This article is from the 2021 NESC Technical Update.

Lithium-ion (Li-ion) cells are widely used in aerospace and terrestrial applications due to their energy storage capability. However, these cells can experience thermal runaway (TR), a failure phenomenon resulting from mechanical, thermal, or electrochemical abuse whereby stored energy is rapidly released at a rate greater than the cell can dissipate the heat. If a battery assembly is not properly designed, TR can propagate to adjacent cells with potentially catastrophic results.

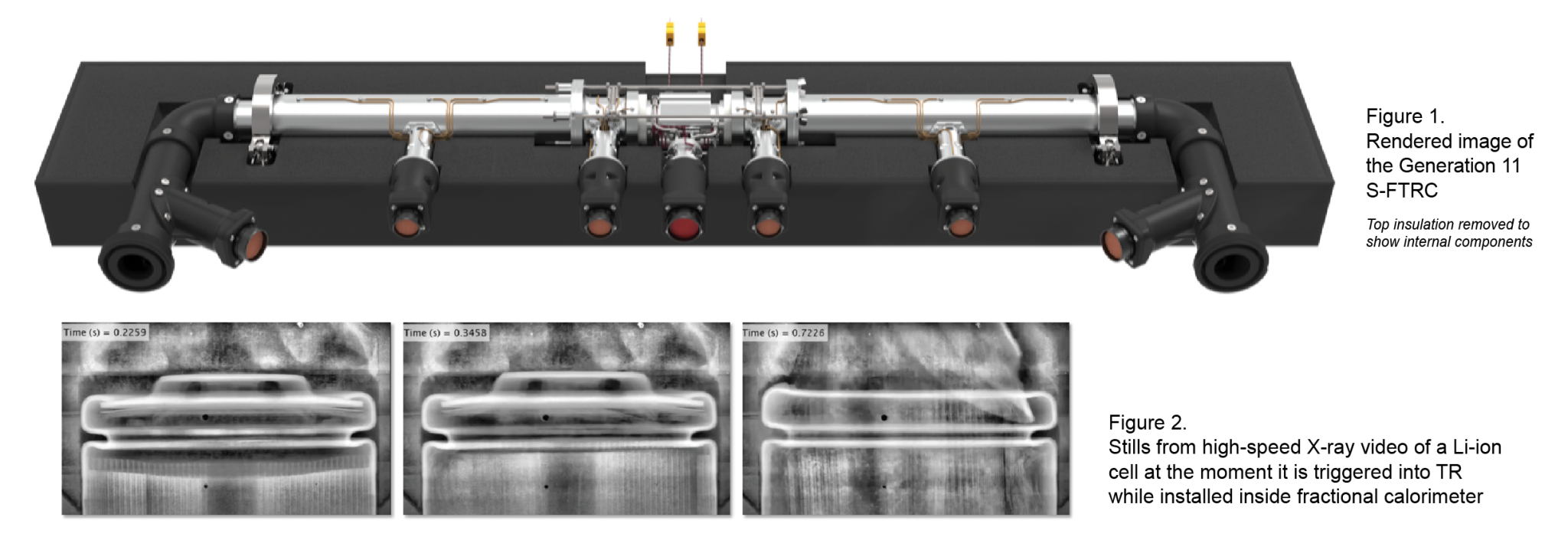

In 2016, the NESC pursued the development of the Small Format Fractional Thermal Runaway Calorimeter (S-FTRC) to measure TR energy yield for the widely used 18650 format Li-ion cell. The S-FTRC was designed to provide unique insight into TR by allowing a tally of the total thermal energy release plus the fractions liberated as vented energy and energy that conducts through the cell casing. These data are important in understanding Li-ion battery thermal design and analysis.

After NESC involvement ended, engineers at the Johnson Space Center continued to use the calorimeter to support NASA’s missions while improving the calorimeter design to further increase both rapid turnaround testing and durability. Experiments can now be conducted with a 25-minute turnaround when working with a team of 3 to 4 people, allowing many experiments to be conducted during a single test campaign. Given that no two TR events are the same, a statistically significant set of tests is required to characterize the range of potential TR behaviors.

