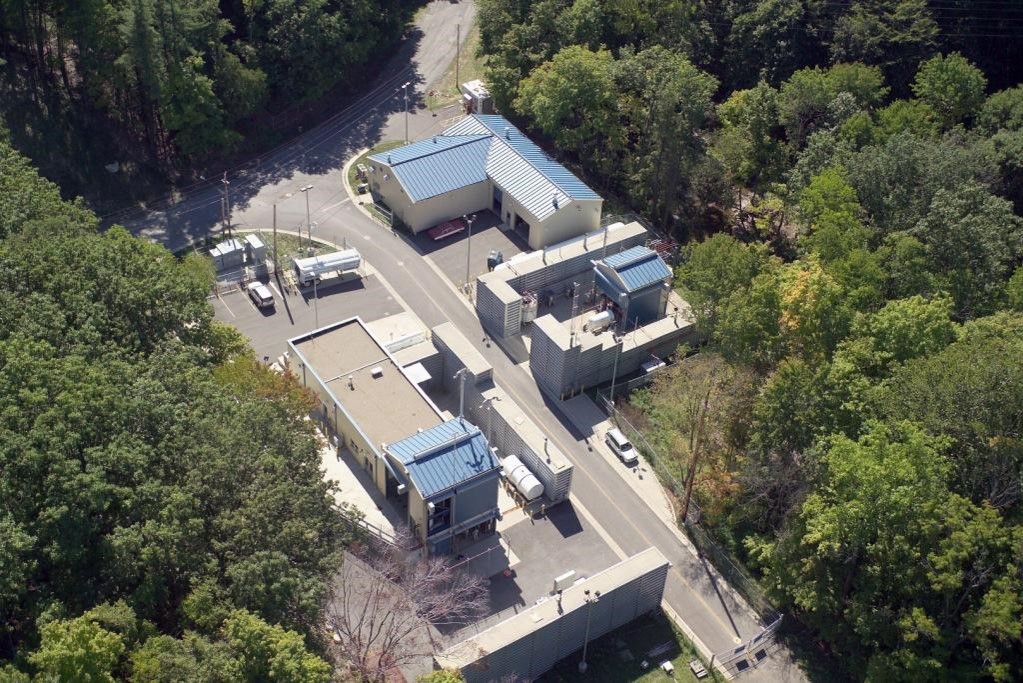

The Creek Road Cryogenics Complex (CRCC) is a state-of-art facility at NASA’s Glenn Research Center in Cleveland. It consists of four separate test cells: the Small Multi-Purpose Research Facility (SMiRF), Cryogenics Components Lab 7 (CCL-7), Cryomotor Test Bed, and 20K to 90K Calorimeter Test Bed.

Facility Overview

Small Multi-Purpose Research Facility

The Small Multi-Purpose Research Facility (SMiRF) evaluates the performance of the thermal protection systems required to provide long-term storage (up to 10 years) of cryogenic propellants in space.

SMiRF provides the ability to simulate space, high altitudes and launch pressure environments; conduct calorimetry tests on prototype insulation systems; planetary simulation; and safely handle gaseous and cryogenic propellant. The facility serves as a low-cost, small-scale screening facility for concept and component testing of a wide variety of hardware. It has performed tests (with LH2 as the test fluid) including insulation performance tests for the X-33 vehicle, demonstration of rapid chill and fill of a subscale propellant tank for the High Energy Upper Stage program, and demonstration of a zero boiloff long-term cryogenic storage concept for the Mars Exploration program.

Cryogenics Components Lab 7

The CCL-7 is a smaller version of SMiRF with similar capabilities. It is a highly configurable test cell providing the ability to simulate space and handle hazardous gaseous and cryogenic flammable fluids without compromising personal safety. It supports concept and component testing for cryogenic fluid management (CFM) technology development, planetary simulation, cryogenic motor development and any hazardous commodity testing.

Cryomotor Test Bed

The Cryomotor Test Bed is used to evaluate the performance of cryogenically cooled motors. Its structure and support systems were originally built to support cryogenic tests of NASA’s 450 hp and AF 2 MW generator.

