In This Week’s Star

- SLS Avionics Get in the Ring for the Journey to Mars

- Steel ‘Flies’ as Second New SLS Test Stand ‘Tops Out’ at NASA Marshall

- NASA Astronaut Kjell Lindgren to Visit Marshall on April 14

- External Tank Departs for the California Science Center

- Indiana and Puerto Rico Schools Roll Away With Top Honors at 2016 Rover Challenge

- Construction Set to Begin on Marshall’s Next Green Building — Building 4221

- From His First Model Rocket to the First Astronauts Launched on a Commercial Craft: NASA Engineer Dan Dorney Is Man With a Mission

- NASA Begins Testing of Revolutionary E-Sail Technology

- ‘Distracted Driving’ Presentations to Anchor Marshall’s SHE Day Activities April 20

- Students Ready to Launch High-Powered Rockets, April 16

- This Week in NASA History: Walt Disney Visits Marshall — April 13, 1965

- Completion of SLS Confidence Fuel Tank Featured on ‘This Week @NASA’

- Obituaries

SLS Avionics Get in the Ring for the Journey to Mars

Ratana Meekham, a Qualis Corp. engineering technician at NASA’s Marshall Space Flight Center, helps install approximately 5 miles of cable on a half-ring structure being used to test the avionics system that will guide the world’s most powerful rocket, the Space Launch System, on deep-space missions. Qualification testing began March 30 and is an important next step in ensuring the system is “go for launch” for the first flight of SLS in 2018. During testing, the avionics team can troubleshoot any problems with subsystems, and make sure the units communicate together as they are designed to do. The complex avionics system, housed in the SLS core stage, is made up of computers, software and related hardware systems. The avionics hardware units are arranged in flight configuration at Marshall’s Systems Integration and Test Facility, and with the flight software, will replicate what will actually fly the rocket. Engineers will run simulations in which the flight software works with the avionics just like they will work together to control the SLS during its launch and flight. The initial developmental designs and first power-on testing, known as “first light,” were completed in 2014. It took technicians 11 months to assemble the avionics ring and install the cables for qualification testing, but watch this time-lapse video to see all that hard work happen in just 60 seconds. (NASA/MSFC/Fred Deaton)

Steel ‘Flies’ as Second New SLS Test Stand ‘Tops Out’ at NASA Marshall

A steel beam is flown into position by crane on the 221-foot-tall twin towers of Test Stand 4693 during topping out ceremonies April 12 at NASA’s Marshall Space Flight Center. When construction is completed, dozens of hydraulic cylinders at the stand will push and pull on the giant liquid hydrogen tank of NASA’s Space Launch System, subjecting it to the same stresses and loads it will endure during liftoff and flight. SLS will be the world’s most powerful rocket for human space exploration, able to take astronauts in the Orion spacecraft on deep-space missions, including our journey to Mars. In March, Test Stand 4697 was also topped out at Marshall, where similar tests will be conducted on the SLS liquid oxygen tank. (NASA/MSFC)

Bob Devlin, deputy director of Marshall’s Office of Center Operations, speaks to the crowd in front of a steel beam destined for Test Stand 4693 during the structure’s topping out ceremony April 12. Topping out is a builders’ rite traditionally held when the highest beam is placed on top of a structure during construction. Before being welded into place, this beam was signed by members of the Marshall Center Operations, SLS and other teams involved in the design and construction of Test Stand 4693 and Test Stand 4697, including the U.S. Army Corps of Engineers; general contractor Brasfield & Gorrie; architects Goodwin Mills and Cawood; architects Merrick & Company; NAFCO Fabrication; and LPR Construction. (NASA/MSFC/Emmett Given)

NASA Astronaut Kjell Lindgren to Visit Marshall on April 14

NASA astronaut Dr. Kjell Lindgren, who lived and worked nearly five months — from July 23 through Dec. 11, 2015 — on the International Space Station as a flight engineer, will visit NASA’s Marshall Space Flight Center on April 14. He will share highlights from his 141-day mission in space as part of the Expedition 44 and 45 crews.

During his stay on the station, Lindgren performed numerous science experiments including research into human physiology, fluid and combustion physics, Earth and space science, and technology development. He worked on the “Veggie” investigation, which included the opportunity to eat lettuce grown in space.

