By Jason Costa

NASA’s Kennedy Space Center

As the nation’s premier, multi-user spaceport, NASA’s Kennedy Space Center in Florida launches critical missions at a regular pace. When unknown substances or unseen contaminants threaten these missions, a team of chemical engineers provides unique solutions to these unusual and urgent problems. Some even say the problem-solvers in the Analytical Laboratories Branch are Kennedy’s “CSI” – the crime scene investigators of the ubiquitous television shows.

“If I had to make up our own acronym for CSI, I would call us the ‘Crumb and Scum Identification’ team,” said Macy Mullen, a chemist from the Chemistry and Life Sciences Laboratory (CLS). “The majority of the samples we get in aren’t very glamorous.”

A small amount of a chemical or residue can yield big clues. But instead of cracking criminal capers, Kennedy’s team studies cases like contaminated flight hardware, failed ground support equipment, or insects in launch or processing facility systems. And, like their fictitious counterparts, the CLS team is just as versatile, dedicated, and good at what they do.

“They support every agency program that operates at Kennedy,” said Scott Murray, chief of NASA Engineering’s Laboratories, Development and Testing Division. “This means they have to be adaptable to working on any and every type of hardware or system you can imagine, at any time, day or night.”

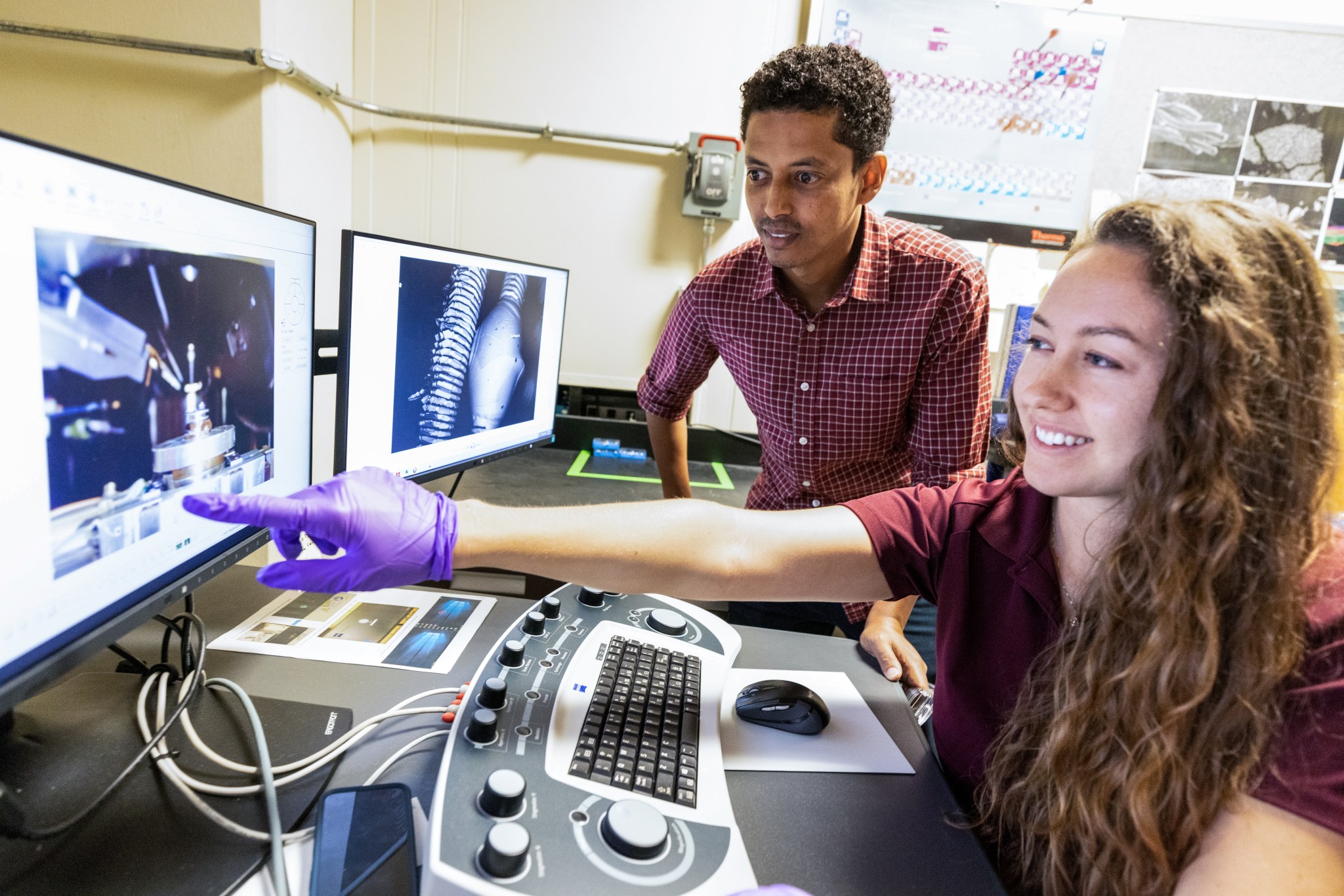

Using analytical chemistry as its primary investigative tool, Kennedy’s CLS relies on specialized instruments to identify unknown particles, residues, and gases. They employ a multi-disciplinary approach, along with various types of microscopy, spectroscopy, chromatography, and chemical analysis techniques. Samples come from contaminated and failed equipment, flight hardware, clean rooms, and other objects from across the programs, commercial companies, and facilities at the spaceport.

“These things we study are tiny and cannot be seen or measured using typical methods,” Mullen said. “Analytical chemistry is the branch of science where we use instruments and chemical tests to probe the infinitesimal in efforts to identify and quantify it.”

The team investigates everything from greasy residue on failed pistons from support equipment to particle samples from spacecraft heat shields after reentry. Even the tiniest particulate debris can compromise performance of expensive flight hardware, corrupt scientific research missions taking place in space, or even lead to explosions.

“When a system or part of a system has a problem or a weird smell, or if an unknown liquid or solid is found in or around a spacecraft, we work to determine what caused the problem or what that smell, liquid, or solid is so that the system can be fixed or cleaned and ready for use or flight again,” said Janelle Coutts, senior analytical chemist who supports failure analysis investigations and unknown identification efforts for all programs at Kennedy.

