approximately 2 million pounds of thrust. The test will run for eight minutes, just as during an actual launch.

NASA has been renovating the B-2 test stand for more than two years in preparation for the SLS test series. The historic test stand was built in the 1960s and previously used to test both the Saturn V and the space shuttle propulsion system. Months of studies and evaluations preceded the start of physical work on the stand.

The project is divided into three stages: restoration, buildout and installation of special test equipment. The first phase involved restoring the stand to meet the SLS test requirements, in which it can be adapted to test any number of stages not exceeding the total thrust of the SLS. The second phase focuses on structural renovations needed to accommodate the SLS core stage. The final phase is installation of all the various interfaces needed to test the stage.

Story continued here.

Jerry Cook Named NASA’s Exploration Systems Development Chief Engineer

NASA’s Marshall Space Flight Center Director Patrick Scheuermann announced Aug. 13 that Jerry Cook has been named to the Senior Executive Service position of chief engineer for Exploration Systems Development for NASA Headquarters. Cook succeeds Paul McConnaughey who was recently reassigned to the position of Marshall’s associate director, technical.

As NASA’s Exploration Systems Development chief engineer, Cook will serve as the lead technical authority on technical and engineering matters of interest to the Office of the Chief Engineer. Reporting administratively to Marshall’s Deputy Director, he has functional responsibility to provide the associate administrator for the Human Exploration and Operations Mission Directorate and the Exploration Systems Development deputy associate administrator with assessments of the impact, effectiveness and efficiency of all exploration systems investments. Additionally, Cook serves as the primary Exploration Systems Development liaison with the NASA chief engineer.

Cook previously served as deputy director of NASA’s Stennis Space Center. Appointed to the position in 2013, he was responsible, with the center director, for coordinating all of NASA’s rocket propulsion testing capabilities and Stennis’ roles in NASA’s applied science programs, as well as managing Stennis.

Cook has over 30 years of experience in both an operational and developmental environment of strategic planning, program management and program execution. He began his NASA career in 1985 as a test engineer at Marshall in the Technology Evaluation Department. He later served as a test conductor for the Space Shuttle Main Engine Test Program. Beginning in 1991, he worked as a systems engineer in Marshall’s Solid Motor Design Branch, where he managed resources required to assemble, install and test hybrid and solid rocket combustion simulator motors. Cook returned to the Technology Evaluation Department in 1995 as a senior test engineer. From 1999 to 2001, he worked at NASA Headquarters in the Space Transportation Directorate and the Office of Aerospace Technology. In 2003, he was named manager of the Acquisition Management Office in the Orbital Space Plane Program at Marshall.

Cook was appointed deputy manager of the Ares I Upper Stage Office in 2005, and was responsible for the planning, procurement, design, development, testing, production and operational aspects of the Upper Stage Project. As space shuttle main engine project manager from 2007 to 2011, he was responsible for leading the design, development, manufacture, test and delivery of critical test and flight hardware of the shuttle’s main engines and associated infrastructure.

In 2012, he was selected as the associate program manager for the Space Launch System Program, while concurrently serving as acting manager of the SLS Program Planning and Control Office. In his dual role, Cook was responsible for formulating and executing cross-program strategic planning activities for the SLS Program. He was also responsible for formulating and executing the program structure, resource requirements, and governance plans and processes necessary to meet the SLS Program’s goals and objectives.

A native of Greensboro, Alabama, Cook earned a bachelor degree in mechanical engineering from the University of Alabama in Tuscaloosa in 1984. He has authored and co-authored numerous technical papers and books on aerospace and propulsion. He was selected as a Distinguished Departmental Fellow of the Mechanical Engineering Department at the University of Alabama in Tuscaloosa in 2007 and was inducted as a Distinguished Fellow into the university’s College of Engineering in 2014. He currently serves as a member of the school’s Mechanical Engineering Department Advisory Board.

Cook and his wife Felicia reside in Huntsville. They have a son and a daughter, who both attend the University of Alabama in Tuscaloosa.

NASA Deputy Administrator Newman Visits Michoud

Five Questions for Marshall Master Planner Melvin McKinstry

Melvin McKinstry, who leads the master planning team in the Marshall Space Flight Center’s Planning & Facilities Utilization Office, oversees facilities construction, demolition and refurbishment efforts across the center. He sat down recently with The Marshall Star to update the workforce on upcoming facilities plans large and small…

What big changes we can expect around Marshall in the next two years?

