In This Week’s Star

- More Hands Make Light Work: Crew Dragon Duo Increases Space Station Science Tempo

- Bruce Tiller Combines Birding, Boosters to Help Launch Artemis I

- Stacking the Space Launch System Solid Rocket Boosters

- Rocket Science in 60 Seconds: How and Why Are the SLS Rocket Boosters Insulated?

- New Data Processing Tool Transforms Workflow for Budget Analysts

- Wallops Safety Office Chief to Give Virtual Presentation

- NASA’s Lee Mason Discusses Kilopower Project at Virtual Tech Talk

- This Week in NASA History: Life and Microgravity Spacelab Launches to Space Station – June 20, 1996

More Hands Make Light Work: Crew Dragon Duo Increases Space Station Science Tempo

By Rick Smith

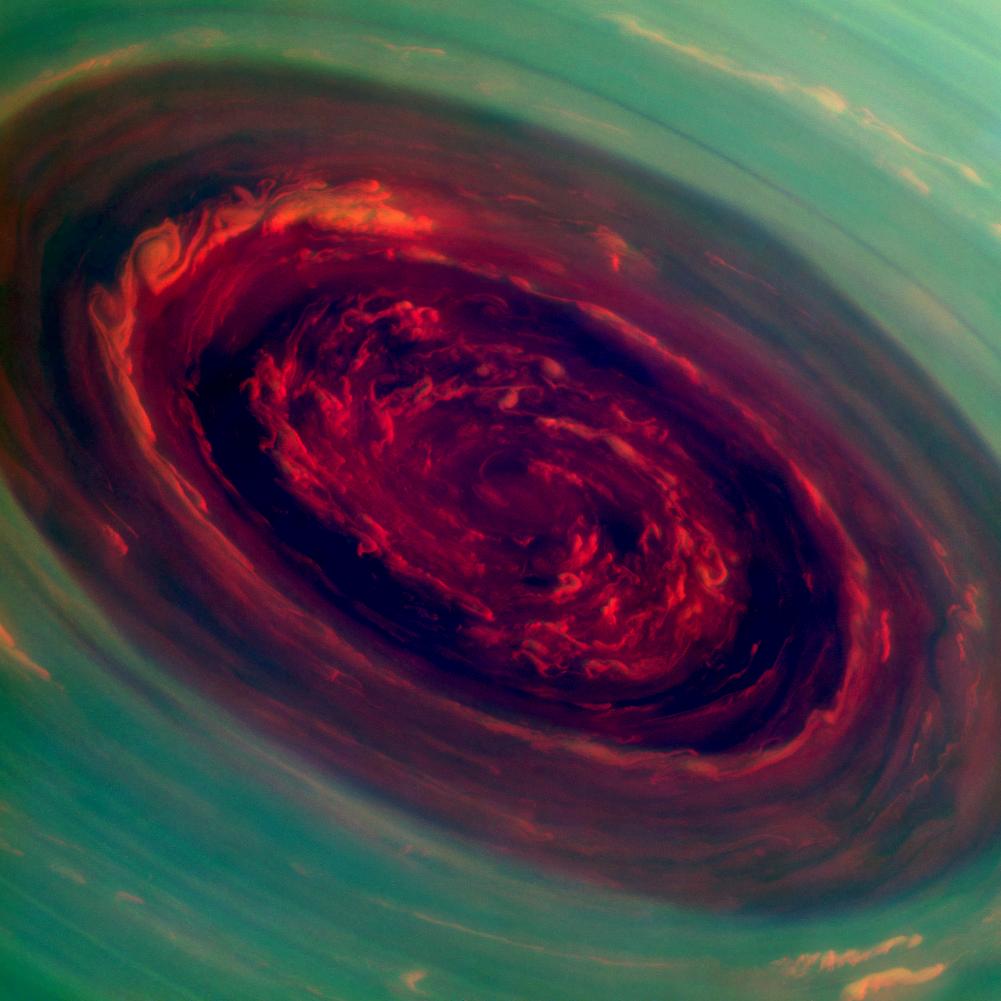

The saying “more hands make light work” is rarely more apt than when those hands are 250 miles up on the International Space Station, overseeing research to extend humanity’s reach into the solar system and offer new scientific breakthroughs on Earth.