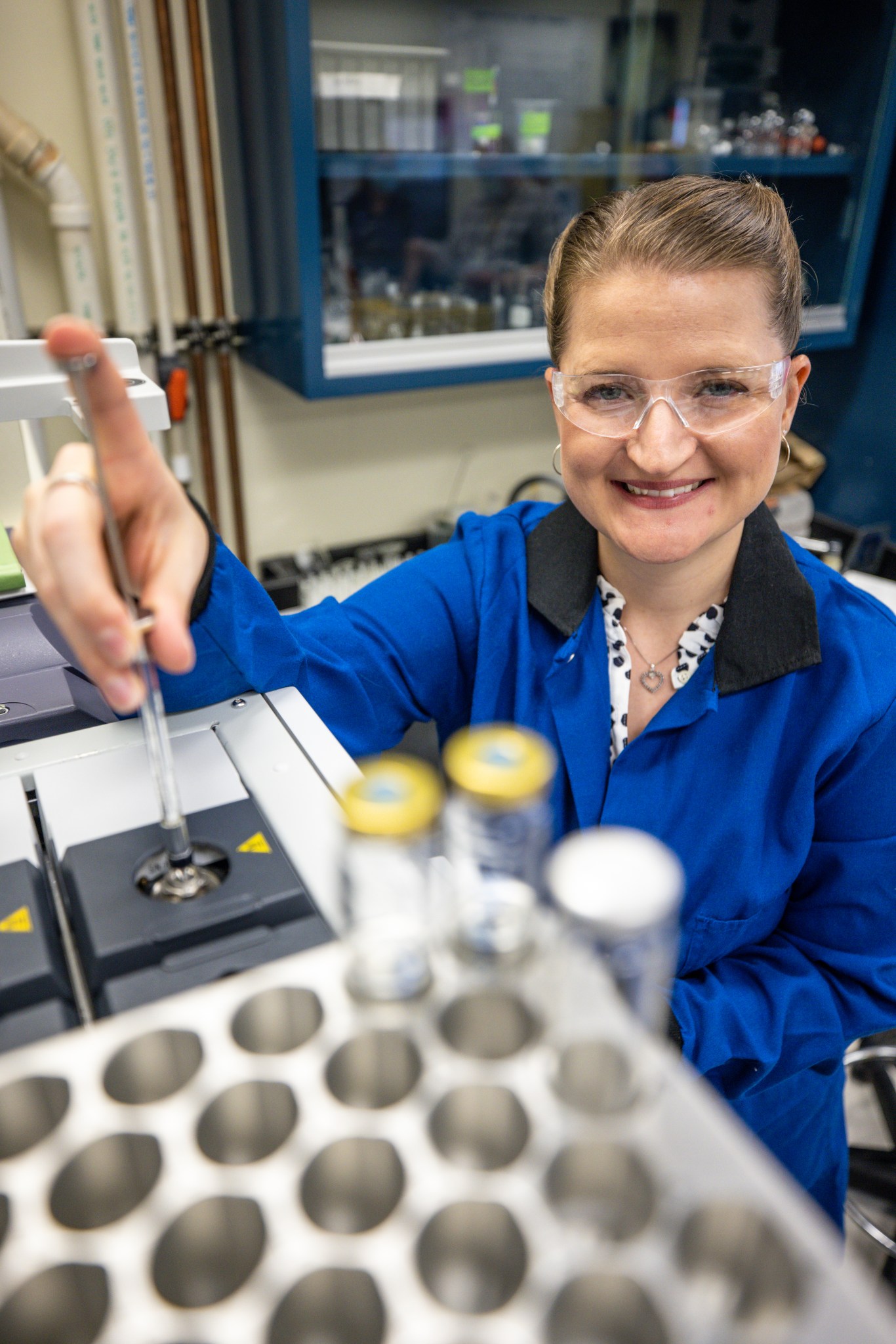

The lab’s chemists use gas chromatography to separate mixtures of volatile liquids or gases so that each component of the mixture can be identified or quantified, and they use liquid chromatography to separate components in a liquid mixture for the same type of analysis. These types of investigations can include analyzing rocket propellant, such as hydrazine, to ensure it is free of contaminants and ready for use during launch.

“The first time I learned how to analyze hydrazine to say the batch was good to use was for the OSRIS-REx mission,” Coutts said. “A couple weeks later, I watched the Atlas V rocket carrying the payload launch from Kennedy and, as it was airborne, I said to myself, ‘Wow, I literally just said that propellant was good to use, and now it’s on its way to an asteroid.’ Getting to witness the first launch I directly contributed my analytical capability to is something I will never forget!”

Typically, the investigations begin by using optical and polarized light microscopes to show color, morphology – or shape and texture – phases, and crystallinity. This is followed by a technique to identify fibers, plastics, lubricants, and resins to indicate if organic material is present and, if so, what kind.

Next comes use of what is considered the workhorse of the lab, the scanning electron microscopy with energy dispersive spectroscopy. This device produces detailed images of morphology and micro-features and helps determine the elemental composition of samples. Finally, if inorganic material is present, such as minerals or oxides, an x-ray tool is used to analyze the crystal structure and identify the material.

“I’ve had the opportunity to sample the exterior of a spacecraft after its reentry journey,” Mullen said. “It’s wild to think you’re touching a surface that has seen the vacuum of space and been touched by the blazing conditions of reentry. I’ve also taken samples from inside the Orion spacecraft, so when it launches, I can say I’ve been where the crew is sitting!”

