Fruit Fly Lab-01: Engineer’s Blog

Sanjoy Som, Ph.D. is the systems engineer for NASA’s Fruit Fly Lab, a new research platform for the International Space Station that will support long-duration fruit fly studies in space. Som is blogging from NASA’s Kennedy Space Center about his experiences while preparing for the maiden voyage of the system that is planned to launch to the station in January 2015 aboard SpaceX’s fifth commercial resupply services mission.

January 10, 2015

I went to bed early to get a good night’s rest before having to get up at 3:30 a.m. to head to the causeway for launch. I could hardly sleep at all! I woke up at midnight and every hour after that. Once the alarm did ring, my eyelids were heavy. A splash of cold water and off I went to join the rest of the team on the causeway. We found each other in the cold windy night, and we followed the live countdown. Everything looked good, countdown was proceeding nominally.

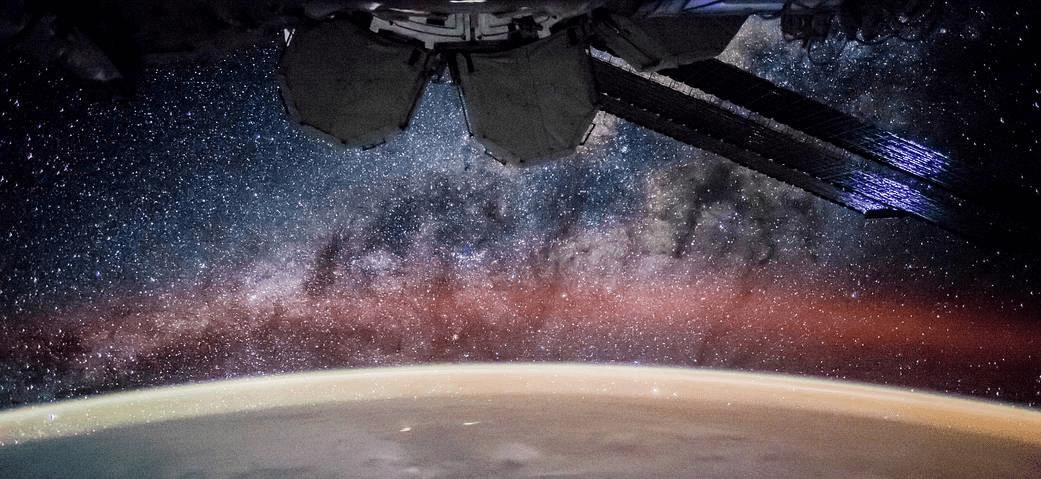

Suddenly, the launch pad lit up! The ball of flame was inching its way up when several seconds later, the roar of the nine Merlin engines reached us. It was exhilarating, and what a relief! It was an awesome sight. This loud flame-throwing device was pushing our payload to the International Space Station! The rocket turned east and we could see it quite a ways before it became too dim. A short time after, we saw, much lower down in the night sky, a bright orange light that lasted two or three seconds. I thought it must have been the first stage re-boosting to reach the launch platform that’s out at sea, but I cannot be sure. If you have not heard of this, SpaceX is trying to lower the cost of spaceflight by controlling the landing of the first rocket stage back to Earth.

I’m so proud of all our team! So many hours, so many meetings, so many scrubs! Finally we’re on our way to space and our mission will actively contribute needed knowledge to enable long-term human spaceflight. In the next 30 days, we will have seven different in orbit operations during which astronauts will use the food changeout platforms to change the food inside the cassettes and preserve flies for study back on Earth. We will be on console at Ames, available to answer any questions that the crew may have. After that, we’ll push forward to get Fruit Fly Lab-02 (the first full science flight of the system) ready for launch on SpaceX-9!

This concludes my mission blog. Thank you and, “Ad astra!“

January 9, 2015

Because we handed over our hardware last night, there was little to do. The science team continued taking care of the fly culture, but on the hardware side of things, it was quite calm. Early wake up tomorrow as the launch is at 4:47a.m.!

January 8, 2015

Handover day! By 9 p.m. tonight everything needs to be ready to go. As I was driving to work, I saw the rocket vertical on the launchpad. “That’s not good” I caught myself thinking. They must be still debugging. The rocket needs to be horizontal to load our payload.

Everyone is very focused. The science team is busy getting the flies ready, and in the hardware lab, we’re focusing our energies on rebuilding all the hardware to have a scrub set ready in case the launch is a “no go” tomorrow. News comes in that the rocket is go with 80% good weather. That’s encouraging!

