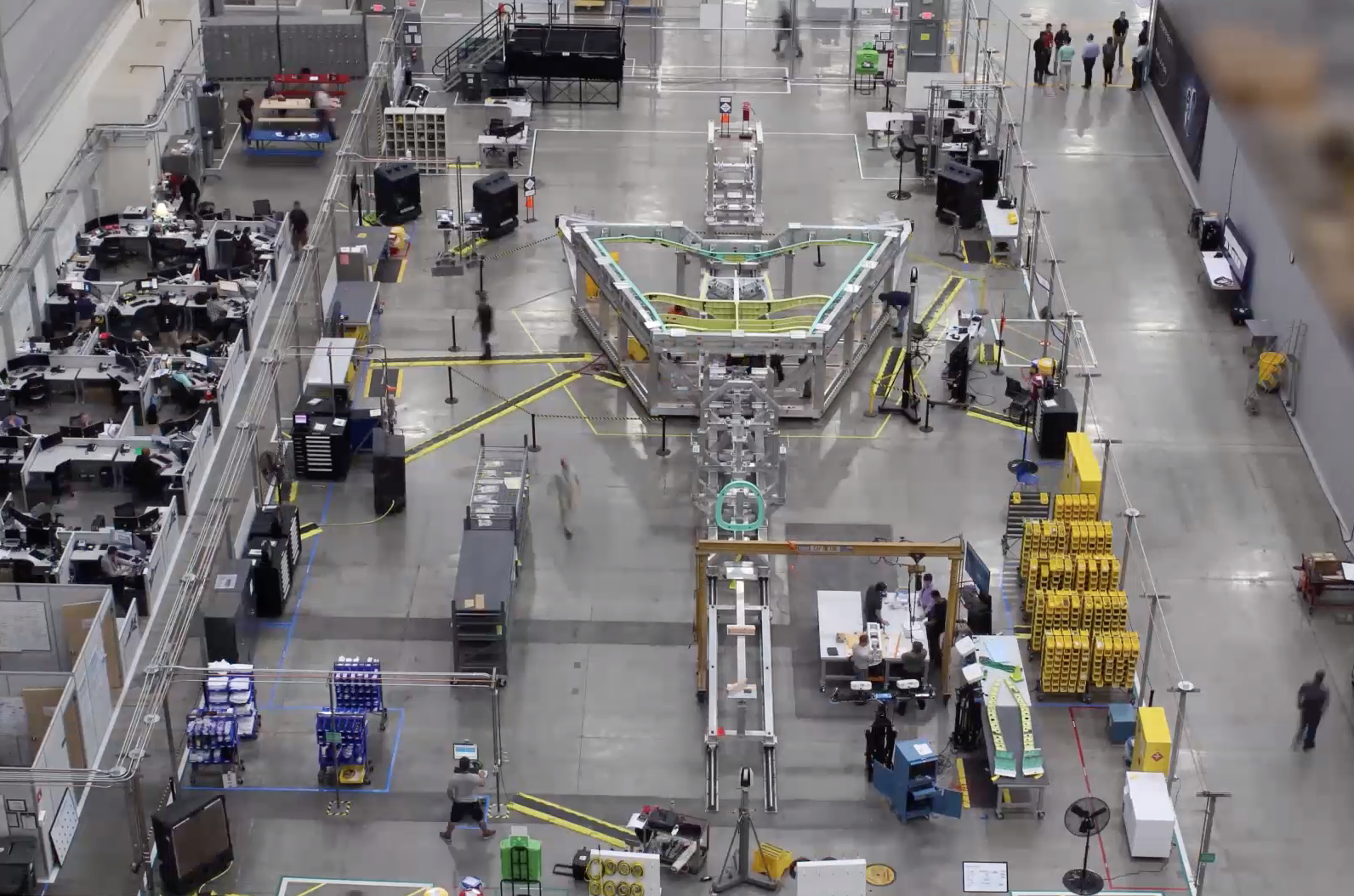

A time-honored tradition employed by the aerospace community for decades is continuing with the assembly of NASA’s X-59 Quiet SuperSonic Technology aircraft at the Lockheed Martin Skunk Works® factory in California.