Lindgren and NASA astronaut Scott Kelly conducted two spacewalks in late 2015. During the first, Lindgren installed a thermal cover on the Alpha-Magnetic Spectrometer, which looks for high-energy radiation emanating from deep space. The second focused on maintenance of the station’s external thermal control systems.

Lindgren will present video highlights from his space station mission and take questions from the Marshall workforce during his presentation beginning at 9:15 a.m. in Building 4316.

His visit coincides with the annual Student Launch competition. In that event, student teams from around the country are challenged with designing and building their rockets during the school year, before bringing their vehicles to Marshall for final inspections and launches. Members of those teams will attend Lindgren’s presentation.

Lindgren, whose biography is available here, also frequently posted to his Twitter social media account during his mission.

External Tank Departs for the California Science Center

NASA’s last remaining space shuttle external tank, ET-94, shipped via barge from the Michoud Assembly Facility April 12 en route to California. The tank’s final mission will be to commemorate past achievements in space, educate and inspire future generations of explorers at the California Science Center in Los Angeles.

ET-94, a lightweight version of the external tank, measures approximately 154 feet long and 27.5 feet in diameter and weighs about 69,000 pounds. External tanks served as the structural backbone of the space shuttle and were designed to absorb and distribute over 7 million pounds of thrust generated at launch. They also fed liquid oxygen and liquid hydrogen to the space shuttle main engines mounted on the shuttle’s orbiter.

ET-94 was designated a test article for the Space Shuttle Program to validate processes and procedures prior to performing the work on the next flight article. ET-94 was a vital part of NASA’s ability to return flight and is a testament to the ingenuity and can-do spirit of the external tank team.

Michoud — NASA’s only large-scale advanced manufacturing facility, managed and operated by NASA’s Marshall Space Flight Center — manufactured 138 external tanks during the Space Shuttle Program. Lockheed Martin of Bethesda, Maryland, managed the external tank project for the agency.

Indiana and Puerto Rico Schools Roll Away With Top Honors at 2016 Rover Challenge

By Christopher Blair

Rafaelina E. Lebron Flores of Patillas, Puerto Rico, won first place in the high school division, while Purdue University Calumet – Team 1, of Hammond, Indiana, won the college division of the 2016 NASA Human Exploration Rover Challenge April 8-9 at the U.S. Space & Rocket Center.

Rover Challenge requires student teams to design, construct and race human-powered rovers through an obstacle course simulating the types of terrain potentially found on moons, asteroids and planets like Mars.

This year’s event added two new and important changes. First, teams were required to design and fabricate their own wheels. Any component used to contact the course surface for traction and mobility had to be original and not an “off-the-shelf” or commercially available item.

The second new feature was an optional Sample Return challenge, where teams attempted to collect four samples — liquid, small pebbles, large rocks and soil samples — using a mechanical arm or grabber they designed and built.

This worldwide competition featured nearly 80 teams of high school, college and university students from 18 states and Puerto Rico, as well as a strong contingent of international teams from Germany, India, Mexico, Italy and Russia.

Managed by the Academic Affairs Office of NASA’s Marshall Space Flight Center, Rover Challenge highlights NASA’s goals for future exploration to Mars and beyond. The event challenges students to solve engineering problems, while highlighting NASA’s commitment to inspiring new generations of scientists, engineers and explorers.

For a complete list of all the winners, please visit, 2016 NASA Human Exploration Rover Challenge Awards.

Blair, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Construction Set to Begin on Marshall’s Next Green Building — Building 4221

By Brian C. Massey

In the coming weeks, construction will begin on NASA Marshall Space Flight Center’s newest “green” building. A site-adapted copy of Building 4220, Building 4221 will be built on the footprint of recently demolished Building 4202 between Buildings 4200 and 4203.

“This new state-of-the-art facility will be great for the missions and the workforce,” said Melvin McKinstry, Marshall’s master planning team lead. “However, much like living in a home during a remodel, there are going to be some temporary challenges.”

These challenges will include increased construction traffic and noise. Team members in the 4200 Complex also should be prepared to walk a little farther to their parking spaces.