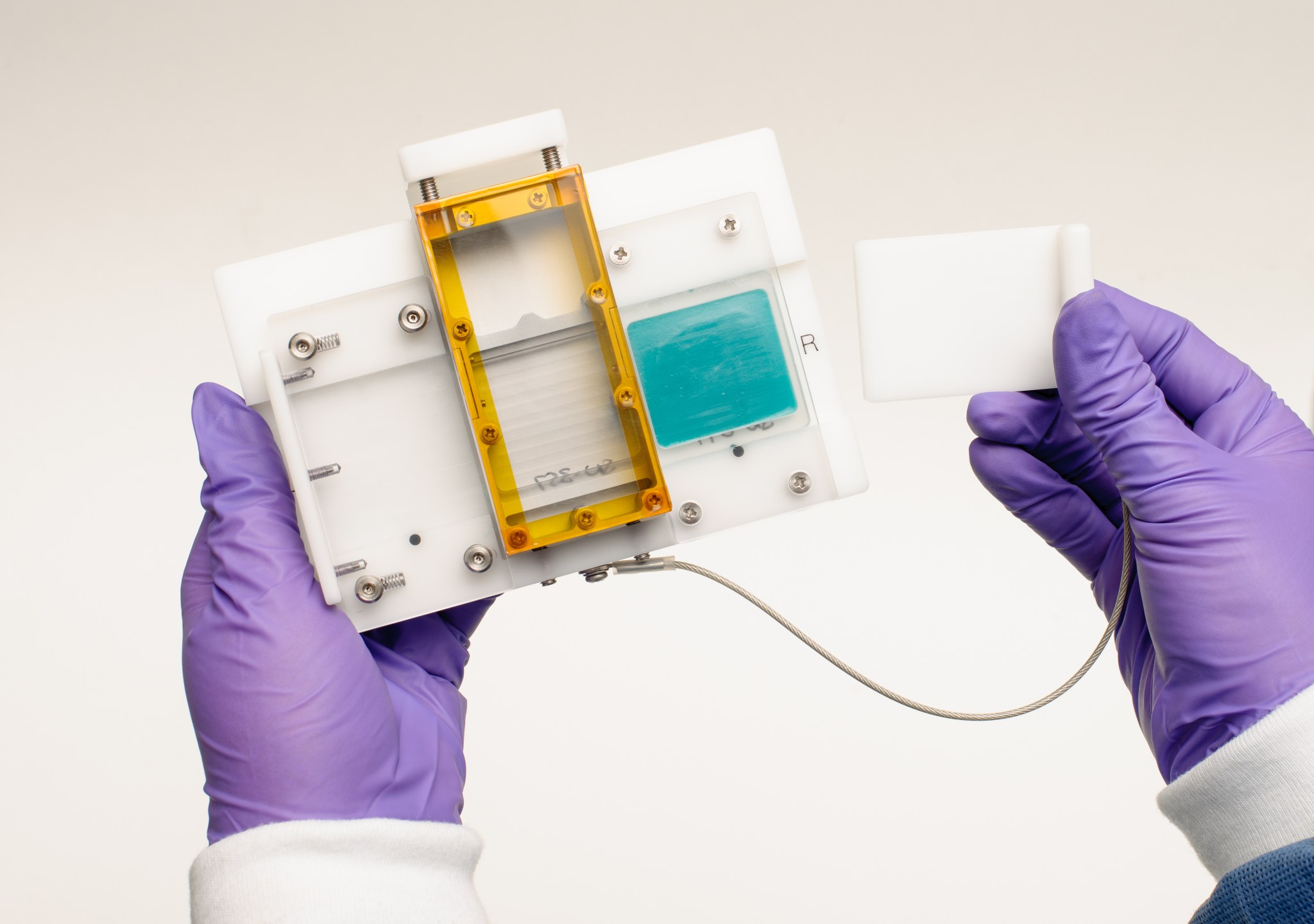

Rebuilding is the right word, as everything is in pieces from yesterday’s disassembly and cleaning. Because these cassettes and food changeout platforms are considered “flight” hardware, they need to be assembled following detailed procedures, where each step is documented, and all critical steps are witnessed and stamped by a person representing quality control. Such rigor is necessary to maximize the quality of the build and ensure there is accountability. We’ve all been in situations where when stressed or following a tight deadline, there is a higher risk of cutting corners. Not here. The procedures in place minimize such a risk, and there is traceability in everything we do. After all, our signatures are on these procedures!

Slowly, all these pieces start looking like flight hardware. There is a lot of paperwork associated with these builds, so progress is slow but steady. We also reprogram the environmental sensors. In the science lab, new fly food is being made, just in case. As the hours progress, it is time to load the twelve fly cassettes with 15 flies each.

9 p.m. roles around quickly and the representatives come to the lab with their cart. It’s time! The protective foam is placed inside the flight CTB, and the loading of the foam is done following procedure. The foam has pre-cut inserts for all our hardware. This will dampen the launch vibrations. Furthermore, other cuts are made to create pockets of air so that the flies don’t suffocate. Again, every step is documented, and a lot of pictures are taken too. I’m feeling good. Although we went through this process only a few days ago, my excitement is the same. The next people to see this hardware will be astronauts! And with that suddenly we’re “done.” The hardware is no longer in our control.

As I drive home late in the evening and cross the causeway, the rocket is not on the pad. “That’s good.”

January 7, 2015

Two days until launch. By 9 p.m. tonight, everything must be turned over again, which means the science team needs to prepare the flies, sterilize all the food trays, and prepare more flight fly food (the blue stuff). The hardware team needs to get all the hardware disassembled, thoroughly cleaned, refurbished, and ready to go. We’ll use our scrub set (our backup set) as our primary set of hardware for this new flight, and the primary hardware, which we don’t have yet (it’s still with SpaceX), will need to get refurbished as the new scrub set.

We got word that the Dragon capsule is unloaded and our hardware is coming back towards the Space Station Processing Facility, where our labs are. In the meantime, we are preparing our backup environmental data loggers.