Perfectly acceptable components from other aircraft – some major, some minor – are finding new life as parts installed on the X-59, an experimental airplane whose mission is to help open a new era of commercial supersonic air travel over land.

Landing gear from an Air Force F-16 fighter, a cockpit canopy from a NASA T-38 trainer, a propulsion system part from a U-2 spy plane and a control stick from an F-117 stealth fighter are among the repurposed parts to be used on NASA’s newest airplane.

It’s all about saving time and money.

“The X-59 is designed so that, as it flies faster than sound, any sonic booms that reach the ground are so quiet they can barely be heard – if at all. That’s what’s new here,” said Craig Nickol, NASA’s X-59 project manager.

The X-59 is designed so that, as it flies faster than sound, any sonic booms that reach the ground are so quiet they can barely be heard – if at all. That’s what’s new here.

CRAIG NICKOL

NASA's X-59 Project Manager

“So, while we’re pushing technology in terms of the X-59’s overall shape and configuration, at the same time we can take advantage of using reliable systems from aircraft we know or have experience with and install those,” Nickol said.

The alternative – designing those same types of parts from scratch – would come with a big downside. Additional years and millions of dollars – no one is sure exactly how much – would be needed to build, test and certify these components and systems as being safe for flight.

And while integrating the repurposed parts so they all safely work together is still a challenging task, going that route is definitely appreciated by the Lockheed Martin team who was responsible for the original design of the X-59 and then earned the $247.5 million contract to build the airplane.

“Development of those systems would be complex and potentially add risk to the program. With the availability of these components we didn’t need to take on that risk to be successful with the X-59,” said Peter Iosifidis, Lockheed Martin’s X-59 program manager.

Another factor in favor of using existing components from other aircraft is the fact the X-59 is a one-of-a-kind-airplane. Only one will be built. There are no plans to build and operate a fleet of airplanes like the X-59.

“That’s not our job at NASA and that’s not the purpose of this research aircraft. As a result, it’s much more efficient to leverage existing components because we’re not going into a large production run,” Nickol said.

It’s Nice to Share

This practice of building a new experimental aircraft like the X-59 with parts large and small from other vehicles is not new, either for aeronautics research or for space exploration.

“Sharing components between airplanes for research programs like this is a pretty common practice used for many years,” said Brian Griffin, the deputy operations lead for the X-59 project at NASA’s Armstrong Flight Research Center in California.

Two examples:

The Shaped Sonic Boom Demonstration aircraft that flew in 2003 and 2004 – a direct precursor project to the X-59 – relied on a used Northrop F-5E fighter jet. Its body shape was modified in a manner that successfully proved supersonic shockwaves could in turn be shaped in way to lessen the loudness of a sonic boom.

Two X-29 aircraft, with their unique forward-swept wings, flew 242 times between 1984 and 1991. They tested new fly-by-wire technologies and the use of composite materials in the construction of the wings. The aircraft design included use of the forward fuselage and nose landing gear of an F-5A, and the main landing gear of an F-16.

On the space side of NASA, sharing of components is just as commonplace.

For example, a helium pressure regulator from a retired space shuttle orbiter was installed and used as part of the descent stage for the Curiosity rover that landed on Mars in 2012.

The Magellan radar mapping probe to Venus, launched aboard the space shuttle Atlantis in 1989, was made from spare parts leftover from the Voyager program to the outer planets, the Galileo program to Jupiter, the Ulysses program to study the sun and the Mariner 9 program to Mars.

And to save money and time, NASA even used a leftover hatch from the Gemini program as an airlock door on the Skylab space station that was visited by three crews flying an Apollo spacecraft in 1973 and 1974.

X-59 Shopping Spree

So, where does one go to find used landing gear from an F-16, a throttle assembly or air turbine starter from an F/A-18, or any of potentially dozens of system components from other aircraft that might still be useful?

A good start is “The Boneyard” at Davis-Monthan Air Force Base at Tucson, Arizona.