“Forecasts show that we will still have ample parking for team members in the 4200 Complex, and we will be adding an additional 384 spaces to help make up for those lost,” said Eric Booher, 4221 project construction manager, who has taken, and will continue to take, steps to help minimize the challenges to the Marshall workforce. “Upon completion we will have more parking spaces than we currently do, but in the interim things may feel a little tight.”

Also, as a result of the construction and to allow for additional parking, North Marshall Road will be closed and will no longer serve as a thoroughfare between Rideout Road and Morris Road. Marshall team members should expect to see new safety barriers in the area as work begins later this month.

“Our primary goal is to make sure the Marshall workforce is safe during the construction,” said Booher. “As we try to ensure minimal impacts on the workforce, it is important that everyone stays aware — there will still be some challenges, since it is a construction site.”

The project — with a two-year construction schedule — was recently awarded to Yates Construction of Philadelphia, Mississippi. Construction is expected to begin in late April.

The 150,000-square-foot, five-story structure will join Building 4220 and the recently completed Building 4260 as Marshall’s newest Leadership in Energy and Environmental Design certified buildings, awarded by the U.S. Green Building Council. According to Booher, the state-of-the-art building is designed to be both energy and operationally efficient and will feature an open office concept complemented with closed offices, conference rooms and support areas in an effort to reduce energy costs and save money for the agency.

The new construction is designed to support an exciting feature in Marshall’s 20-Year Master Plan — a greenway originating in the 4200 Complex and extending south through the center, eventually all the way to Building 4619 on Beacon Street. According to McKinstry, the greenway concept’s primary goal is to establish a more open, pedestrian-friendly Marshall.

“With current planning and future construction, we are systematically and comprehensively attempting to bring Marshall’s organizations, synergies and capabilities closer together,” he said. “This will create a more open environment for our workforce.”

Upon completion of the 4221 projects, Building 4201 will be demolished, creating an open courtyard between buildings 4200, 4221, 4203 and 4220, which will serve as the head of Marshall’s new greenway.

“This an exciting time at Marshall,” said McKinstry. “Big things are happening everyday all across the center, from the beginning of Building 4221, to the completion of Building 4260 and out to the Test Area where huge construction projects are underway building test stands to support NASA’s Space Launch System. There are going to be some growing pains, but the work taking place at Marshall is something we can all take pride in.”

Any organization interested in a presentation about the construction and its expected impacts are encouraged to contact McKinstry.

To view a map of Marshall’s 20-Year Master Plan, click here.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

From His First Model Rocket to the First Astronauts Launched on a Commercial Craft: NASA Engineer Dan Dorney Is Man With a Mission

By Bill Hubscher

NASA’s Dan Dorney has never been afraid to think big.

As a 7-year-old boy growing up in Kalamazoo, Michigan, in 1969, Dorney watched the Apollo 11 moon landing from his living room and decided he needed to build his own rocket. He sent a letter to NASA asking how to do that. Much to his parents’ surprise, he got a response — NASA sent him plans to build a simple model rocket. Which he immediately rejected.

“I wanted the real wiring schematics and engine plans,” Dorney says. “I wanted to build my own life-size rocket to go to the moon. I was ready to be an aerospace engineer.”

Today, Dorney is living his dream as part of the team building the first American commercial launch vehicles that will take astronauts to the International Space Station. He is one of three launch vehicle chief engineers for the Commercial Crew Program managed by NASA’s Kennedy Space Center.

While Dorney’s office is at NASA’s Marshall Space Flight Center, he is often on the road working closely with the commercial crew providers building vehicles for the upcoming crew launches to the station. This means collaboration with United Launch Alliance at facilities in Decatur, Alabama, where they are building the Atlas V rockets that will launch Boeing’s CST-100 Starliner spacecraft being built at Kennedy; and to SpaceX in Hawthorne, California, where they are building the Falcon 9 launch vehicle and Crew Dragon spacecraft.

Dozens of systems are involved in the design, construction and successful launch of a new vehicle. ULA’s Atlas 5 and SpaceX’s Falcon 9 currently only launch satellite and cargo resupply missions to the space station. Right now, those rockets are not rated to carry humans.