With the arrival on station of two new sets of hands — NASA astronauts Robert Behnken and Douglas Hurley, whose May 30 launch on NASA’s SpaceX Demo-2 test flight was the first such flight for Americans on American rockets since the space shuttle era ended — the Expedition 63 crew swelled to five. As a result, more crew time is available for research activities.

“Those extra hands are one reason NASA’s Commercial Crew Program is so important to research planners,” said Bryan Dansberry, space station associate program scientist at NASA’s Johnson Space Center. “Any business owner or homeowner understands a number of maintenance and cleaning tasks are required to keep things running smoothly. The more available hands, the more time you can spend doing the tasks that make your business successful. In our case, that means more science — conducting research in the unique laboratory that is the space station to conduct more experiments and technology demonstrations.”

During their stay, Behnken and Hurley have their own priority tasks — mainly continuing to test the Crew Dragon spacecraft in support of the Commercial Crew Program. But they’re also helping fellow NASA astronaut and Expedition 63 Commander Chris Cassidy and Russian cosmonauts Anatoly Ivanishin and Ivan Vagner support some 240 new and ongoing experiments during the latest station expedition, also known as an increment.

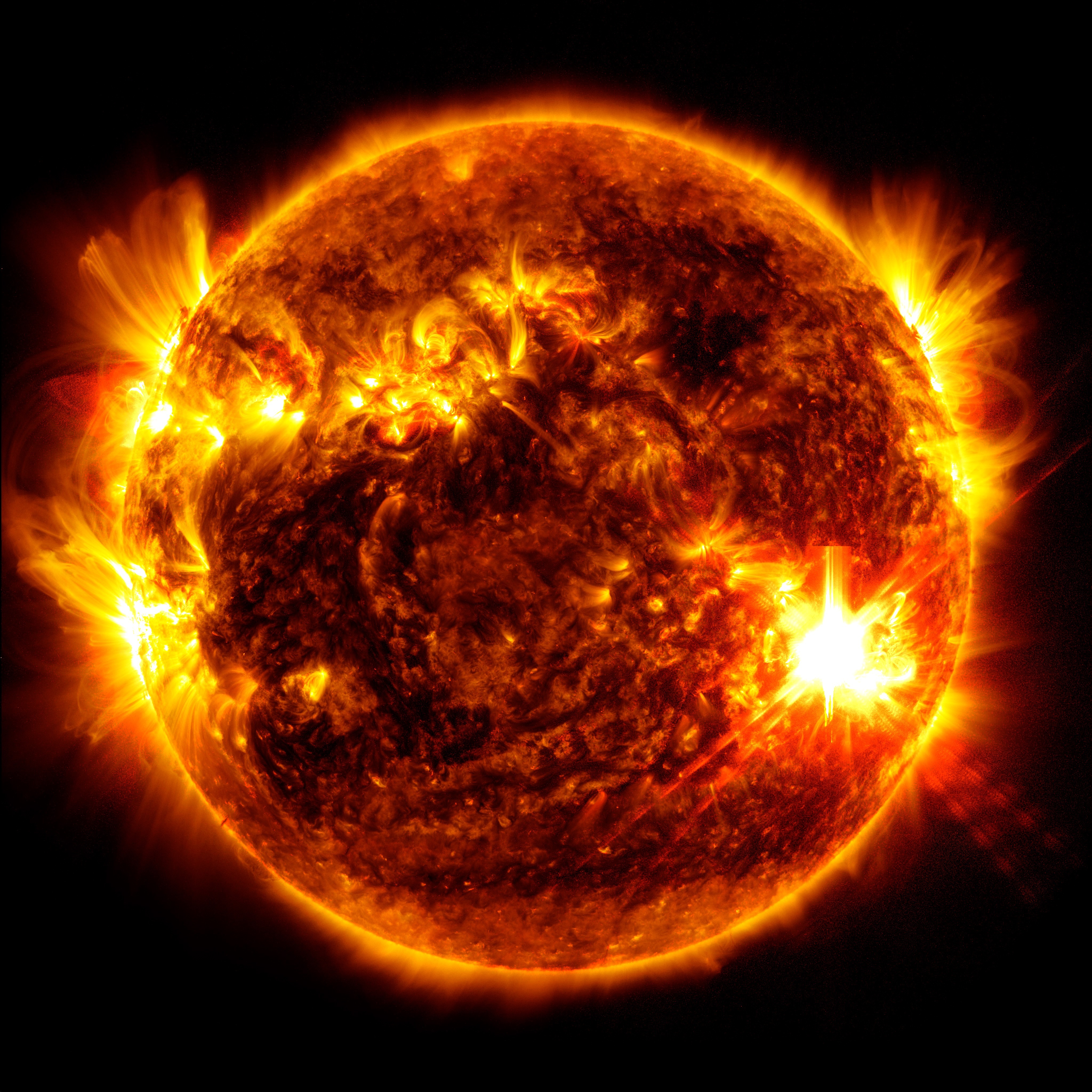

That science tempo is the station’s hallmark, said Beau Simpson, payload operations manager in the Payload Operations Integration Center at NASA’s Marshall Space Flight Center — the round-the-clock science hub linking global researchers to the astronauts overseeing their experiments on station.

What has really impressed the payload operations team at Marshall, Simpson said, is how Behnken and Hurley — trained exhaustively for Crew Dragon’s groundbreaking flight — have also hit the ground running with science on station. “These are seasoned pilots, sharp guys dedicated to NASA’s mission,” he said. “They got their space legs pretty quickly and jumped right into the mix.”

They even helped launch several studies. They’re both supporting the Electrolysis Measurement experiment, which studies how gravity influences electrolytic gas evolution. That electrochemical process generates bubbles that can help adjust pressure in devices such as skin patches used to deliver medication. Hurley also worked on the Capillary Structures investigation, which studies the management of fluid and gas mixtures for next-generation life support systems to better recycle water and remove carbon dioxide from cabin air on spacecraft. Behnken also is prepping the Plant Habitat-02 facility for the cultivation of edible plants — critical to future long-duration missions in space.

Integrating even industrious self-starters such as Behnken and Hurley into the science mix relies on months of work by planners at Marshall, space station leads at Johnson and partner scientists around the world.

“Science scheduling and crew training starts six months out,” said Lori Meggs, lead payload communications manager at Marshall for Increment 63. That pace never slows. A week before each expedition starts, the payload planning team delivers final, step-by-step guidelines to walk the crew through each science activity.