The scrub food changeout platforms are brought to the science team, so that they can load the food trays containing fresh food into the platforms. The reason we need to swap them is that the food quality starts degrading. To maximize the health of the flies in orbit and thus the mission science return, we want the freshest fly food possible. Ah, here is the cold stowage team, who arrive with our primary changeout platforms, and we swap. Good. That part is done. We’re on schedule.

“January 9th is out, new launch target is the 10th” says one of our colleagues here at Kennedy Space Center. All the team takes a deep breath. So is the nature of the business. It is bittersweet to see our CTB (Cargo Transfer Bag), the flight bag which contains all our flies in their cassettes in addition to our environmental sensors, being returned to the lab. I was expecting to next see the CTB in Long Beach, CA, where the Dragon capsule will be brought to following splash down at the end of the mission! However, considering that some of the early estimates had the CTB returning from SpaceX late in the afternoon, this is good. It gives us more time to refurbish.

The cool thing, though, is that the environmental sensors were recording while the rocket was sitting on the pad, so we could at least check out the stowage conditions inside the Dragon capsule as it sat overnight! To our relief (although we weren’t really worried), everything looked good. Temperature and humidity values were well within the acceptable range for the flies. At least that’s some good news.

We gave the cassettes containing the flies to the science team. It was cool to see that the flies had already laid eggs on the food! These eggs appeared as tiny white dots. After the science team got all the flies out, we started the long process of disassembling the cassettes and parts of the food changeout platforms. Following disassembly, we soaked everything in a soapy solution, scrubbed and rinsed every part, and placed them on moisture absorbing pads to air dry overnight.

No turnover at 9 p.m. because of the launch delay, so that’s good. We can head back to town early. I can’t believe it is 7 p.m. already.

January 6, 2015

Launch day! We got to the causeway, the road connecting Cape Canaveral Air Force Station and the Kennedy Space Center, at 5:30 a.m. The causeway is the best place to view the launch. It was dark, but the rocket was all lit up and excitement was in the air. At 5:50 a.m., we were treated by the sight of the International Space Station flying overhead. It appeared from the south, heading northeast as a bright star traveling through the sky. The destination of our hardware! We listened with great anticipation to SpaceX Launch Control as the clock slowly ticked down.

“Hold hold hold!” – those three words uttered at T-1 minute and 21 seconds ended the launch attempt. Little motors that control the movement of the nozzles on the rocket’s second stage were drifting unexpectedly. Scrubbed again! We couldn’t believe it; what a disappointment.

We regained some spirits with coffee and bagels and headed back to the Space Station Processing Facility at Kennedy Space Center to anticipate and prepare for the return of our hardware tomorrow. We’ll have to clean everything, reassemble, prepare more food and bacterial cultures and select new flies. Tomorrow is going to be a long day. We’re not quite sure when we’ll receive our hardware back. SpaceX is keeping the rocket vertical on the pad to debug.

In anticipation of all this activity, the science team started a new bacterial culture, made fly food, and started selecting flies for flight. In the hardware lab, we got all of our procedures ready for all the work that awaits once we receive our hardware, and prepared our “scrub set”—an additional set of hardware that we can swap quickly.

Indeed, the cold -towage team will pick up our hardware mid-day tomorrow, which does not give us enough time to turn around all the hardware that’s currently on the rocket. We’ll hand over those scrub changeout platforms to the science team so they can load the food trays before we hand them over to the cold-stowage team. A lot of logistics are also being reassessed, including our operations once the Fruit Fly Lab is in orbit.

Time to roll up those sleeves, it’s going to get quite busy.

January 5, 2015

Because we handed over our hardware last night, there was little to do. The science team continued taking care of the fly culture, but on the hardware side of things, it was quite calm. I’m quite excited for the launch tomorrow!

January 4, 2015

Today is a big day! By the end of tonight, we’ll have turned over all of our hardware to the folks responsible for getting it to the rocket and loaded. Our turnover time is 10 p.m., so it is going to be a long day. Because we are flying biological samples, we are considered a “late load”. This means that we are loading our experiment hardware as late as we can prior to launch so that the health of the flies is within our control as close to launch as possible. Because the life cycle of a fruit fly (from egg, to adult, back to egg) is only a few days, every hour counts.