To certify the rockets to safely carry astronauts, Dorney is helping to guide the team making adjustments to this existing and proven technology. The Commercial Crew Program learns something new about these designs every time one of the unmanned rockets flies, evaluating the vehicle data in partnership with NASA’s Launch Services Program.

“We are reevaluating every technical aspect of both rockets to ensure they are capable of meeting our requirements to safely launch humans,” Dorney says. “These are two very different vehicles, each with unique technical challenges.”

These challenges mean the commercial crew launch vehicle team pores over reams of data about propulsion, structural integrity, avionics, mechanical systems and software. It’s a major responsibility that Dorney and his team do not take lightly.

“We need to be knowledgeable about the entire vehicle because it is carrying valuable cargo in the form of our astronauts,” Dorney says. “Rating a rocket to carry humans is not easy, but I work with people who are fiercely intelligent, highly motivated and dedicated experts.”

Dorney enrolled at the University of Illinois at Urbana-Champaign, earning a bachelor’s degree in aeronautical and astronautical engineering in 1985, and a master’s two years later.

After earning his doctorate in 1992 in aerospace engineering from the Pennsylvania State University in State College, he and his wife spent the next few years looking for places where they could both work in their chosen field.

Finally, in 2000, a call came for both of them to join Marshall’s Applied Fluid Dynamics branch working on, among other efforts, the Space Shuttle Main Engine Program.

Dorney has never looked back, considering his work at NASA his true calling. He taps into his experience of working on a human-rated space vehicle to manage the resources and technical team that will return the capability of flying humans from American soil.

“I’ve always loved spaceflight,” Dorney says. “NASA has a rich history and I want to live up to what some of the brightest minds in this nation have accomplished at NASA, and that includes some of the people I work with now. I love being part of the team that explores our solar system and I look forward to sending humans on the journey to Mars.

“There is literally nothing else I would rather be doing.”

To learn more about Dorney and his journey, click here.