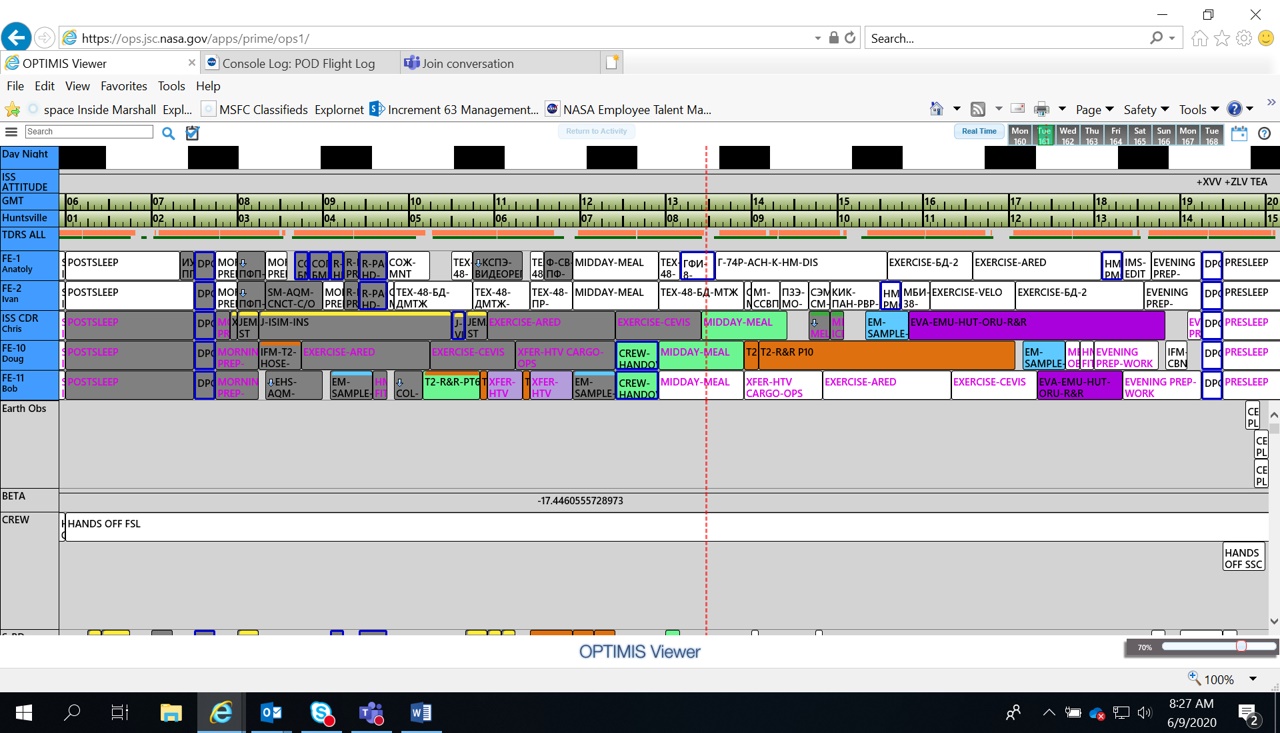

By then, station science planners also have used a real-time, interactive database, which includes instructions for each experiment and task on station, to meticulously schedule the crew’s research activities, exercise, personal time and sleep cycles.

The team also prepares for launch slips caused by unforeseen contingencies — such as the weather that scrubbed the Dragon’s first launch attempt May 27. “We had multiple backup schedules, based on possible delays of various lengths,” Simpson said.

The schedule is key, he said. Crew and flight controllers monitor it all day, keeping an eye on the marching red bar which identifies where they should be at any moment. Simpson calls that “chasing the red line” — and he credits the crew for consistently finishing tasks early, not chasing the line so much as challenging it to keep up.

Nor is finishing early a license to kick back, Meggs added. “They can use unscheduled time however they like, but we keep ‘honey-do’ lists, noncritical tasks that can be pursued any time. Whenever they finish scheduled work, each can choose duties from that list until it’s time for their next activity,” she said.

Each astronaut’s average schedule calls for six-and-a-half hours of scheduled science and maintenance tasks, two daily planning meetings with NASA and its global partners, two mandatory workout hours to mitigate the effects of microgravity on bones and muscles, and eight-and-a-half hours reserved for a good night’s sleep. Then they get up and do it all over again, for months on end.

“Our crew on station is so good,” Meggs said. “They’re having the time of their lives — and we’re living it with them. It’s a thrill to be part of the history they’re writing in orbit.”

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Bruce Tiller Combines Birding, Boosters to Help Launch Artemis I

By Adam Farragut

Bird watching and rocket launching aren’t normally mentioned in the same breath. One activity combines the beauty and grace of nature with a relaxing personal hobby, while the other is the culmination of thousands of hours of work, calculation and dedication that results in a massive object traveling to the stars.

For Bruce Tiller, however, the two are more alike than most would think. A lifelong bird watcher, Tiller has spent decades appreciating the effortless flight of warblers and finches while simultaneously working to advance the hard-fought flight of humankind. It’s only fitting, then, that Tiller is manager of NASA’s Space Launch System rocket Boosters Office at NASA’s Marshall Space Flight Center.

On a daily basis, he and his team take steps to help launch the biggest bird there is: SLS.

Tiller works closely with SLS booster manufacturer Northrop Grumman, which builds the boosters in pieces that are delivered to NASA’s Kennedy Space Center for final assembly.

The largest, most powerful solid propellant booster ever built for flight, the SLS booster stands 17 stories tall and generates more thrust than 14 four-engine jumbo commercial airliners. Together, the SLS twin boosters provide more than 75% of the total SLS thrust at launch.

Tiller has always been a bird of a different feather. In a family of doctors and nurses, he was the rebel who became a rocket scientist. Yet, despite his 31-year career with the agency, being a part of the NASA team almost didn’t happen. In fact, space exploration wasn’t something he ever saw in his future.

“Space wasn’t something that drove me as a kid, but I’ve always loved the technical aspects behind it,” Tiller said. “My parents’ involvement with medicine very much influenced me to ultimately pursue a career in science.”