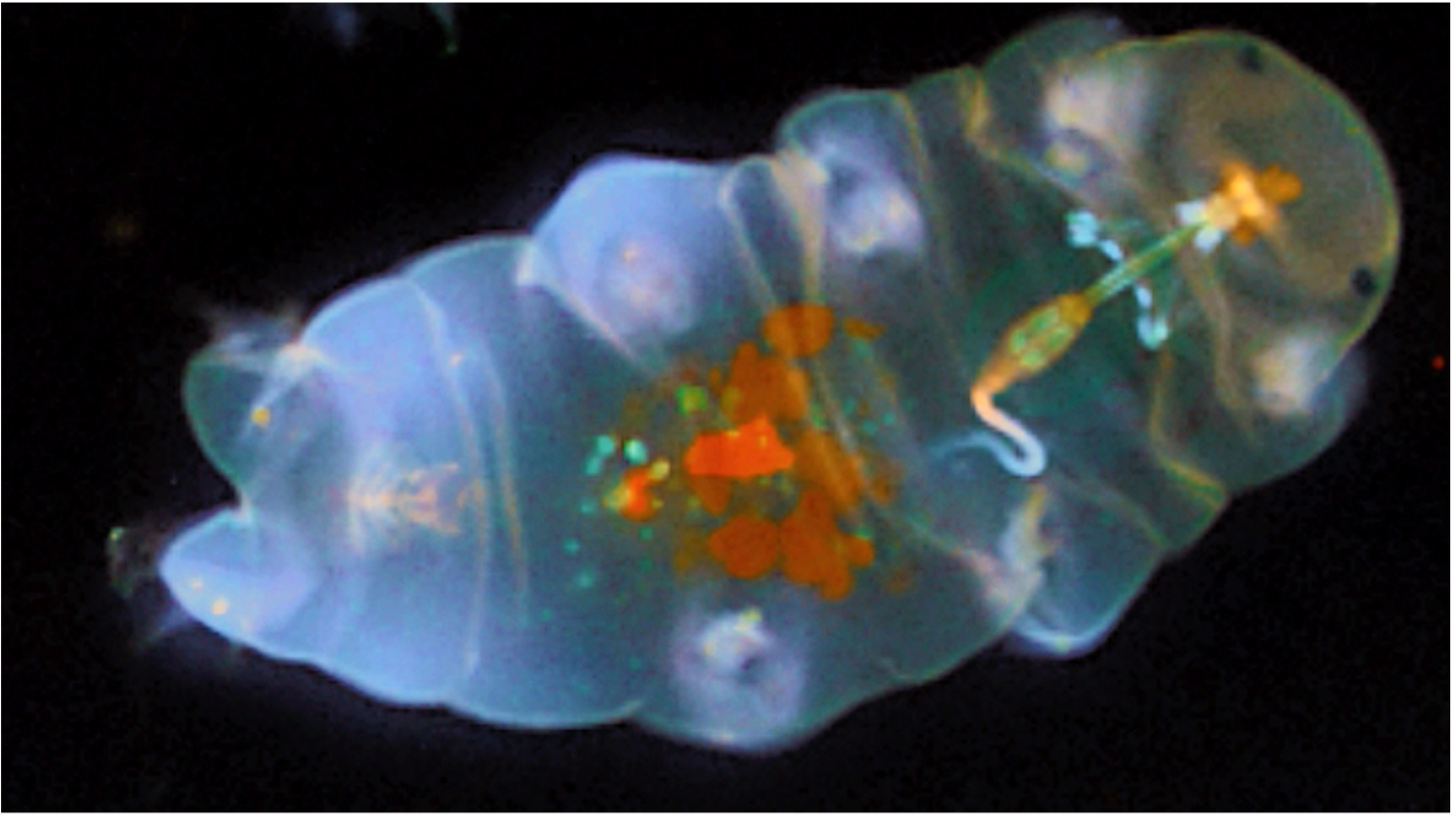

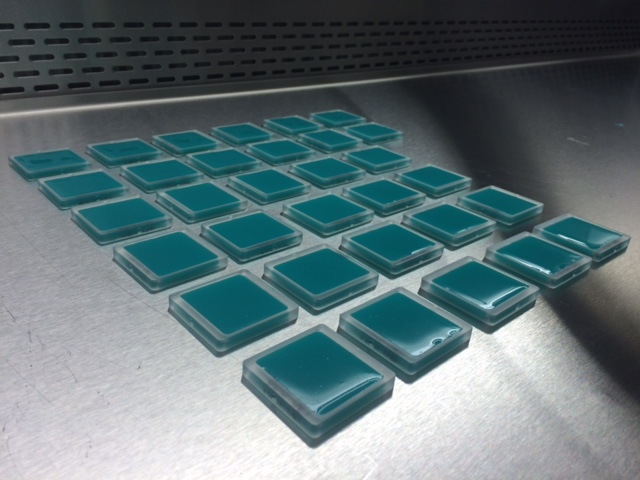

The science team has been at work since 6 a.m. preparing the blue-colored fly food used for spaceflight. As I noted yesterday, the blue color allows us to see the food being ingested by the transparent fruit fly larvae. Some food will also contain the bacteria that we are using to test the immune response of the flies and to study how spaceflight affects the immune response. At 10:30 a.m., the cold-stowage team is coming to the lab to take our changeout platforms that we loaded with fresh food. The cold-stowage team will store the changeout platforms at four degrees Celsius, eventually inside “cold bags” on the rocket. As a reminder, astronauts will use these changeout platforms to exchange trays of partially consumed food (that will also contain fruit fly larvae) for trays of fresh food without breaching containment of the fly cassettes. The astronauts will freeze these “old” food trays full of larvae to preserve them for study back on Earth.

I focused my attention on retesting and resetting all of the environmental sensors. This was done to make sure they are working properly, and to program them to gather data at specific intervals so as to not fill-up their internal memory before the mission ends. Aboard the station, the Fruit Fly Lab will go inside Express Rack 3, which is a fancy “cupboard” designed for payloads inside the Japanese module, Kibo. Express Rack 3 does not have sensors to measure temperature and humidity, so we are flying our own sensors.