Hubscher, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

NASA Begins Testing of Revolutionary E-Sail Technology

By Brian C. Massey

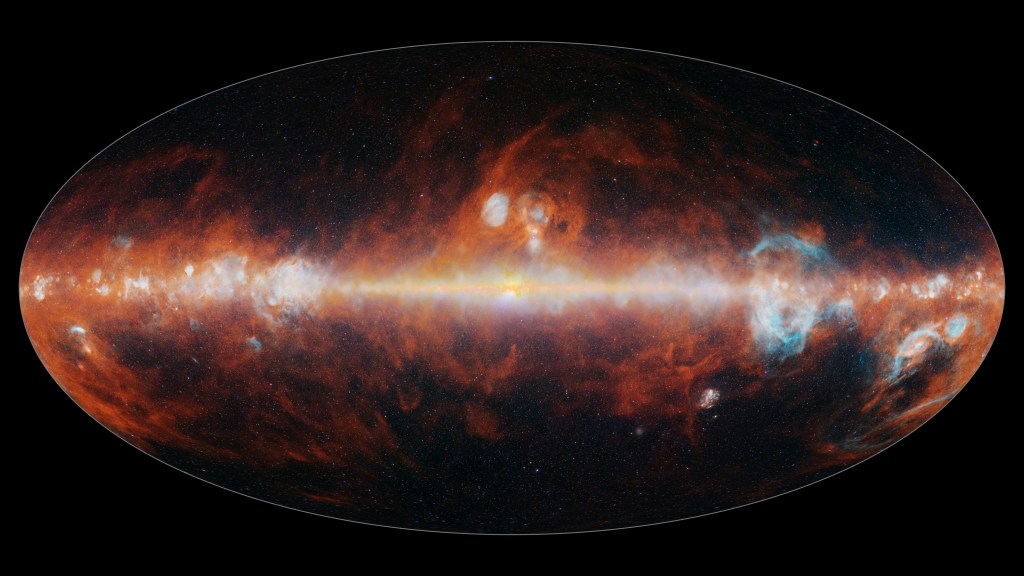

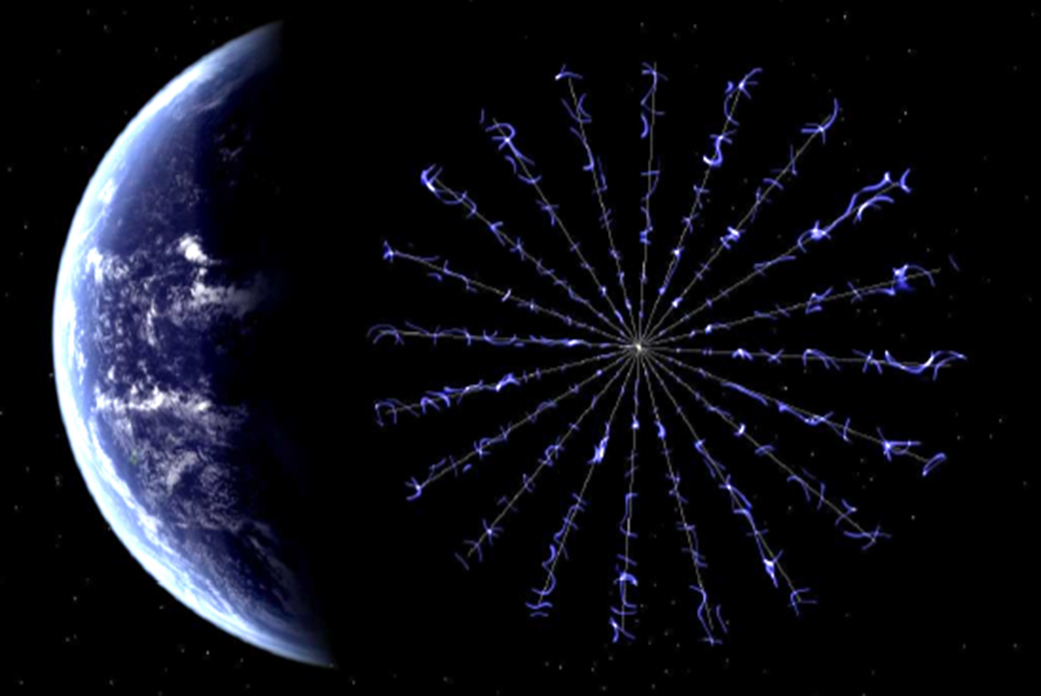

Testing has started at NASA’s Marshall Space Flight Center on a concept for a potentially revolutionary propulsion system that could send spacecraft to the edge of our solar system, the heliopause, faster than ever before.

The test results will provide modeling data for the Heliopause Electrostatic Rapid Transit System. The proposed HERTS E-Sail concept, a propellant-less propulsion system, would harness solar wind to travel into interstellar space.

“The sun releases protons and electrons into the solar wind at very high speeds — 400 to 750 kilometers per second,” said Bruce Wiegmann, an engineer in Marshall’s Advanced Concepts Office and the principal investigator for the HERTS E-Sail. “The E-Sail would use these protons to propel the spacecraft.”

Extending outward from the center of the spacecraft, 10 to 20 electrically charged, bare aluminum wires would produce a large, circular E-Sail that would electrostatically repel the fast moving protons of the solar wind. The momentum exchange produced as the positively charged wires repel the protons would create the spacecraft’s thrust. Each tether is extremely thin, only 1 millimeter — the width of a standard paperclip — and very long, nearly 12.5 miles — almost 219 football fields. As the spacecraft slowly rotates at one revolution per hour, centrifugal forces will stretch the tethers into position.

The testing, which is taking place in the High Intensity Solar Environment Test system, is designed to examine the rate of proton and electron collisions with a positively charged wire. Within a controlled plasma chamber simulating plasma in a space, the team is using a stainless steel wire as an analog for the lightweight aluminum wire. Though denser than aluminum, stainless steel’s non-corrosive properties will mimic that of aluminum in space and allow more testing with no degradation.

To send a scientific probe on a deep space journey, the sail would have to have a large effective area. Space travel is generally measured in astronomical units, or the distance from Earth to the sun. At 1 AU, the E-Sail would have an effective area of about 232 square miles, slightly smaller than the city of Chicago. The effective area would increase to more than 463 square miles– similar to Los Angeles — at 5 AU.