Tiller’s father was the embodiment of the classic, black-bag doctor from the 1950s. Gifted with nearly perfect recall, he often drove around town in his Volkswagen making house calls while Tiller’s mother, also a doctor, worked full-time in public health. It was a dynamic that was unique for the era, but one that instilled an appreciation of hard work and education into the Tiller children.

With plans of being a geologist, Tiller originally received a bachelor’s degree in geology from the University of North Carolina in Chapel Hill before deciding engineering was a better fit for the future. He returned to school to earn his bachelor’s degree in mechanical engineering from the University of Alabama in Birmingham before becoming a thermal analyst at SRS Technologies in support of Marshall. He liked it enough to later get a master’s degree in mechanical engineering from the University of Alabama in Huntsville.

Three decades after joining the agency as a thermal analyst supporting the space shuttle, Tiller is still combining his love of science with the work ethic he learned from his parents.

“Space exploration isn’t something that you can do on your own. It takes thousands of people to do what we do,” Tiller said. “That’s the fun part. This is great work and you always feel like you’re a part of something big. It’s an amazing thing to be a part of.”

Focused on expanding humanity’s presence beyond Earth, the Artemis program is the beginning of the next era of space exploration. By putting the first woman and next man on the Moon, the program aims to establish a sustainable lunar presence with the ultimate goal of sending humans to Mars.

The ambitious nature of Artemis is something Tiller believes will impact the space program and generations of children for years to come.

“Who doesn’t want to do this? You don’t have any trouble getting people excited about NASA’s mission,” Tiller says. “I’m fired up to be a part of the NASA team. All the stuff we do from monitoring Earth to exploring the Moon, Mars and beyond is pretty fantastic.”

For more information on SLS, visit here.

Farragut, an ASRC Federal/Analytical Services employee, supports Marshall’s Office of Strategic Analysis & Communications.

