In This Week’s Star

- Booster Segment Answers ‘Casting’ Call for First Flight of SLS

- Jody Singer Harnesses ‘Need For Speed’ to Make Things Move at NASA

- NASA Rocket Fuel Pump Tests Pave Way for Methane-Fueled Mars Lander

- Work Safety, Distracted Driving Awareness Central to SHE Day 2016 at Marshall

- This Week in NASA History: Hubble Space Telescope Deployed — April 25, 1990

- Flight Hardware Welding and Test Stand 4693 Featured on ‘This Week @NASA’

- Retired Marshall Center Engineer and Manager Bob Ryan Dies

Booster Segment Answers ‘Casting’ Call for First Flight of SLS

The first of 10 flight segments for the two solid-rocket boosters of NASA’s Space Launch System has been cast at Orbital ATK’s facility in Promontory, Utah. Casting involves filling the insulated metal case with propellant and allowing it to solidify or “cure” for several days. This hardware, which is the aft segment, will eventually be integrated with four other segments to make up one of the two, five-segment solid rocket boosters for the first flight of SLS in 2018. During this flight, called Exploration Mission-1, SLS will carry an unmanned Orion spacecraft thousands of miles beyond the moon over the course of about a three-week mission and help NASA prepare for human missions to deep space, including Mars. Orbital ATK is the prime contractor for the boosters. (Orbital ATK)

Jody Singer Harnesses ‘Need For Speed’ to Make Things Move at NASA

By Kenneth Kesner

Jody Singer likes to make things move. Fast.

At 9 she was galloping horses. Later came cars — and rockets.

“There really was a need for speed,” Singer said recently, smiling in her new office, surrounded by spacecraft models and astronaut photos. She has worked at NASA for more than 30 years and is the newly named deputy director of NASA’s Marshall Space Flight Center.

Singer grew up in Hartselle, Alabama, only about 35 miles from Marshall, where some of her school friends’ moms and dads worked on the moon rockets. A self-described “tomboy,” she loved the horses, cattle and other animals on the family’s small farm, and even thought about becoming a veterinarian. But Singer also loved reading about science and space. She liked to tinker, to get her hands dirty figuring out what made things move and work.

“I had one of the most Disneyland childhoods on the farm that anyone could wish for,” Singer said. “There were bumps and bruises, but it gave me confidence. And it taught me basics: to not be afraid of hard work and to know that, no matter how hard you work on some things, they don’t always turn out the way you want.”

Her parents were powerful role models, and never gave any indication that there was anything she couldn’t do. Her father, David Sandlin, was a Morgan County sheriff and also worked as a machinist at Wolverine Tube. He died when Singer was 17 and her mother, Edith Sandlin, who lives in Danville, Alabama, earned an accounting degree and took on new roles to care for her family solo, working at Copeland Corp. in Hartselle, which manufactures compressors and other equipment.

Singer’s family made education a top priority, and she was interested in engineering by the time she went to Morgan County High School in Hartselle, where “a great education and teachers really helped shape me.” She went on to earn her bachelor’s degree in industrial engineering at the University of Alabama in Tuscaloosa in 1983.

She applied for a position at NASA after graduation, but there was little hiring at that time. Singer’s first engineering job was for General Motors, at a plant in Jackson, Mississippi, that produced wiring harnesses. It was tough work, and it was her first time truly on her own, away from home. “I really pulled up roots and proved to myself that I could do it on my own,” she said.

Singer liked that job a lot. But in 1985 NASA called about a position at Marshall. And from day one, Singer knew that making things move at NASA was her dream job.

“I thought, ‘Wow, am I really here, working in the space program?’ I have always had a sense of pride when I tell people I’m with NASA,” she said.

Over the years in college and in the workplace, Singer was aware that as a female engineer, she was in the minority. But gender never held her back. Many mentors along the way, men and women, guided her to tackle new and difficult assignments. Now, as deputy director of one of NASA’s largest field centers, her biggest rewards aren’t just developing spacecraft systems — they come from working with people and developing a workforce capable of collaborating to make NASA’s missions successful.

“I want them to be better than me,” Singer said. “They’re the next generation. They’re the ones who are going to keep us moving forward.”

Her career seems custom-crafted to shape the Marshall team at a time when NASA is on the verge of flight-testing the Space Launch System, the launch vehicle that will make it possible for astronauts to reach Mars.

They can’t get there fast enough for Singer. For over three decades, she has played an important part in making it possible for men and women to fly very high, very fast, to explore living and working in space for the benefit of everyone on Earth.