Situated in the desert at the edge of the city, the base is host to the 309th Aerospace Maintenance and Regeneration Group (AMARG) and home to more than 4,400 aircraft – either retired or in storage – from the Air Force, Navy, Marines, Army, and Coast Guard.

With little rain, low humidity and a hard-packed soil to park on, airplanes there can sit outdoors for years and experience little deterioration. Those aircraft that are wrapped in a covering or otherwise especially prepared for long-term storage can be brought back into service with less effort than building a new airplane.

It’s the perfect place to get a good deal on a used aircraft part.

But if the vision of some NASA engineers walking around, kicking tires and peeking under the hood looking for a decent-looking part they can grab is flashing through your mind, you have the wrong picture of how it really works.

“No, we didn’t go there and have that used car lot type of approach where we got to pick and choose whatever we wanted,” Griffin said.

Instead, most of the searching was done by Air Force officials looking through aircraft databases for parts that met NASA’s specifications. Once the Air Force made a selection, it was up to Griffin and his team to go to Tucson and ensure everything looked in order.

“Once the paperwork was done, we worked with the people at AMARG to prepare and ship the hardware to us at Armstrong,” Griffin said.

Some of the parts were dismantled from their original aircraft and shipped in crates to California, while, in the case of the F-16 landing gear, the F-16 fuselages were shipped on a flatbed truck with the gear still installed.

A New Chapter in History

Even before the X-59 first takes flight in 2021 to write a new chapter in aviation history, many of the refurbished parts that will be used in its final assembly already have their own fascinating stories to tell about the airplanes they came from.

Based on aircraft serial numbers and publicly available information compiled by the not-for-profit F-16.net website, several interesting details about the two F-16C fighter jets that are supplying landing gear parts for the X-59 are known.

For example, one of the F-16C’s began military service in 1985 with the 363rd Tactical Fighter Wing at Shaw Air Force Base in South Carolina. It was retired from the Air Force as part of the 40th Flight Test Squadron at Eglin Air Force Base in Florida and moved to AMARG in 2015.

The other F-16C began its service in 1986 with the 86th Tactical Fighter Wing stationed in Ramstein, Germany. It ended its military career in 2014 with the 62nd Fight Squadron at Luke Air Force Base in Arizona and transferred to AMARG after cracks were found in the aircraft structure associated with the canopy – a problem that grounded dozens of F-16s at the time.

According to the F-16.net database of unit assignments and years served at each unit, neither F-16C aircraft flew any combat missions. Both were officially transferred from AMARG to NASA on June 9, 2017.

The heritage of the two NASA T-38’s is even more compelling.

These are the type of aircraft that, even today, NASA astronauts fly to remain proficient in high-performance aircraft – a necessary experience to prepare for spaceflight whether you’re a pilot or not – and to travel around the nation as needed.

During the Space Shuttle Program, they were most visible as the sleek aircraft with a crew of astronauts for that mission seen flying to the Kennedy Space Center in Florida at the beginning of each countdown.

With tail numbers of N912NA and N914NA, they were assigned to the Johnson Space Center in Houston. NASA 912 was retired and delivered to AMARG in 2011 following the final spacesShuttle mission earlier that year.

NASA 914 had a more dramatic conclusion to the first chapter in its history.

On February 24, 1987, astronaut Brewster Shaw – who at that time had already flown in space twice and would fly again in 1989 – was cruising to California in the T-38 with NASA research pilot Rob Rivers, who also was aboard and flying in the front seat.

As an investigation later determined, the jet was hit by lightning as the twin-engine airplane was over the Pacific Ocean, about 10 miles from their destination runway. Within moments the right engine was out and on fire, the left engine also was on fire but still working, and the cockpit was filling with smoke.

Shaw, who was more familiar with the area than Rivers, took control of the airplane and was able to get the two of them and the aircraft safely on the ground without having to eject and endanger anyone below.

In auto insurance terms the airplane was “totaled,” removed from service and put in storage. Three decades later parts of its cockpit and the other T-38 will find use again not only on the X-59 itself, but in a pair of ground-based simulators and an egress trainer.