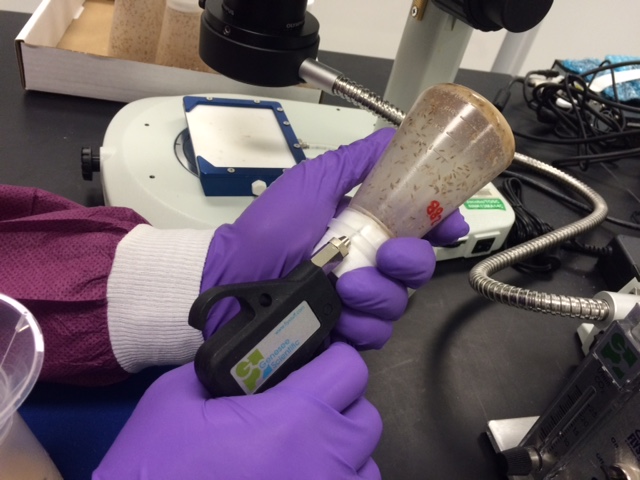

In the science lab, flies were being selected for flight! Each of our 12 cassettes will house 15 flies (ten females and five males). Before selecting them, carbon dioxide gas is injected in existing bottles of fruit flies. This puts the flies into a stasis (anesthesia) which allows the scientists to separate them by gender and insert them into the cassettes. Female fruit flies tend to be a bit larger than the males, and the males have a rounder abdomen. After being coached by a science team member, I could easily identify which were males and which were females.

Evening approached and we were doing well, with everything on schedule. Even the rocket seems to be on schedule. Fingers crossed.

Handover was a very rewarding experience. The flies were in the cassettes, and had awakened from their stasis. We loaded the cassettes in specially built foam, inside of which empty cavities provide pockets of air for the flies to breathe while they are being transported to the space station. The foam was placed in a CTB (how NASA loves its acronyms!), which stands for Cargo Transfer Bag. This CTB is what will be loaded in the rocket.

Handover was finally completed around 10:30 p.m. Now we can only hope for good weather!

January 3, 2015

And we’re back! After being able to spend the holidays with family and friends, I arrived back to the Kennedy Space Center quite refreshed for the sprint of activities that will lead, hopefully (!), to our Jan. 6 launch. But of course, the rumor-mill is alive and well, and I’ve been hearing “60 percent go” for Jan. 6 due to weather related causes. I’m not too concerned though, as weather forecasts this far out tend not to be particularly accurate.

Today was the return date for most of the team. However, half the science team and our project manager had returned to the Cape on Dec. 28 to make sure the flies were all ok and fed. Their task was thus preparing fly food, and “flipping” the flies over. This means transferring flies from bottles that contain old food into new bottles that contain fresh food. Fly selection for flight started yesterday.

Because everything cannot go as planned, the scientists were greeted with an incubator failure yesterday. The incubator is essentially a temperature and humidity controlled fridge-looking appliance. Such control is important to maintain a healthy fruit fly colony and food quality. However, where NASA shines is with redundancies, and in no time a new incubator was installed and made operational, with no loss to the flies or their health.

Today was more of a “get everything ready” day regarding the hardware. We made sure all our procedures were printed and ready to go, and all the tools were where we had left them. We also inspected all our food changeout platforms, whereas the scientists came to pickup the food trays.

Tomorrow, the food trays will be filled with fly food that is blue, in contrast to the beige fly food we use in the bottles. Blue food is used so that it can be easily observed inside the transparent larvae. A good indication of health! The scientists will sterilize all of the food trays with ultraviolet light prior to injecting the food into the trays. Once the food has settled in the trays, they will be installed in the food change-out platforms and transferred to the “cold-stowage” team, so that everything is kept at four degrees Celsius—the optimal temperature for fly food storage—but that’s a task for tomorrow.

December 19, 2014

I hadn’t even started my computer when the news spread through the hallways. Launch is delayed until January 6, 2015. Bummer. On the one hand, I’m relieved that we are working towards a date that isn’t rumor-based, but on the other, we’ve worked so hard to meet the December launch schedules that it is frustrating. We’ve spent two weeks (or more, for some members of the science team) in Florida away from friends and families during this festive season, only to be told to come back in January.

So it goes.

Because the fly food is perishable, we have no choice but follow what is called a “scrub” procedure. The launch has been “scrubbed”, and so we need to reload the food trays with fresh fly food. We’ll do so in January, but in the meantime, our task today is to remove all the food trays that were preloaded in food changeout platforms, clean the trays, disassemble all the platforms, clean them, and put them back together. It’s going to be a long day as we have many of them to process.