The main thing we’re working on is continued implementation of our Marshall Center master plan, which means delivering more high-performing, aesthetically pleasing, LEED®-certified buildings. Marshall is a NASA and government leader in LEED certification, the U.S. Green Building Council’s award for leadership in energy and environmental design.

Most prominent among upcoming work is the launch of construction on Building 4221, likely in early 2016. That new facility will be erected slightly north of the empty site where Building 4202 stood, before it was demolished in early 2015.

And just as most of the occupants of 4202 moved into new quarters in Building 4220, which we built and opened in 2014, most team members currently working in Building 4201 will move into 4221, once we complete that construction near the end of 2017. We’ll then demolish 4201.

The end result? Two old structures removed, and two thriving new facilities taking their place. It’s all part of NASA’s repair-by-replacement plan, which offers health, safety and cost benefits by replacing expensive, outdated structures with energy-efficient, environmentally friendly ones. The 4221 construction project also will include plans for a new parking lot. We will permanently close a significant section of North Marshall Road and add the new lot there, extending it into the pasture directly north of that road. Once construction starts in earnest, employees will see traffic patterns change to accommodate the new building and parking area.

We are also continuing construction of Building 4260 on Rideout Road. That facility, which is set to open in early 2016, will house a number of logistics and administrative personnel in the Office of Center Operations. And looking beyond the 4200 complex, while it isn’t part of the Marshall facilities master plan, we’re continuing work on the new SLS test stand, a critical resource for testing the Space Launch System, NASA’s next heavy-lift launch vehicle — and we anticipate seeing steel rising there very soon.

Meanwhile, we’re also conducting numerous smaller projects, including what we call “system resets,” which entail the renewal of aging mechanical and electrical systems and the replacement of old, underperforming exterior siding in various Marshall buildings. For example, we’re now residing Building 4619, Marshall’s Structural and Dynamics Laboratory — home to structural integrity research, such as recent “shell-buckling” studies in which force and pressure were applied to an empty rocket fuel tank to help engineers design, build and test the gigantic SLS tanks. Building 4619 is a critical facility, one we plan to keep around awhile, so we’ve targeted it for multiple improvements. Residing a building replaces aging, underperforming siding, and offers greater thermal performance, which saves heating and cooling costs. We often end up removing asbestos in the process, protecting the health of our team members as well. And it’ll look a whole lot better, too! But the primary thing we hope to achieve is functional improvement — enhancing facility performance and saving NASA and the taxpayer money.

How sizeable will be the relocation of personnel for these efforts?

Prior to the demolition of Building 4201, we’ll relocate the roughly 260-300 occupants of that building. The majority — 200 or more — will move into the newly constructed 4221. As for the rest, we’ll figure out the best fit for our people. We always try to keep teams together. Often, these moves provide a welcome opportunity to make changes on a large scale, allowing us to rearrange organizations to make the best possible use of our available space.

What’s been the Marshall team’s reaction to our recently opened facilities, and has their feedback influenced future plans?

Overall, the response to our ongoing efforts has been extremely positive. Our new buildings aren’t just more energy-efficient and cost-effective, they’re more pleasant to work in, too. Our new conference rooms are outfitted with state-of-the-art technologies to support versatile conferencing capabilities. Large, open spaces such as the atrium in 4220 provide new venues for all-hands gatherings and other team functions. And because these new buildings are LEED-certified, they have higher indoor air quality, their open floor plans promote better collaboration and they’re outfitted with more functional, ergonomical furniture. In short, they’re better designed to meet all the needs of people in high-pressure, high-value NASA jobs.

We continue to welcome feedback, which allows us to continuously improve our designs and make each new cycle of facilities even better than the last. The response so far has been incredibly positive — making these facilities even more fun to design, plan and construct and certainly making them much more attractive places in which to work.

Looking 5-10 years out, what are the biggest infrastructure challenges we face?

There are many challenges today which also present opportunities when addressed in a smart and disciplined manner. My priority is to continue to add value to our center and agency mission while reducing institutional costs. Every dollar we save can be reinvested in the mission. So the question becomes — how do we do this? We do it strategically, by rightsizing our assets and reducing our footprint, by getting rid of what’s no longer needed and by reducing our infrastructure.