20K to 90K Calorimeter Test Bed

The 20K to 90K Calorimeter Test Bed is used to evaluate the performance of different insulation materials. The facility consists of a vacuum vessel 72 inches high by 36 inches in diameter. Warm and cold guards are used to set the boundary conditions being tested, and cryocoolers are used to achieve controllable boundary temperatures. In addition, the facility makes use of scroll and turbo pumps to maintain a steady vacuum level of 1 x 10-7 torr.

Quick Facts

| Small Multi-Purpose Research Facility | (SMiRF) |

|---|---|

| Dimensions | 100 inches long by 72 inches in diameter |

| Vacuum System | Three 10-inch ODPsa |

| No Load Pressure | 8.5 x 10-6 torr |

| Pumping Speed (air) | 7,000 L/s |

| Cryogenics Components Lab 7 (CCL-7) | |

|---|---|

| Dimensions | 30 inches wide by 56 inches long |

| Cryogenic Test Fluids | LHe, LH2, LN2, LAr, LO2, LCH4 or other as required |

| No Load Pressure | 1 x 10-6 torr |

| 20K to 90K Calorimeter Test Bed | |

|---|---|

| Dimensions | 36 inches wide by 72 inches long |

| No Load Pressure | 1 x 10-7 torr |

Capabilities

Small Multi-Purpose Research Facility

The SMiRF vacuum chamber can accommodate test articles as large as 90 inches high by 71 inches in diameter. A programmable thermal shroud system can be used inside the SMiRF chamber to control background temperatures over a temperature range of 200°R to 650°R. Test article size is limited to 65 inches high by 44 inches in diameter when the shroud is installed.

The SMiRF chamber can maintain a vacuum environment of 8.5 x 10-6 torr. The chamber can be evacuated along the Space Shuttle Pressure Ascent profile. Various purge gases are available onsite (GHe and GN2). The facility has also handled GH2 and G02 tests. Up to 512 channels of data can be collected at a nominal rate of 1/s. Data is collected and processed by a dedicated workstation computer and is archived on Glenn’s central computer.

Cryogenics Components Lab 7

- Cryogenic test fluids: LHe, LH2, LN2, LAr, LO2, LCH4, or other as required

- Gases: He, H2, N2, Ar, O2, CH4, or other as required

- Vacuum environment: continuous 1 x 10-6 torr

- Test article size: 30 inches wide by 56 inches high (0.76 by 1.42 meters)

- Data system

- 320 recordable channels at a nominal speed of 1 Hz

- Six recordable channels at speeds up to 6,250 Hz

- Numerous pressure vessels ranging from 0.2 ft3 (0.006 m3) to 23 ft3 (0.65 m3) with pressures up to 100 psig (6.9 bar)

- Residual gas analyzer

- Ejector system to sub-cool cryogens

20K to 90K Calorimeter Test Bed

- 72 inches high by 36 inches in diameter vacuum vessel

- Warm and cold guards used as boundary conditions

- Cryocoolers used to achieve controllable boundary temperatures

- Scroll and turbo pumps to maintain a steady vacuum level of less than or equal to 1 x 10-7 torr

- Cylindrical test section for evaluating insulation performance in a temperature regime not well modeled

- Calibrated conduction rods used to obtain the heat transfer rate through the test specimen

- Fully automated control

- Non-hazardous test setup allows for test operations in occupied shop

Contact

Chemical Propulsion Research Complex

Facility Manager: Jonathan Kubiak

216-433-8347

Jonathan.M.Kubiak@nasa.gov

Test Facility Management Branch

Acting Chief: Tony Doglio

216-433-2402

James.A.Doglio@nasa.gov

Using Our Facility

NASA’s Glenn Research Center in Cleveland provides ground test facilities to industry, government, and academia. If you are considering testing in one of our facilities or would like further information about a specific facility or capability, please let us know.

/Hubble%20Space%20Telescope%20(A).png)