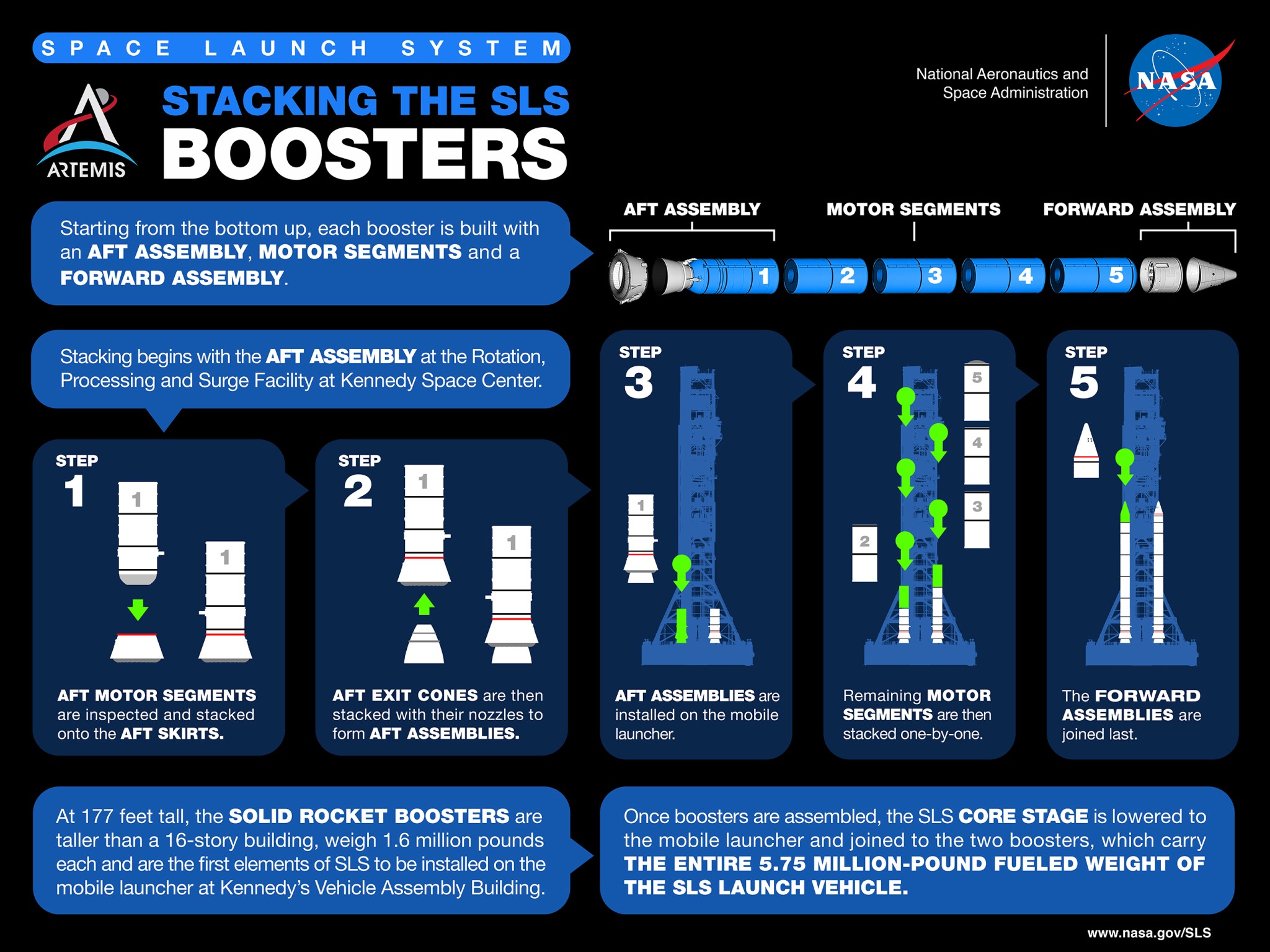

Stacking the Space Launch System Solid Rocket Boosters

With the arrival of booster segments for NASA’s Space Launch System rocket at the agency’s Kennedy Space Center, NASA’s Exploration Ground Systems team is preparing the rocket motors for stacking activities. Stacking of the twin, five-segment solid rocket boosters begins with the aft assembly at Kennedy’s Rotation, Processing and Surge Facility. The boosters are the first elements of the SLS rocket to be installed on the mobile launcher at Kennedy’s Vehicle Assembly Building in advance of the first launch of NASA’s Artemis program. (NASA)

Rocket Science in 60 Seconds: How and Why Are the SLS Rocket Boosters Insulated?

Rocket Science in 60 Seconds gives you an inside look at the work being done at NASA to explore deep space. Chelsea Walker is a Northrop Grumman materials and process design engineer for NASA’s Space Launch System solid rocket boosters manufactured by Northrop Grumman in Utah. These boosters will help launch the SLS when it takes off on the Artemis missions to the Moon. In this episode, Walker explains why the two solid rocket boosters are insulated to protect them from the extreme heat they’ll experience during launch and flight, and how that insulation is produced. For more on SLS, visit here.

New Data Processing Tool Transforms Workflow for Budget Analysts

By Daniel Boyette

Dorothy Venable knew as she viewed the computer screen that she was on to something big.

Venable, a budget analyst in the Engineering Support Office at NASA’s Marshall Space Flight Center, was watching a demonstration of a new data processing tool during a teleconference with NASA’s Johnson Space Center in December 2019. The Johnson-developed tool automates labor-intensive steps in the creation of purchase requisitions – documents used by employees to order products and services for their organization.