Finish this sentence: “As Marshall’s master planner, I’m most proud of…”

…being a small part of a large, diverse and talented team of professionals with a passion for construction and all things NASA. Planning, designing and constructing high-performing facilities is not easy. But the reward of seeing something go from paper to actual construction is huge, and it’s habit-forming. Master planning is just the beginning of this highly integrated process. It’s about having a vision and articulating the value of that vision to stakeholders whom you hope will ultimately buy in. This vision that became the Marshall master plan started way before I came to NASA. I’m humbled, however, that my leadership has entrusted me and my team with carrying it forward — and realizing it one construction project at a time.

The Planning & Facilities Utilization Office is part of Marshall’s Facilities Management Office. Visit its website for more information.

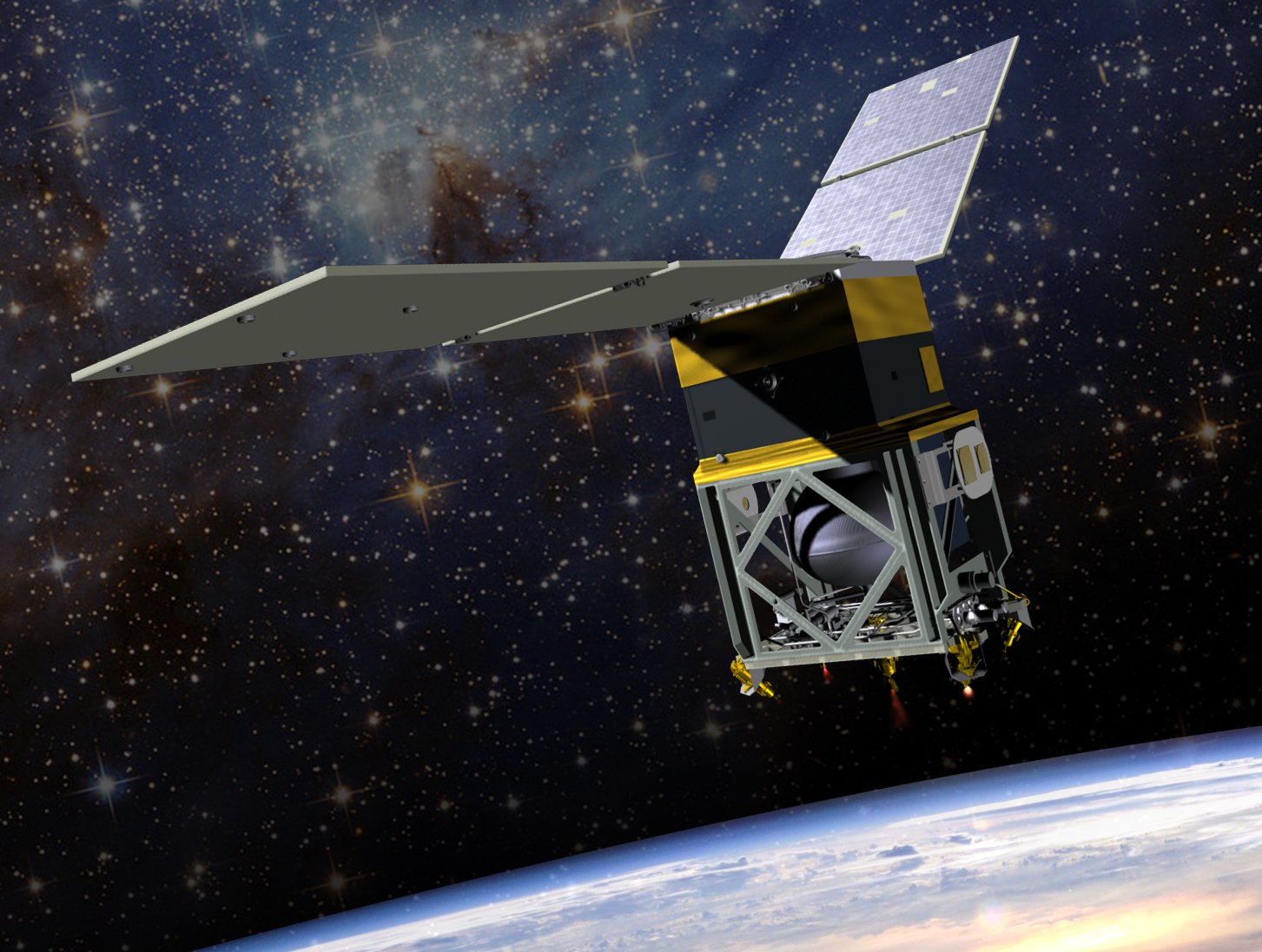

Green Propellant Infusion Mission Receives Propulsion System; On Track for 2016 Launch

Space exploration is about to go “greener.”

