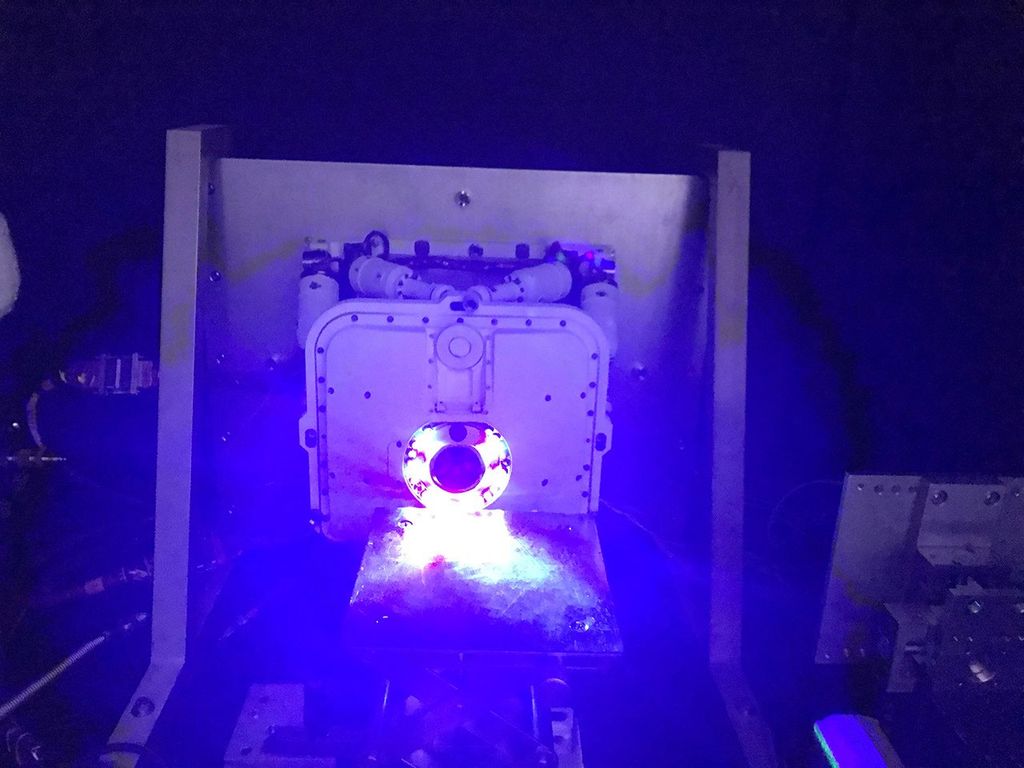

Stennis Space Center employees installed a 96-inch valve March 26 as part of an ongoing project to upgrade the high-pressure industrial water system that serves the site’s large rocket engine test stands. When completed, the upgraded system will have the capacity to flow 335,000 gallons of water a minute at 300 psi, which is needed during rocket engine tests. Water is a critical element for rocket engine testing. At Stennis, engines are anchored in place on large test stands and fired just as they are during an actual space flight. The fire and exhaust from the test is redirected out of the stand by a large flame trench. A water deluge system directs thousands of gallons of water needed to cool the exhaust. Water also must be available on the stand and to the adjacent barges – which supply cryogenic rocket propellants to fuel the engine during the test – for fire suppression in the event of a mishap. The original water system was installed in the 1960s; the upgrade will ensure and enhance its continued capability. The system will serve the A-1 Test Stand during testing of RS-25 rocket engines that will be used on NASA’s new Space Launch System (SLS). It also will be critical for testing of the SLS core stage on the B-2 Test Stand. Core-stage testing will involve mounting an actual flight stage on the stand and simultaneously firing four RS-25 rocket engines, producing more than 2 million pounds of thrust. In addition to others uses, about 87,000 gallons of water a minute will be used during core-stage testing for vibro-acoustic suppression, essentially creating a curtain of water around the engines to dampen the loudness of the test and protect the core stage from noise damage. The recently installed valve represents a milestone for the water system project. Weighing in at 160,000 pounds and standing 30 feet tall on end, it was the largest product ever manufactured by Kennedy Valve in Elmira, N.Y. Once completed, the valve was transported by truck to Stennis, where it was lifted and placed by crane.

2 min read