“I knew that if we could get it to do what we needed it to do at Marshall, it was going to be a huge time saver and it was going to improve accuracy,” said Venable, who joined Marshall as a contractor in February 2017 before becoming a civil servant in April 2019.

Venable piloted the tool with the Engineering Services and Science Capability Augmentation contract held by Jacobs Technology of Tullahoma, Tennessee, testing various aspects in January and February before putting it to full use in March. Previously, loading the project data for the $1.2 billion contract took 25-30 hours each month. Venable modified the tool to meet Marshall’s requirements. The result? The error checking and loading time decreased to 2-3 hours per month.

“Contracts the size of ESSCA require working with large volumes of codes and data, and this new tool simplifies the entire process,” said Clark Boaz, supervisory budget analyst in the Engineering Support Office. “Dorothy and everyone involved with implementing the tool did amazing work that could ultimately provide benefits for offices across the center.”

The tool – which Venable’s office dubbed the “Automated PR Tool” – uses scripts in Microsoft Excel to catch errors. Venable said that the traditional process for creating a purchase requisition in the SAP software often proved to be cumbersome. She explained that an analyst can manually put in nine lines of data at a time. But if there is an error in any of those lines, the analyst isn’t alerted until after completing the entry. If an error was found, the analyst would have to restart the process.