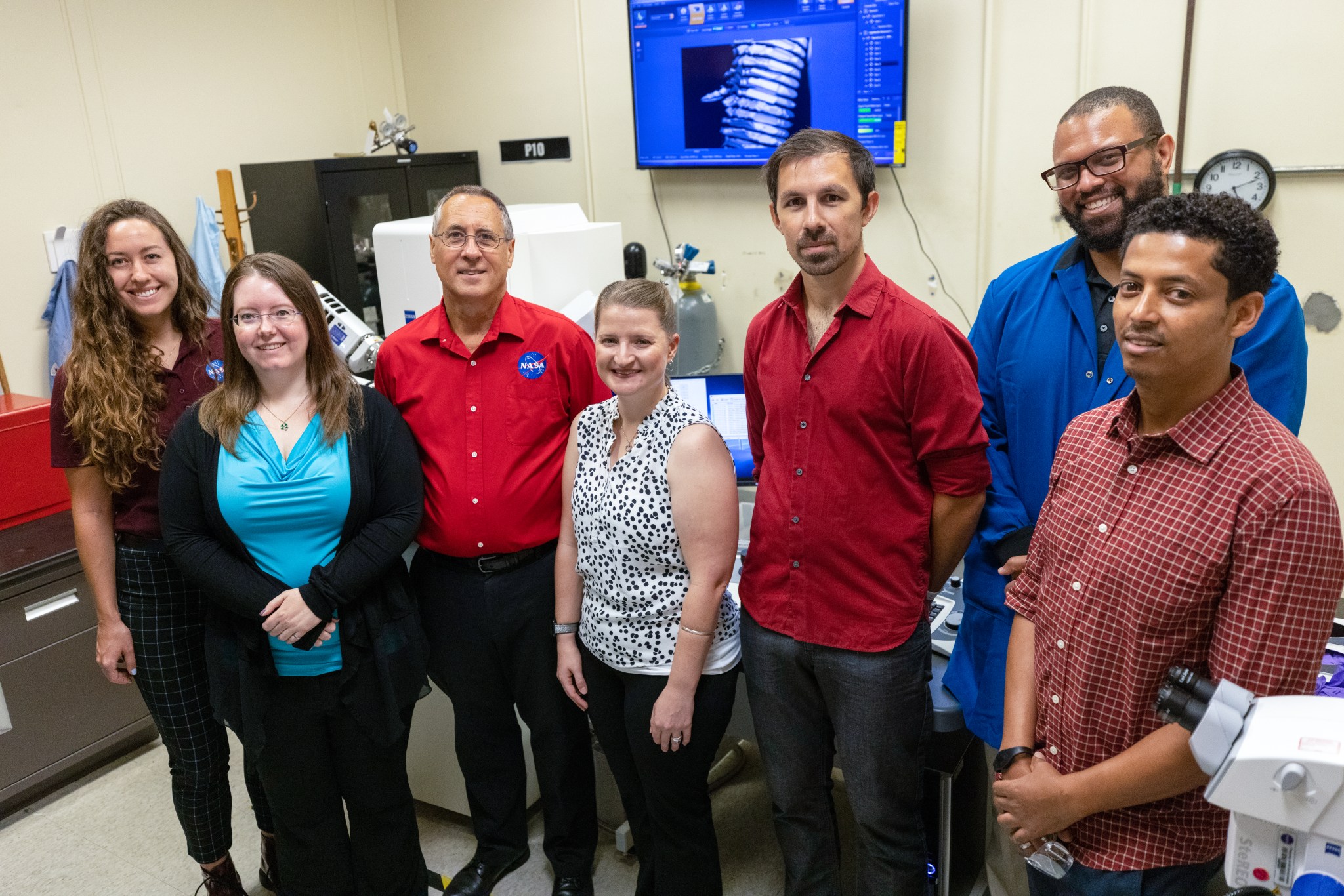

“We have a highly skilled group of engineers and chemists working in the Analytical Laboratories who are also extremely dedicated to NASA’s mission,” Murray said. The Analytical Laboratories Branch is one of seven branches in the division, which not only provides science and engineering services to NASA programs and projects, but also external customers such as other government agencies, aerospace companies, and academia.

While Kennedy’s CLS team spends much of its time investigating things that are tiny, the team knows the impact of their work on NASA’s mission is huge.

“A lot of the analysis we do has direct impact to mission success,” said Coutts. “When a problem with contamination arises, we have to work quickly to identify the problem and provide solutions. We get to see our work firsthand feed into fixing problems that get missions back on track for flight or ground operations, and that is really cool to me