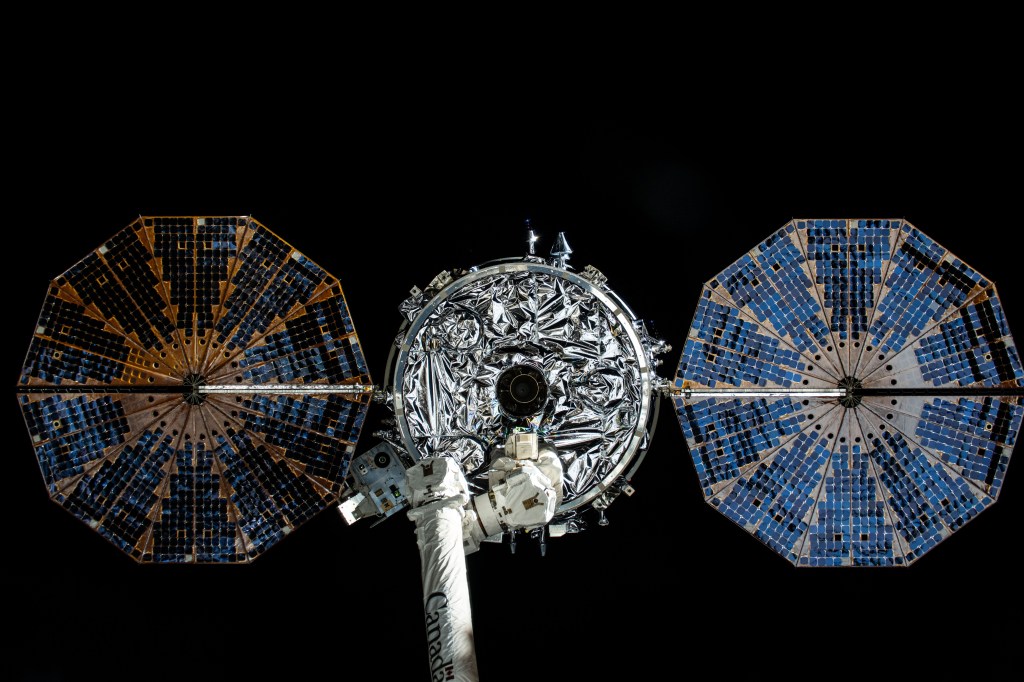

The most recent version of the S-FTRC is depicted in Figure 1. Additionally, the FTRC architecture has been expanded to support pouch format cells and large format prismatic cells with capacities greater than 100 A-h. NASA has pursued a patent on the S-FTRC and has advertised the calorimeter as a licensable technology through NASA’s Technology Transfer (T2) Office, which has already sparked interest by private sector entities. The T2 Office actively works today to license the technology to interested parties.

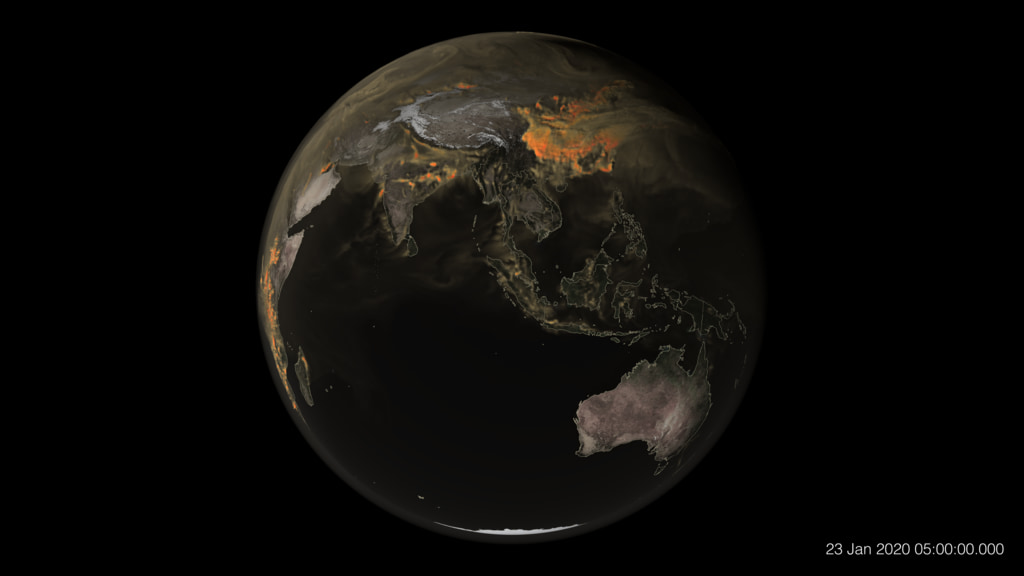

NASA engineers and collaborators at the National Renewable Energy Laboratory (NREL) and the University College London have executed hundreds of calorimeter runs to date. The majority of the experiments have been conducted at synchrotron facilities in the United Kingdom (Diamond Light Source) and in France (European Synchrotron Radiation Facility). These special experiments allow the internal failure mechanisms of the cell to be studied with high-speed X-ray videography capturing recordings in excess of 1700 frames-per-second; a still image captured from one of these experiments is shown with Figure 2. These combination synchrotron/S-FTRC experiments provide researchers and engineers with data that helps to link internal failure mechanisms to the external thermal characteristics of a cell undergoing TR.

The bulk of the data gathered by these experiments has been compiled into a publicly accessible resource known as the Battery Failure Databank. The databank can be downloaded from NASA.gov/ftrc and is also available via NREL web channels. The databank consists of a spreadsheet containing the tabular S-FTRC results with hyperlinks to the X-ray videos hosted on the NREL YouTube channel when applicable. The structure of the spreadsheet is designed to be compatible with modern visual analytics techniques.

In the years to come, NASA engineers aim to use the FTRC data to inform the design of battery assemblies created for NASA programs and also hope to see the S-FTRC hardware and data contained in the Battery Failure Databank leveraged by private industry to help make batteries safer here on Earth.