“The tool goes around and automates that; it bypasses some of those restrictions,” Venable said. “The tool will flag anything that is an issue and, right off the bat, find where there’s a mismatch. All of that is seen before you ever start to put it into SAP.”

Venable’s ability to customize an existing product and use it to augment Marshall’s processes is an example of digital transformation — using powerful digital tools, such as data analytics and personalized information and interfaces, to dramatically improve how a process is accomplished. NASA’s Digital Transformation strategy, approved in spring 2019, aims to harness evolving digital technologies to advance agency missions, enhance efficiency and encourage a culture of innovation. The initiative has eight goals, with Venable’s efforts falling under the “Increased efficiency and effectiveness of business processes” category.

“Digital tools and processes have the potential to dramatically enhance NASA’s mission impact by reinventing ways of doing business that save time and money, and foster enterprisewide collaboration,” said Preston Jones, Marshall associate director, technical.

Venable is teaching others how to use the tool, which In turn is helping her learn more about its capabilities. The tool will continue to be used on the Engineering Services and Science Capability Augmentation contract and there are plans to use it with other contracts at Marshall, according to Randy Silver, lead budget analyst in Marshall’s Budget Integration and Analysis Office.

Boyette, an ASRC Federal/Analytical Services employee and Marshall Star editor, supports the Office of Strategic Analysis & Communication.

Wallops Safety Office Chief to Give Virtual Presentation

Glen Liebig, the chief of the Safety Office at NASA’s Wallops Flight Facility, will deliver a virtual Mission Success is in Our Hands lecture via Webex at 11:30 a.m. June 18. He will present an overview of the failure response to the October 2014 Antares rocket failure. The rocket was carrying supplies to the International Space Station when it failed shortly after launch. Liebig will discuss the importance of planning for such an event and explain how the lessons learned can be applied to NASA’s future missions. The Mission Success Is in Our Hands initiative at NASA’s Marshall Space Flight Center is a campaign led by the center’s Safety and Mission Assurance Directorate and partner Jacobs Engineering of Huntsville that promotes and strengthens Marshall’s focus on mission, hardware and crew safety. (NASA)

NASA’s Lee Mason Discusses Kilopower Project at Virtual Tech Talk

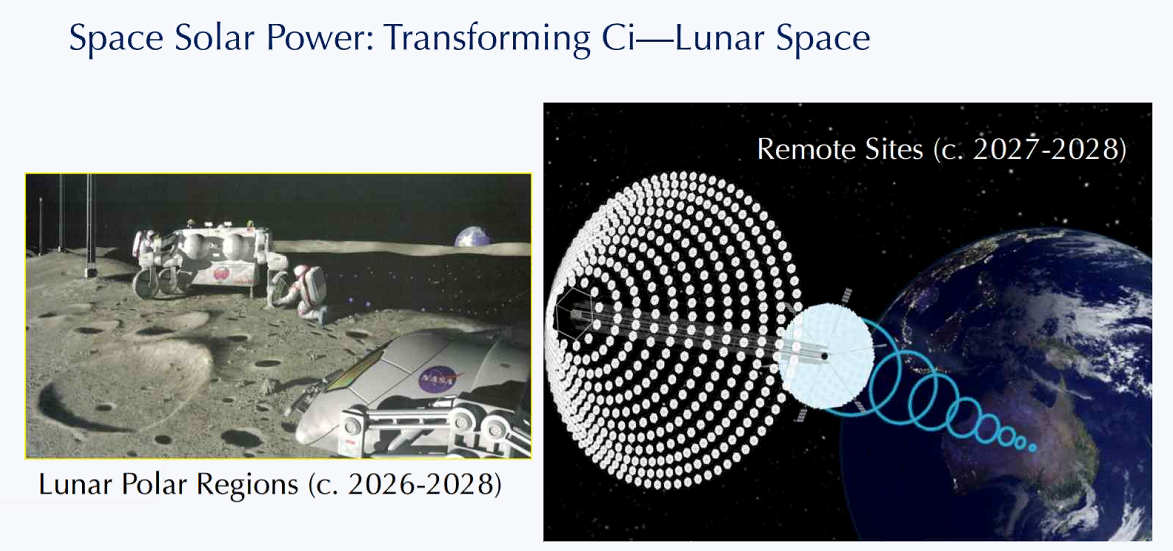

Lee Mason, deputy chief engineer in NASA’s Space Technology Mission Directorate at NASA Headquarters, gave a virtual Tech Talk on NASA’s Kilopwer project June 11.