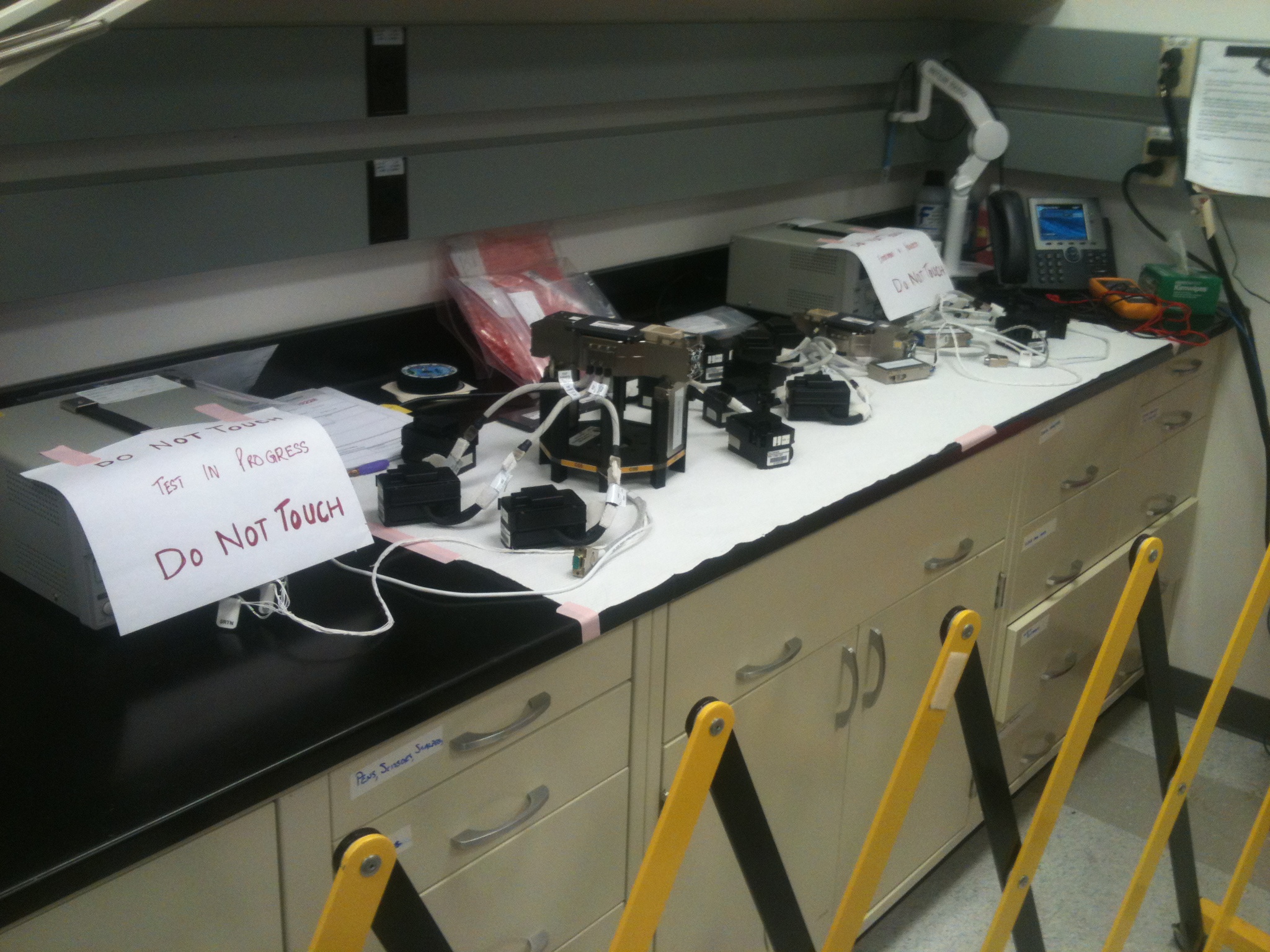

Because all this hardware is classified as “flight” it needs to be handled with extra caution. Procedures are followed for disassembly, cleaning, and reassembly. For example, screws need to be inserted and screwed-in not too tight, not too loose. This is done with a torque wrench, where the “tightness” can be selected on the wrench, and when the proper tightness is achieved, the wrench slips. Other parts of the hardware have other requirements that need to be met for assembly to proceed. In our team we have a person responsible for safety to make sure everything is done properly. This is fundamentally important because all this hardware is going to be manipulated by humans in space. Everything needs to be guaranteed safe. These extra cautionary steps thus minimize the risk of something going awry.

The scientists were busy in the fly lab preparing more fly food so that our “Florida-born flies” will be available when we come back in late December (or early January, depending on the team member).

To cheer us all up, a fun thing happened after lunch. As we were walking back from the cafeteria, the Orion crew capsule was on a flatbed truck returning to its processing facility, with a chopper overhead. Welcome back Orion! It was cool to witness it there after seeing it launch, circle the Earth twice, and splash down in the Pacific Ocean not two weeks ago.

I’m returning to NASA Ames tomorrow, so I’ll end this blog with Seasonal Greetings! I’ll start writing again when I return to the Kennedy Space Center on January 3

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 17, 2014

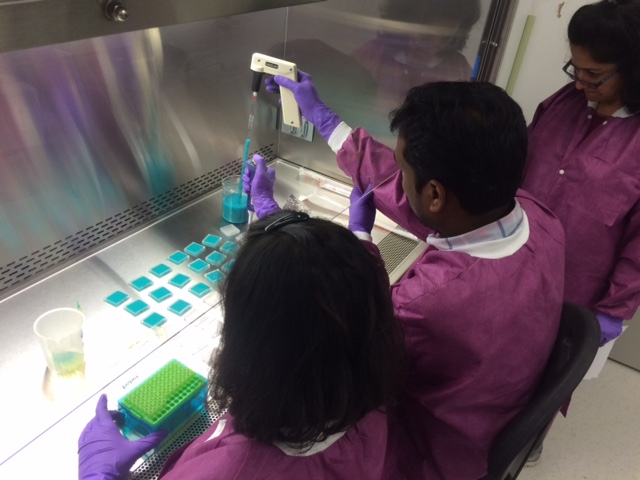

We are two days from launch! While there are still rumors floating around about a possible launch delay, we are still “go” for Friday (Dec. 19), so there was quite a bit of activity in both the science and engineering labs of Fruit Fly Lab! In the science labs, the team was busy preparing fly food and pouring them in the food trays. In addition, the bacterial cultures were also placed in some food trays. These cultures are needed because Fruit Fly Lab-01 mission is an immunity study, so this bacterial treatment will be administered to the flies in orbit and compared to a similar treatment back on Earth to see how spaceflight affects the immune system. Remember that more than 70% of the genes in humans that deal with immune response have analogues in flies, Fruit Fly Lab is laying some important foundational stones in understanding the long-term effect of spaceflight for humans.