This increase in area would lead to continued acceleration much longer than comparable propulsion technologies. For example, when solar sail spacecraft reach the asteroid belt at 5 AU, the energy of the solar photons dissipates and acceleration stops. Wiegmann believes the E-Sail would continue to accelerate well beyond that.

“The same concerns don’t apply to the protons in the solar wind,” he said. “With the continuous flow of protons, and the increased area, the E-Sail will continue to accelerate to 16-20 AU — at least three times farther than the solar sail. This will create much higher speeds.”

In 2012, NASA’s Voyager 1 became the first spacecraft to ever cross the heliopause and reach interstellar space. Launched in 1977, Voyager 1 took almost 35 years to make its 121 AU journey. The goal of HERTS is to develop an E-Sail that could make the same journey in less than one-third that time.

“Our investigation has shown that an interstellar probe mission propelled by an E-Sail could travel to the heliopause in just under 10 years,” he said. “This could revolutionize the scientific returns of these types of missions.”

The HERTS E-Sail concept development and testing is funded by NASA’s Space Technology Mission Directorate through the NASA Innovative Advanced Concepts Program. NIAC projects study innovative, technically credible, advanced concepts that could one day “change the possible” in aerospace.

Selected as a Phase II NIAC Fellow in 2015, the HERTS team was awarded an additional $500,000 to further test the E-Sail and possibly change not only the way NASA travels to the heliopause, but also within our solar system.

For more information on the Heliopause Electrostatic Rapid Transit System, click here.

Massey, an ASRC Federal/Analytical Services employee and the Marshall Star editor, supports the Office of Strategic Analysis & Communications.

‘Distracted Driving’ Presentations to Anchor Marshall’s SHE Day Activities April 20

By Rick Smith

NASA’s Marshall Space Flight Center will hold its annual SHE Day activities April 20. Center Director Todd May has authorized a six-hour safety stand-down, encouraging team members to spend the day focused on personal and professional safety and health and environmental awareness in the workplace and home.

This year’s theme is “SHE Begins With Me!” Anchoring the events are activities designed to raise awareness of the most common cause of accidents and injuries: simple distraction.

“Most injuries recorded at Marshall last year resulted from a lack of situational awareness,” said SHE Day 2016 chair Edward Kiessling, manager of Marshall’s Environmental Engineering and Occupational Health Office. “It’s our goal with this year’s event to raise awareness of that pervasive threat — distraction, as we go about our daily business.”

Distraction can be especially dangerous behind the wheel of a car, particularly when talking or texting on cell phones and other handheld devices, Kiessling said. Some 431,000 Americans were injured in 2014 alone in motor vehicle crashes involving distracted drivers, the federal website Distraction.gov reports, and nearly 3,200 were killed.

To address this threat, the highlight of Marshall’s SHE Day will be a presentation by Kramer Entertainment of Grand Rapids, Michigan, which specializes in seminars about drunk-driving and distracted-driving. “It will be an experience,” Kiessling said, ”that I hope Marshall team members won’t soon forget.”

Register now for high-impact presentations

Two presentations will be offered in Activities Building 4316. A hosted seminar will offer sobering first-hand accounts of past distracted-driving tragedies and tips for discussing the danger with those at the greatest statistical risk: teens. A hands-on session will put individuals into high-tech simulators that vividly recreate driving activities and demonstrate how even brief distractions can result in catastrophe.

The seminar, with a capacity of 700 team members, will be held from 8-11 a.m. and again from noon to 3 p.m. Two simulator sessions, each with a 60-person capacity, will be available during the same morning period and two more during the afternoon.

Because only 1,400 people can join the seminars and the immersive simulator experience can accommodate just 240, team members are asked to register for the sessions, entering their appropriate organization codes to properly identify which teams they represent.

“It’s our hope that at least one team member from each civil-service organization and contract firm will take part,” Kiessling said. “That way, they can take what they’ve learned back to their team, and share it at a subsequent safety meeting.” He added that the earlier individuals sign up, the more likely they’ll get the session times they prefer.

Contractor personnel are particularly encouraged to take part. “We know that many tend to miss out due to contract performance obligations. This year, we’re working to ensure each contract is able to send a few team members to take part and share this powerful experience with the rest of their contractor team,” he said.