NASA’s Green Propellant Infusion Mission to develop a high-performance, low-toxicity fuel and propulsion system for spacecraft has passed a major milestone. A green propellant propulsion subsystem, built by Aerojet Rocketdyne in Redmond, Washington, has been delivered to the mission’s prime contractor, Ball Aerospace & Technologies Corp. in Boulder, Colorado.

The mission will demonstrate the practical capabilities of a hydroxyl ammonium nitrate based fuel/oxidizer propellant blend, known as AF-M315E. This innovative propellant, developed by the U.S. Air Force Research Laboratory at Edwards Air Force Base in California, offers higher performance but is safer to handle and easier on the environment than traditional chemical fuels such as hydrazine now used in thrusters. It also requires fewer handling restrictions and potentially shorter launch processing times, resulting in lowered costs.

The new propellant is 40-percent denser than hydrazine, meaning more of it can be stored in containers of the same volume. This provides a 50-percent increase in maneuvering capability for a given volume. It also has a lower freezing point than hydrazine, requiring less spacecraft power to maintain its temperature. These characteristics make it ideal for a wide range of emerging small, deep space satellite missions.

“It’s time to see this kind of breakthrough technology with green propellant,” said Larry Gagliano, manager of the Technology Demonstration Missions Program at NASA’s Marshall Space Flight Center. “This small spacecraft mission will represent the United States’ first attempt to test green propellant technology for future space exploration.”

The green propellant propulsion subsystem consists of a propellant tank and five 1-newton thrusters that will use the new fuel. Because AF-M315E burns hotter than hydrazine, it required new metals to withstand the temperatures in the thrusters aboard the propulsion system.

“This propulsion system delivery marks the success of more than 10 years of research and development,” said Julie Van Kleeck, vice president of Advanced Space and Launch Systems at Aerojet Rocketdyne. “The Green Propellant Infusion Mission is the culmination of excellent teamwork between NASA, the Air Force, Ball Aerospace and Aerojet Rocketdyne.”

The propulsion subsystem will be the primary payload on the mission’s spacecraft — a Ball Configurable Platform 100 small satellite. Ball has already begun integrating the propulsion subsystem onto the space vehicle. The spacecraft will also carry three experimental payloads.

“This is a critical milestone for the program that will be a game-changer for in-space propulsion,” said Jim Oschmann, vice president and general manager of Civil Space and Technology at Ball Aerospace. “This new technology offers longer mission durations, additional maneuverability, increased payload space and simplified launch processing for future spacecraft.”

The Green Propellant Infusion Mission is scheduled for a launch to low-Earth orbit in 2016 in partnership with the Army Space and Missile Defense Command. Additional team members include the Air Force Space and Missile Systems Center; Kirtland Air Force Base, New Mexico; and NASA’s Glenn Research Center, Goddard Space Flight Center and Kennedy Space Center.

During the test flight, researchers will conduct orbital maneuvers to demonstrate the performance of the propellant during attitude control shifts, changes in orbital inclination and orbit lowering.

The mission is part of a portfolio of technology demonstration flight and ground projects led by NASA teams and industry partners across the country, managed by the Technology Demonstration Missions program office at Marshall.

Technology demonstration missions are sponsored by NASA’s Space Technology Mission Directorate, which is innovating, developing, testing and flying hardware for use in future missions. NASA’s technology investments provide cutting-edge solutions for our nation’s future. For more information about the directorate, click here.

For more information about the NASA’s Green Propellant Infusion Mission, click here.

For more information about NASA’s Technology Demonstration Missions, click here.

Marshall Team Invited to Retirement Reception Honoring Teresa Vanhooser

NASA’s Marshall Space Flight Center team members are invited to attend a retirement reception to honor Marshall Deputy Director Teresa Vanhooser Aug. 31 at 3 p.m. The reception will be held in Building 4316 and include refreshments. Vanhooser has served in a variety of leadership roles since joining Marshall in 1980. As center deputy director, she has assisted the center director in managing all aspects of Marshall since being named to the position in November 2012. For more information about Vanhooser, click here.

New ‘Golden Eagle’ Award Showcases Artwork by Marshall Engineer

By Molly Porter

For NASA Marshall Space Flight Center engineer Caroline Wang, creativity and technical thinking go hand in hand.