The “rack” in which the Fruit Fly Lab system will be installed aboard the space station doesn’t have built-in environmental monitoring capabilities, so we’re installing our own that will monitor air temperature and humidity. In the engineering lab, we spent a good chunk of the day verifying that the sensors work, programming them for data collection, and installing them into their vented enclosures to be installed on the rack.

As I finish writing this, there is now confirmation that the launch won’t happen as advertised on Dec 19. Dec. 20th is looking unlikely as well, with the 23rd being the next launch opportunity. Dec. 26th was slated as well, but due to the high-beta orbit of the International Space Station, this is a no-go. Beta is the angle between the orbital place of the International Space Station and the orbital place of the Earth. When this angle is high, the station spends very little time, if any, in Earth’s shadow, creating thermal constraints for both the station and the Space-X Dragon capsule. This is a tough pill to swallow, the team has been working hard these past few months to meet launch schedule, and several Fruit Fly Lab project team members have been at the Cape for a month preparing for this December launch.

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 16, 2014

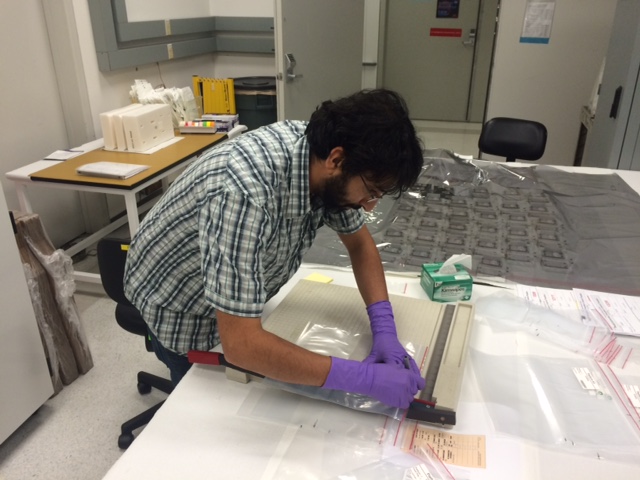

Given that we were ahead of schedule, we took the opportunity to visit the Atlantis exhibit at the Kennedy Space Center visitor complex. It’s always been an important place for me, as I remember going there with my family as a teenager growing up in Europe. It’s a good feeling to be back, working at NASA, and launching a payload in a few days. Dreams do come true! The Atlantis exhibit showcases the space shuttle Atlantis, which last flew in 2011. I don’t want to give anything away, but the exhibit is very well done, and the first time visitors set eyes on Atlantis is very inspiring. Of course, as karma would have it, more work appeared. Indeed, the people responsible for “cold stowage”, i.e. stowage of items in freezers on the International Space Station came over to our hardware lab and mentioned that we would need smaller bags to house our food changeout platforms. These platforms are the ones that astronauts will use aboard the space station to change the food inside the fly cassettes. The reason these changeout platforms are in cold stowage is that they each contain a fresh tray of fly food that needs to stay fresh. Smaller bags? We weren’t ready for that, nor did we have smaller bags at our disposal (those are not your typical grocery zip locks unfortunately!). After discussions, our solution was to use a vulcanizer and a table-top paper shearer to create smaller bags out of our current bags. This took most of the evening, but we got it done to their satisfaction. We couldn’t really rejoice as there was another rumor of a launch delay. This quite affected the energy of the team, as it meant that the new launch delay would impact family Christmas plans for most of the team. It’s just a rumor for now, so knock on wood.

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 15, 2014

Today we continued preparing hardware for handover! We packed our “Cargo Transfer Bag-A” (CTB-A) full of our cassettes, within which space-born flies will grow, mature and reproduce. We also packed a “demo kit” for the astronauts, so they can get acquainted with our hardware without utilizing hardware that is already dedicated for the experiment. In addition, we packed the “fixation” kit. Fixation is a procedure commonly done in biology where organisms needed to be “fixed”, in other words “preserved”, so that their genetic material does not degrade in the time between preservation and laboratory studies. The liquid used is called RNALater, which is approximately seawater. This RNALater was loaded into syringes that are part of the “fixation” kit. During our mission, we have a procedure where astronauts will remove a food tray full of larvae from a cassette and place the food tray into a small plastic bag. After pulling air out of the plastic bag with a syringe, another syringe will inject the RNALater into the plastic bag, thus preserving the organisms.

In the fly lab at Kennedy Space Center, fruit fly lab scientists were busy keeping the stock of flies healthy and ready for flight!