The distracted-driving activity will be augmented by a host of additional safety-themed displays, exhibits and training opportunities in buildings 4203, 4315 and 4316. Team members can find the complete list of events and activities on ExplorNet.

“Statistics show that unsafe acts, not unsafe conditions, are the most common causes of workplace injuries and accidents,” Kiessling said. “By redoubling our focus on personal accountability and situational awareness, we hope to eradicate distraction and keep our team members and their families safe in every part of their daily lives and activities.”

For more information, contact Kiessling or SHE Day committee members Sonya Dillard or Amy Black.

Students Ready to Launch High-Powered Rockets, April 16

By Christopher Blair

Static stability margin, thrust-to-weight ratios, center of gravity and composite propellants – these phrases may read like a foreign language to some, but it’s everyday lingo for the dozens of young rocket scientists competing at this weekend’s Student Launch, on April 16, near NASA’s Marshall Space Flight Center.

With another year of sky-high fun upon us, nearly 50 high school and college teams from across 22 states will compete for awards and cash prizes by launching rockets a mile high. Each team has spent the past eight months designing, fabricating and testing a single-stage rocket. During the competition, they will attempt to launch their rocket to an altitude of one mile, or 5,280 feet, above ground level.

Back for the second year is the Mars Ascent Vehicle Challenge, running parallel with Student Launch. MAV requires teams to design an autonomous system capable of retrieving and storing a mock Martian sample into a rocket. Sponsored by the Centennial Challenges program — NASA’s citizen prize program — MAV focuses on teaching students how to develop autonomous capabilities that one day could be used on the surface of Mars.

Teams will also participate in “Rocket Fair,” an open-house event where they give technical presentations about their rocket and any autonomous systems to hundreds of team members from NASA and Orbital ATK of Promontory, Utah — longtime corporate sponsor of Student Launch. This provides students an opportunity to gain valuable feedback from real rocket scientists and engineers.

After the smoke clears from dozens of high-powered rocket launches, teams will gather at an awards banquet for a well-earned evening of celebration recognizing their hard work and dedication with a bevy of awards, including Best Design, Altitude, Safety and more.

Orbital ATK offers an overall cash prize of $5,000 to the highest-ranking college/university team to meet the Student Launch objectives. The MAV challenge offers a share of $50,000 for the top three teams completing their objectives.

More than just a friendly competition, Student Launch and MAV Challenge provide real-world experiences in the STEM fields of science, technology, engineering and math. Throughout this authentic project, students learn valuable skills needed for careers in engineering and aerospace industries.