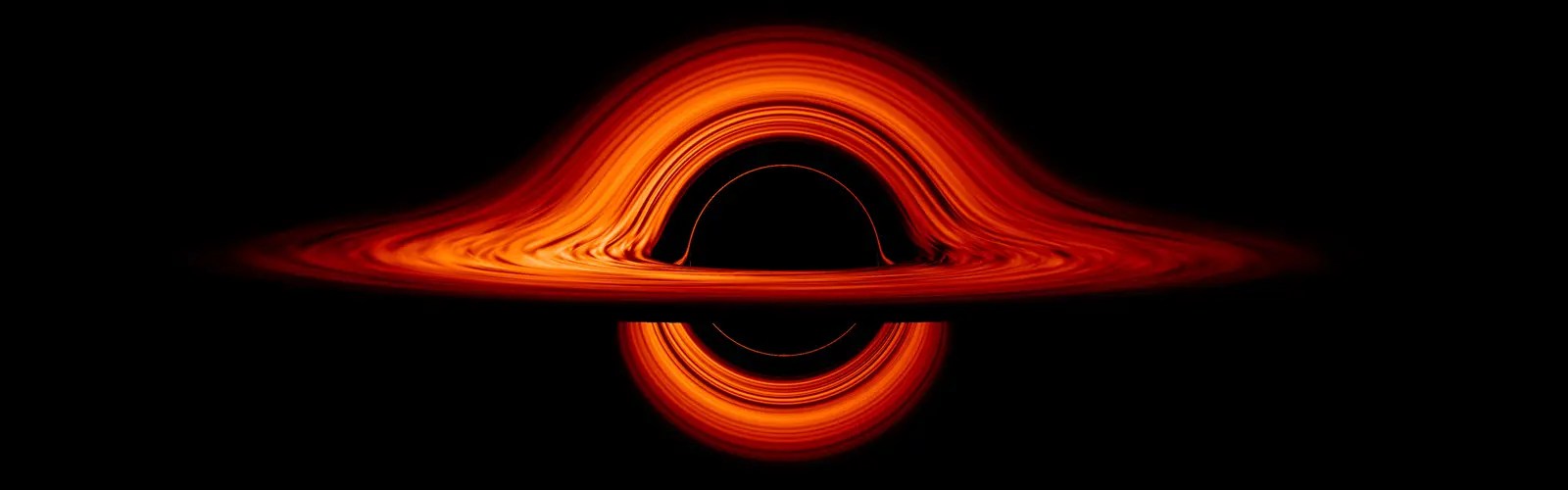

The project — which developed a new type of nuclear reactor — is designed to be a small and simple system for long-duration, solar-independent power generation for use on space-based or extraterrestrial-based spacecraft. It was initiated following a technology assessment in the 2010 Planetary Science Decadal Survey to study potential alternate nuclear power generation systems for robotic, planetary spacecraft. The Kilopower team completed a successful test of the Kilopower Reactor Using Stirling Technology experiment in March 2018. Future potential uses include power generation for human bases on the Moon and Mars, on robotic spacecraft in deep space and, possibly, to melt spots on icy worlds for scientific study.

The Tech Talk series is presented by the Chief Technologist’s Office at NASA’s Marshall Space Flight Center.

This Week in NASA History: Life and Microgravity Spacelab Launches to Space Station – June 20, 1996

This week in 1996, space shuttle Columbia, mission STS-78, launched from NASA’s Kennedy Space Center. The mission’s primary payload, the Life and Microgravity Spacelab, was managed by NASA’s Marshall Space Flight Center. Here, the spacelab module is loaded into Columbia’s cargo bay. During 17 days of flight, researchers from the United States and Europe shared resources, such as crew time and equipment, to conduct experiments in life science and microgravity investigations. Five space agencies — NASA, the European Space Agency, the French Space Agency, the Canadian Space Agency and the Italian Space Agency — along with research scientists from 10 other countries worked together on the design, development and construction of the Life and Microgravity Spacelab. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)