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 12, 2014

Busy and exciting day today! The 24-hour final test of the software that will control camera operations concluded and the resulting data analyzed. Everything worked according to plan, with the different cameras turning on when they should and the lights turning on and off as expected. Now some hardware can be packed for launch! All of our hardware will be placed inside the rocket in “Cargo Transfer Bags” or CTBs. Fruit Fly lab has three of them, A, B, and C. We were able to pack CTB-B, as it contains the hardware that won’t need to be unpacked if the rocket scrubs. A “scrub” is when the rocket is packed and ready to go, but something happens that causes a launch delay like weather, a faulty valve, a boat too close to close to the launch path (yup, this has happened). It was a great feeling to pack the two controllers, the fourteen fly cameras, and the four hard drives into their flight back. The next time these bags will be opened, it will be aboard the International Space Station! There is some hard-to-explain satisfaction with placing this hardware in the bags. We’ve worked hard on those for so long! Intrigued at first with the concept, debating initial design details, testing the engineering mockups, finalizing the drawings, testing the finished product, and finally, packing them for spaceflight. It was very satisfying.

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 11, 2014

Bad news today. The launch has slipped from December 16 to December 19. Everyone is a little down as that’s more time away from our families in the days preceding Christmas. Given that we were already ahead of schedule and worked overtime the past few days, we took the afternoon off to decompress.

We did analyze the video footage of the spinning centrifuge and confirmed that it was spinning per our requirements!

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 10, 2014

Today was quite the big day as we had two major milestones. The first was the reprogramming of the centrifuge aboard the International Space Station. We were on console here at Kennedy Space Center with live footage of astronaut Terry Virts updating the configuration file of the centrifuge within which our payload will operate. We had to update the spin rate of the centrifuge to make sure our flies would experience 1g (Earth’s gravity) during the study. This was a complete success! The operation took a bit over two hours. Thanks Terry!

Secondly, all our hardware was reviewed by the Human Factors Integration Team (HFIT). HFIT review is necessary for all payloads handled by astronauts on the International Space Station. These experts make sure all appropriate labeling is correct, and they check every piece of hardware that astronauts will handle to make sure there aren’t any burrs or sharp edges that could accidently injure an astronaut. A bleed in microgravity would be difficult to clean up! This took several hours because of the large amounts of hardware pieces we have (over 100!), but we passed with flying colors.

Lastly, after verifying yesterday that all the hardware was working, we connected everything and started a 24-hour software test, to make sure the fly cameras and lights turn on and off as they should to maximize the science return of the mission. We’ll know tomorrow if it is successful!

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 9, 2014

Today was another busy day at the Cape. Spaceflight is of course more than the glamorous launch and the meaningful science. It’s also a lot of preparatory work and today was no exception. Our flight hardware was unpacked and powered up via pre-written procedures. Such procedures are needed whenever expensive flight hardware is handled, so that testing steps are done correctly, carefully and meticulously to prevent mistakes. In addition, labeling is an important component of flight hardware. Labeling ensures that all hardware is tracked and accounted for.

Labeling has been a time consuming yet very important task. Fruit Fly Lab has over 100 pieces of hardware that need to be easily identifiable and traceable. One of our main tasks is to keep the astronaut in mind at all time when we build, as they will be handling our hardware, so they have to know it’s safe. Labeling also makes it clear which ones to pick up during the multiple operations that Fruit Fly Lab will require on its 30+ day mission aboard the International Space Station.

Today, our colleague from Airbus Defense & Space arrived. His task was to prepare the fly cameras for the full integration test. Each individual fly camera was tested as a unit and the camera lens cleaned. Then, all fly cameras were connected to the controller (the electronics brain behind our science operations) and everything was powered up and a simulated run-through was begun.

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center

December 8, 2014

Today was a busy day at Cape Canaveral! In pouring rain, we made it to the Space Station Processing Facility, a big building devoted to getting payloads ready to fly to the International Space Station. I was quite giddy walking towards it (despite getting soaked). I was telling my project manager how this was a realization of a boyhood dream to be actively involved in space flight, and he replied, “me too!” He was as excited as I was.

We got acquainted with the local support staff who showed us our office space. The view out of the window points straight to the pad where the Delta IV rocket took off to send the Orion test capsule into history. There is so much history here! It oozes out of every wall. It’s a great feeling.

We also got to see our three labs! A fly lab, a microbiology lab, and an engineering lab. The fly lab is where the flies are grown and prepared for launch, the microbiology lab is where the fly bacterial treatment is prepared. This treatment will allow the scientists to study how well the fly’s immune system responds to this treatment in space flight compared to Earth based flies. This will tell us, perhaps surprisingly, a great deal about how the immune system of humans adapts to spaceflight too.

The team has been working together for almost two years now, so it was great to see everyone get to work at the Cape, without needing to be told what to do. We’re a well oiled machine! The spirits are high, smiles are abundant, we’re just very happy to be here. This week is the rewarding culmination of much hard work.

Tomorrow is going to be an important day for the team and myself, as we’ll unpack our hardware that we shipped from NASA Ames Research Center. We’ll have to fully test it to make sure nothing happened during shipment. This will mean powering everything up and following precisely the procedures we have already written in order to do this methodically and without mistakes.

—Sanjoy Som Ph.D., Flight Systems Implementation Branch, Space Biosciences Division, NASA’s Ames Research Center