“NASA is one of the places where you feel you can really make a difference,” Singer said. “Not just for the people immediately around you, but for the nation and world.”

She’s not slowing down now.

Kenneth Kesner, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

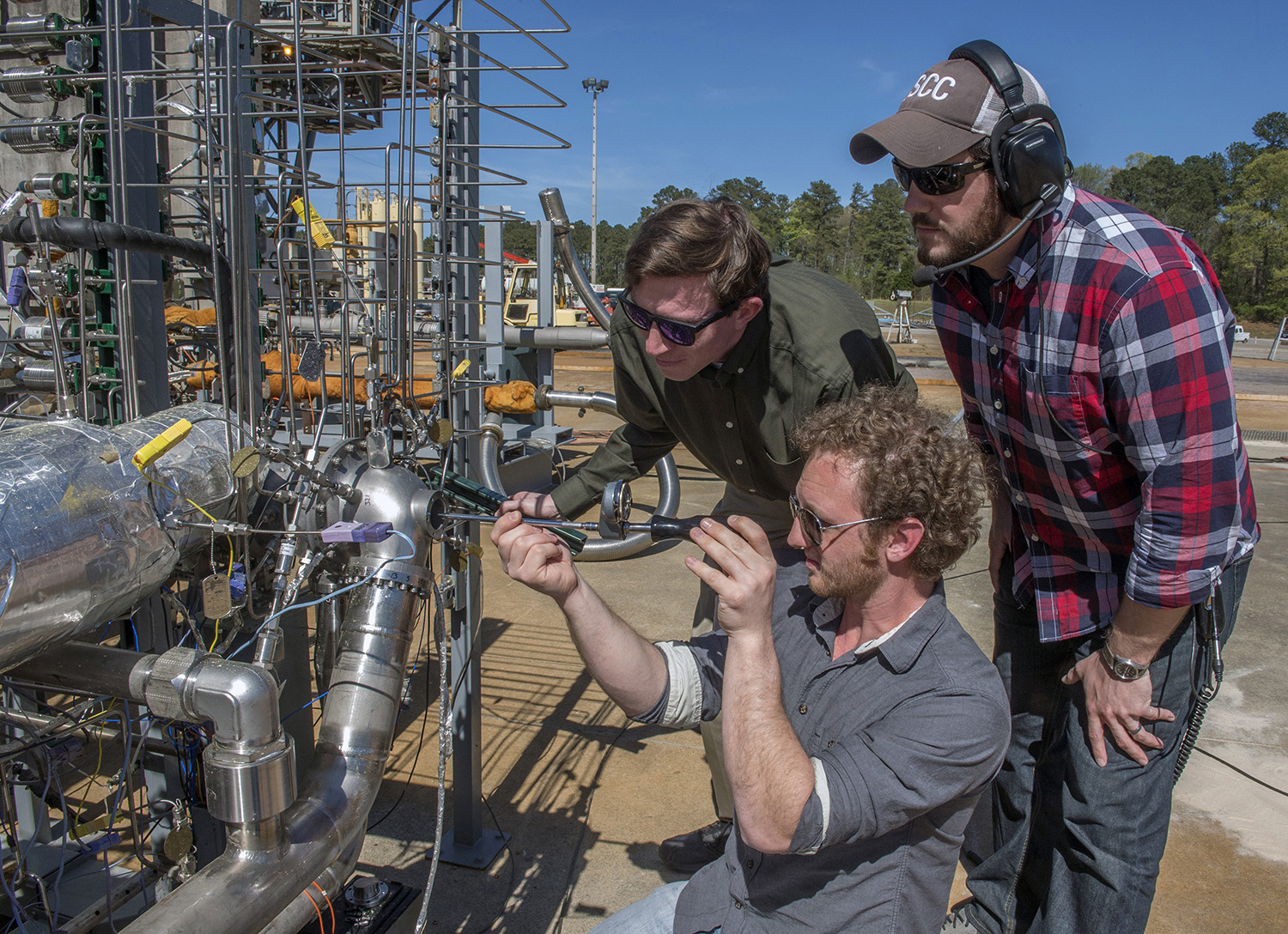

NASA Rocket Fuel Pump Tests Pave Way for Methane-Fueled Mars Lander

NASA has tested a 3-D printed rocket engine turbopump with liquid methane — an ideal propellant for engines needed to power many types of spacecraft for NASA’s journey to Mars.

“This is one of the most complex rocket parts NASA has ever tested with liquid methane, a propellant that would work well for fueling Mars landers and other spacecraft,” said Mary Beth Koelbl, manager of the Propulsions Systems Department at NASA’s Marshall Space Flight Center. “Additive manufacturing, or 3-D printing, made it possible to quickly design, build and test two turbopumps with identical designs that worked well with both liquid methane and liquid hydrogen propellant.”