Wang, a software assurance lead in the Safety & Mission Assurance Directorate’s Avionics & Software Branch, recently created a painting that was incorporated into a new Marshall award — the Golden Eagle award. She came up with the idea for the painting when SMA Deputy Director Steve Pearson asked her to create a design for the new award.

“When considering memorabilia for the Golden Eagle award, which is intended to recognize individuals who have made significant contributions to flight safety and mission assurance, I immediately thought of Caroline and her passion for her art,” said Pearson. “She is so dedicated to making sure her brushstrokes tell the story she is trying to share. We had numerous conversations about the Golden Eagle award and what we wanted it to portray and I feel she has really demonstrated this message with her painting.”

In Wang’s original 16-inch-by-24-inch watercolor, the white head and brown-feathered breast of a bald eagle appear before orange and golden plumes of smoke and fire as NASA’s Space Launch System rises into a blue sky.

“SLS represents NASA, the world-leading organization in space exploration,” said Wang, “and the eagle symbolizes wisdom, the intelligence and authority.”

Drawing and painting have always come easy to her, Wang said. She found her niche in art when she was 5. In elementary school, she won first place in a citywide art competition in Taipei, Taiwan. Since then, she has received many awards and won numerous competitions.

Today, the painting she calls “Design for the Golden Eagle Award” hangs in the main branch of the Huntsville-Madison County Public Library. In July, it appeared on the cover of the North Alabama publication Valley Planet. Soon, framed prints of the artwork will grace the walls of Marshall team members who are selected by an awards committee.

The Golden Eagle award is part of the “Mission Success Is in Our Hands” initiative that aims to promote awareness and appreciation for the connections between employees’ everyday work, the success of NASA and Marshall missions and the safety of our astronauts.

This isn’t the first time Wang has donated her time and talent to help a cause. She also volunteers as a public speaker. Through speaking and art, she hopes to inspire others to use creativity and self-expression to go above and beyond.

On the relationship between engineering, science and the arts, Wang said, “They work together. I use artwork as a platform to develop my creative mind. You have to be creative to become better, to do something revolutionary.”

To see more of Wang’s artwork, visit her website.

To nominate someone for the Golden Eagle award, visit the online form.