Blair, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

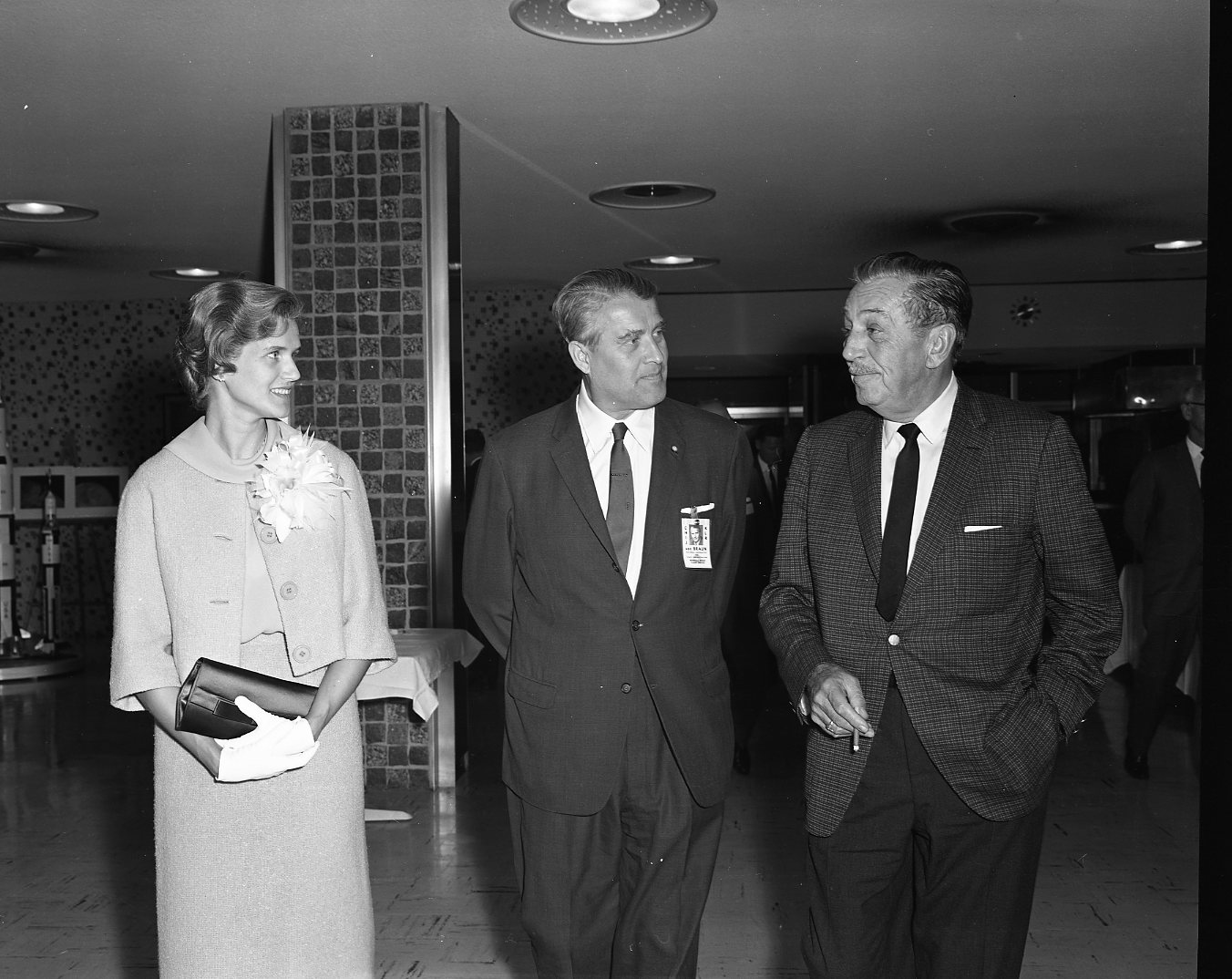

This Week in NASA History: Walt Disney Visits Marshall — April 13, 1965

This week in 1965, world-renowned filmmaker and animator Walt Disney, right, visited NASA’s Marshall Space Flight Center. Marshall Center Director Wernher von Braun, center, began his association with Walt Disney in the 1950s when he appeared in three Disney television productions related to the exploration of space. Years later, von Braun and his wife Maria, left, invited Disney, his brother Roy and other Disney executives to tour Marshall. The NASA History Program documents and preserves NASA’s remarkable history through a variety of products — photos, press kits, press releases, mission transcripts and administrators’ speeches. For more pictures like this one and to connect to NASA’s history, visit the History Program’s Web page. (NASA)

Completion of SLS Confidence Fuel Tank Featured on ‘This Week @NASA’

The final welding of a liquid oxygen tank confidence article for NASA’s new rocket, the Space Launch System, is featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

The welding was completed at NASA’s Michoud Assembly Facility in New Orleans. The rocket’s 200-foot-tall core stage includes two tanks, one for liquid oxygen and another for liquid hydrogen. Both tanks are designed to fuel SLS’s four RS-25 engines that, along with two, five-segment solid rocket boosters, will power the SLS during liftoff and ascent.

Confidence hardware verifies weld procedures are working as planned and tooling-to-hardware interfaces are correct. It also will be used in developing the application process for the thermal protection system, which is the insulation foam that gives the tank its orange color. All welding for the core stage is expected to be completed this summer in preparation for the rocket’s first uncrewed test flight with NASA’s Orion spacecraft in 2018. SLS will be the world’s most powerful rocket, able to carry astronauts on deep-space missions in the Orion to Mars and beyond.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.

Obituaries

Charles H. Sparks, 96, of New Site, Mississippi, died April 10. He retired from the Marshall Center in 1974 as quality assurance specialist. He is survived by his wife, Hazel Moore Sparks.