A turbopump is complex because it has turbines that spin fast to drive the pump, which supplies fuel to the engine. During the full power test, the turbines generated 600 horsepower and the fuel pump got its “heartbeat” racing at more than 36,000 revolutions per minute, delivering 600 gallons of semi-cryogenic liquid methane per minute — enough to fuel an engine producing over 22,500 pounds of thrust. Three other tests were completed at lower power levels.

Hydrogen turbopump component testing and testing with a liquid oxygen/liquid hydrogen breadboard engine were completed in 2015. These tests, along with manufacturing and testing of injectors and other rocket engine parts, are paving the way for advancements in 3-D printing of complex rocket engines and more efficient production of future spacecraft, including methane-powered landers.

“Methane propulsion and additive manufacturing are key technologies for the future of exploration including NASA’s journey to Mars,” said Graham Nelson, a Marshall propulsion engineer who helped with the testing. “We’re excited to complete testing that advances both of these technologies at the same time and improves the capabilities of future missions.”

Liquid methane is cooled to 255 degrees below zero Fahrenheit (-159 degrees Celsius) whereas liquid hydrogen is cooled to 400 degrees below zero Fahrenheit (-240 degrees Celsius). The higher temperature of liquid methane means it boils off more slowly and thus is easier to store for longer periods, a benefit for Mars missions. Also, technologies exist today to make it possible to manufacture methane rocket fuel from carbon dioxide, which is plentiful in the Red Planet’s atmosphere.

“By demonstrating the same turbopump can work with different fuels, we’ve shown that a common design would work for either engines fueled by methane or hydrogen,” said Marty Calvert, the Marshall engineer who designed the turbopump. “Because liquid methane is much more dense than hydrogen, it requires the turbopump to spin at a different speed to deliver the same amount of mass flow to the engine.”

Testing ensures 3-D printed parts operate successfully under conditions similar to those experienced by landers, ascent vehicles and other space vehicles. Test data are available to American companies working to drive down the cost of using this new manufacturing process to build parts that meet aerospace standards. All data on materials characterization and performance are compiled in NASA’s Materials and Processes Technical Information System, called MAPTIS, which is available to approved users.

“Additive manufacturing allowed us to build the turbopump with 45 percent fewer parts,” said Nick Case, the Marshall propulsion engineer who led the testing. “This made it affordable to build two turbopumps, get them on the test stand quickly, and get results. Our next step will be to test the liquid methane turbopump with other 3-D printed engine components in a similar configuration to the liquid hydrogen tests completed last year.”

Work Safety, Distracted Driving Awareness Central to SHE Day 2016 at Marshall

A Huntsville Utilities worker demonstrates why it’s important to avoid power lines and other potentially dangerous utility equipment during Marshall Space Flight Center’s SHE Day 2016 activities April 20. This year’s event included a variety of activities and presentations “designed to promote situational awareness,” said SHE Day chair Edward Kiessling, manager of Marshall’s Environmental Engineering and Occupational Health Office. Simple awareness, he said, underpinned this year’s theme, “SHE Begins With Me!” and is the easiest means of improving personal and professional safety and health in the workplace and at home. (NASA/MSFC/Emmett Given)

Marshall accountant Marissa Key takes part in a distracted-driving demonstration, a key element of SHE Day 2016 activities. The activity provided a firsthand look at the dangers of distracted driving, a factor in 431,000 motor vehicle crash injuries in 2014 alone, according to the federal website Distraction.gov. Hundreds of Marshall team members took part in various SHE Day distracted-driving seminars and demonstrations, presented by Kramer Entertainment of Grand Rapids, Michigan. (NASA/MSFC/Emmett Given)

Lieutenant-General David L. Mann, front left, commander of the U.S. Army Space & Missile Defense Command and Army Forces Strategic Command at Redstone Arsenal, greets fellow participants in the 9th annual MSFC Running Club’s 5K, held April 20 during SHE Day 2016 activities. The 5K run is a popular element of the annual SHE Day event and draws participants from all across Team Redstone. (NASA/MSFC/Emmett Given)