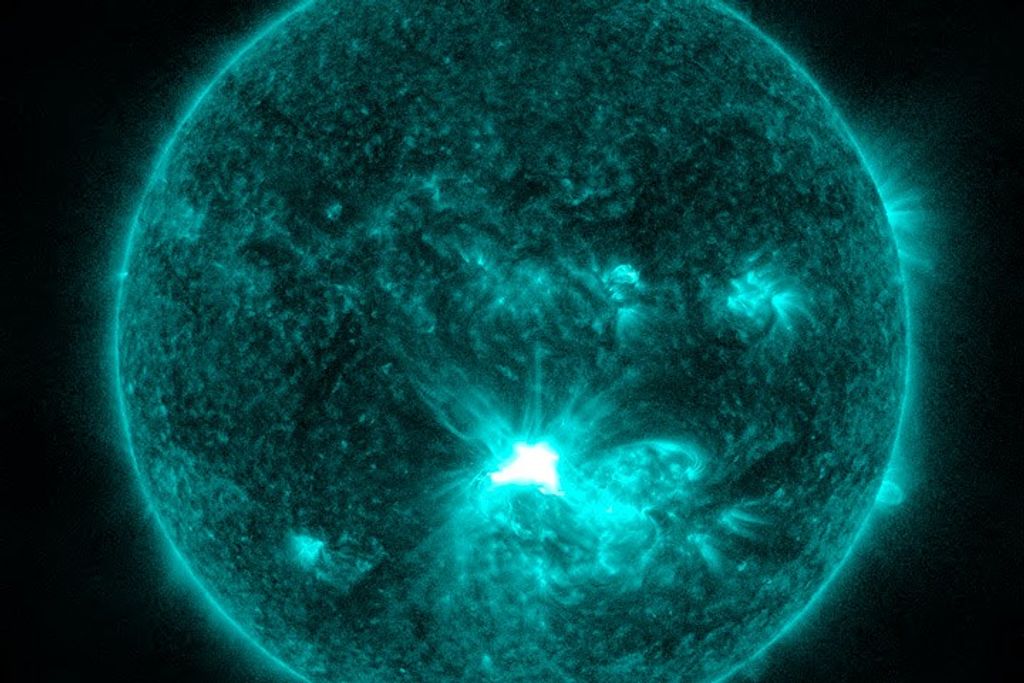

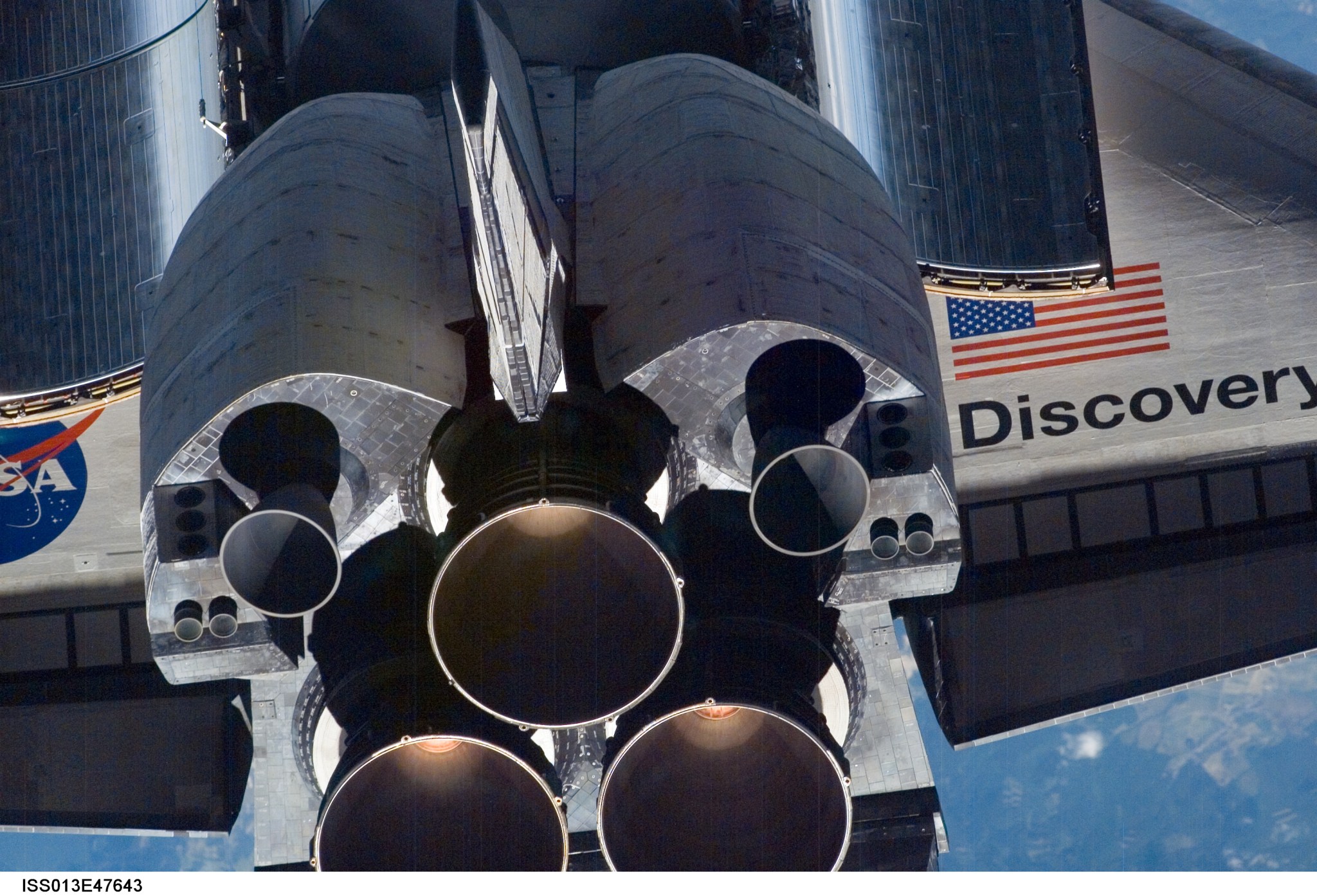

This Week in NASA History: Discovery Makes Maiden Spaceflight — Aug. 30, 1984

This week in 1984, Space Shuttle Discovery makes its maiden spaceflight after launching from NASA’s Kennedy Space Center. On board STS-41D was Judith Resnik, America’s second women in space. The NASA History Program documents and preserves NASA’s remarkable history through a variety of products — photos, press kits, press releases, mission transcripts and administrators’ speeches. For more pictures like this one and to connect to NASA’s history, visit the History Program’s Web page.