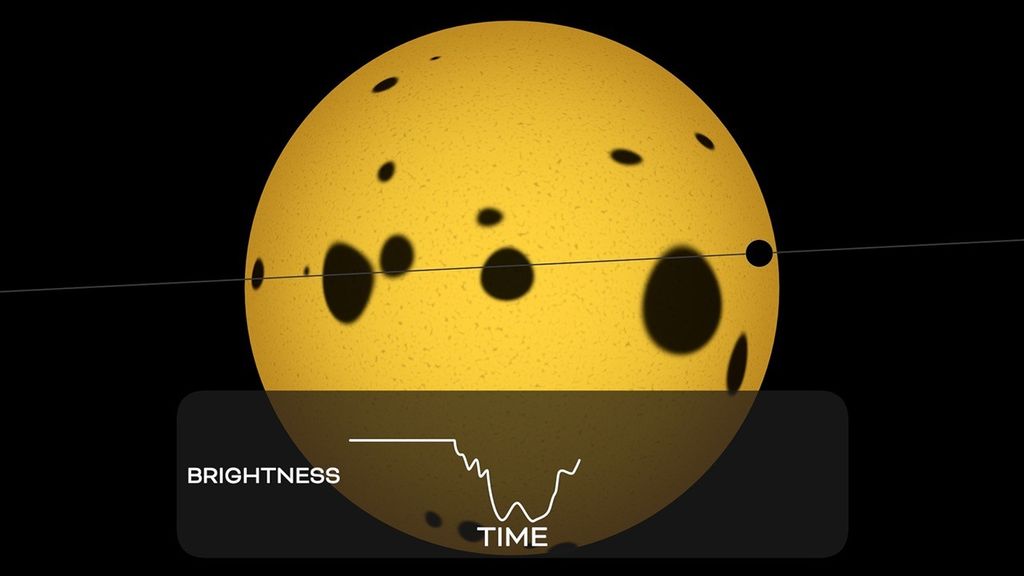

This Week in NASA History: Hubble Space Telescope Deployed — April 25, 1990

This week in 1990, the Hubble Space Telescope was deployed from space shuttle Discovery during STS-31. Since its launch, the school-bus-sized Hubble has made more than 1.2 million observations and peered back into the very distant past, to locations more than 13.4 billion light years from Earth. The revolutionary observatory was designed, developed and constructed by NASA’s Marshall Space Flight Center. The NASA History Program documents and preserves NASA’s remarkable history through a variety of products — photos, press kits, press releases, mission transcripts and administrators’ speeches. For more pictures like this one and to connect to NASA’s history, visit the History Program’s Web page. (NASA)

Flight Hardware Welding and Test Stand 4693 Featured on ‘This Week @NASA’

Welding at NASA’s Michoud Assembly Facility on flight hardware for the Space Launch System and the topping out of NASA Marshall Space Flight Center’s Test Stand 4693 are both featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

Final welding was completed on the first major piece of flight hardware for the SLS core stage at Michoud. The component, part of the rocket’s engine section, will house the four RS-25 engines for the first flight of the SLS with NASA’s Orion spacecraft in 2018. The SLS core stage will be more than 200 feet tall and store cryogenic liquid hydrogen and liquid oxygen to feed the rocket’s RS-25 engines.

SLS, which is managed by Marshall, will be the world’s most powerful rocket for human space exploration, able to take astronauts in the Orion spacecraft on deep-space missions, including to Mars.

At Marshall, engineers placed the top-most beam into place on Test Stand 4693. When construction is completed, the structure will be used to evaluate how the SLS’s giant liquid hydrogen tank holds up to the same stresses and loads it will experience during liftoff and flight.

For more on these and other stories follow us on social media and visit www.nasa.gov/twan.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.

Retired Marshall Center Engineer and Manager Bob Ryan Dies

Marshall retiree Robert “Bob” Ryan, 90, of Madison, died April 15.

A native of Morgan County, Alabama, and a World War II veteran, Ryan was a teacher and basketball coach before becoming an engineer.

He was an aerospace engineer for the Army Ballistic Missile Agency at Redstone Arsenal, from 1956 to 1960, working on the Redstone, Jupiter and Pershing missile programs, Explorer and Juno satellites, and the Saturn I rocket. In 1960, he transferred with Wernher von Braun’s team to NASA’s Marshall Space Flight Center as chief of Marshall’s Dynamic Analysis Branch.

During his career, he served in numerous positions and received many awards before retiring as deputy director of the System Dynamics Laboratory in 1996. At Marshall, Ryan worked on the Saturn V launch vehicle, the Skylab space station, space shuttle, Spacelab, the Hubble Space Telescope and numerous other scientific payloads.

After retirement, he continued working as a consultant to the aerospace industry and NASA, sharing his knowledge and passion through several technical and managerial short courses.

To learn more about Ryan’s career, click here or here.

-Carolyn_Y._Ng.jpeg?w=1024)